5

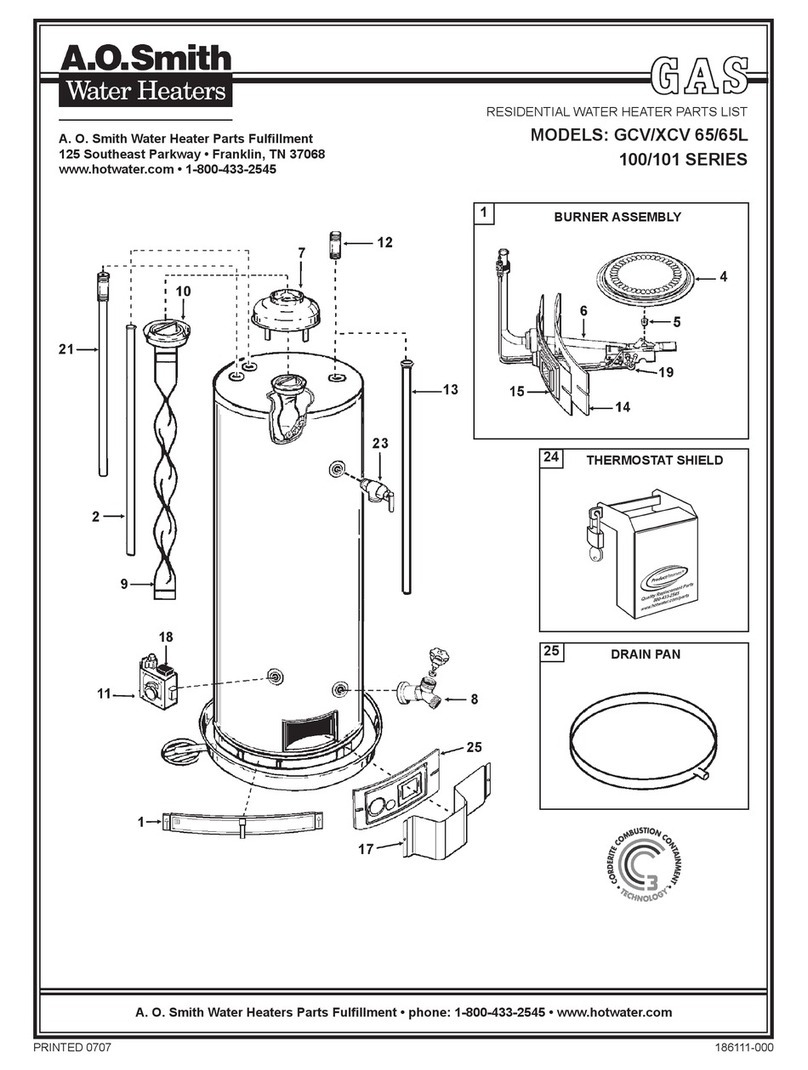

CLOSED WATER SYSTEM

A closed system will exist if a back-flow preventer (check valve),

pressure reducing valve, or other similar device is installed in

the cold water line between the water heater and the street main

(or well). Excessive pressure may develop due to the thermal

expansion of heated water causing premature tank failure or

intermittentreliefvalveoperation. This typeoffailure is not covered

by the limited warranty. An expansion tank may be necessary in

the cold water supply to alleviate this situation, see Figure 1.

Contact the local plumbing authority.

If the temperature and pressure relief valve on the appliance

discharges periodically, this may be due to thermal expansion

in a closed water supply system. Contact the water supplier or

local plumbing inspector on how to correct the situation. Do not

plug the temperature and pressure relief valve.

GAS CONNECTIONS

The minimum gas supply pressure for input adjustment is

5.0" W.C. (1.25 kPa) for natural gas 11.0" W.C. (2.74 kPa) for propane.

THEHEATERISNOTINTENDED FOROPERATIONATHIGHER

THAN 10.5" (2.6 kPa) FOR NATURAL & 13.0" (3.24 kPa) FOR

PROPANE WATER COLUMN SUPPLYPRESSURE. EXPOSURE

TO HIGHER GAS SUPPLY PRESSURE MAY CAUSE DAMAGETO

THECONTROLWHICHCOULDRESULTIN FIRE OR EXPLOSION.

If overpressure has occurred such as through improper testing of gas

lines or emergency malfunction of the supply system, the control must

becheckedfor safe operation. Makesurethat the outsideventson the

supply regulators and the safety vent valves are protected against

blockage. These are parts of the gas supply system not the

heater. Vent blockage may occur during ice storms.

IT IS IMPORTANT TO GUARD AGAINST CONTROL FOULING

FROM CONTAMINANTS IN THE GAS WAYS. SUCH FOULING

MAYCAUSE IMPROPER OPERATION, FIREOREXPLOSION.

All piping must comply with local codes and ordinances or with

the National Fuel Gas Code (ANSI Z223.1, NFPA 54) whichever

applies. Copper and brass tubing and fittings (except tin lined

copper tubing) shall not be used.

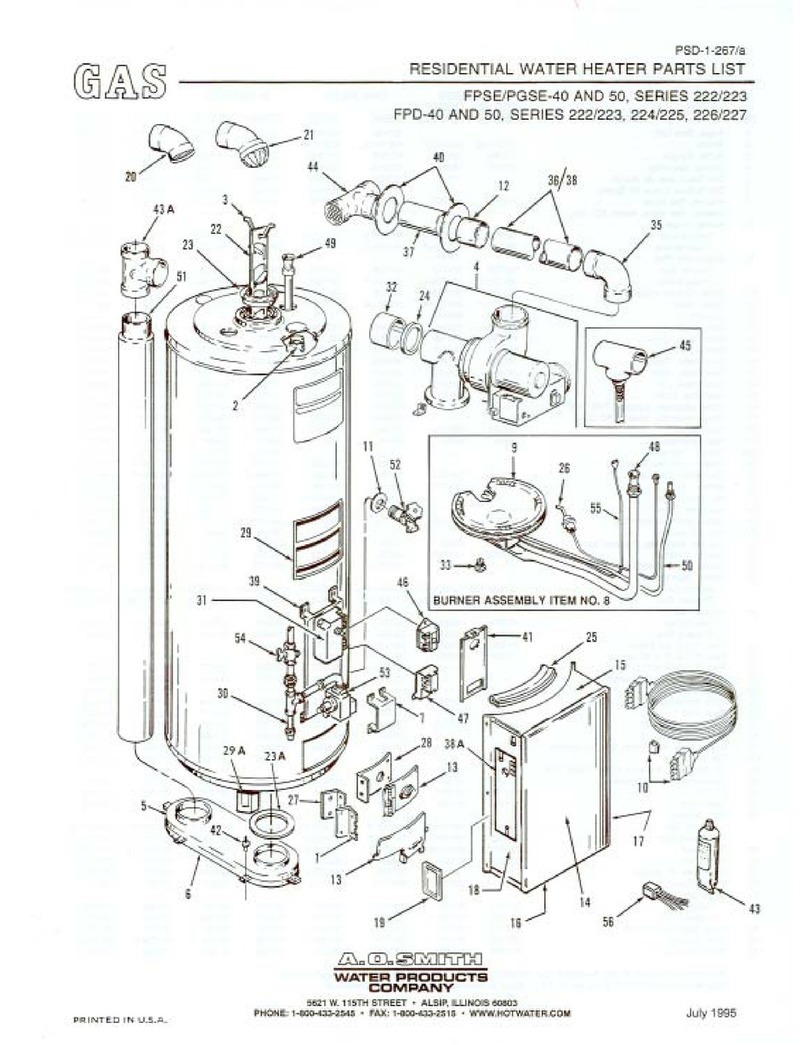

REFER TO FIGURE 1 FOR CONNECTION DETAILS. BEFORE

ATTACHING THE GAS LINE BE SURE THATALL GAS PIPE IS

CLEAN ON THE INSIDE.

TOTRAPANYDIRTORFOREIGNMATERIALINTHEGASSUPPLY

LINE, A DIRT LEG (SOMETIMES CALLED DRIP LEG) MUST BE

INCORPORATED IN THE PIPING, SEE FIGURE 1.The dirt leg must

be readily accessible. Install in accordance with recommendations of

serving gas supplier. Refer to the current edition of ANSI Z223.1.

To prevent damage, care must be taken not to apply too much

torque when attaching gas supply pipe to gas valve inlet. The

valve inlet has a hexagon shape for use with a backup wrench.

Apply joint compounds (pipe dope) sparingly and only to the

male threads of pipe joints. Do not apply compound to the first

two threads. Use compounds resistant to the action of liquefied

petroleum gases. Do not use teflon tape on gas valve.

DISCONNECT THE APPLIANCE AND ITS INDIVIDUAL SHUT OFF

VALVE FROM THE GAS SUPPLY PIPING SYSTEM DURING ANY

SUPPLY PRESSURE TESTING EXCEEDING 1/2 PSI

(3.5 kPa). GAS SUPPLY LINE MUST BE CAPPED WHEN

DISCONNECTEDFROMTHEHEATER.FORTESTPRESSURESAT

1/2 PSI (3.5 kPa) OR LESS, THE APPLIANCE NEED NOT BE

DISCONNECTED, BUT MUST BE ISOLATED FROM THE SUPPLY

PRESSURETESTBYCLOSINGTHEMAIN MANUALGAS VALVE.

BEFORE PLACING THE HEATER IN OPERATION, CHECK

FOR GAS LEAKAGE. USE SOAP AND WATER SOLUTION OR

OTHERMATERIALACCEPTABLEFORTHISPURPOSE.DONOT

USE MATCHES, CANDLES, FLAME OR OTHER SOURCES OF

IGNITIONTOLOCATE GASLEAKS.

RELIEF VALVE (P)- See FIGURE 1.

A NEW TEMPERATURE AND PRESSURE RELIEF VALVE

COMPLYING WITHTHE STANDARD FORRELIEF VALVESAND

AUTOMATIC GAS SHUT OFF DEVICES FOR HOT WATER

SUPPLY SYSTEMS, ANSI Z21.22 (CURRENT EDITION) MUST

BE INSTALLED IN THE HEATER IN THE MARKED OPENING

PROVIDED. THE VALVE MUST BE OFA SIZE (INPUT RATING)

THAT WILLBE ADEQUATE FOR YOUR SIZE HEATER.

Check the metal tag on the relief valve and compare it to the

heater’s rating plate. The pressure rating of the relief valve must

not exceed the working pressure shown on the rating plate of the

heater. In addition, the hourly Btu rated temperature steam

discharge capacity of the relief valve shall not be less than the

inputrating of the heater. NOVALVEISTOBE PLACED BETWEEN

THERELIEFVALVEANDTANK. DO NOTPLUGTHERELIEFVALVE.

The drain line connected to this valve must not contain a reducing

coupling or other restriction and must terminate near a suitable

drain to prevent water damage during valve operation. The

discharge line shall be installed in a manner to allow complete

drainage of both the valve and line. DO NOT THREAD, PLUG OR

CAP THE END OF THE DRAIN LINE.

VENTING

WARNING

NEVER OPERATE THE HEATER UNLESS THE INTAKE AND

EXHAUSTAREVENTEDTOTHEOUTDOORSANDHASADEQUATE

AIR SUPPLY TOAVOID RISKS OF IMPROPER OPERATION, FIRE,

EXPLOSION,ORASPHYXIATION.IFTHEWATERHEATERISBEING

INSTALLED AS A REPLACEMENT FOR AN EXISTING POWER

VENTED HEATER IN PRE-EXISTING VENTING, A THOROUGH

INSPECTION OF THE EXISTING VENTING SYSTEM MUST BE

PERFORMEDPRIORTOANYINSTALLATIONWORK.VERIFYTHAT

THECORRECTMATERIALASDETAILEDABOVEHASBEENUSED,

AND THAT THE MINIMUM OR MAXIMUM VENT LENGTHS AND

TERMINALLOCATIONASDETAILEDINTHISMANUALHAVEBEEN

MET. CAREFULLY INSPECTTHE ENTIRE VENTING SYSTEM FOR

ANYSIGNSOFCRACKSORFRACTURES,PARTICULARLYATTHE

JOINTS BETWEEN ELBOWS AND OTHER FITTINGS AND THE

STRAIGHTRUNSOFVENTPIPE.CHECKTHESYSTEMFORSIGNS

OFSAGGINGOROTHERSTRESSESINTHEJOINTSASARESULT

OFMISALIGNMENTOFANYCOMPONENTSINTHESYSTEM.IFANY

OF THESE CONDITIONS ARE FOUND, THEY MUST BE

CORRECTED IN ACCORDANCE WITH THE VENTING

INSTRUCTIONS IN THIS MANUAL BEFORE COMPLETING THE

INSTALLATIONANDPUTTINGTHEWATERHEATERINTOSERVICE.

WARNING

THESE MODELS ARE CERTIFIED FOR VERTICAL VENTING

ANDSIDE WALLVENTING. THEUNITCONSISTSOFAN INTAKE

VENT TERMINALAND AN EXHAUST VENT TERMINAL WHICH

MUSTBEUSEDTOTERMINATETHE VENTINGARRANGEMENT.

IF THE VENT TERMINALS SUPPLIED WITH THIS UNIT ARE

NOT USED TO TERMINATE THE VENTING ARRANGEMENT,

THERISK OF IMPROPER OPERATION,FIRE, EXPLOSION, OR

ASPHYXIATION WILLINCREASE.