Mechanical Operation

The shredder uses two rotating cuttingshafts,

which are driven by an electrical motor to shred

paper.

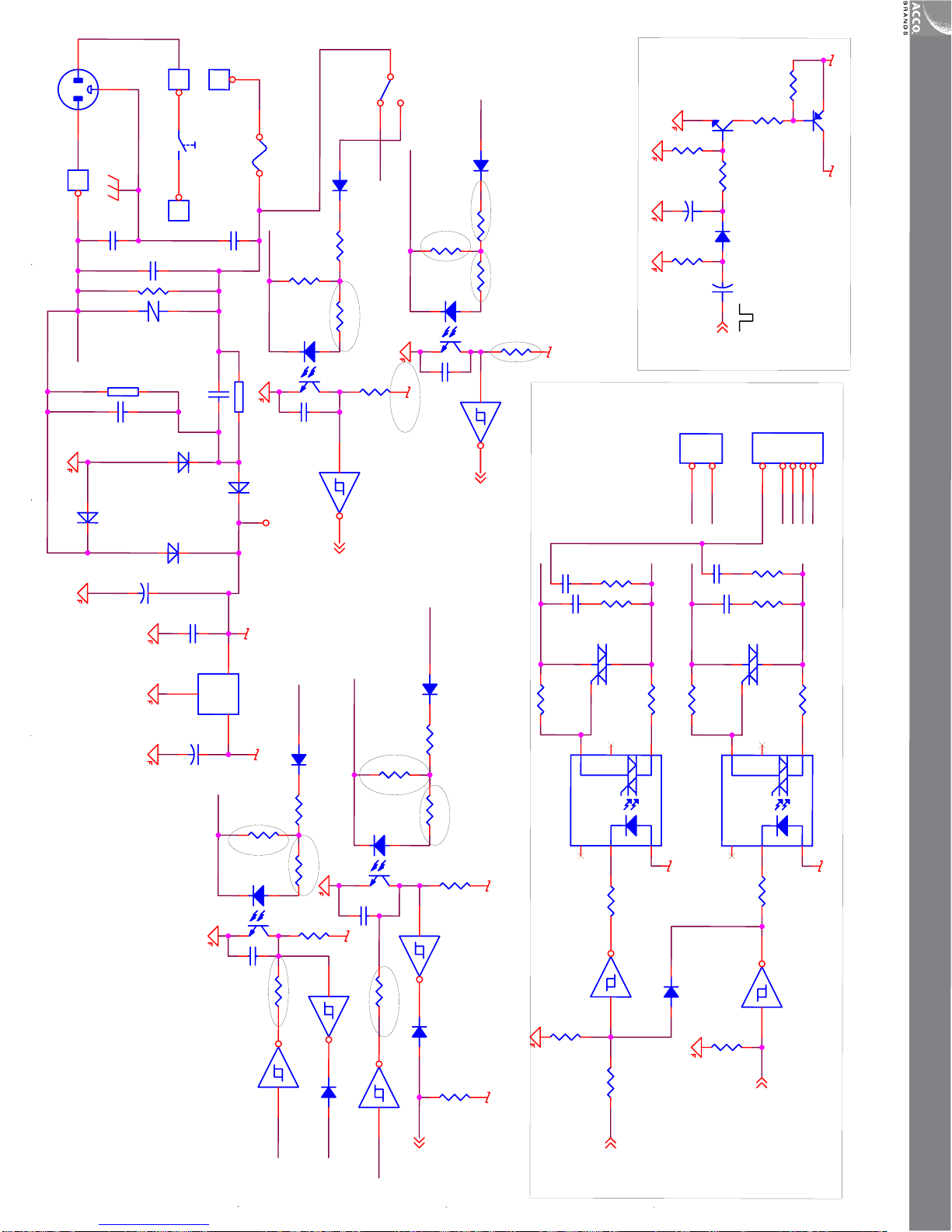

Electrical Operation

When the on/o switch on back of unit is on,

and center auto button is pressed. This will

The shredder will now

be in standby mode and the “Power-on” symbol

on the indicator panel will be illuminated amber.

When the shredder is in standby mode and the the

cabinet door is opend,the normally closed door

adjar micro switch is opened and prevents power to

the motor until the door is closed.. When the bag full

sensor is triggered, the bag full icon will illuminate.

The control board will then disable the motor circuit

until the shredder bag is either cleared or emptied.

When the shredder is severely loaded down, the

control board will illuminate red and disable the

motor circuit.

Electrical Components

Motor - Thermally protected motor designed for

continous operation.

Capacitor -AC motor run capacitor.

Poweron/Autofeed on switch - The Power on

/Auto feed on switch, when depressed, connects

the hot and neutral circuits to electrical components

of the shredder.

Doorajar, Machine head safety switch - The safety

switch is a normally open micro switch which is

actuated by a trigger located inside ofthe cabinet door.

The switch is normally closed when the door is

closed and when the machine head is installed on the

cabinet.

Bag Full Flap Sensor - The Bag Full Sensor is a normally

closed switch actuated by paper blockingsensor path.

When the shredbag becomes full of shredded material,

the bag full sensor is blocked and power is then

removed from the motor circuit.

Paper Sensors - Located in the throat area consist-

ing of two components, the emitter and receiver.

Emitter - The infrared light beam from the light emit-

tingdiodeis sensed by the receiverto activate/deac-

tivate the control board.

Receiver - The receiver is a light activated diode,

which works in conjunction with the emitter to acti-

vate/deactivate the control board.

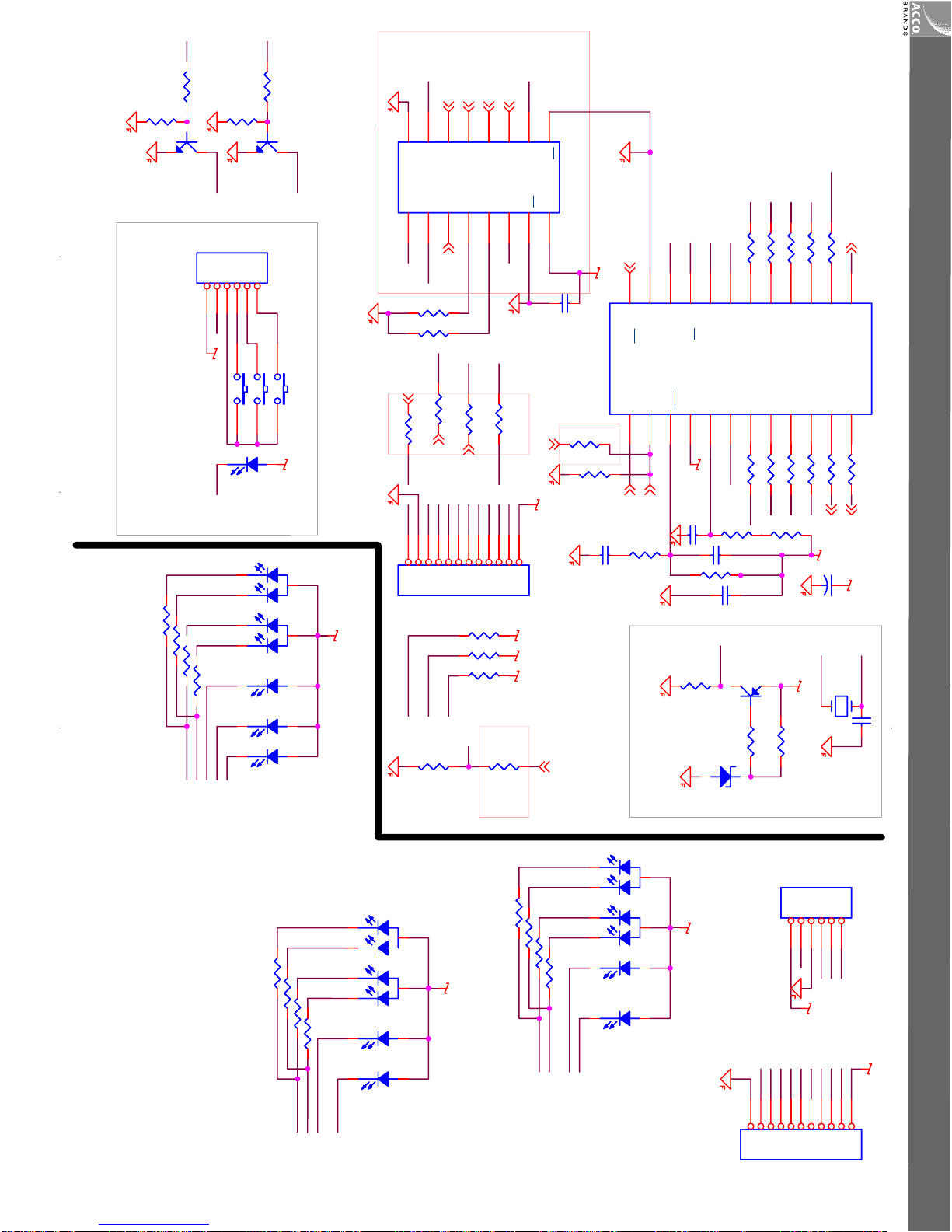

Testing Electrical Components

WARNING!

Always disconnect the power cord from receptacle

before making continuity or resistance tests.

Switches

Set meter to read resistance. Check switches for

continuityfrom common toclosed contactsand

ity from common to the open contact.

Emitter - Set meter to the diode setting. Disconnect

emitters from the control board. With the positive

meter probe on the emitter wire and the negative

meter probe on the black-stripped emitter wire,

check for approximately .639 ohms. Reverse the

meter leads and should be read.

Receiver- Set meter toread 20Mohms. Disconnect

thereceiverfromthecontrolboard. Withthepositive

meter probe on thereceiver wire and the negative

meter probe on the receiver wire check for app-

roximately 4.62 Mega ohms under normal room

light. The resistance will increase when blocked.

Reverse the meter leads and should be read.

5.0 T 8

Troubleshooting 3

inatetheanti-jamindicator illum-