3

INSPECT SHIPMENT

There may be hidden damage caused in transit. Check to be certain

all parts of the venting system, as listed below, are present. Inspect

the upper and lower air inlet boxes, rear air tube and all parts of the

venting system. CAUTION!!! IF THERE ARE ANY DAMAGED

PARTS, DO NOT INSTALL THIS WATER HEATER. REPORT ANY

SHORTAGE TO YOUR DISTRIBUTOR OR DAMAGE TO YOUR

CARRIER.

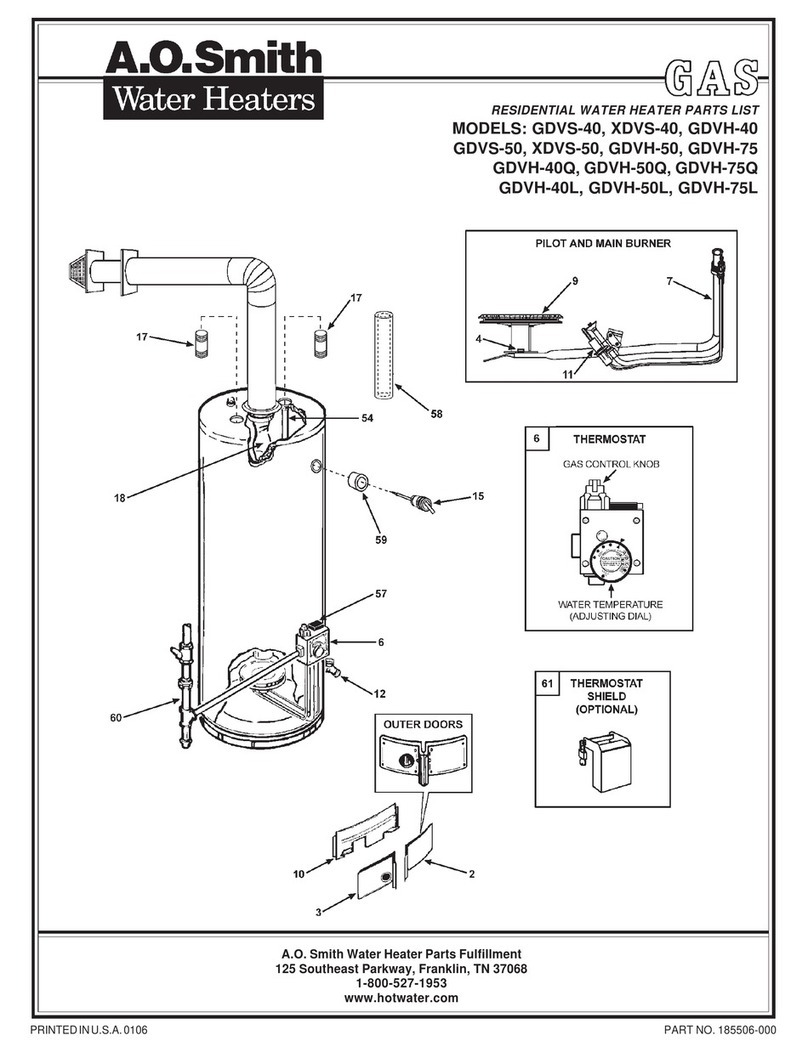

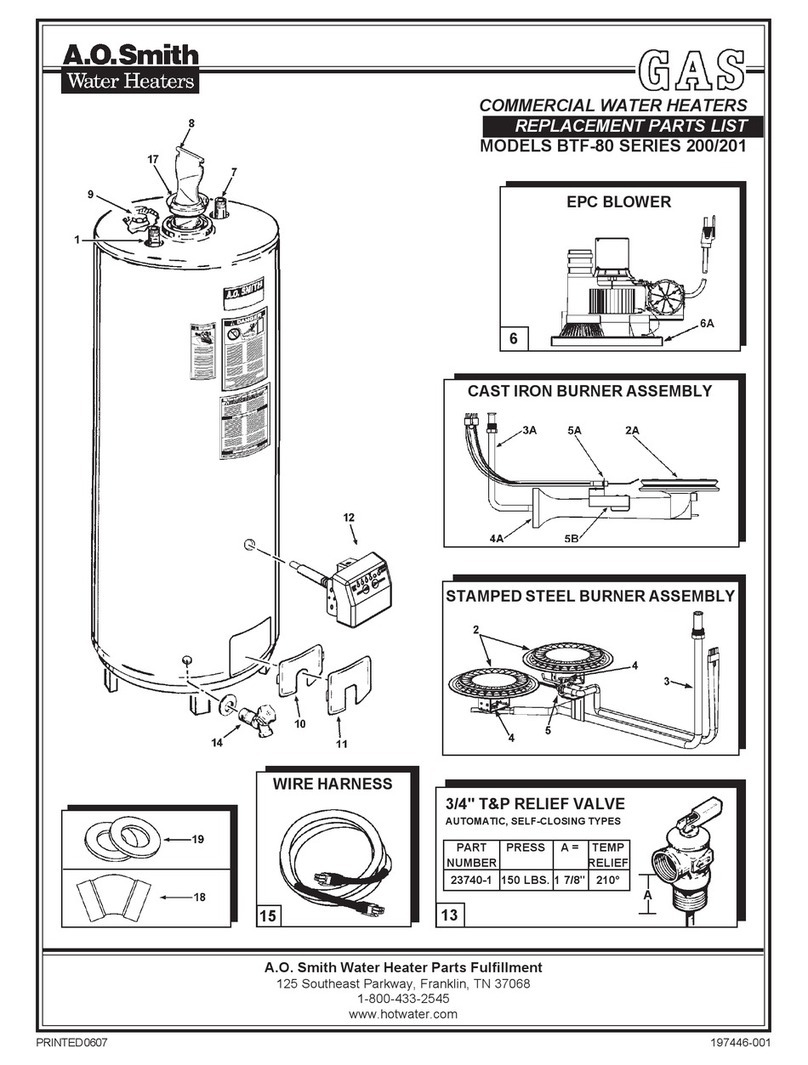

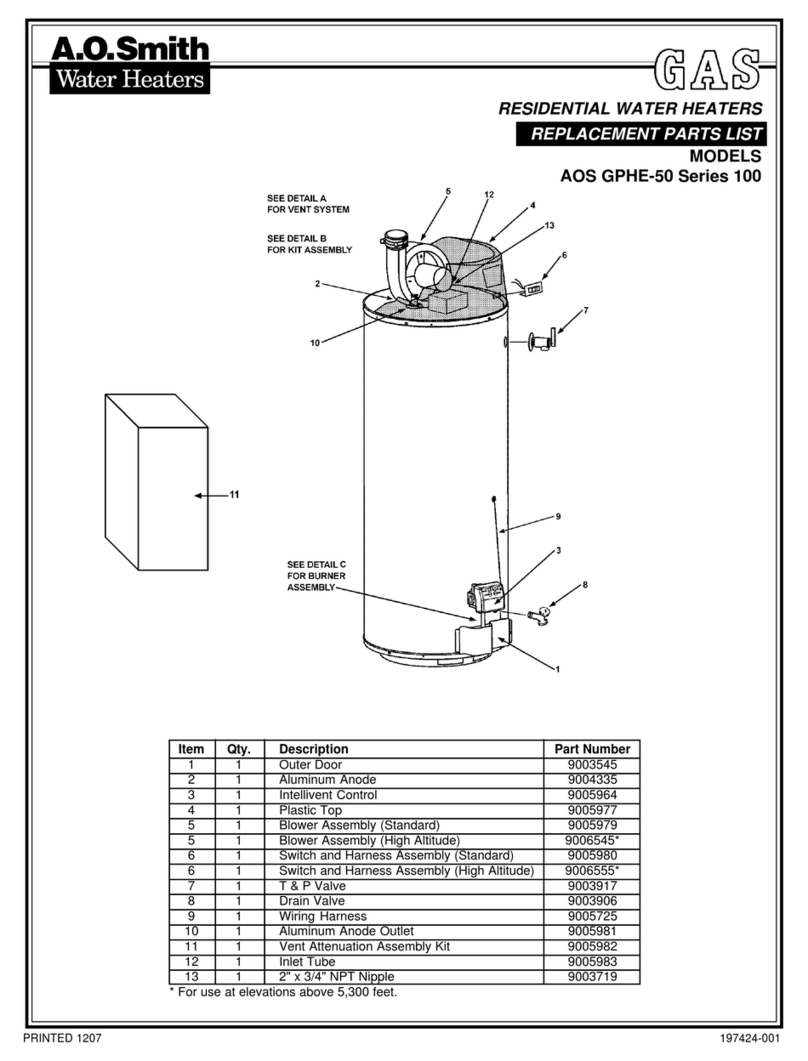

VENT KIT ASSEMBLY COMPONENTS

1 — 3" 90° steel elbow

1 — 5" 90° aluminum elbow

1 — 3" tube assembly (2-pcs. meshed)

1 — 5" tube assembly (2-pcs. meshed)

1 — Finishing collar (inside)

1 — Finishing collar (outside)

1 — Terminal Vent Cap Assembly

1 — Tube silicone sealant

8 — Sheet metal screws

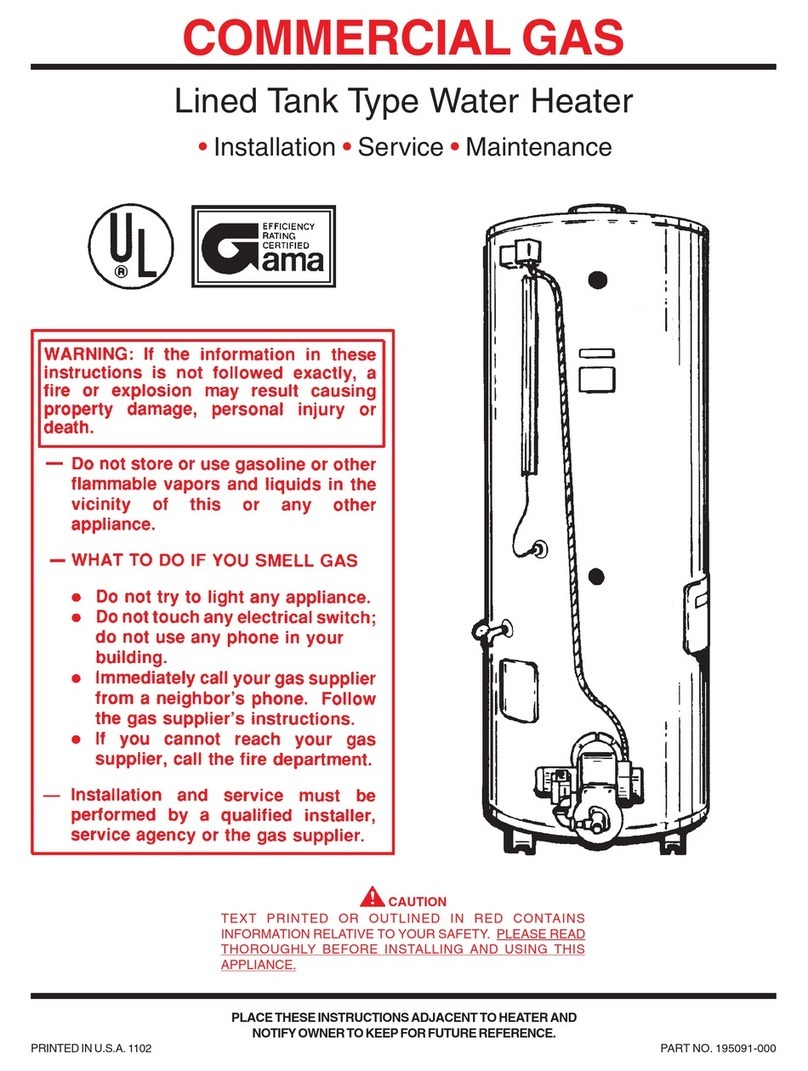

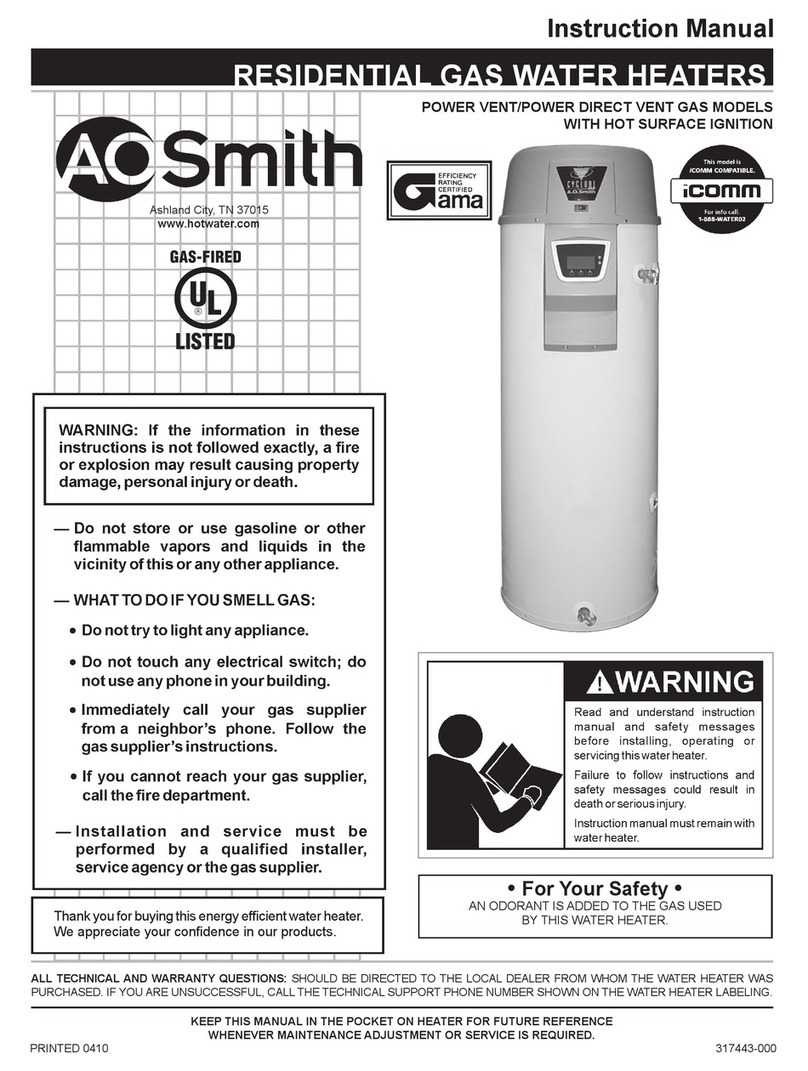

GENERAL SAFETY INFORMATION

EXTERNAL DAMAGE

Do not operate the water heater until it has been fully checked out

by a qualified technician, if the water heater:

•Has been exposed to fire or damage.

•Displays evidence of sooting.

•Produces steam or unusually hot water.

If the water heater has been flooded it must be replaced.

CHEMICAL VAPOR CORROSION

WARNING

CORROSION OF THE FLUEWAYS AND VENT SYSTEM MAY

OCCUR IF AIR FOR COMBUSTION CONTAINS CERTAIN

CHEMICAL VAPORS. SUCH CORROSION MAY RESULT IN

FAILURE AND RISK OF ASPHYXIATION.

Spray can propellants, cleaning solvents, refrigerator and air

conditioning refrigerants, swimming pool chemicals, calcium and

sodium chloride (water softener salt), waxes and process chemicals

are typical compounds which are potentially corrosive.

Do not store products of this sort near the heater. Also, air which is

brought in contact with the heater should not contain any of these

chemicals. If necessary, uncontaminated air should be obtained

from remote or outside sources. The limited warranty is voided

when failure of water heater is due to a corrosive atmosphere. (Refer

to the limited warranty for complete terms and conditions).

EXTENDED NON-USE PERIODS

WARNING

HYDROGEN GAS CAN BE PRODUCED IN A HOT WATER

SYSTEM SERVED BY THIS HEATER THAT HAS NOT BEEN USED

FOR A LONG PERIOD OF TIME (GENERALLY TWO WEEKS OR

MORE). HYDROGEN GAS IS EXTREMELY FLAMMABLE. To

reduce the risk of injury under these conditions, it is recommended

that the hot water faucet be opened for several minutes at the kitchen

sink before using any electrical appliance connected to the hot water

system. If hydrogen is present, there will probably be an unusual

sound such as air escaping through the pipe as the water begins to

flow. THERE SHOULD BE NO SMOKING OR OPEN FLAME NEAR

THE FAUCET AT THE TIME IT IS OPEN.

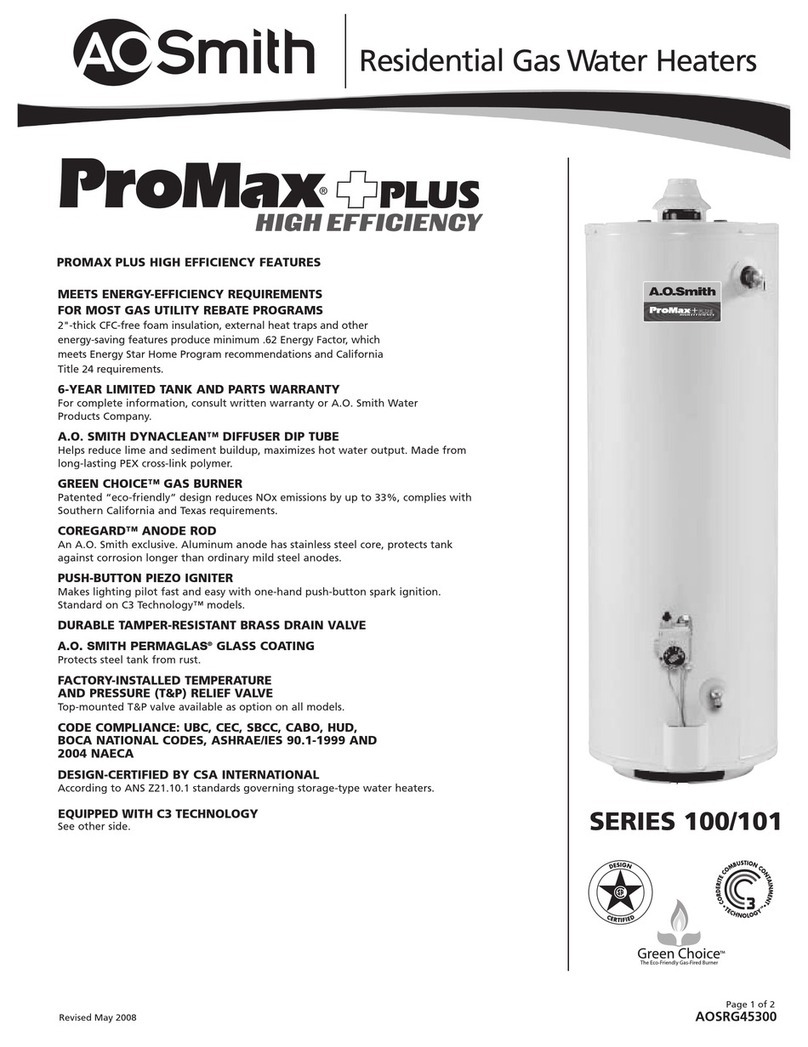

INSULATION BLANKETS

Insulation blankets available to the general public for external use

on gas water heaters are not necessary with A. O. Smith products.

The purpose of an insulation blanket is to reduce the standby heat

loss encountered with storage tank water heaters. Your A. O. Smith

water heater meets or exceeds the National Appliance Energy

Conservation Act standards with respect to insulation and standby

loss requirements, making an insulation blanket unnecessary.

WARNING

Should you choose to apply an insulation blanket to this heater,

you should follow these instructions (See Figure 1 for identification

of components mentioned below). Failure to follow these

instructions can restrict the air flow required for proper combustion,

resulting in fire, asphyxiation, serious personal injury or death.

•Do not cover the outer door, thermostat or temperature &

pressure relief valve.

•Do not cover the instruction manual. Keep it on the side of the

water heater or nearby for future reference.

•Do obtain new warning and instruction labels from A.O. Smith

for placement on the blanket directly over the existing labels.

INSTALLATION

REQUIRED ABILITY

INSTALLATION OR SERVICE OF THIS WATER HEATER

REQUIRES ABILITY EQUIVALENT TO THAT OF A LICENSED

TRADESMAN IN THE FIELD INVOLVED. PLUMBING, AIR

SUPPLY, VENTING AND GAS SUPPLY ARE REQUIRED.

GENERAL

The installation must conform to these instructions and the local

code authority having jurisdiction. In the absence of local codes,

conform to the latest edition of National Fuel Gas Code ANSI Z223.1

The code manual can be purchased from the American Gas

Association Laboratories, 8501 East Pleasant Valley Road,

Cleveland, OH 44131.

LOCATION OF HEATER

This is a direct vent water heater which draws combustion air from

outside the structure and exhausts all products of combustion to

the outside of the structure. All air for combustion and all products

of combustion are routed through the ducting provided, directly

from and to the outside of the building. It therefore must be located

next to the outside wall within the range of the adjustments illustrated

in fig. 15. DO NOT attempt to extend the air supply tube or inner

flue vent tube beyond the dimensions specified on page 7 vent

connections, steps 6 and 7.

The heater is design certified by the American Gas Association for

installation on combustible flooring in a closet having minimum

clearances from combustible material of: 0" clearance from sides,

rear, and top air tube, 4" from the front and 18" from the top. If

clearances stated on the heater differ from standard clearances,

install water heater according to clearances stated on heater.

A minimum clearance of 4" must be allowed for access to re-

placeable parts such as the thermostats, drain valve and relief valve.

Adequate clearance for servicing this appliance should be

considered before installation, such as changing the anodes, etc.

When installing the heater, consideration must be given to proper

location. The water heater should be located as close to or

centralized to the water piping system as possible. The water heater

should be located in an area not subject to freezing temperatures.