3

—

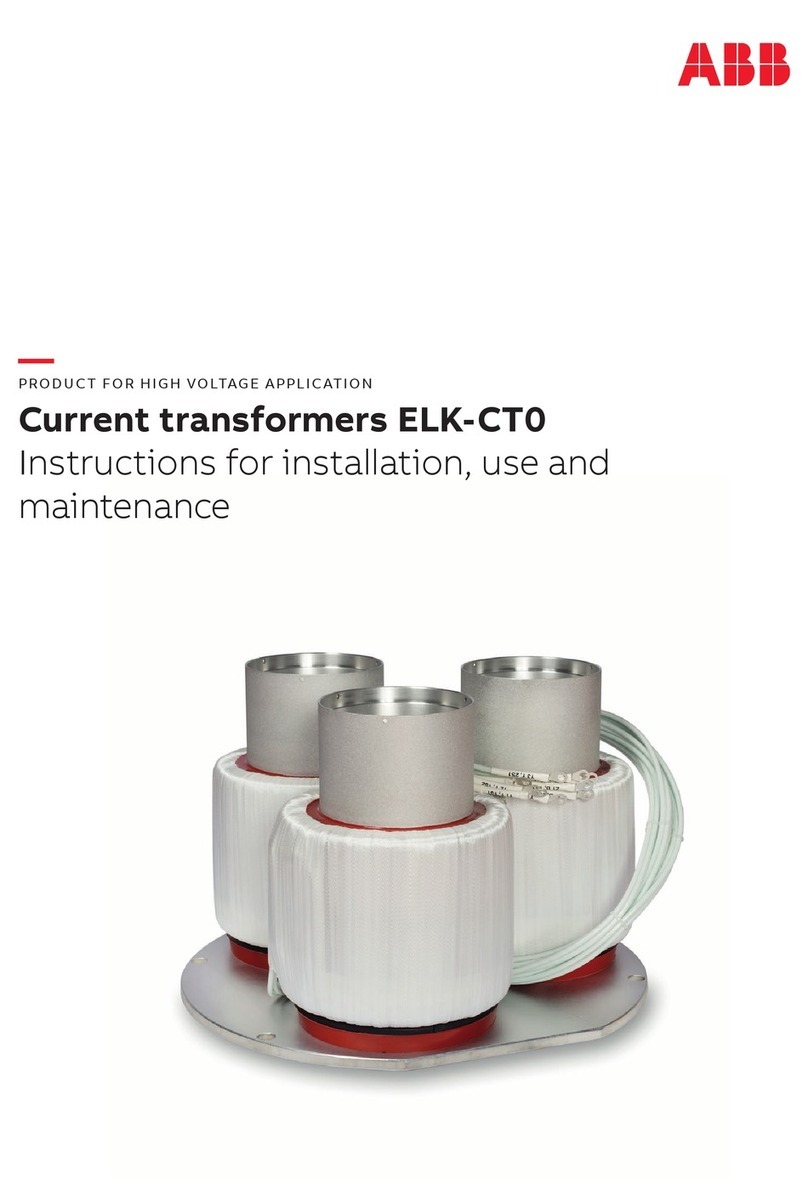

Instructions for installation, use and

maintenance for current instrument

transformers

1. Service conditions

The transformers need to be installed in indoor

conditions where the ambient air is not signifi-

cantly polluted by dust, smoke, corrosive gases,

vapor or salts.

The transformers are designed for standard ambi-

ent temperatures between -20°C and +105°C and

altitudes below 1 000 m above sea level. The trans-

formers can also be operated at higher or lower

ambient air temperatures and higher installation

altitudes if such are agreed with the manufacturer.

2. Technical details

Technical parameters and specifications of each

of the transformers are shown on a rating plate

fixed to the transformer body. It is not allowed to

operate the transformer at values exceeding the

rating plate data.

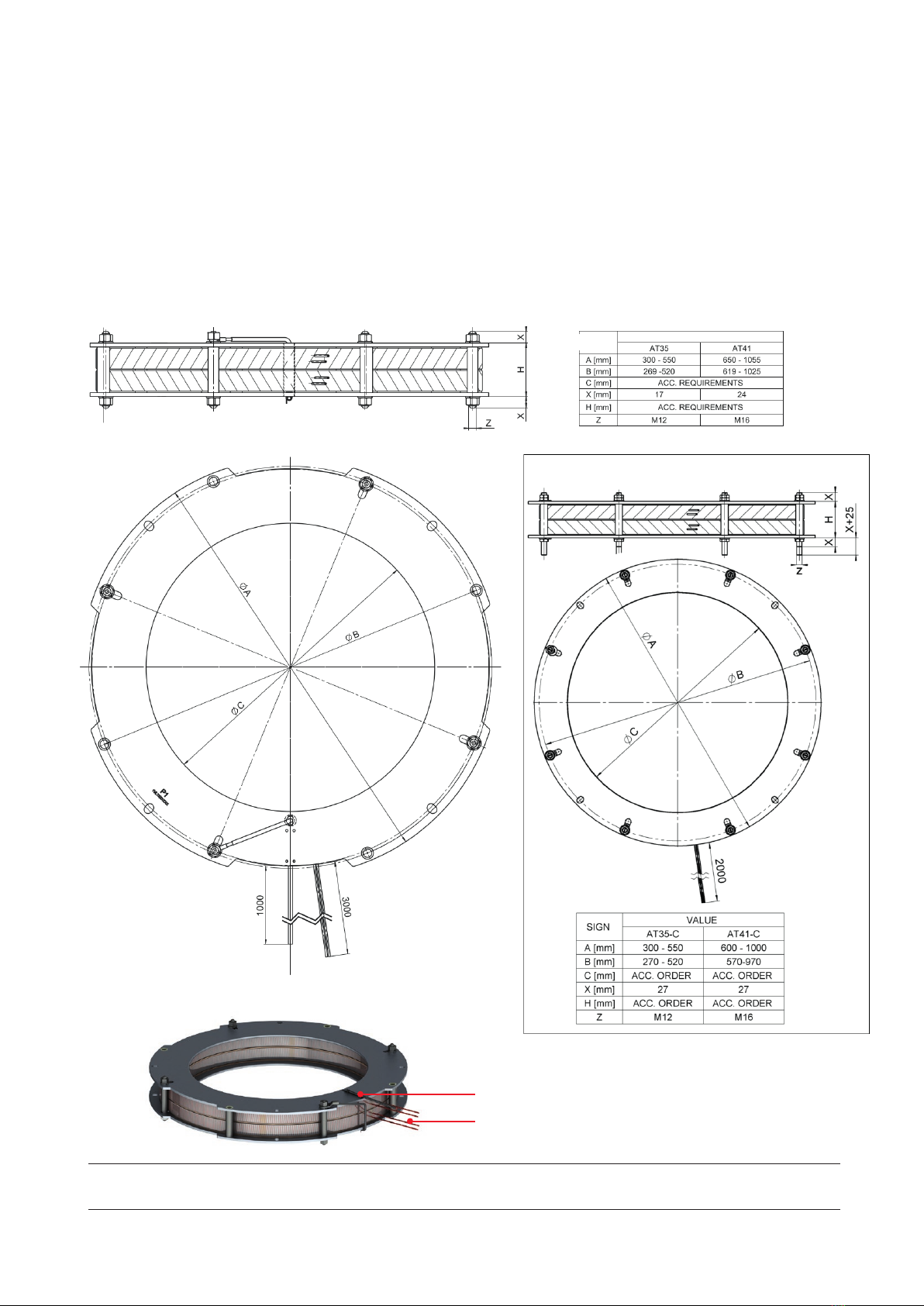

Dimensional drawing of AT transformer is shown

in Appendix 1. Dimensions of the transformer

may vary and depend on required parameters and

the application they are intended for. This is why

the customer is required to specify the highest or

lowest dimensions, in line with the dimensional

drawing in Appendix 1.

Where:

type code of transformer

corresponding standard

rated short-time thermal current

rated dynamic current

rated frequency

terminal marking for tap of transformer

rated transformer ratio

extended current

accuracy classes

year of manufacture

serial number

Label abbreviation definitions

3. Instruction for installation

General information

Instrument transformer is an electrical equip-

ment and the electrical installation of the instru-

ment transformer can be done by skilled person-

nel, only. The level of experience, age and

eligibility criteria for persons working with, on or

near electric installations is governed by national

legislation. If no such eligibility legislation is avail-

able the corresponding requirements can be

found in EN 50110-1 standard.

Safety instructions

1. Always consider the transformer as a

part of electric circuit which it is con-

nected to.

Don´t touch incoming connectors and

terminals, or any other parts of the

transformer, except you know for sure

these are earthed.

—

01

—

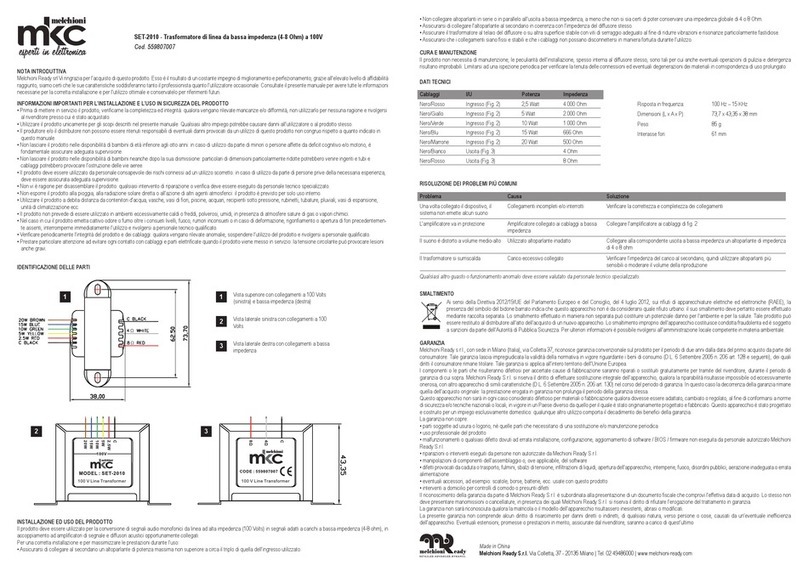

01 Example of rating

plate

These installation, use and maintenance instructions apply for current instrument

transformers intended for outdoor operation. The instructions refer to current

instrument transformers of the following types:

AT41 – up to 10 000 A; up to 1.2/6/- kV 40 kA(1s) and 100 kA

AT35 – up to 5 000 A; up to 1.2/6/- kV 100 kA(1s) and 120 kA

AT38 – up to 5 000 A; up to 1.2/6/- kV 100 kA(1s) and 120 kA

CURRENT TRANSFORMER

Type: AT41-1055/6701IEC 60044-12

1,2/6/- kV Ith:30(1s) kA3 Idyn:75 kA450 Hz5

201411

Serial:1VLTS11400000712

1S1-1S263 000/1A7ext.120%83 VA9cl.TPY10

Rb=3 Ohm, Kssc=10, Tp=100 ms

C-O-C-O t´-t´al-tfr-t´´-t´´al=100-60-500-100-60 ms

Rct=10 Ohm, Ts=1,00 s, Ktd=27,2