15000-MNL-01 Rev A 8

6System Overview

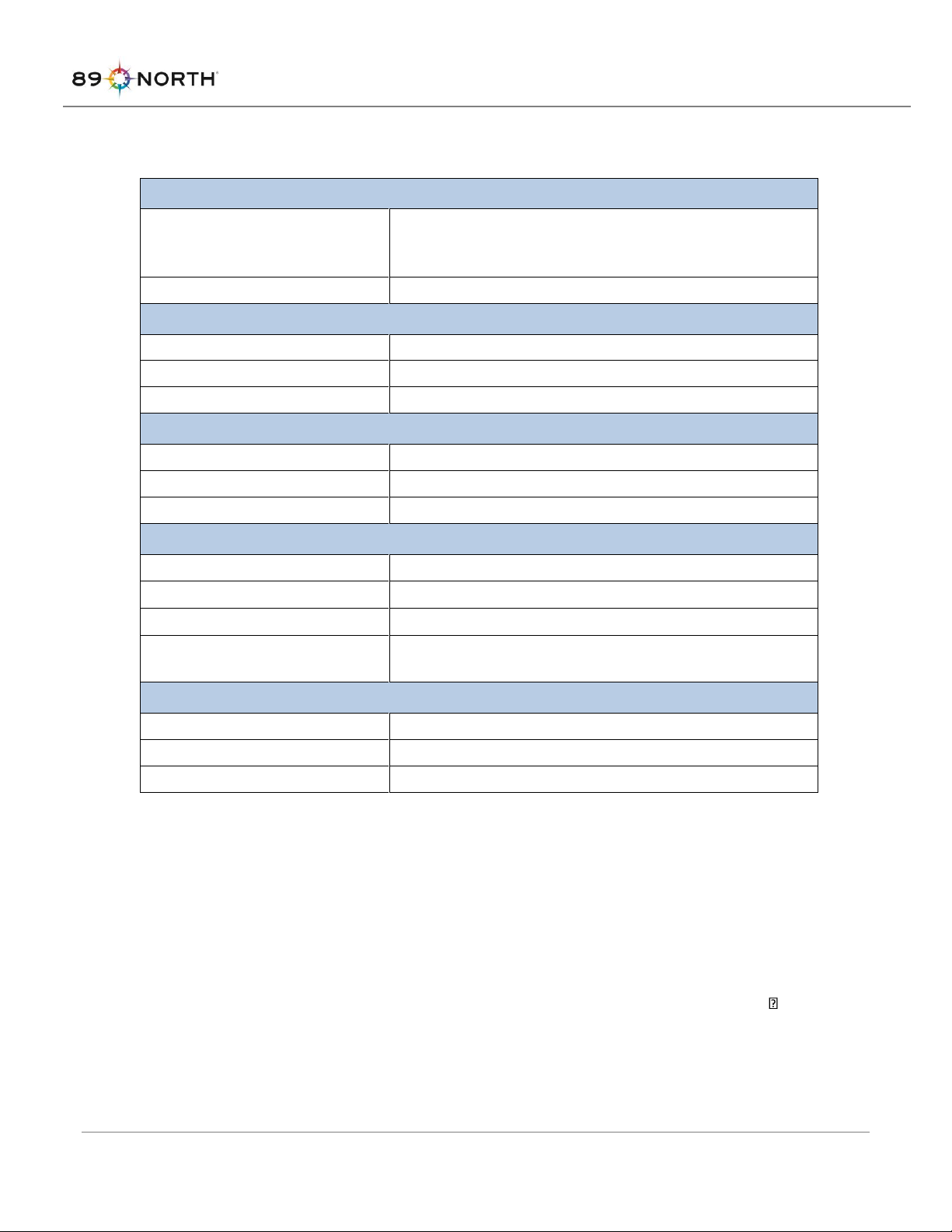

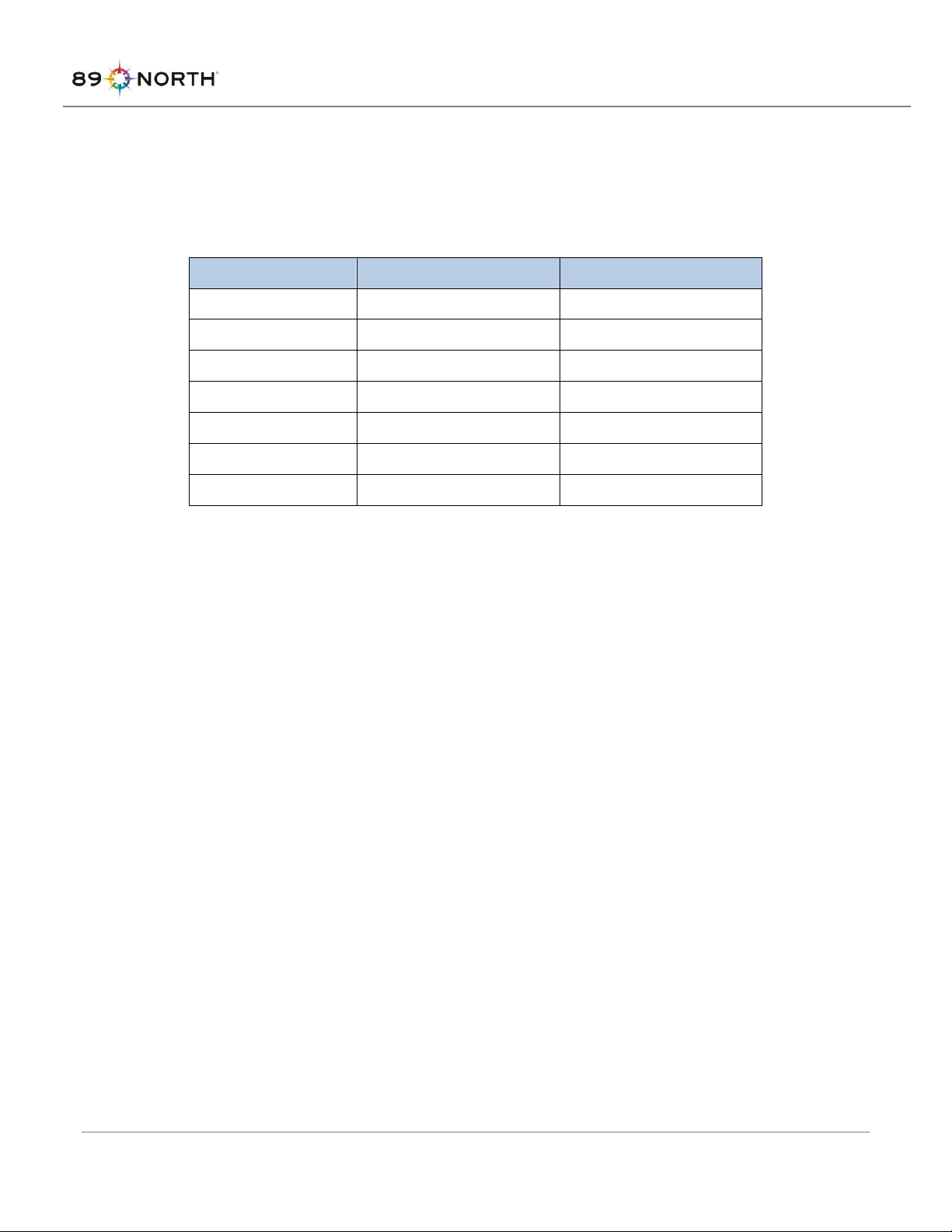

The LDI-6 has six laser lines while the LDI-7 has seven laser lines. Values of the maximum output power of

available laser lines in either pulsed or continuous operation are given in Table 1:

Table 1: Maximum output power values for each laser line.

Laser emission is delivered from the LDI through optical fibers which are connected to SMA optical

connectors on the top of the LDI in the fiber access area. For the LDI-6 and -7, one SMA output (right side

of unit when viewed from the front) corresponds to a multi-color laser diode module which contains the

six laser lines 405nm, 445nm, 470nm, 520nm, 528nm, 640nm. This output is labelled “RGGBBV” where

the fiber exits the LDI. On the LDI-7, a second SMA output (left side of unit when viewed from front)

corresponds to the 555nm laser line. This fiber output is labelled “555”.

Output beam divergence is dependent on the external output fiber installed.

The 555nm laser line can be pulsed up to 120Hz, 50% duty cycle at 100% intensity before performance

degradation is evident (4 msec pulse). The RGGBBV lines can be pulsed up to 8000 Hz, 50% duty cycle at

100% intensity before performance degradation is evident (0.625 msec pulse). ‘Performance degradation’

could be laser line failing to achieve full set intensity or irregularity of pulse shapes, depending on the

laser line and exact operating parameters. Laser diode lines cannot be overdriven for pulsed operation,

i.e. the maximum output powers above hold for continuous wave and pulsed operation.