--

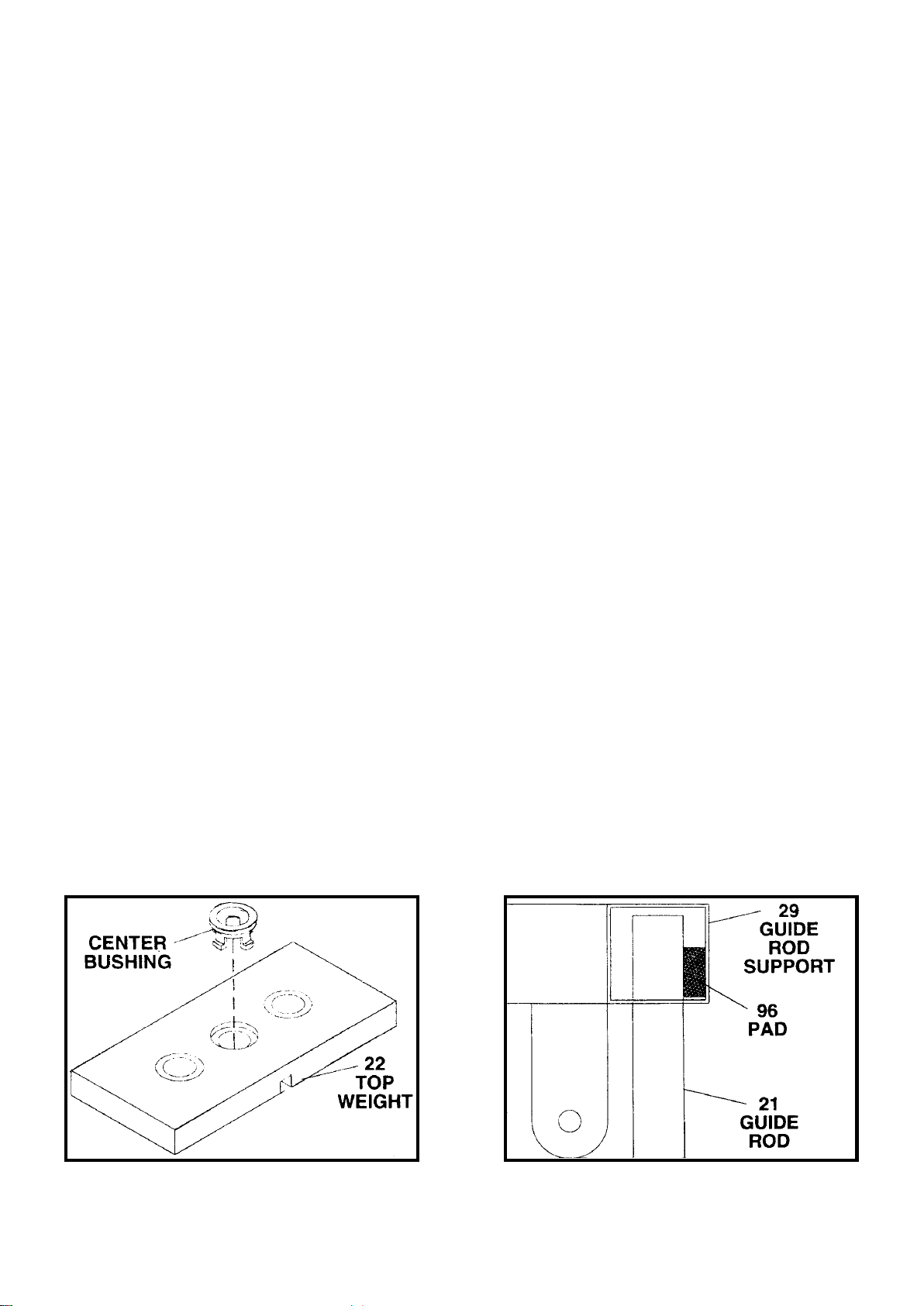

FIGURE 5

Step 16. Carefully slide WEIGHTS (22), one at a time with GROOVE on bottom and facing outside,

down GUIDE RODS (21).

NOTE: Remove CENTER BUSHING from TOP WEIGHT –see DETAIL “A” below.

Step 17. Insert WEIGHT SELECTOR ROD (23) into CENTER HOLE of PLATE (24) and fasten, at

TOP HOLE, with SOCKET SCREW (25).

Step 18. Slide PLATE (24) down GUIDE RODS (21), with SOCKET SCREW (25) facing outside,

and insert PULLPIN (26) through GROOVE in BOTTOM WEIGHT (22) and BOTTOM

HOLE of WEIGHT SELECTOR ROD (23).

Step 19. Slide COVER (27) down GUIDE RODS (21), with HOLE facing outside, and over PLATE

(24) until SOCKET SCREW (25) locks into HOLE in COVER.

Step 20. Attach DIP STANT SUPPORT (28) to DIP STAND BASE (3) with BOLT (6), WASHERS (7)

and LOCKNUT (8).

Step 21A. Push a PAD (96) into each side of GUIDE ROD SUPPORT (29), between GUIDE RODS

(21) and wall of GUIDE ROD SUPPORT –see DETAIL “B”.

Step 21B. Push 2” SQUARE PLUGS (10) into GUIDE ROD SUPPORT (29).

Step 22. Slide GUIDE ROD SUPPORT (29) onto GUIDE RODS (21).

Step 23. Attach GUIDE ROD SUPPORT (29) and DIP STAND SUPPORT (28) to TOP SUPPORT

(15) with BOLTS (6), WASHERS (7) and LOCKNUTS (8).

Step 24. Insert HANDLE (30) into DIP STAND SUPPORT (28) and fasten with BOLT (31) and

WASHER (7).

Step 25. Push SMALL GRIP (32) onto HANDLE (30).

Step 26. Apply WEIGHT LABELS (33) to WEIGHTS (22) as follows:

20lb. LABEL to TOP WEIGHT.

(WEIGHT SELECTOR ROD (23) and PLATE (24) weigh 10lbs.)

Continue applying WEIGHT LABELS until 2001b. LABEL is applied