2IM 725 (1-02)

Table of Contents

Safety Information and Tools Required ............................................................ 2

Pre-Installation Considerations ......................................................................... 2

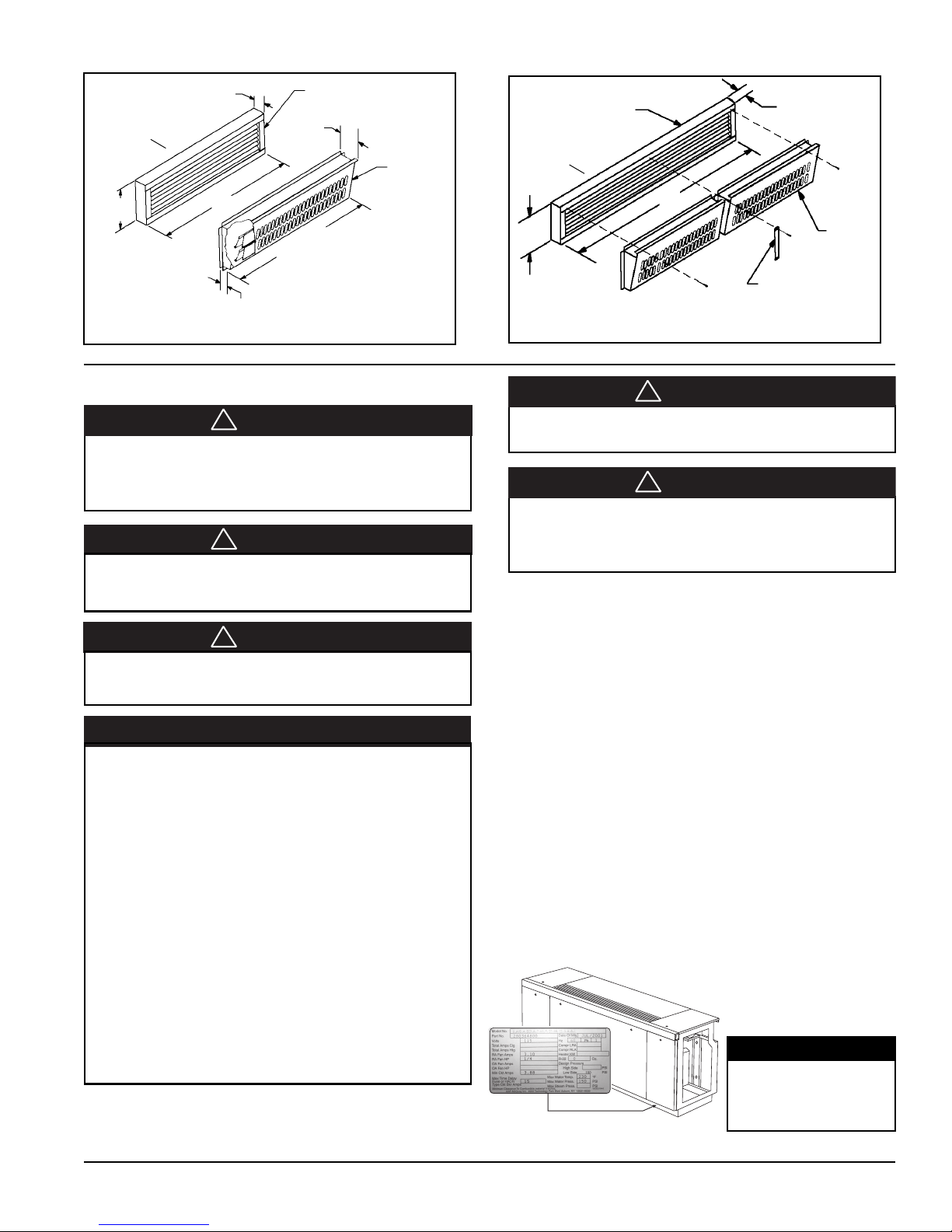

Wall Openings, Louvers, and VentiMatic Shutter ............................................ 3

Installing Louvers .............................................................................................. 7

Installing the VentiMatic Shutter Assembly ...................................................... 8

Installing The AV Unit Ventilator .............................................................. 9

Step 1 - Uncrate and Inspect the Unit Ventilator(s) .......................................... 9

Model AV Data Plate - Specific Information ................................................... 10

Step 2 - Position the Unit Ventilator ............................................................ 11-12

Step 3 - Make Piping Connections .................................................................. 12

In All Systems .................................................................................................. 12

In Water Systems ............................................................................................ 13

Coil Header, Locations ............................................................................... 14-16

(Heating Only, Cooling Only) ..................................................................... 14

(Heat/Cool) ................................................................................................. 15

(Reheat) ...................................................................................................... 16

Valves and Piping (diagrams and dimensions) ......................................... 17-19

2-Way and 3-Way End of Cycle Valves ..................................................... 17

2-Way and 3-Way Modulating Valves ........................................................ 18

End of Cycle (In Steam Systems) Valve Piping ........................................ 19

Typical Coil Piping ...................................................................................... 20-21

Condensate Piping .......................................................................................... 22

Unit Ventilator Split Systems Guidelines (DX) Systems ........................... 23-25

Step 4 - Make Electrical Connections .............................................................. 26

Unit Mounted MicroTech™ Direct Digital Controls (DDC) Components .... 27-28

Typical Wall Mounted Room Air Sensor ......................................................... 29

Step 5 - Prepare AV Unit Ventilator for Start-up ............................................. 30

Installing Unit Ventilator End Panels .............................................................. 30

Oiling the Fan Shaft Bearing ........................................................................... 30

AV Unit Ventilator Start-Up ............................................................................. 30

Model AH Ceiling Unit Installation .......................................................... 31

Safety Information and Tools Required .......................................................... 31

Model AH Data Plate - Specific Information ................................................... 32

Typical Ceiling AH Unit Air Arrangements ................................................ 33-34

Pre-Installation Condsiderations ..................................................................... 34

Duct System Design for Noise Control ...................................................... 35-36

Anchoring The Ceiling Unit ............................................................................. 36

Filters ............................................................................................................... 37

Same End Piping Connections ....................................................................... 37

Remote Two Speed Control Switch ................................................................ 38

Prepare AH Ceiling Unit Ventilator for Start-up ............................................. 39

Installing AH Unit Ventilator End Panels ........................................................ 39

Check, Test and Start Warranty Notice .......................................................... 39

Warranty .......................................................................................................... 39

Tools Required

A forklift or other lifting device is needed to install this product. Applicable tools for lifting, hook-up of piping, electrical and insulation. Unit comes

with an allen wrench and four (4) lagging washers in the envelope in end compartment of the unit. (see photo below)

Install this product in accordance with good engineering practices and workmanship, following these general instructions, plus the job-specific

AAF®-HermanNelson®submittal drawings provided for specific dimensions, unit arrangements, controls and electrical details, pipe stub-up

locations, etc.

Pre-Installation Considerations

Storage – If equipment is stored for any length of time before installation, it should remain in its shipping packaging in a clean, dry, climate

controlled area.

Safety Information

Follow all safety codes. Wear safety glasses and work gloves. Use a quenching cloth for brazing operations. Have a fire extinguisher available. Follow all warnings and

cautions in these instructions and attached to the unit. Consult applicable local building codes and National Electrical Codes (NEC) for special requirements.

Recognize safety information. When you see a safety symbol on the unit or in these instructions, be alert to the potential for personal injury. Understand the meanings

of the words DANGER, WARNING, and CAUTION. DANGER identifies the most serious hazards that will result in death or severe personal injury; WARNING means

the hazards can result in death or severe personal injury; CAUTION identifies unsafe practices that can result in personal injury or product and property damage.

Improper installation, adjustment, service, maintenance, or use can cause explosion, fire, electrical shock, or other conditions which may result in personal injury or

property damage. This product must be installed only by personnel with the training, experience, skills, and applicable licensing that makes him/her “a qualified

professional HVACR installer.”

DISCONNECT ALL ELECTRICAL

POWERBEFORESERVICINGUNIT

TO PREVENT INJURY OR DEATH

DUE TO ELECTRICAL SHOCK.

WARNING

HAZARDOUS VOLTAGE!

DISCONNECT ALL ELECTRIC POWER IN-

CLUDING REMOTE DISCONNECTS BEFORE

SERVICING. FAILURE TO DISCONNECT

POWER BEFORE SERVICING CAN CAUSE

SEVERE PERSONAL INJURY OR DEATH.

!CAUTION

USE COPPER CONDUCTORS ONLY.

UNIT TERMINALS ARE NOT DESIGNED TO

ACCEPT OTHER TYPES OF CONDUCTORS.

FAILURE TO DO SO MAY CAUSE DAMAGE

TO THE EQUIPMENT.

!

Forklift lifting location

(see Caution above and table 2, page

11 for unit weights)

Shipping Envelope Contents - Located in

right end compartment of unit.

CAUTION

!

Use 72" length forklift tines, short tines will damage the unit

bottom.

!DANGER