Automatic Fire Detector in Threshold Alarm Technology

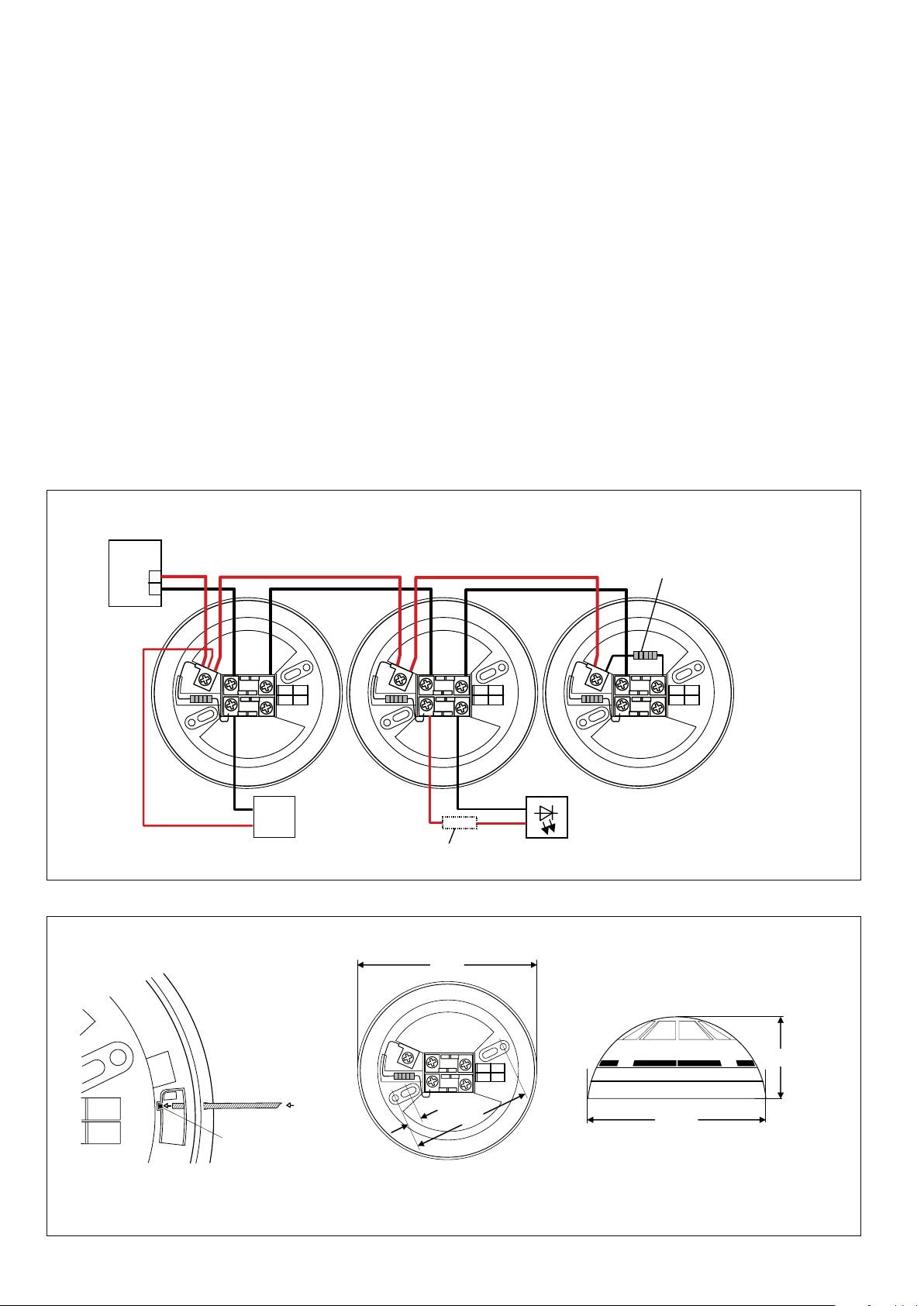

Installation

The detector bases are fixed on the ceiling with 2 screws,

after the corresponding preparations have been made.

The detector is mounted horizontally as standard.

The location of the mounting bores can be found in the

“Dimensional drawing” section.

During installation, it is important to ensure that the base does

not warp when installed on an uneven ceiling, as it may make

it difficult or impossible to plug-in the detector. The detector

is placed against the base and screwed onto the base in a

clockwise direction.

Cable connection

With flush-mounted cabling, it is necessary to ensure that all

the required conductors for standard wiring are located on the

“R+” terminal side. The incoming and outgoing conductors

can be inserted through the same aperture on the socket

base (also see the dimensional drawing).

With flush-mounted cabling, it is also advantageous if

both cables are inserted on the side of the base, where

the terminal “R+” and the terminals for all other standard

applications are located.

When introducing the cable from 2 sides, the location of the

base should be selected, so that the breaking points for the

cable entry on the base are offset longitudinally to the cable

path by 180 °. The individual wires can be fed both within the

base interior as well as from underneath the base, from one

half of the base to the other. Cables up to 2 x 2 x 0.8 mm

can be inserted to the base together with the sheath; thicker

cables will require removal of the sheath outside the base.

If the cable shield (sheath wire) of incoming and outgoing

cables is to be looped through, this must be implemented in

the base, e.g. using a ferrule or similar device.

Test activation

A test activation can be undertaken by holding a permanent

magnet at the smoke inlet aperture level (these are also

available on the heat detectors) located at about 100° in a

counter-clockwise orientation starting from the rectangular

opening on the side of the detector base on the detector.

Inspection/Maintenance

Every detector must be physically activated at least once a

year to test its function in accordance with VDE 0833 part 1.

A suitable testing aerosol is recommended for activation of

smoke detectors; heat detectors should be activated using a

heat gun or a hair drier.

Technical Data

Electrical values

Operating voltage 10 to 30 V DC

Quiescent current

consumption

FC650/O

FC650/TMAX-TDIFF

Typ. 90 µA, at typ. 24 V DC line voltage

and 25 °C

Typ. 90 µA, at typ. 24 V DC line voltage

and 25 °C

Alarm current Max. 40 mA, limited by alarm resistor

in detector base (do not short-circuit)

General data

Temperature range -30 °C to +70 °C

Application temperature

Max. 45 °C (FC650/TDIFF)

Max. 60 °C (FC650/TMAX)

Activation temperature

57 °C (FC650/TDIFF)

78 °C (FC650/TMAX)

Air humidity Max. 95 % relative (without condensation)

Enclosure IP30

Manufacturing date Label on detector base

Dimensions W x H

Detector

Base

Detector + Base

106 mm x 46 mm

110 mm x 16 mm

110 mm x 54 mm

Weight Approx. 80 g

Colour White

Material Plastic

Approvals

FC650/O

FC650/TMAX

FC650/TDIFF

VdS No. G 210145

VdS No. G 210151

VdS No. G 210151

Applicable standard

FC650/O

FC650/TMAX

FC650/TDIFF

EN 54-7

EN 54-5 – class B

EN 54-5 – class A1R

Specifications according to Building Products Act

0832

10

0832-CPD-1417 FC650/O

0832-CPD-1418 FC650/TMAX

0832-CPD-1418 FC650/TDIFF

EN54-7:2000 + A1:2002

Smoke detectors - Point detectors using

scattered light

EN54-5:2000 + A1:2002

Heat detectors - Point detectors

Side aperture

on detector base

About 100 °

Hold at

aperture height