Scorpio 1800 Installation Instructions

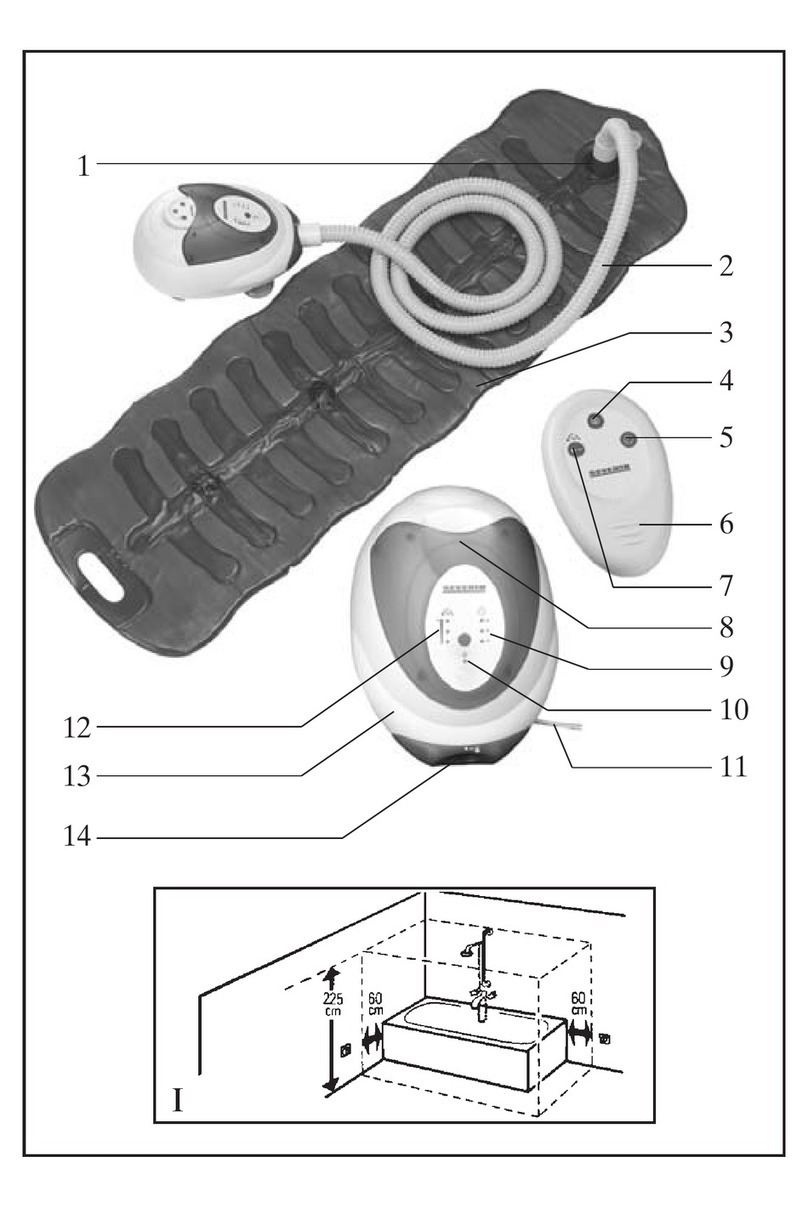

Plumbing Manifold

Tap & Waste Connecction

Connect the taps using the flexible water pipes provided making sure they do not snag when the bath

is lifted.Trimming of the inner lower & outer upper panels may be required to fit the panels around

the pipe.The waste is pre-assembled. Connect the flexible pipe to the waste outlet. Fit the manifold to

the floor and connect as detailed.

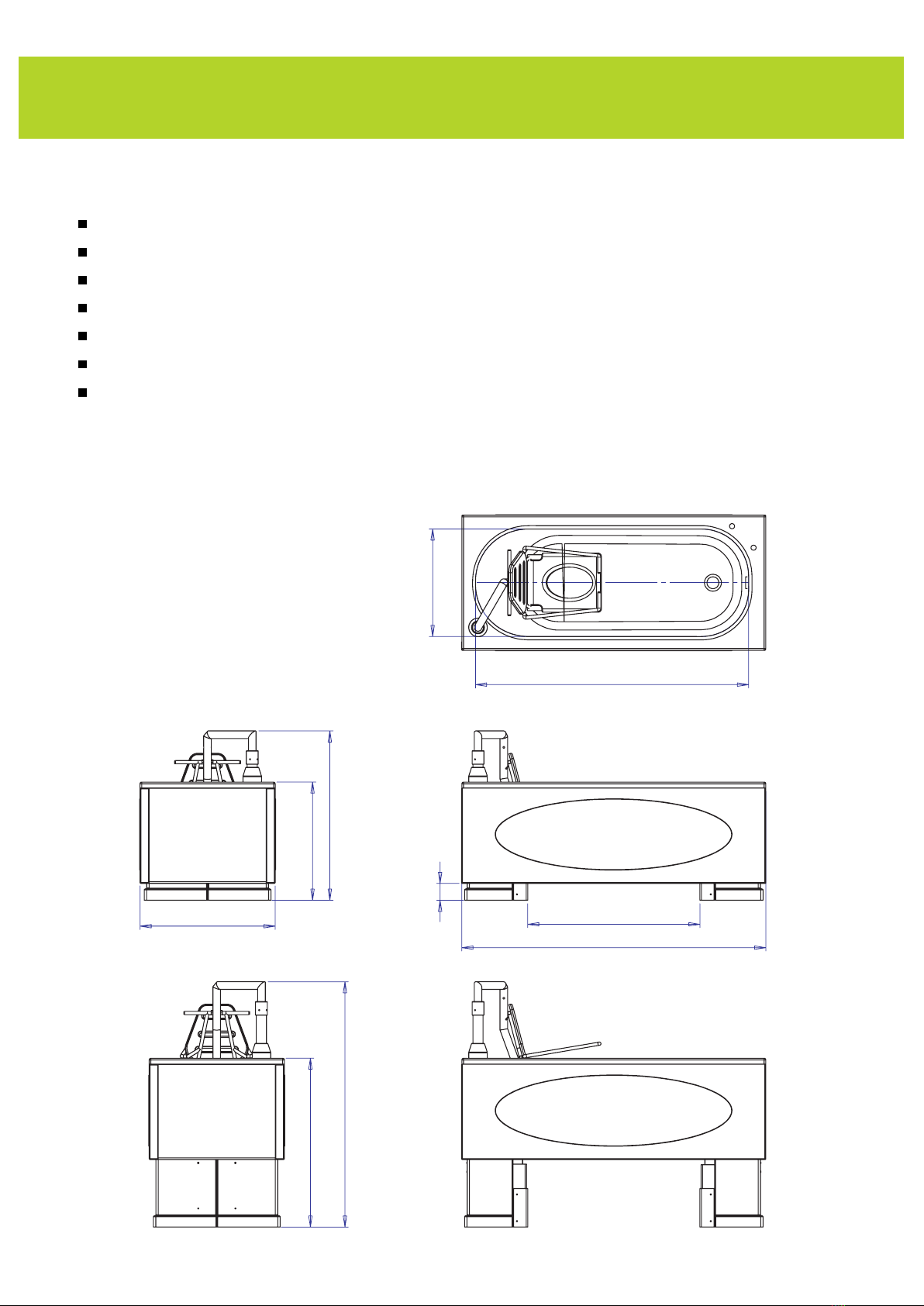

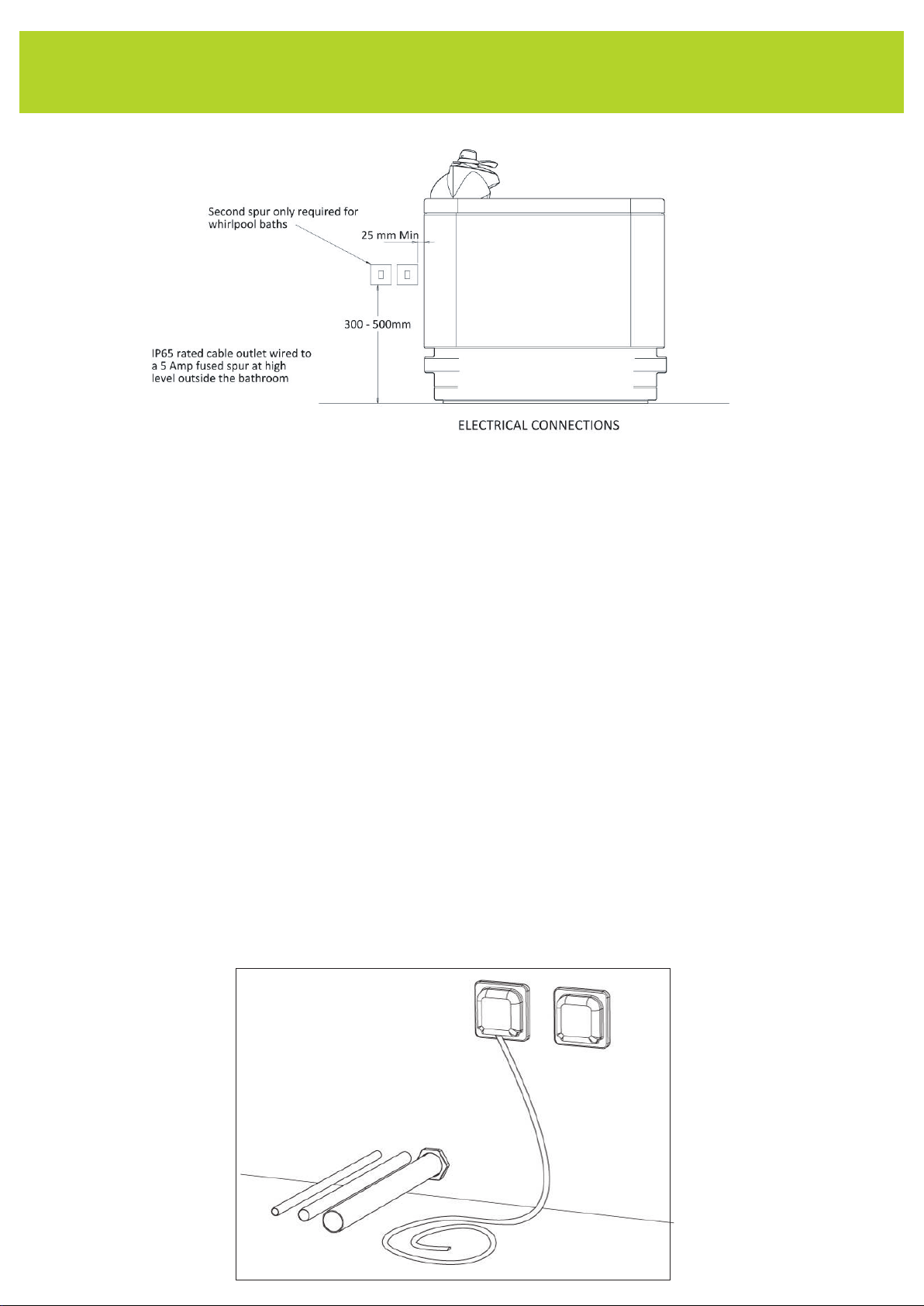

Electrical Connection

The control unit is located in the centre of the underside of

the bath. A prewired lead is supplied and this should be run to

the mains supply as per the pre-install connections.The

handset should be plugged in the control box as per FIG 3.

Ensure the lead retaining clip is refitted once the

handset has been connected.

Panel Fixing

The bath shell comes complete with the outer upper panels fitted.These should fit outside the inner

lower panels and should not touch them. Note: if the upper and lower panels touch, marking will occur.

Adjustment is possible on the bayonet clip if required.

Inner Panel Fitting

Offer the corner inner end panels (right and left) up to the bath and secure

using the M4 x 12mm white plastic topped machine screws

supplied (Fig.a) Screw through holes in panels and into

the rivnuts positioned in the frame uprights.

Use the white plastic binding fixings (Fig. b) to secue the inner panels together.

There will be one half of the screw assembly already bonded in each hole. Use

a quantity of 2 to connect the right corner inner panel to the left corner inner panel.

Use a quantity of 2 to connect the inner centre panel to the right and left corner

panels either side.

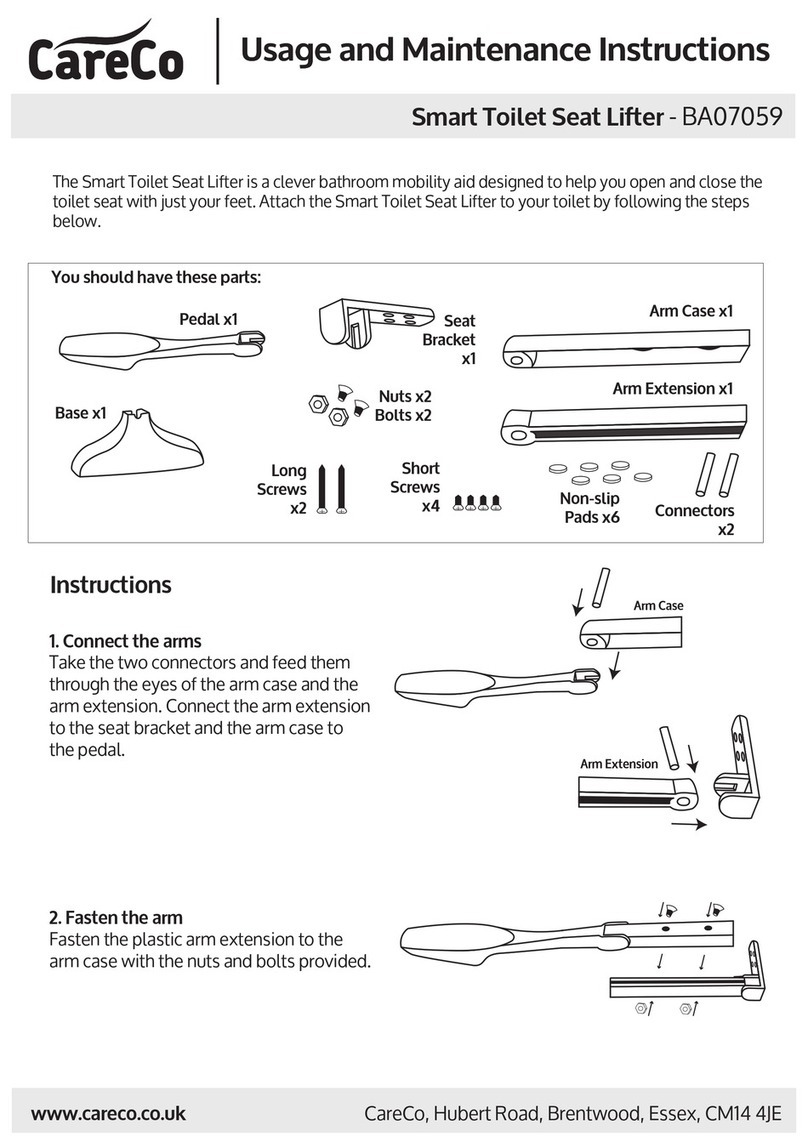

Sliding Panels

The Bath will be delivered with the sliding bracket metal-work

assembled (Fig. c)

This assembly will be fixed to the bath using 2

M8 Hex bolts through the slots and into the threaded

holes in the bath support bars.

It is important that the plate is square to the support

bars as it is crucial that the sliding brackets are

parallel to the sliding panel. If not the

panel will not rise and

fall as intended.

a.

b.

Sliding Panel Bracket

Qty x4 per bath Sliding Panel Plate

Qty x2 per bath

c.

10