3

GENERAL INFORMATION

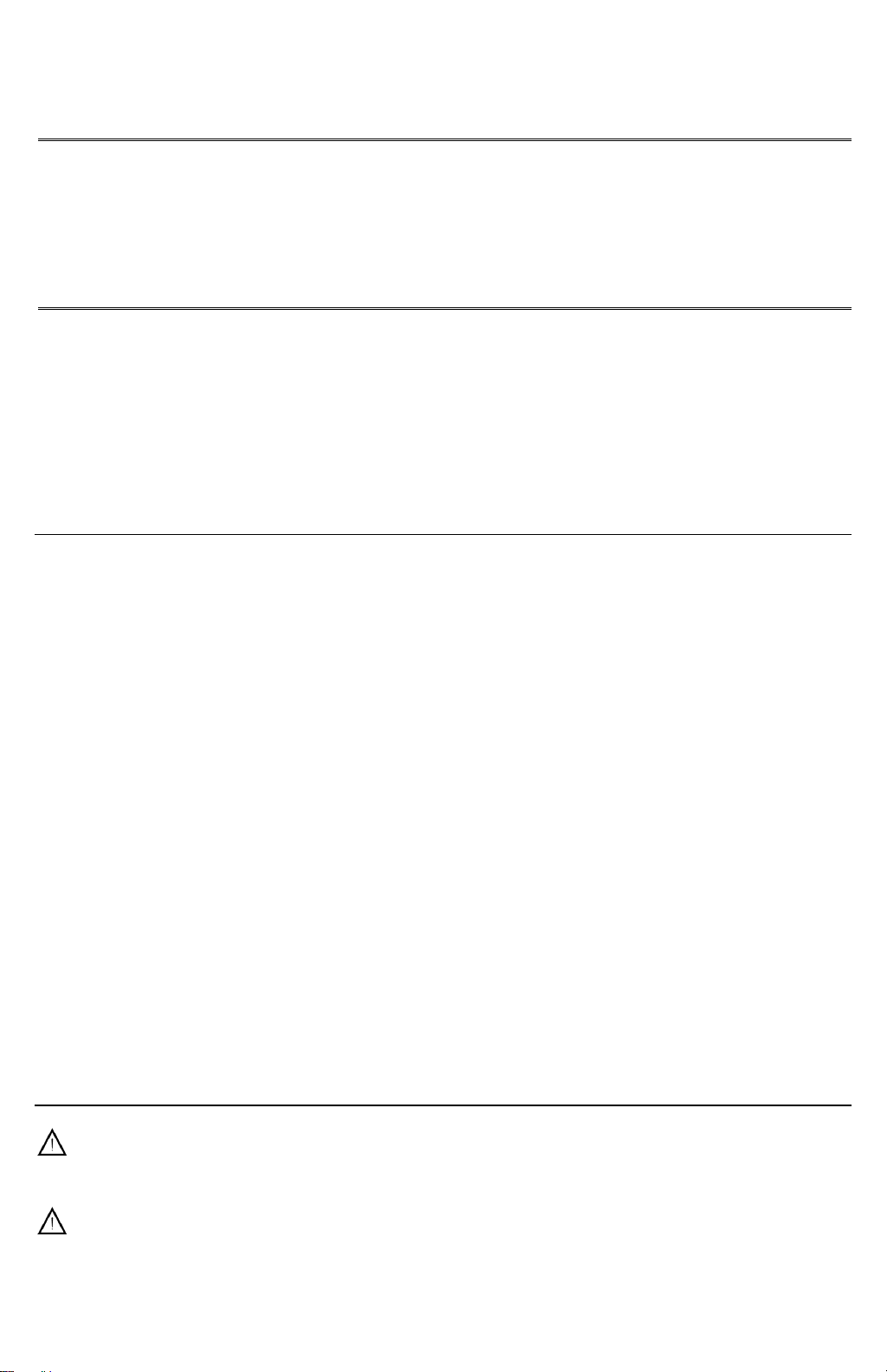

The AIRE GUARDIAN® AG8000 is a mobile containment unit designed to capture and

contain particulate during ceiling access work on ceiling heights up to 10'-2". Ceiling

heights up to 12'-2" can be reached with the Extension (P/N: AG8000-EXT24, sold

separately). Additionally, a Side Access Panel (P/N: AG8000-SA, sold separately) can be

installed to provide containment while doing wall access projects. Numerous user-friendly

featureshelp maintain superior levels of patient protection, worker safety, and productivity

unmatched by any other hard sided cart.

The AG8000 is designed to comply with ICRA requirements for projects requiring ceiling

access and limited wall access. The unit and its accessories can be used to meet various

mitigation activities which are required by the ASHE Infection Control Risk Assessment

2.0 Matrix of Precautions for Construction, Renovation and Operations and other

regulating documents. These activities include, but are not limited to

•Airborne dust dispersion prevention.

•Neutral to negative pressurization.

•Barriers that extend to the ceiling.

•Indoor air exhaust that is HEPA filtered.

•An impermeable temporary containment vessel.

The AIRE GUARDIAN® AG8000 is designed to be used with the provided extension

ladder only and should not be used with any other ladder. Read all instructions within this

manual as well as all danger, caution, and instruction labels affixed to the ladder.

This unit should be used in conjunction with an air scrubber in order to meet ICRA

requirements where required. The AG8000 was designed to accept the PAS750 Portable

Air Scrubber (sold separately) inside the unit, but has the flexibility to have an external air

scrubber ducted to the unit's port (P/N: AG8000CADK, sold separately).

This manual provides instructions on how to use the features of the AIRE GUARDIAN®

AG8000, however, the procedure and/or order of operations in which it is used should be

determined by the healthcare facility's ICRA plan. Any procedural information

contained within this manual is to be taken as a suggestion only to help the user

understand some of the design intent of the unit.

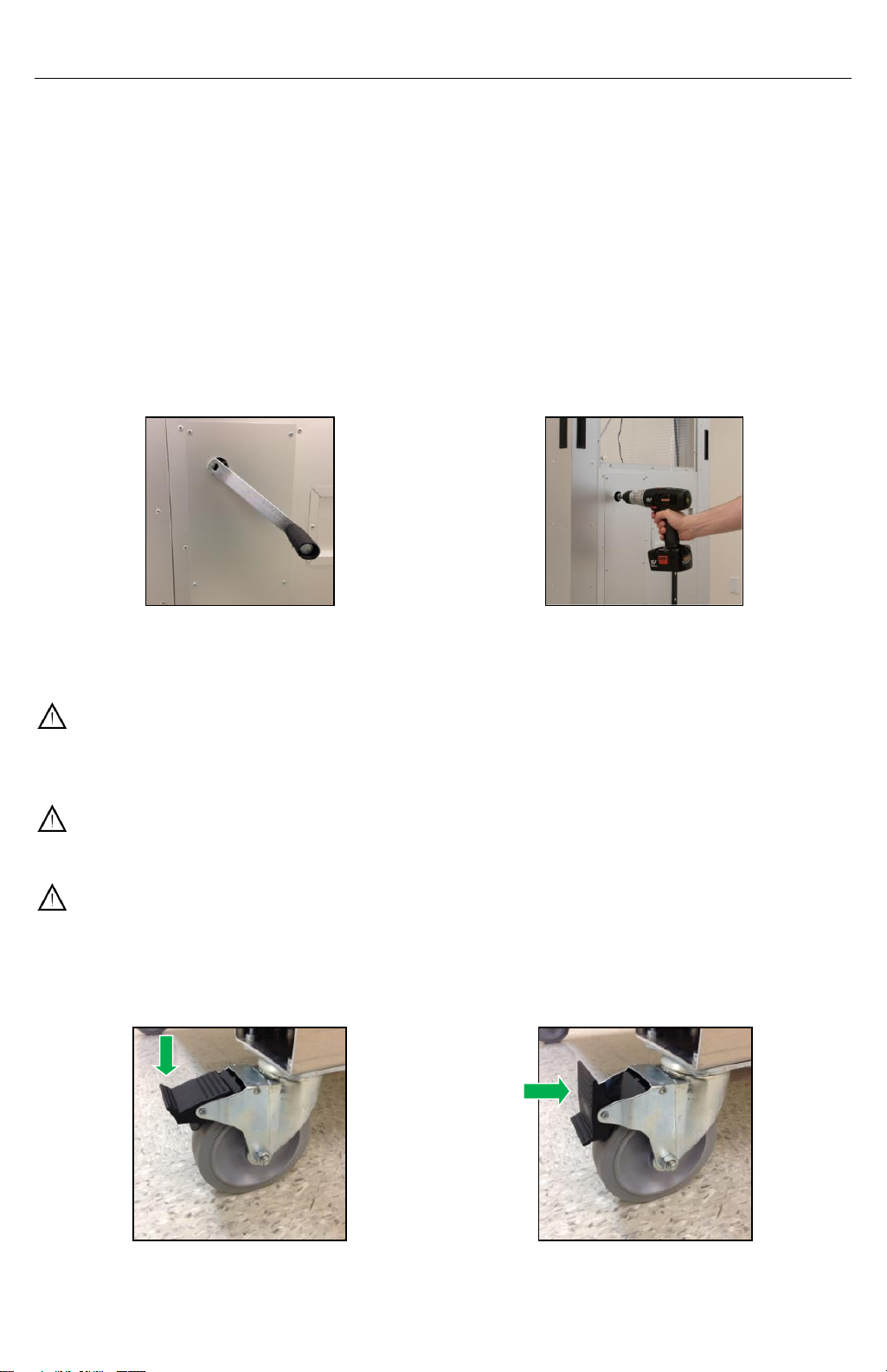

TRANSPORTING BETWEEN FACILITIES

The AG8000 should be secured to ensure that the

unit does not roll during transport and transported

in its normal position (resting on its casters). If

extremely poor road conditions exist, or excessive

shock and vibration are expected, take

precautionary measures by padding the unit to

provide impact absorption during transport.

Additionally, secure the ladder to the floor with the

included ratchet strap (P/N: HARDWRE209).