Installation and Operating Instructions 11

ABS submersible wastewater pump ASABS submersible wastewater pump AS

5 Commissioning

mThe safety hints in the previous sections must be observed!

gIn explosive zones care must be taken that during switching on and operation of the pumps the pump

VHFWLRQLV¿OOHGZLWKZDWHUGU\UXQQLQJRUDOWHUQDWLYHO\LVVXEPHUJHGRUXQGHUZDWHUZHWLQVWDOODWLRQ

Ensure in this case that the minimum submergence given in the data sheet is observed, Other types

of operation e.g. snore operation or dry running are not allowed.

Before commissioning the unit should be checked and a functional test carried out. Particular attention should

be paid to the following:

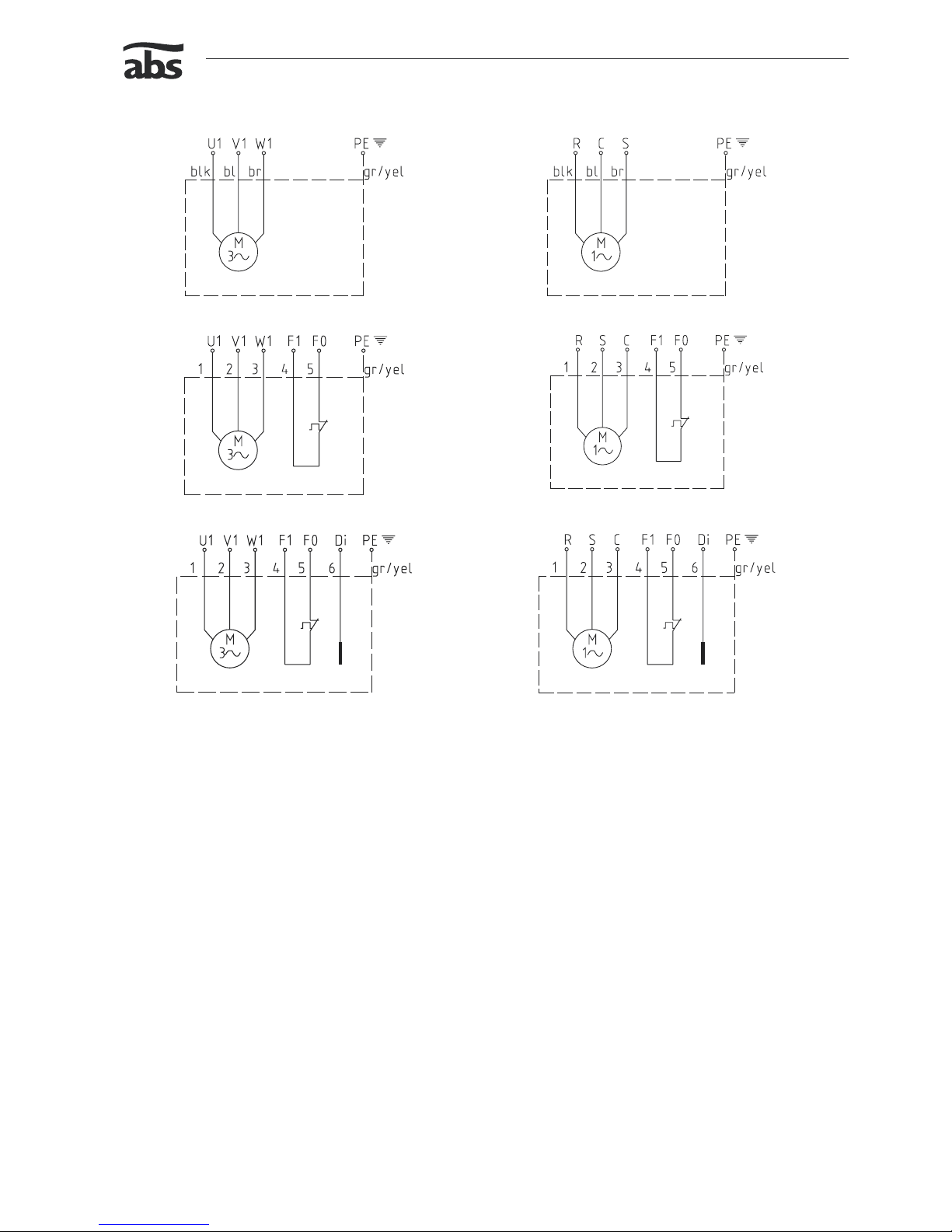

Have the electrical connections been carried out in accordance with regulations?

Have the thermal sensors been connected?

,VWKHVHDOPRQLWRULQJGHYLFHZKHUH¿WWHGFRUUHFWO\LQVWDOOHG"

Is the motor overload switch correctly set?

+DYHWKHSRZHUDQGFRQWUROFLUFXLWFDEOHVEHHQFRUUHFWO\¿WWHG"

Was the sump cleaned out?

+DYHWKHLQÀRZDQGRXWÀRZVRIWKHSXPSVWDWLRQEHHQFOHDQHGDQGFKHFNHG"

Is the direction of rotation correct - even if run via an emergency generator?

Are the level controls functioning correctly?

$UHWKHUHTXLUHGJDWHVYDOYHVZKHUH¿WWHGRSHQ"

'RWKHQRQUHWXUQYDOYHVZKHUH¿WWHGIXQFWLRQHDVLO\"

Have the hydraulics been vented in the case of dry installed pumps?

6 Maintenance

cBefore commencing any maintenance work the unit should be completely disconnected from the

PDLQVE\DTXDOL¿HGSHUVRQDQGFDUHVKRXOGEHWDNHQWKDWLWFDQQRWEHLQDGYHUWHQWO\VZLWFKHGEDFNRQ

mWhen carrying out any repair or maintenance work, the safety regulations covering work in enclosed

areas of sewage installations as well as good general technical pratices should be followed.

NOTE The maintenance hints given here are not designed for “do-it-yourself” repairs as

special technical knowledge is required.

NOTE A maintenance contract with our works service department will guarantee you the

best technical service under all circumstances.

6.1 General maintenance hints

$%6VXEPHUVLEOHSXPSVDUHUHOLDEOHTXDOLW\SURGXFWVHDFKEHLQJVXEMHFWHGWRFDUHIXO¿QDOLQVSHFWLRQ

Lubricated-for-life ball bearings together with monitoring devices ensure optimum pump reliability provided that

the pump has been connected and operated in accordance with the operating instructions.

Should, nevertheless, a malfunction occur, do not improvise but ask your ABS customer service department for

assistance.

This applies particularly if the pump is continually switched off by the current overload in the control panel, by

the thermal sensors of the thermo-control system or by the seal monitoring system (DI).

Regular inspection and care is recommended to ensure a long service life.

-

-

-

-

-

-

-

-

-

-

-

-