NOTE: If the main tanks are to be fueled individually, fuel the right main tank

first.

(12) Observe right main tank master fuel quantity indicator.

NOTE: The right main tank should be approximately 1/4 full to ensure a

continuous fuel supply to the right tank boost pumps when transferring

fuel to the center and forward auxiliary tanks.

(13) Place forward and aft right main tank fuel boost pump switches in on position.

NOTE: Fuel boost pump switches are located in the flight compartment on

forward overhead switch panel.

(14) Maintain maximum fuel flow through right main tank overwing fill adapter.

(15) Place right main tank boost pump switches in off position when desired partial fuel

load in center and forward auxiliary tank is attained.

(16) If center and forward auxiliary tank maximum fuel load is desired, continue to

transfer fuel until tank (s) fuel fill valve automatically close; place right main tank

boost pump switches in off position.

NOTE: Maximum usable capacity loads are:

(a) 6440 lbs. for center tank.

(b) 4118 lbs. for forward auxiliary tank.

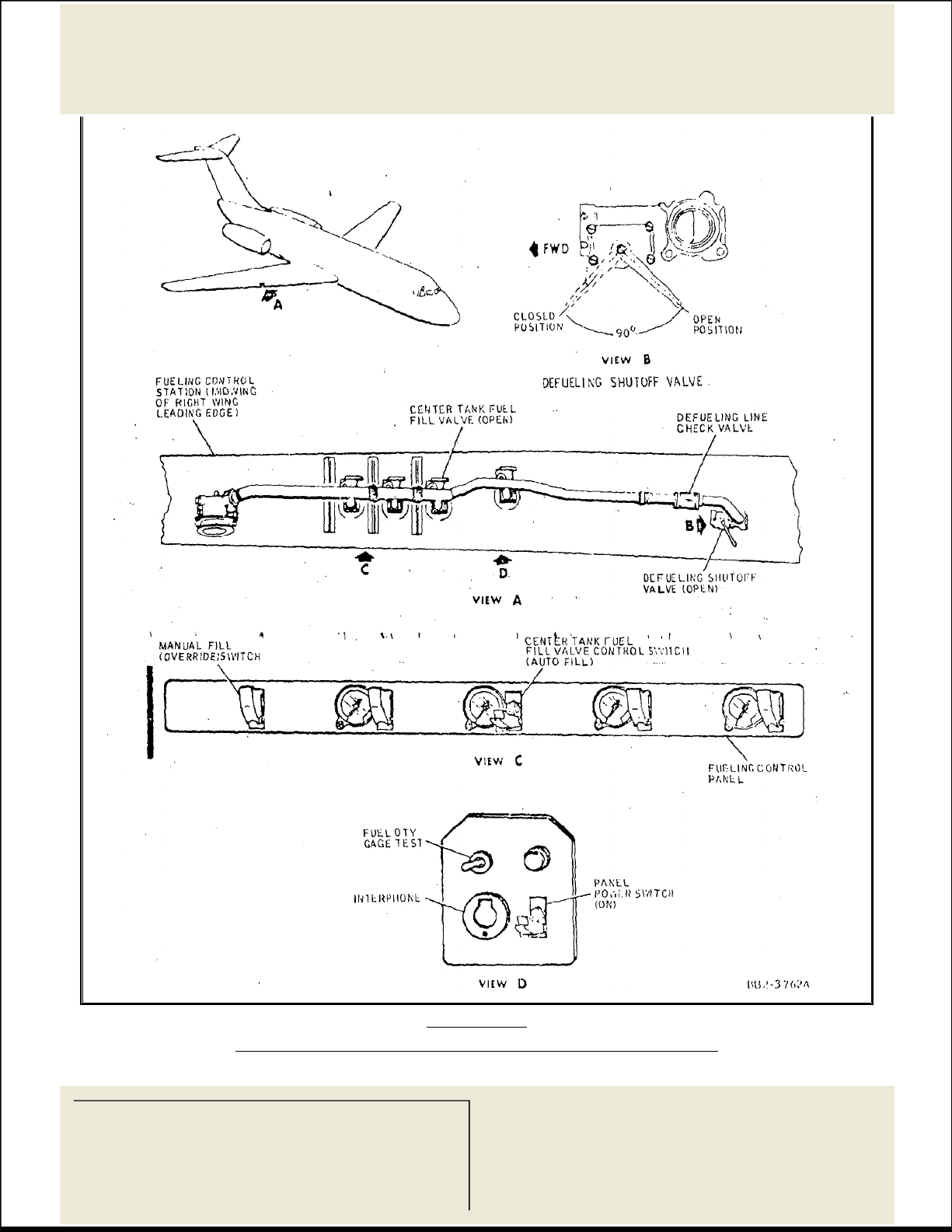

(17) If center and forward auxiliary tank fuel fill valve(s) required manual control to

open, place boost pump switches in off position when either partial or full tank(s)

fuel loading is attained.

(18) Place fueling control panel center and forward auxiliary tank fuel fill valve(s)

control switch in closed position.

(19) If main tank maximum fuel load is desired, fuel each main tank until fuel level

reaches overwing fill adapter screen retainer bead.

NOTE: Maximum usable capacity loads are 9841 lbs. for each main tank.

(20) If main tanks are to be fueled to less than maximum capacity (see paragraph 3.A.).

(21) Remove fueling nozzle; disconnect nozzle grounding plug.

CAUTION: MAKE CERTAIN FILL ADAPTER CAP IS LOCKED.

(22) Install overwing fill adapter cap; lock cap.

(23) If center and forward auxiliary tank fuel fill valve(s) requires manual control to

open, use following procedure.

(a) Place applicable tank fuel fill valve manual control lever to closed position.

ABX Air Inc.

Printed: 8/27/2010 at 12:10:53

PM

REV 11 2008/12/11

DC-9

MAINTENANCE MANUAL

EFFECTIVITY: 900-905, 909, 928, 930, 934, 939,

953-960, 962-964, 980-984, 986 12-12-00-3

CONFIG 00

Page 5

1999/11/15

This

a

e must not be retained for reference