Contents

1. Safety instructions.......................................................................................................................................................1

2. Product introductions.................................................................................................................................................3

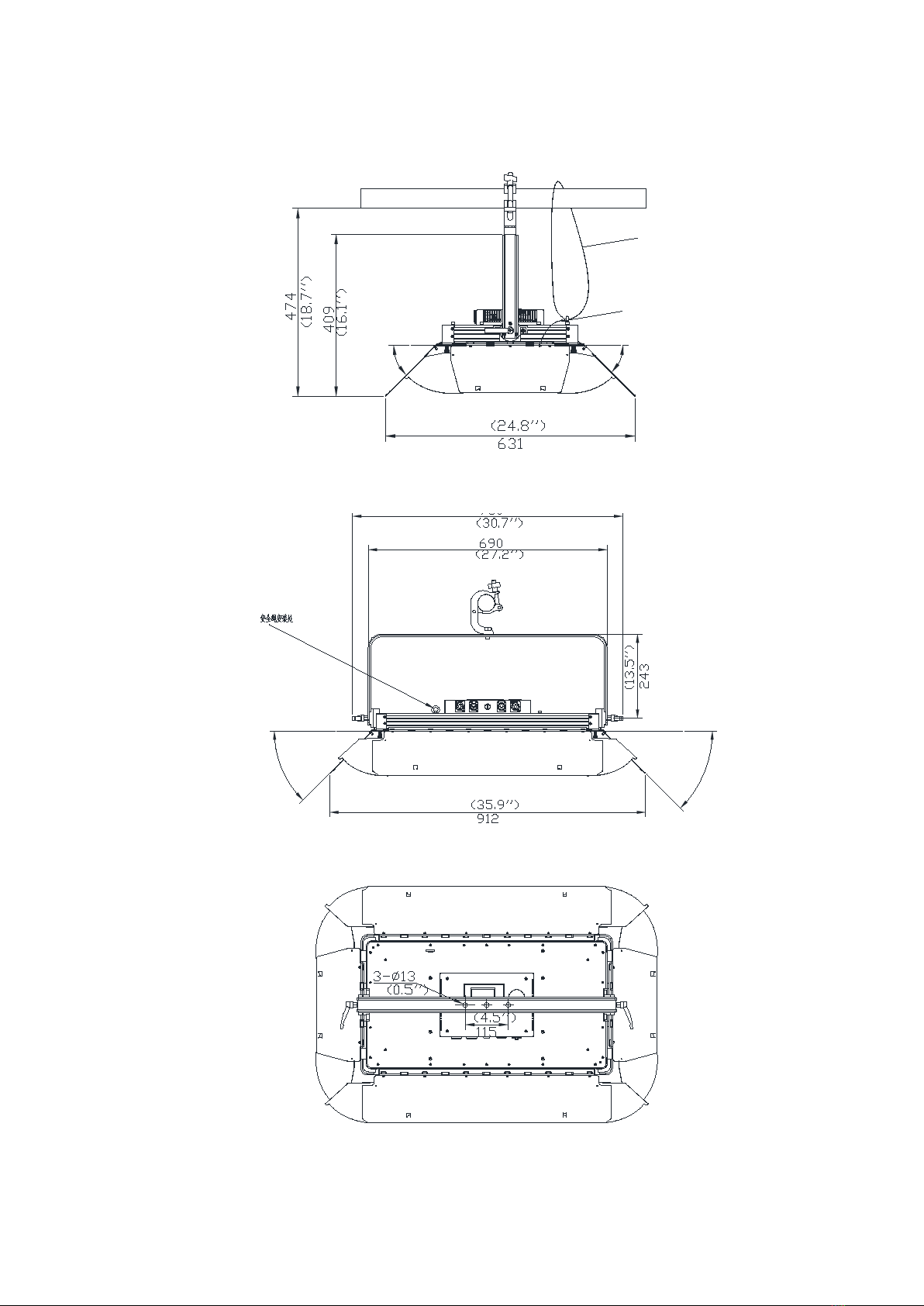

2.1 Dimensions..............................................................................................................................................................3

2.2 Accessories..............................................................................................................................................................3

3. Packing and shipping..................................................................................................................................................4

3.1 Unpacking ...............................................................................................................................................................4

3.3 Packing after use .....................................................................................................................................................4

4. Installation...................................................................................................................................................................4

4.1 Clamps installation..................................................................................................................................................4

4.2 Device installation...................................................................................................................................................5

5. Power / Control connection ......................................................................................................................................5

5.1 Power connection....................................................................................................................................................5

5.2 Control connection..................................................................................................................................................5

5.3 Testing.....................................................................................................................................................................6

6. Control panel...............................................................................................................................................................6

6.1 Panel instruction......................................................................................................................................................6

7. Technical specification................................................................................................................................................7

8. Menu structure............................................................................................................................................................9

9. DMX protocol............................................................................................................................................................10

10. System wiring diagram...........................................................................................................................................11

12. Maintenance and Troubleshooting........................................................................................................................12

12.1 Cleaning and maintenance...................................................................................................................................12

12.2 Troubleshooting...................................................................................................................................................13

13. Spare parts list.........................................................................................................................................................15