5.1 You must use the engraver only in accordance with the purpose indicated in the manual.

5.2 When operating it is necessary to comply with all the requirements of this manual, handle the engraver carefully, do not

expose it to shocks, overloads, or dirt.

5.3 The use of a double-insulated commutator drive ensures maximum electrical safety when operating from a 230 V AC

mains without the use of personal protective equipment and grounding devices.

5.4 During the work of the engraver, the following rules must be observed:

- use personal protective equipment. Use a face shield or goggles depending on the type of operation. If necessary, use a

respirator, hearing protection, protective gloves or a special apron that protects you from abrasive particles of the processed

material. Eyes must be protected from foreign shredding flying in the air, produced during various operations;

- the outer diameter and thickness of the bit supplied with the tool must correspond to the dimensions of the collet chuck of

your power tool;

- the allowable number of revolutions of the working tool must be no more than the maximum number of revolutions

indicated on the engraver;

- use clamping devices to fasten the workpiece;

- keep your hands at a safe distance from the rotating bit;

- it is forbidden to put down the tool when the electric motor is running and before the moving parts stop;

- in no case do not tie the key for clamping the collet chuck to the tool with wire, twine, etc.;

- do not place the power tool on a dusty surface, dust particles may get inside the mechanical part of the power tool;

- keep in mind that even during normal operation wire brushes lose their wires. Do not overload wire brushes with excessive

pressure;

- if it is recommended to use a dust-proof collet for work, then exclude the possibility of contact between the wire brush and

the collet.

5.5 When using the engraver It is prohibited:

- drop the engraver;

- use the engraver in rooms with an explosive, chemically active environment that destroys metals and insulation;

- insert a larger shank into a smaller collet;

- operate the engraver in conditions of drops and splashes exposure, in open areas during snowfall and rain;

- work with the engraver at temperatures above 40°C;

- press the stopper button while the tool is running;

- leave activated engraver unattended;

- carry the tool by the cord and pull the cord to remove the plug from the socket;

- do not turn on the engraver again while the abrasive bit is inside the workpiece;

- install attachments that are not provided and recommended by the manufacturer specifically for this power tool;

- operate the engraver if, during its operation, at least one of the following malfunctions occurs:

a) damage to the power plug or power cord;

b) the switch is faulty or its operation is fuzzy;

c) sparking of brushes on the armature collector, which is accompanied by the appearance of an all-round fire on its surface;

в) искрение щёток на коллекторе якоря, которое сопровождается появлением кругового огня на его поверхности;

d) damage to the abrasive stone; circles, brushes or other attachments;

e) the appearance of a smell or smoke of burning insulation;

f) breakage or appearance of cracks in body parts.

6. Preparations

6.1 Disconnect the power cord from the mains before installing and fixing the working head.

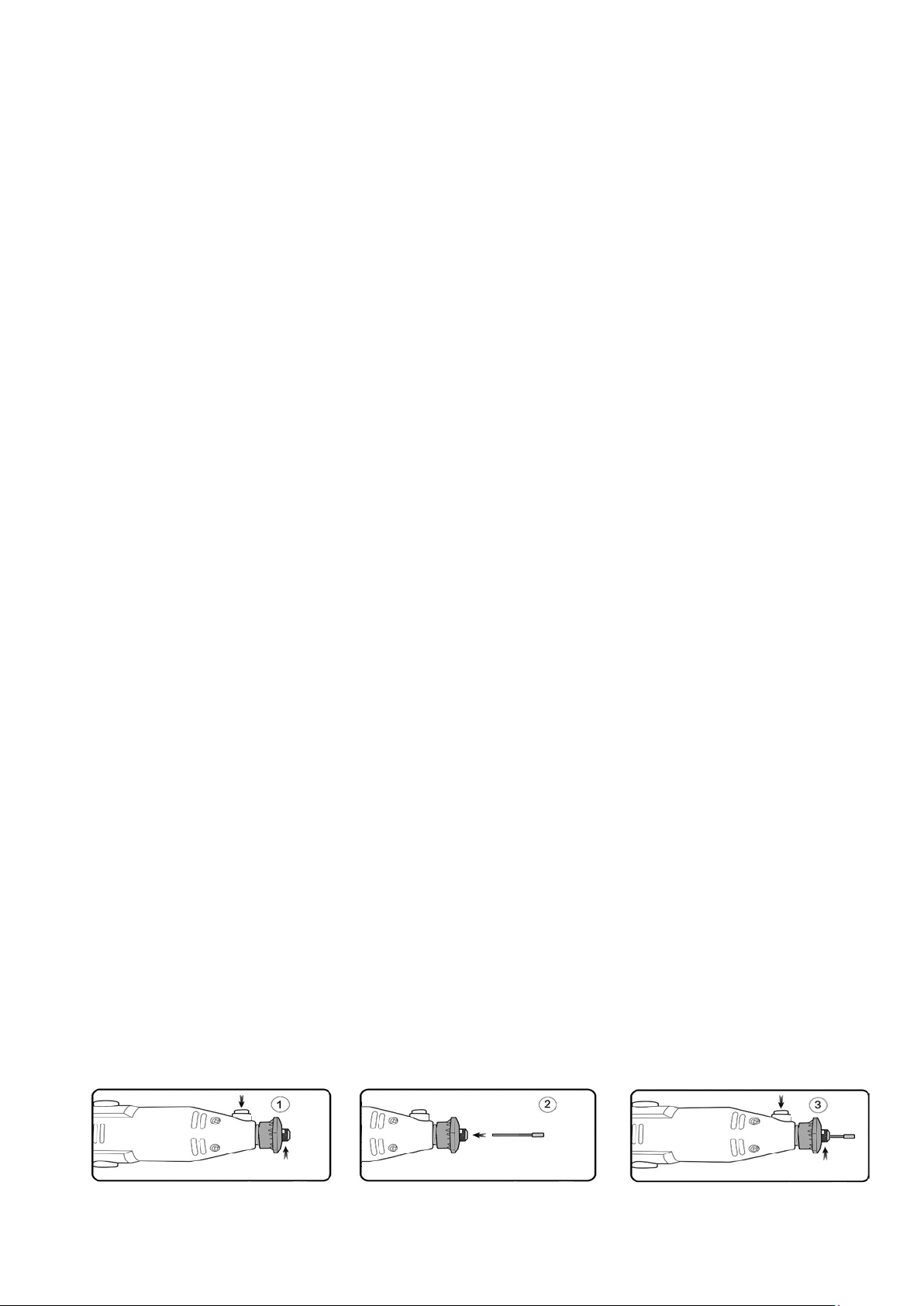

6.2 Setting up the working tool (see fig.3)

1) Press the shaft lock button. Loosen the collet clamping nut with the wrench provided.