5

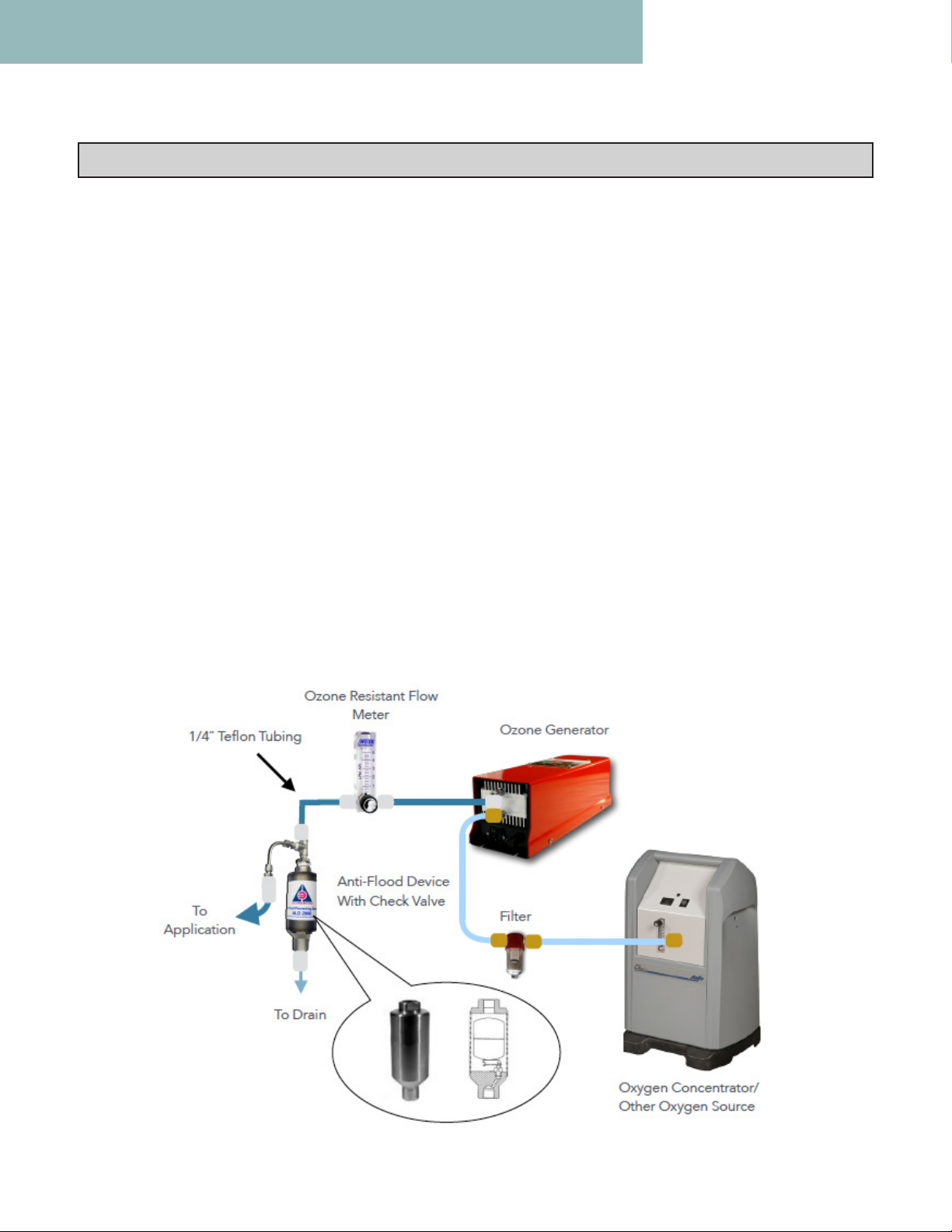

SECTION 1 GENERAL INFORMATION

1A. Description

TheNANOisanozonegeneratorthatproduces15gramsofozone

perhourwithanozoneconcentrationofupto10%byweightoras

speciedintheperformancetestreportsuppliedwitheveryunit.

TheNANOozonegeneratorisdesignedtoproduceozoneforavari-

etyofapplicationssuchas:

• WaterDisinfectionforBottledWaterPlants,Medical&Pharma-

ceuticalFacilities,SwimmingPools,etc.

• IndustrialProcesses,ChemicalProductionandLaboratories,Elec-

tronicProduction,Mining

• AquaticLifeSupportSystemsforMarineMammals,FishHatcher

ies,LargeAquarium

• FoodProcessing,FoodProcessingFacilitiesDisinfection,Food

Preservation

• SoilRemediation,GroundWaterRemediation

• WineriesFacilitiesDisinfection,BarrelDisinfection

• CoolingTowersWaterTreatment,TechnologicalProcessesWater

Treatment

• PotableWaterDisinfectionforSmallCommunities

• WasteWaterTreatmentforIndustrialPlants,TechnologicalPro

ductionProcesses,CommercialFacilitiesWasteWaterTreatment,

DangerousChemicalandBacteriaTreatment,etc.