6KOKM CABLE CURRENT INSTRUMENT TRANSFORMERS

INSTRUCTION FOR INSTALLATION, USE AND MAINTENANCE

The use of current transformer for other purpose

then described above is forbidden if not agreed

with the producer.

Routine test report

The routine test report of a current instrument

transformer includes:

a) verification of terminal markings;

b) inter-turn overvoltage test;

c) determination of errors.

On customer request the following information

can be provided free of charge:

• -

placement values;

•

Additional reports for supplementary charge,

made available on request:

• test report on accuracy;

•

• additional nameplates (if more than 2 are re-

quired);

verification tests for measuring cores (classes

0.2; 0.2 S; 0.5; 0.5 S).

5. Instructions for maintenance

Excessive dust sediments or any other type of

contamination must be removed from the trans-

former by a soft brush, in a way not to damage

the insulation or cables taken out from the trans-

former.

6. Transport & Storage

Permitted temperature for transport and storage

ranges from -40°C to +70°C. During transport and

storage the transformers have to be protected

from direct impact of solar radiation. The trans-

formers are delivered in wooden crates or fixed

on transport pallets.

7. Disposal

Materials used in instrument transformers are

considered as materials without environmental

impact and materials are not toxic. Instrument

transformers have to be disposed of in accor-

dance with national legislation relevant to do-

mestic waste disposal.

8. Handling

Most of the KOKM transformers weight less than

25 kg and, consequently, they can be handled

manually. In case of higher weight it is necessary

to use carry belts threaded through the trans-

former internal opening.

ATTENTION: The process of transformer han-

dling has to comply the occupational health and

safety rules. It is forbidden to stay or move be-

low a suspended load. Always make sure the

load is safely tied and secured, what makes its

loosening or turnover impossible. All transform-

ers has to be carried carefully to prevent any

damage to the transformer.

9. Normative references

IEC 61869-1 Current instrument transformers

IEC 60529 Degrees of protection provided by en-

closures

ISO 12100 Machine safety – basic concepts, gen-

eral principles of design

EN 50110-1 Operation of electrical installations

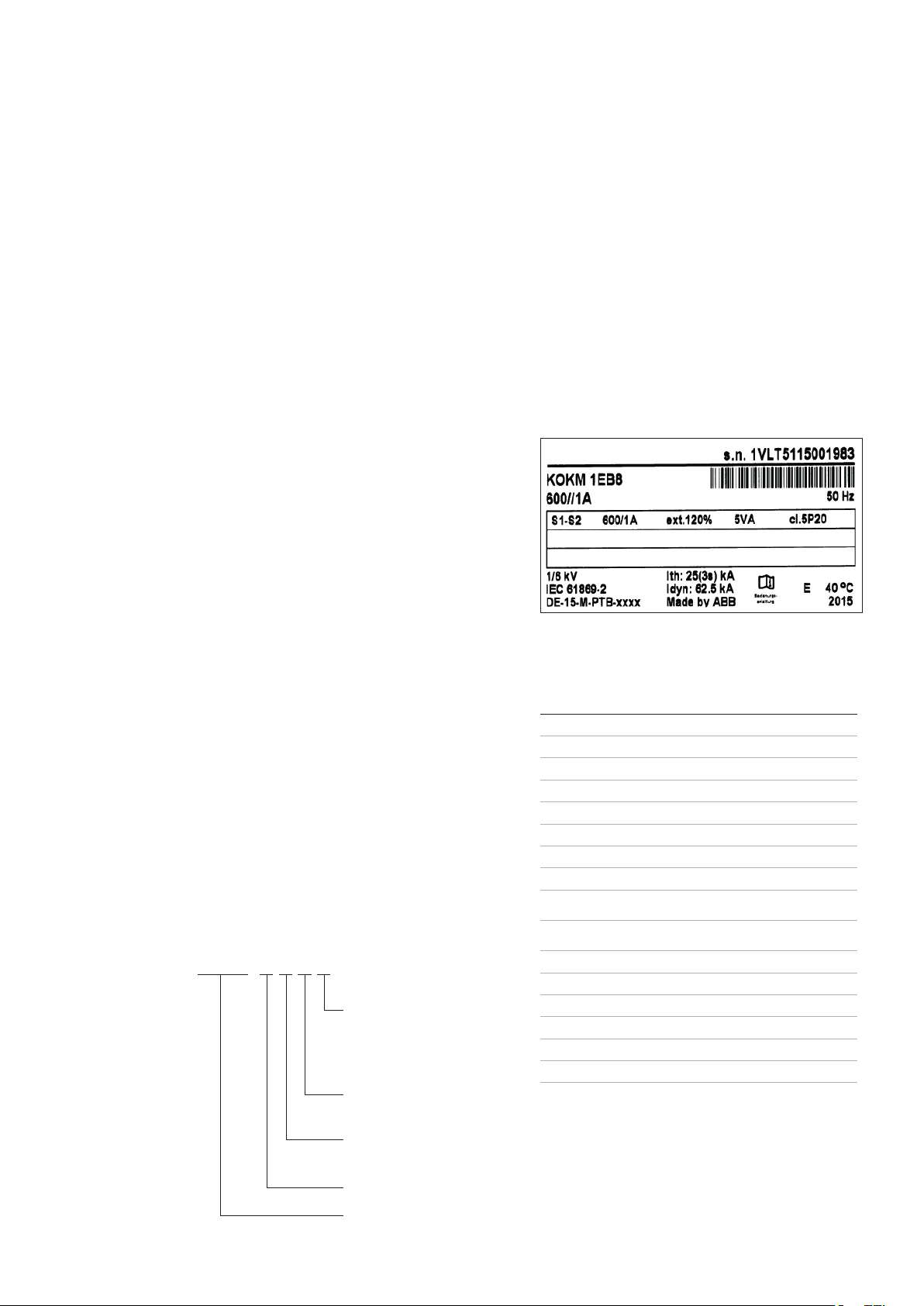

Current instrument transformers are designed,

tested and manufactured in accordance with in-

ternational or national standards, the customer

requirements, based on an agreement between

the customer and the manufacturer. The specific

standard is always mentioned on the transformer

nameplate.

As an example the following standards can be

mentioned:

IEC 60044-1; IEC 60044-6; IEC 61869-1;

IEC 61869-2;

AS 60044-1; AS 1243-1982;

IEEE Std C57.13.6-2005;

ANSI C57.13-1978;

CSA Std CAN3-C13-M83;

GOST 1516.3-96; GOST 7746-2001;

When agreed transformers made in accordance

with other standards can also be supplied, or in

accordance with other release version of the

above standards.