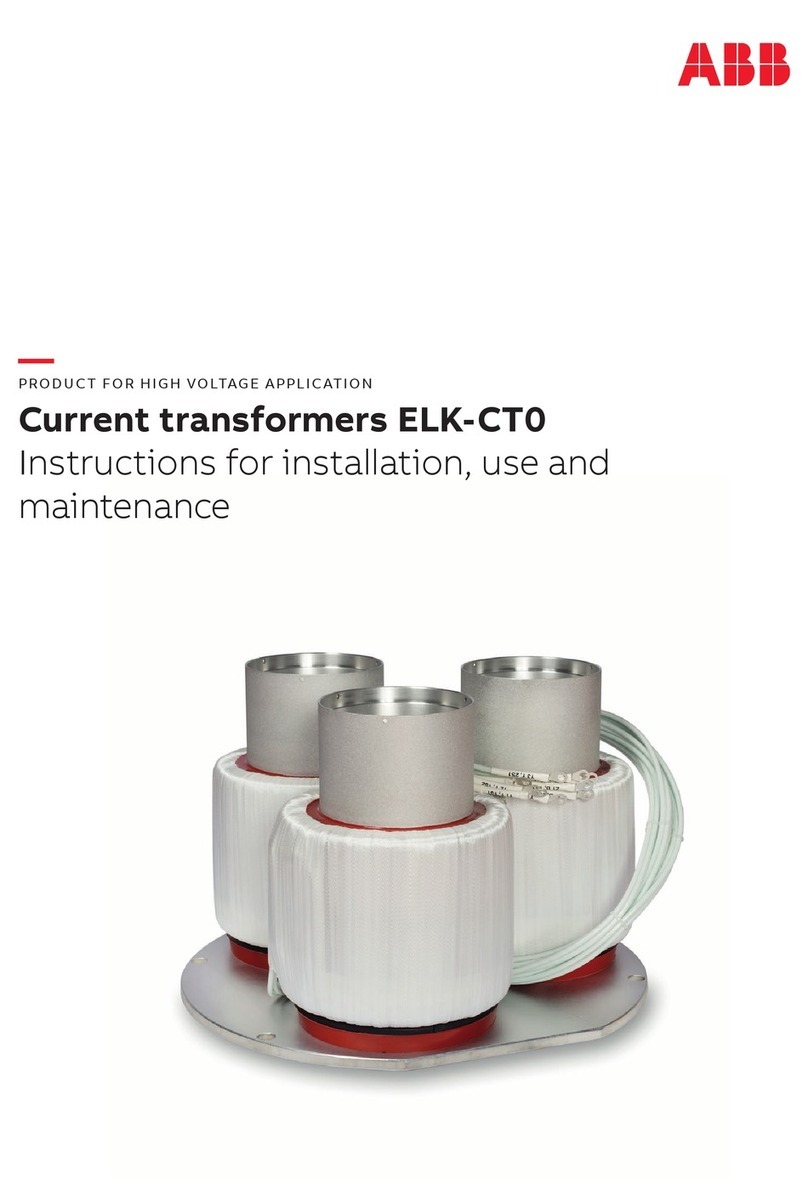

4CURRENT AND VOLTAGE INSTRUMENT TRANSFORMERS

INSTRUCTIONS FOR INSTALLATION, USE AND MAINTENANCE

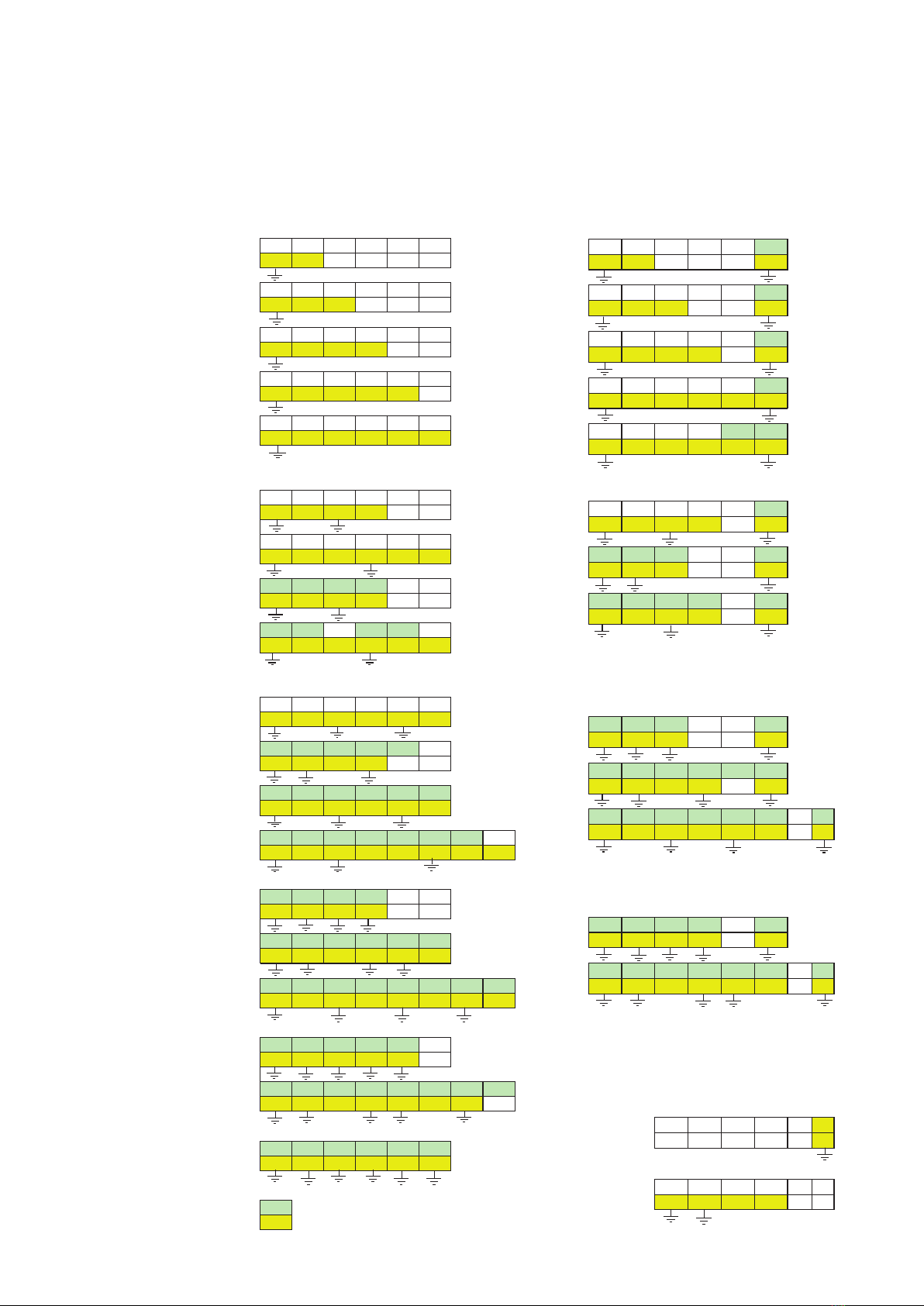

Where:

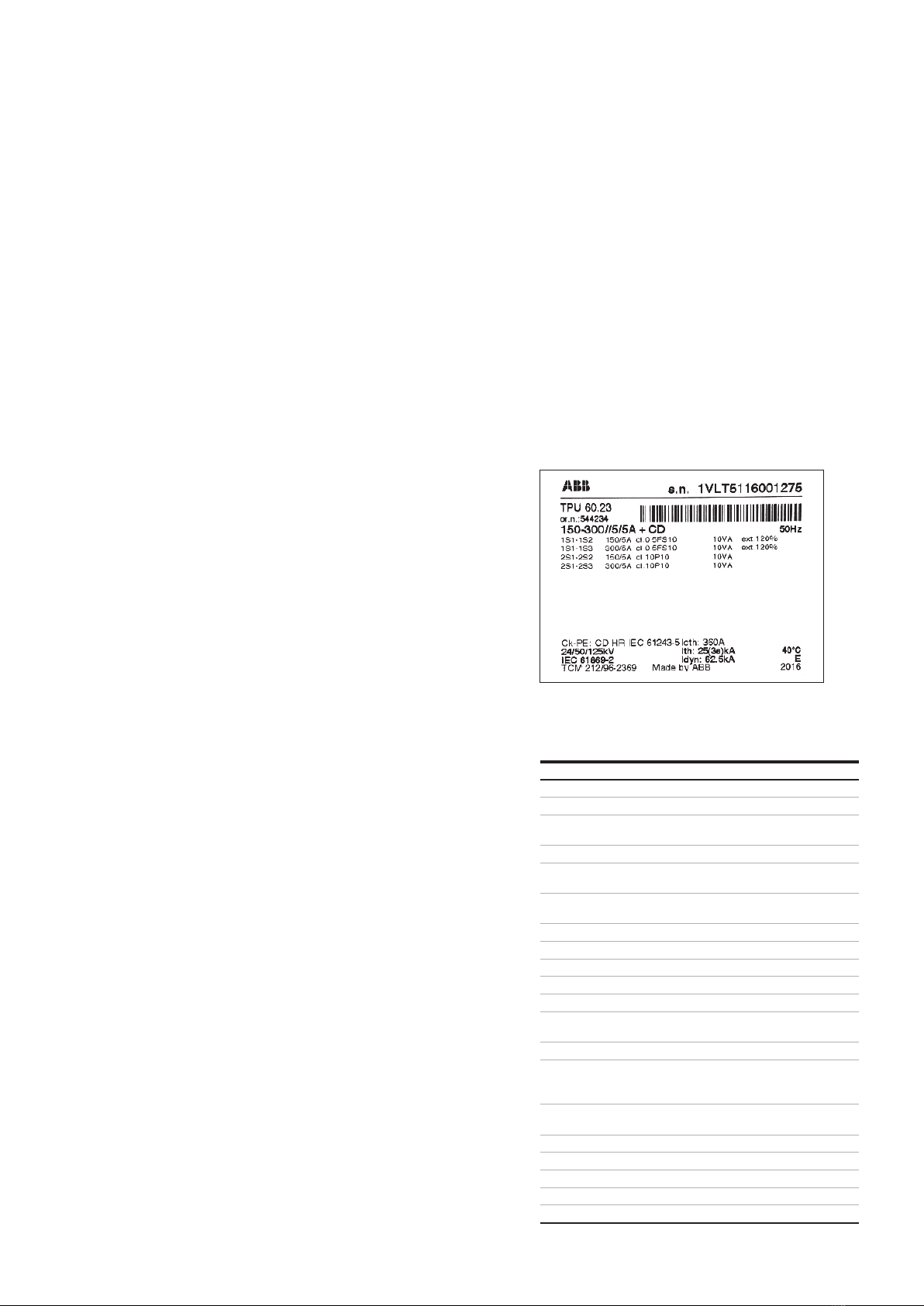

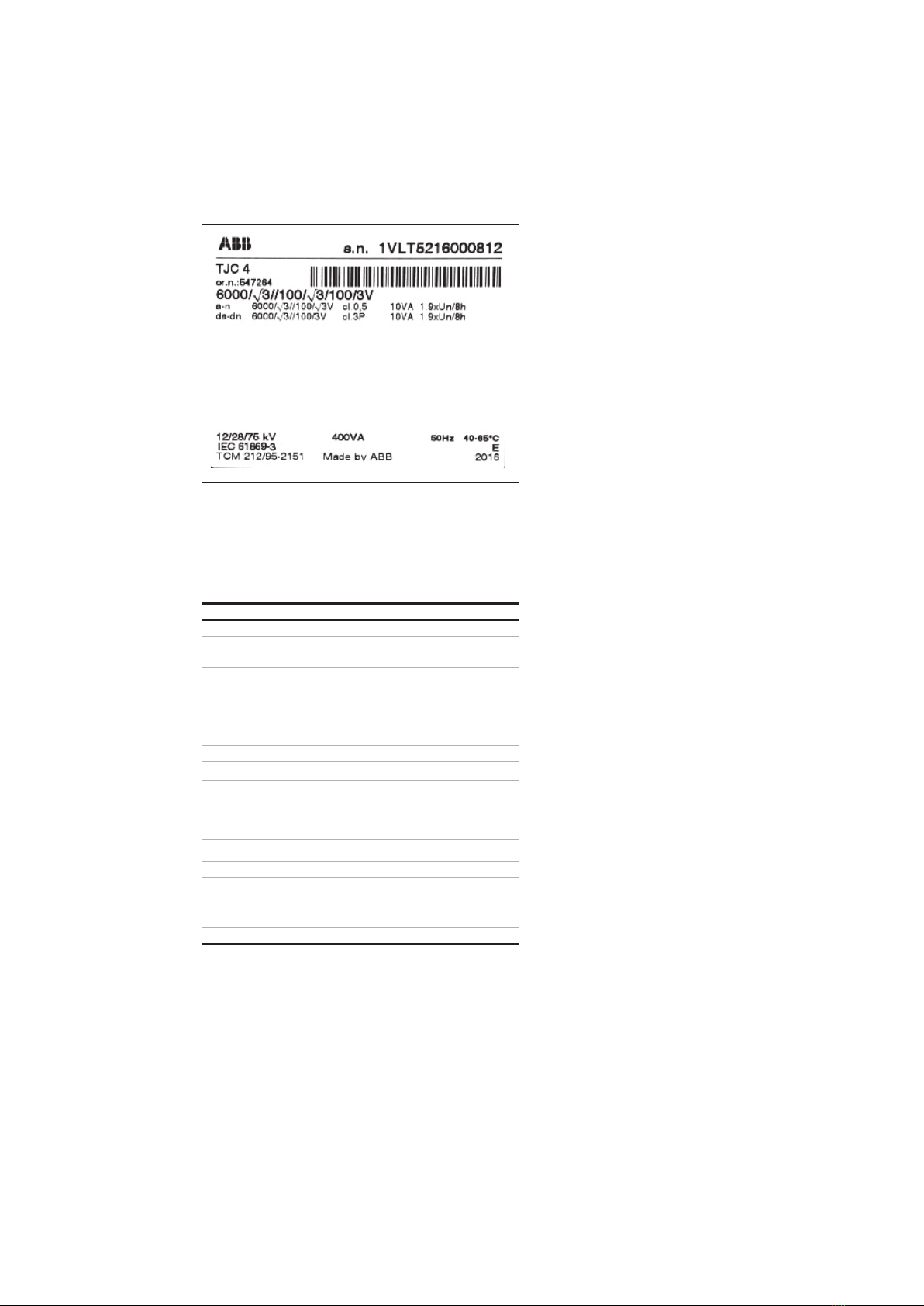

serial number + barcode

transformer type code

√

√

terminal marking for measuring

secondary winding

terminal marking for residual

accuracy classes

rated output

rated output

rated frequency

ambient temperature

referred standard

Etemperature class

year of production

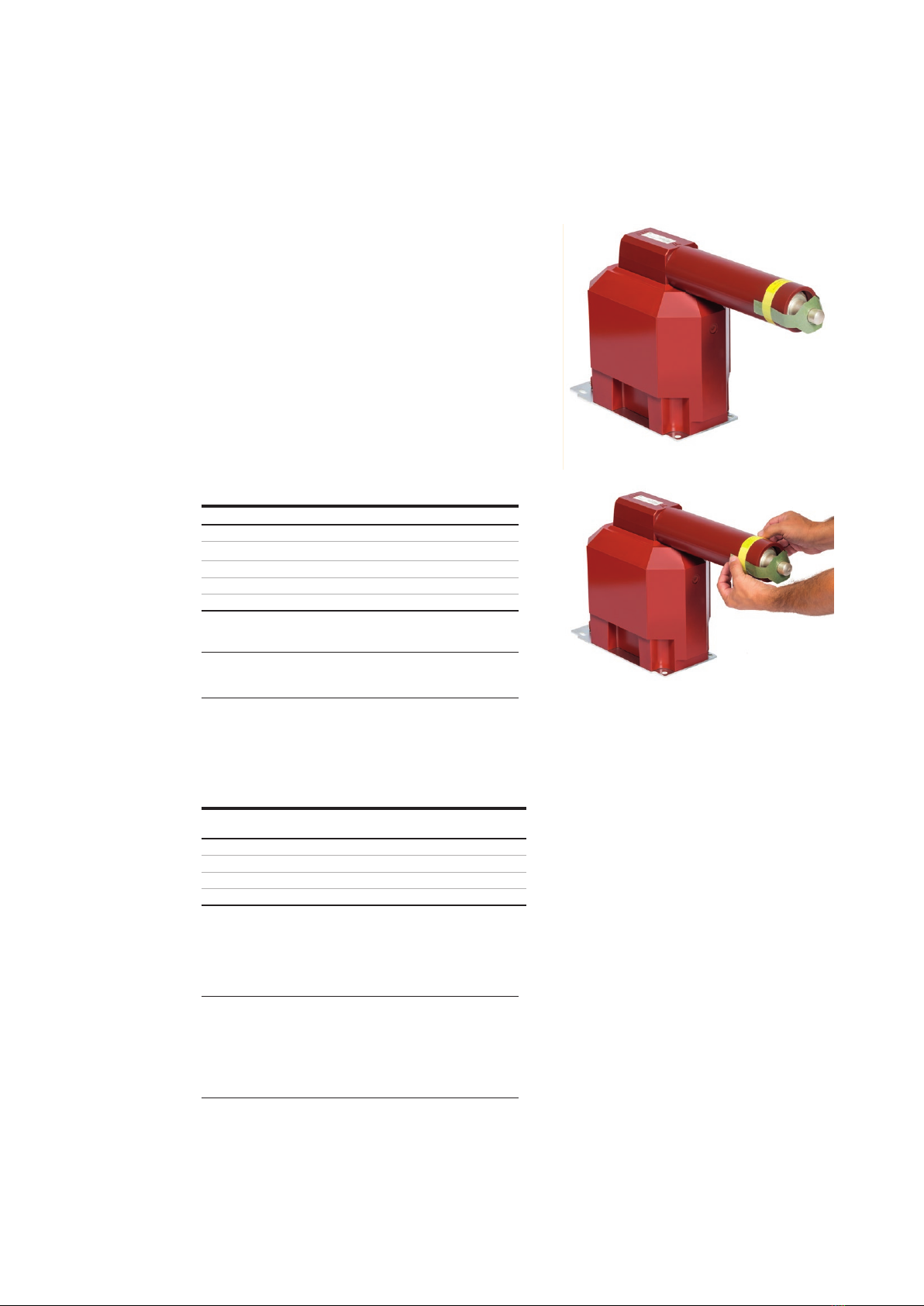

3. Instructions for installation

General informations

Instrument transformer is an electrical equipment

and the electrical installation shall be done by

skilled person only. National legislation can set

down the minimum age and the criteria for com-

petence of skilled persons working on, with,

or near an electrical installation.

Where is not the national legislation requirements

for competence, the criteria shall be used at least

according to EN 50110-1.

Safety instructions

1. Always consider transformer as a part of the

cir cuit to which it is connected, and do not

touch the leads and terminals or other parts

of the transformer unless they are known to

be grounded.

2. Always ground the metallic bases of instru-

ment transformer.

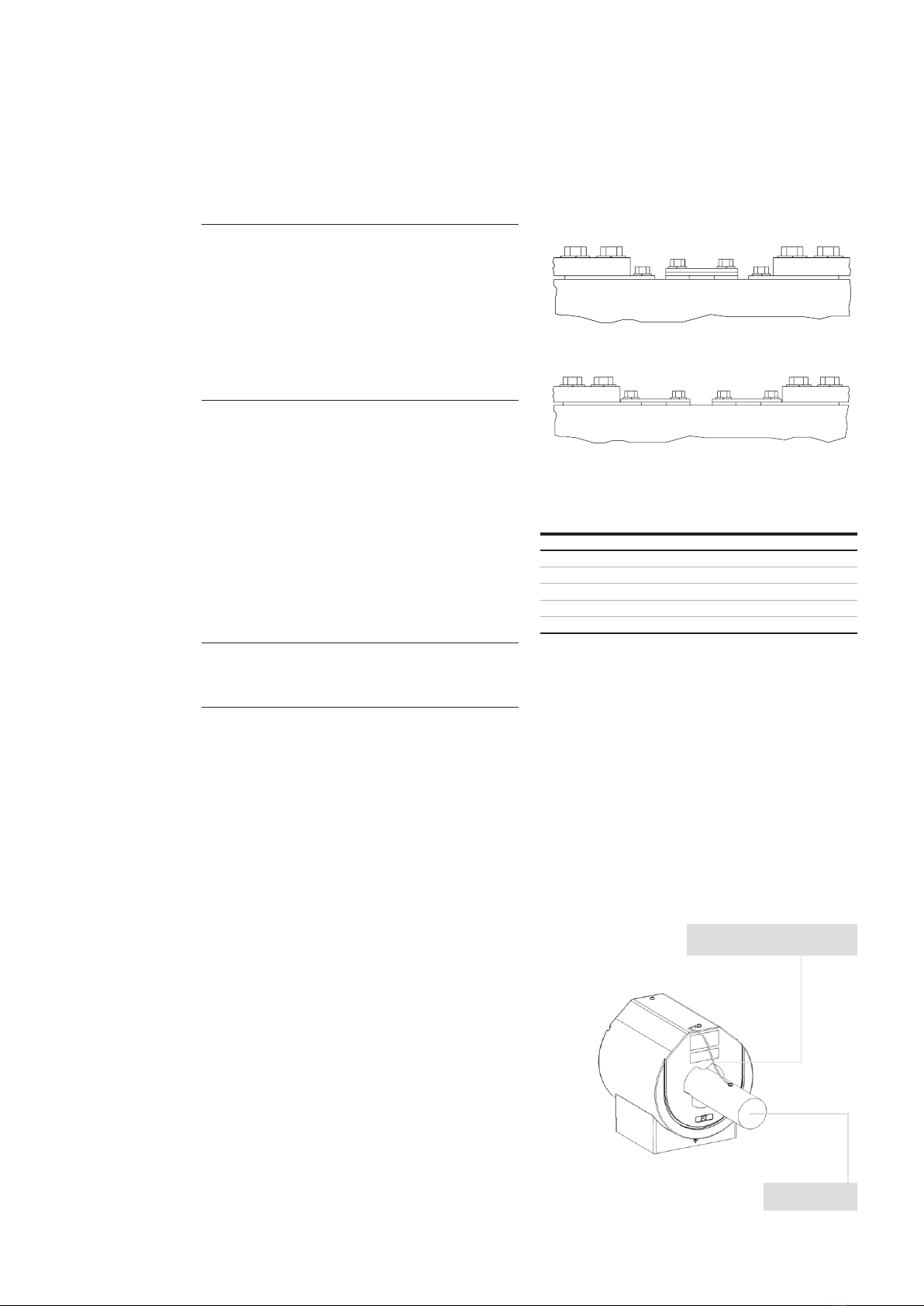

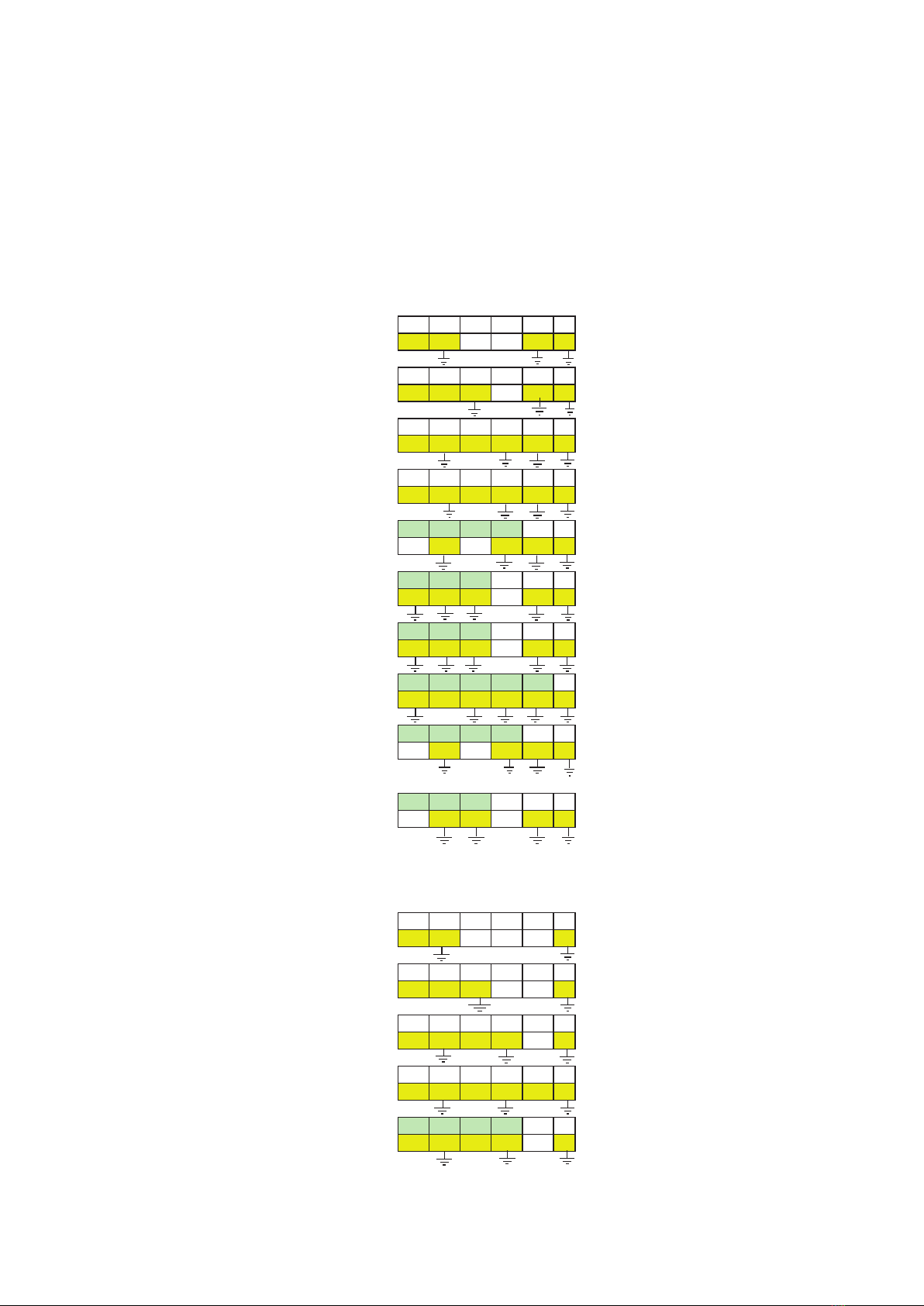

3. Always ground one secondary terminal of the

transformer, except if the windings of voltage

transformer are connected to open delta. Re-

sidual voltage windings connected to open

delta must have dn terminal earthed only on

one of three transformers (earthing screws at

dn terminals of others two transformers have

to be removed). When the secondary of trans-

former is interconnected, there should be only

one grounded point to prevent accidental par-

alleling with system grounding wire. In case of

disconnection from the ground, the ground-

ing screw has to be removed from the second-

ary terminal. Connection between secondary

terminal and base plate (ground) is shown on

the picture “Crossection of double line termi-

nal box“

4. Always short-circuit the secondary of the cur-

rent transformer, which is not currently in use

to prevent secondary voltages which may be

hazardous to personnel or damaging to the

transformer’s secondary. The secondary like

this must be additionally grounded.

5. Never short-circuit the secondary terminal of

a voltage transformer even this is not in use. A

secondary short-circuit will cause the unit to

overheat and fail in a very short period of

time.

6. Protection of single pole insulated voltage

transformers against feroresonance phenom-

ena is stated in Appendix 3. – Damping of the

ferroresonance in Voltage transformers type

range TJx.

7. In case of the current transformer with volt-

age indication (coupling electrode included) is

secondary terminal box equiped with PE ter-

minal, which is connected with earthing screw

to the base plate, which must be generally

earthed. Connection between secondary ter-

minal and base plate is shown on the picture

“Crossection of single line terminal box“

—

transformer label

—

02