2

CONTENTS

GETTING STARTED ............................................................................................... 1

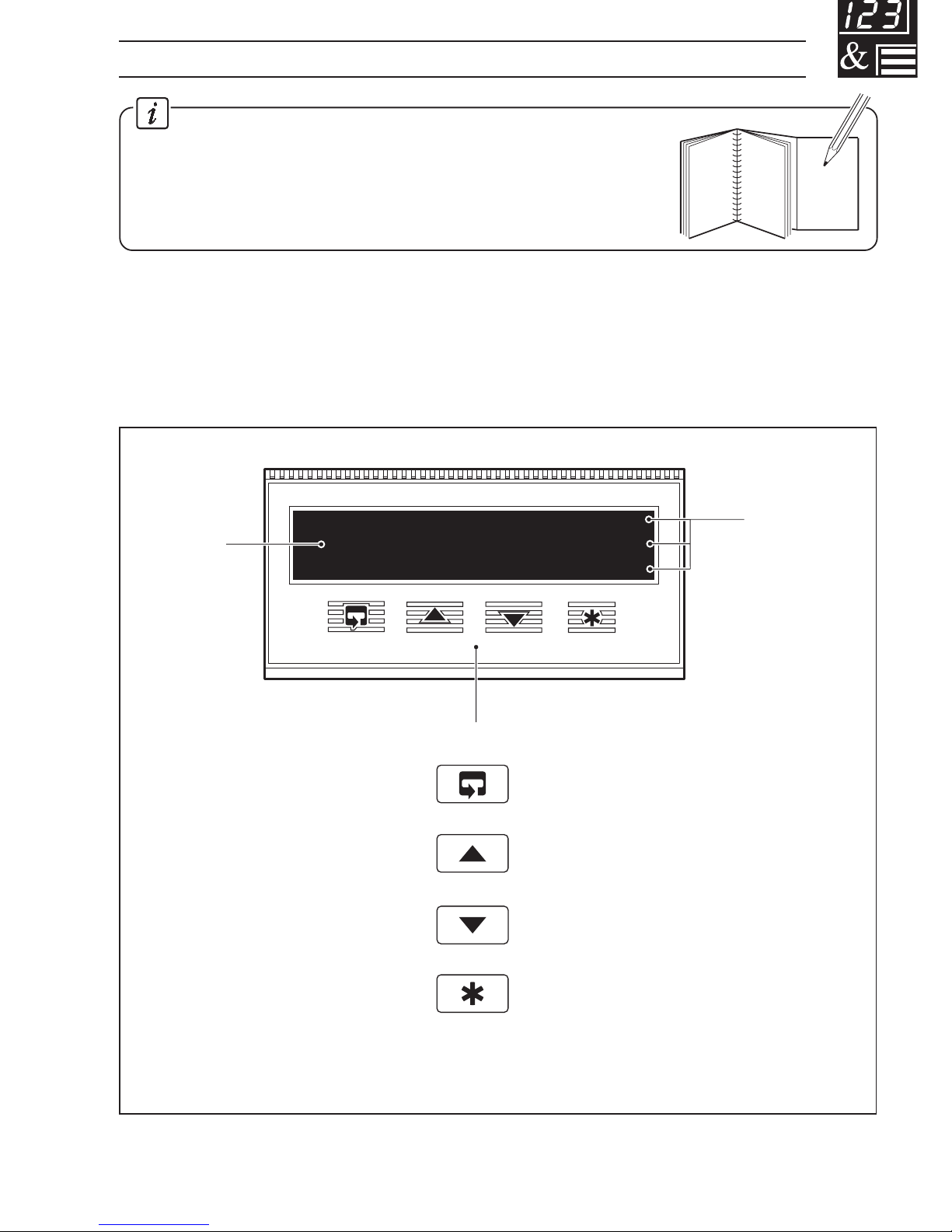

1 DISPLAYS AND FUNCTION KEYS .................................................................. 3

1.1 Introduction ............................................................................................... 3

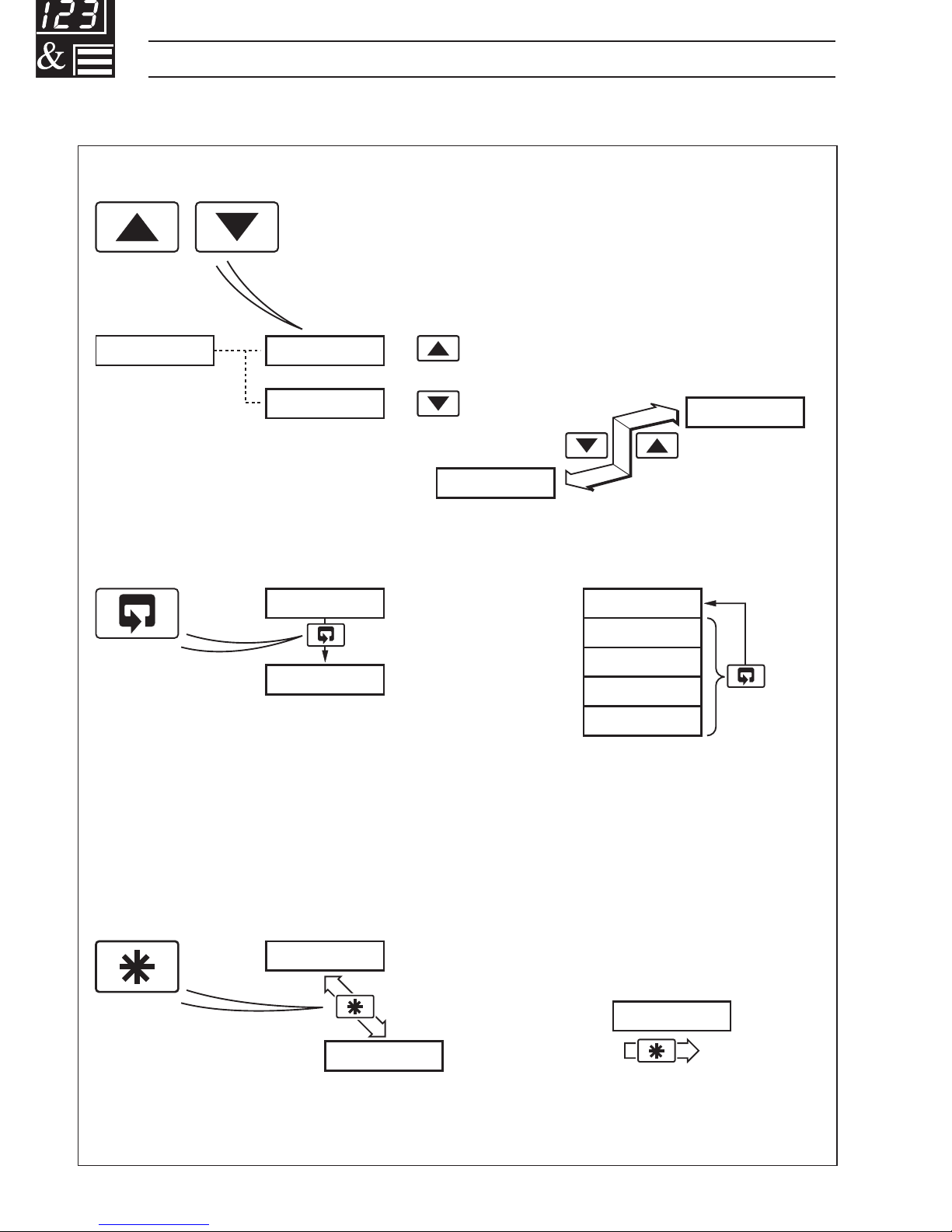

1.2 Use of Function Keys ................................................................................. 4

1.3 LED Alarms and Indicators ........................................................................ 5

1.4 Error Messages ......................................................................................... 6

2 OPERATOR MODE ........................................................................................... 7

2.1 Introduction ............................................................................................... 7

2.2 Operating Page – Standard (Level 1) ......................................................... 8

2.3 Operating Page – Totalizer (Level 1) .......................................................... 9

2.4 Operating Page – Maths Functions (Level 1) ........................................... 11

3 SET UP MODE ............................................................................................... 13

3.1 Introduction ............................................................................................. 13

3.2 Setup Level (Level 2) .............................................................................. 14

4 CONFIGURATION MODE ............................................................................... 18

4.1 Introduction ............................................................................................. 18

4.2 Accessing the Configuration Mode .......................................................... 18

4.3 Basic Hardware and Configuration (Level 3) ............................................ 20

4.3.1 Hardware Assignment and Input Type ........................................ 20

4.3.2 Alarms ....................................................................................... 22

4.3.3 Operator Functions and Totalizer Set Up .................................... 24

4.3.4 Digital Input and Serial Communications .................................... 26

4.4 Ranges and Passwords (Level 4) ............................................................ 28

5 INSTALLATION .............................................................................................. 31

5.1 Siting ....................................................................................................... 31

5.2 Mounting .................................................................................................. 33

5.3 Electrical Connections ............................................................................ 35

5.4 Relays, Arc Suppression, Inputs and Outputs ......................................... 35

5.4.1 Relay Contact Ratings ............................................................... 35

5.4.2 Arc Suppression ........................................................................ 35

5.4.3 Logic Output .............................................................................. 35

5.4.4 Retransmission Analog Output ................................................... 35

5.4.5 Digital Input ................................................................................ 35