2 Installation, Operating and Maintenance Instructions (Original Instructions)

ABS Piranha submersible grinder pump S10 - PE125

ABS reserves the right to alter specifications due to technical developments!

ABS Piranha submersible grinder pump

S10/4W-50 S10/4W-50 Ex PE30/2C-50 Ex S10/4-60 S10/4-60 Ex PE25/2W-C-60 Ex PE80/2-E-60 Ex

S12/2-50 S12/2-50 Ex PE 55/2E-50 Ex S10/4W-60 S10/4W-60 Ex PE28/2-C-60 Ex PE100/2-E-60 Ex

S12/2W-50 S12/2W-50 Ex PE70/2E-50 Ex S20/2-60 S20/2-60 Ex PE35/2-C-60 Ex PE110/2-E-60 Ex

S13/4-50 S13/4-50 Ex PE90/2E-50 Ex S20/2W-60 S20/2W-60 Ex PE35/2W-C-60 Ex PE125/2-E-60 Ex

S17/2-50 S17/2-50 Ex PE110/2E-50 Ex S26/2W-60 S26/2W-60 Ex PE45/2-C-60 Ex

S17/2W-50 S17/2W-50 Ex S30/2-60 S30/2-60 Ex PE45/2W-C-60 Ex

S21/2-50 S21/2-50 Ex

S26/2-50 S26/2-50 Ex

Contents

1 Application areas �������������������������������������������������������������������������������������������������������������������������������������������������������3

1.1 Explosion-proof approval..............................................................................................................................................3

2 Safety���������������������������������������������������������������������������������������������������������������������������������������������������������������������������3

2.1 Use of explosion-proof pumps in explosive zones. ......................................................................................................3

2.2 Special conditions for safe use of S-type, explosion-proof motors.............................................................................. 3

3 Technical data�������������������������������������������������������������������������������������������������������������������������������������������������������������4

3.1 Nameplate ....................................................................................................................................................................4

4 General design features �������������������������������������������������������������������������������������������������������������������������������������������5

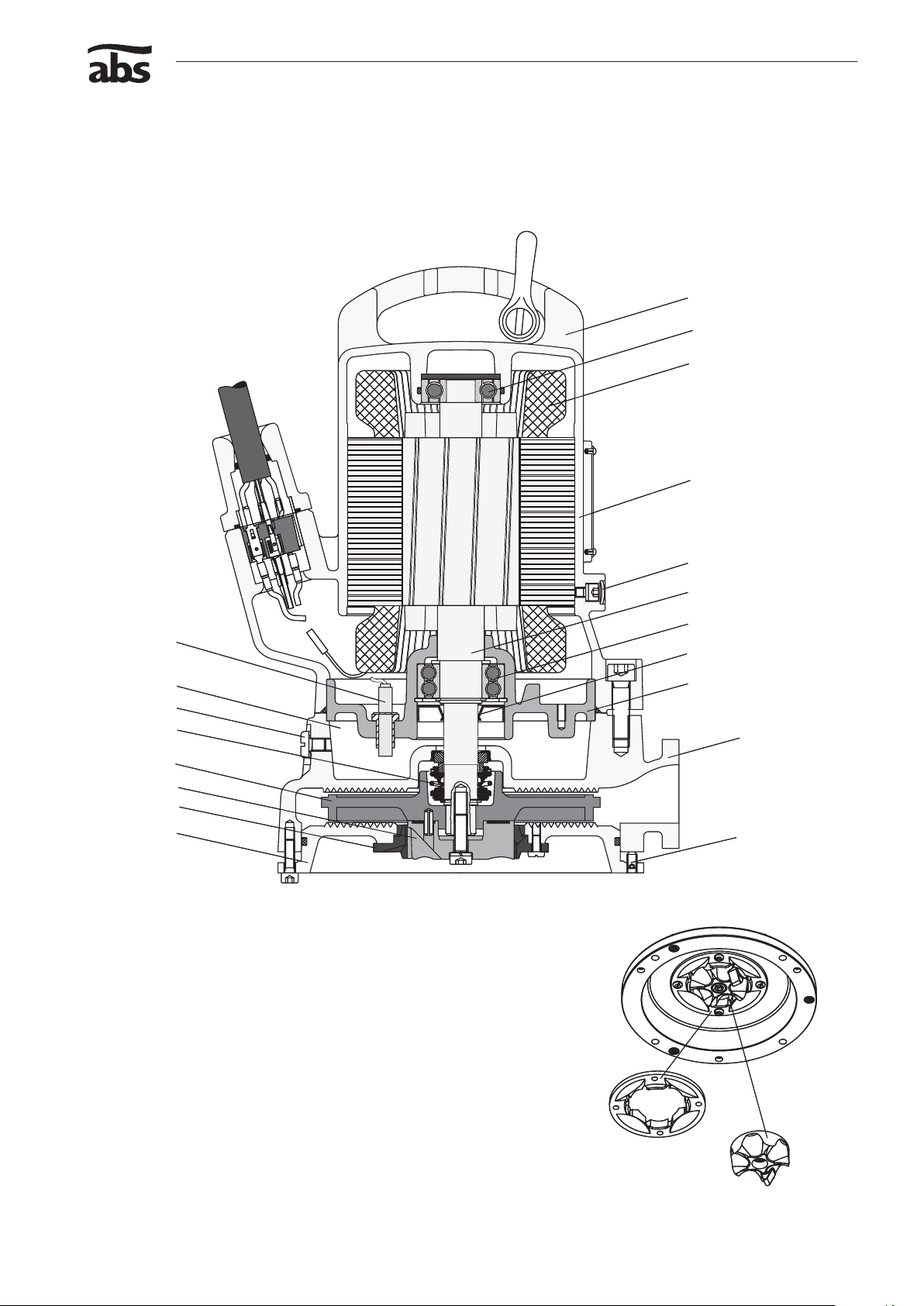

4.1 Design features Piranha-S ...........................................................................................................................................5

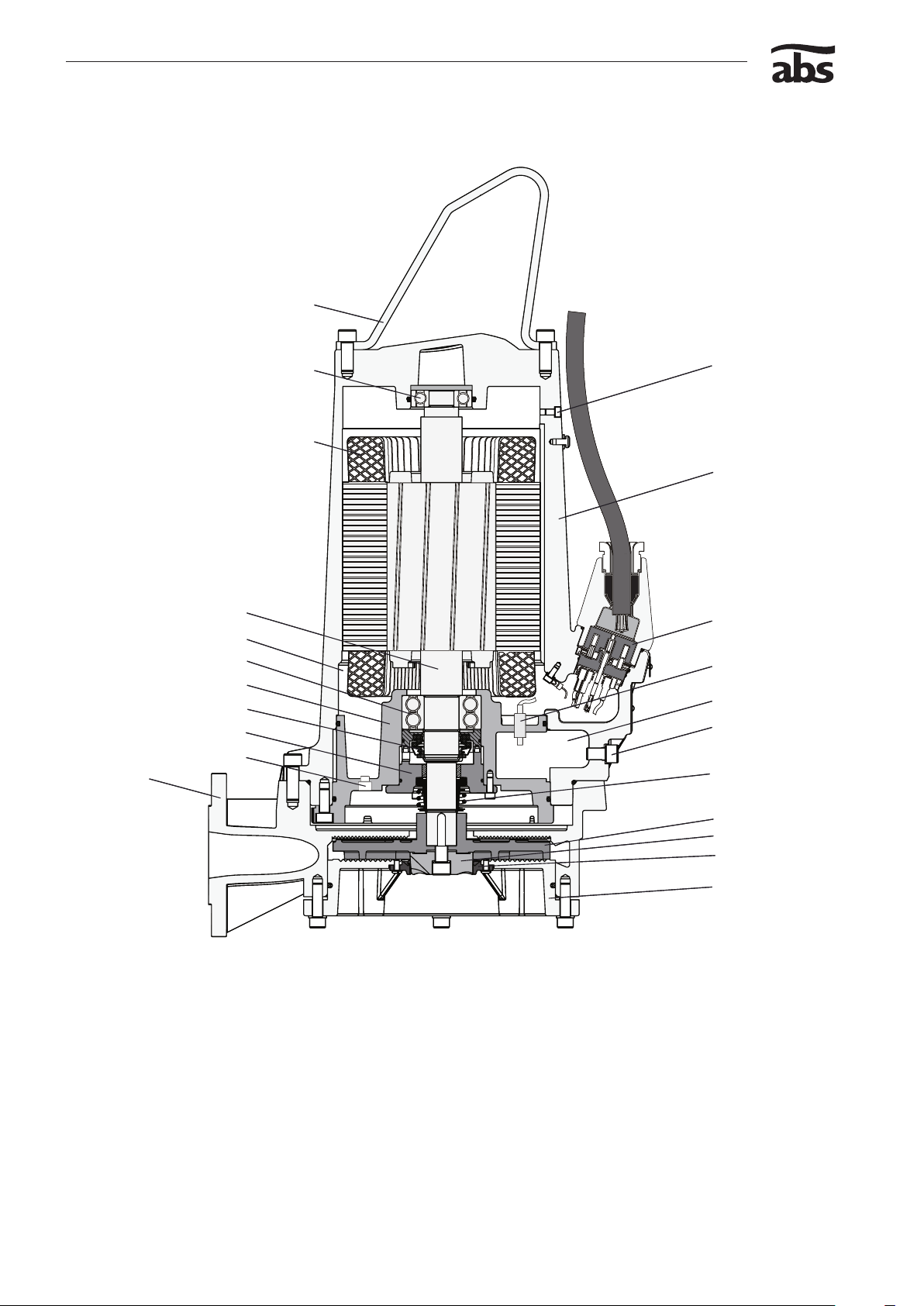

4.2 Design features Piranha-PE.........................................................................................................................................6

5 Transport and Storage�����������������������������������������������������������������������������������������������������������������������������������������������7

5.1 Transport ......................................................................................................................................................................7

5.2 Storage .........................................................................................................................................................................7

5.2.1 Moisture protection of motor connection cable ............................................................................................................7

6 Mounting and installation �����������������������������������������������������������������������������������������������������������������������������������������8

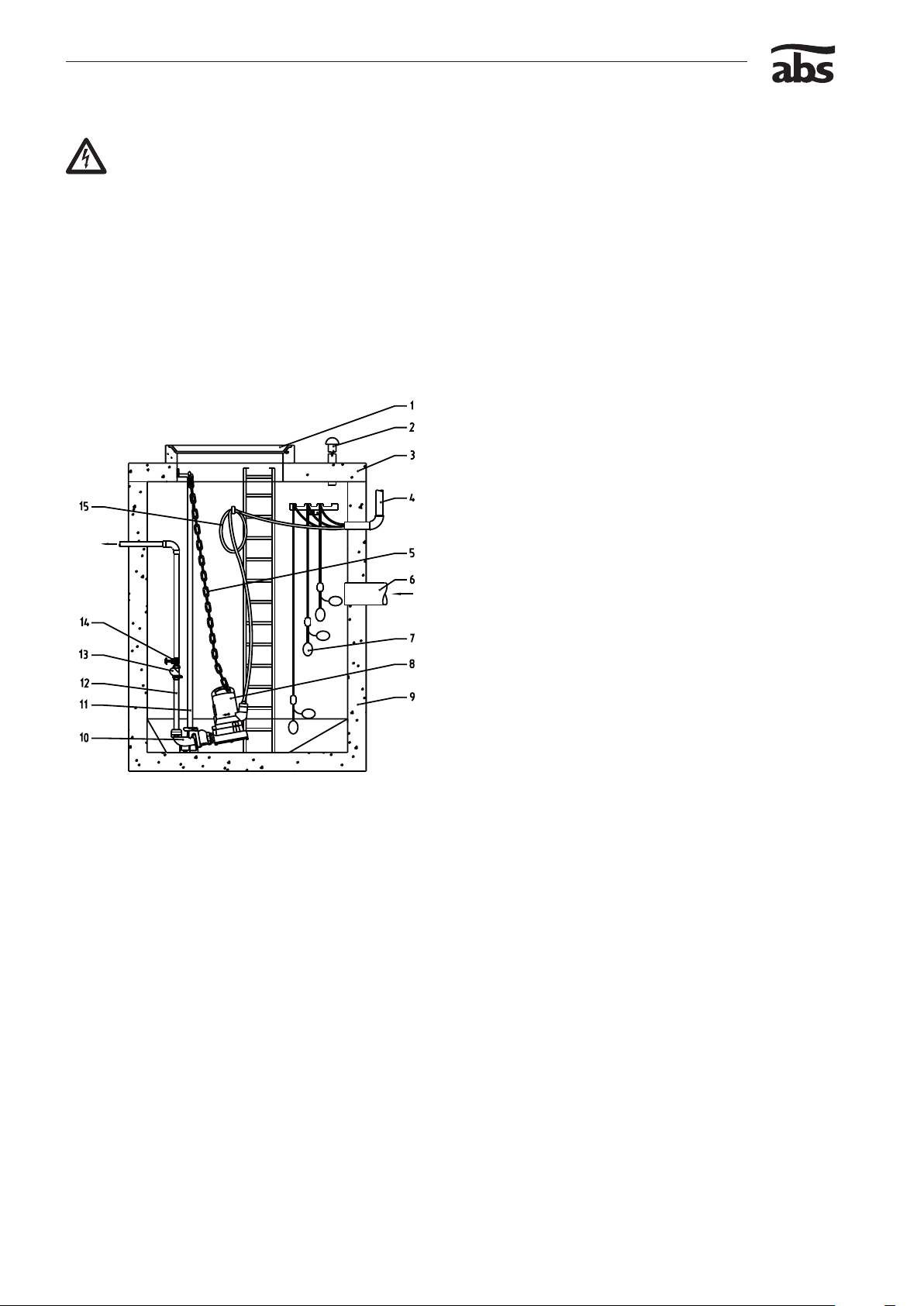

6.1 Installation example in concrete sump .........................................................................................................................8

6.2 Discharge Line..............................................................................................................................................................8

7 Electrical Connection ������������������������������������������������������������������������������������������������������������������������������������������������9

7.1 Temperature monitoring ...............................................................................................................................................9

7.2 Seal monitoring.............................................................................................................................................................9

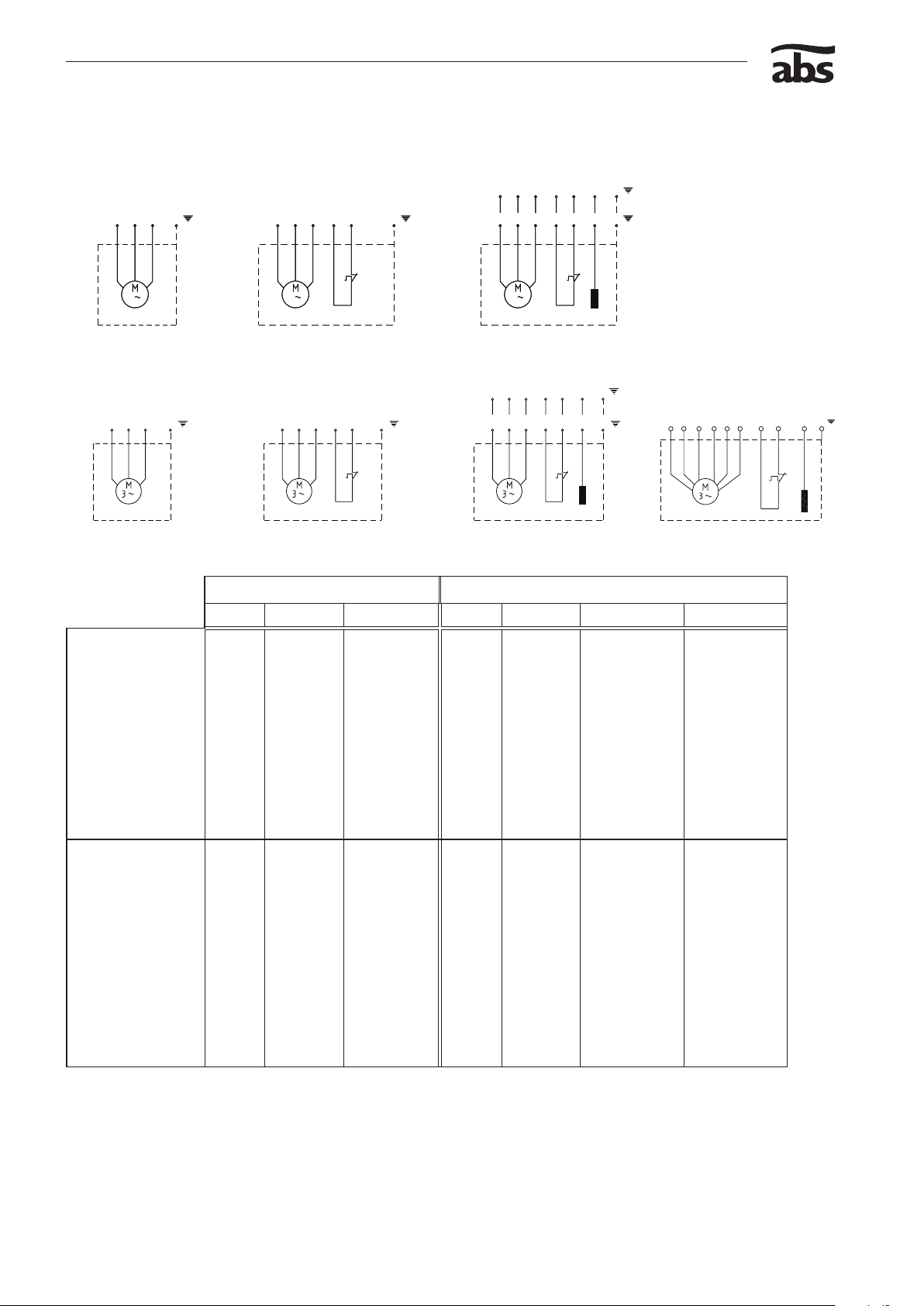

7.3 Wiring diagrams.......................................................................................................................................................... 10

7.4 Checking direction of rotation..................................................................................................................................... 11

7.5 Changing direction of rotation ................................................................................................................................... 11

8 Commissioning �������������������������������������������������������������������������������������������������������������������������������������������������������� 12

9 Maintenance�������������������������������������������������������������������������������������������������������������������������������������������������������������� 12

9.1 General maintenance hints......................................................................................................................................... 12

9.2 Shredding system ....................................................................................................................................................... 13

9.3 Oil filling and oil changing........................................................................................................................................... 13

9.4 Oil-fill quantities .......................................................................................................................................................... 13

9.5 Bearings and Mechanical Seals .................................................................................................................................14

9.6 Maintenance of Lifting Stations in accordance with EN 12056.................................................................................. 14

9.7 Cleaning...................................................................................................................................................................... 14

9.8 Venting of the volute ................................................................................................................................................... 14

10 Troubleshooting Guide��������������������������������������������������������������������������������������������������������������������������������������������15

EC Declaration of Conformity ���������������������������������������������������������������������������������������������������������������������������������������������� 16