REPLACEMENTFILTER

CartddgeFilter........................................................65250

I.IAINTENANCE:

waB!!!g MAINTENANCEONTHIS

UNITSHOULD

BE

PERFORMEDONLY

BY

QUALIFIED,

TRAINED

TECHNICIANS.

1. Motorbrushesareavailable

fromlhe

factoryby

ordedng

PartNo.65077.

Theuseofhigh

perfo.mance,

ballsleeve

motors

provide

about500hoursofbrush

operation

(depending

upon

filtercondilion).

Btushes

shouldb€periodically

checked

after500

hoursuseandif

wom,replaceasamatter

or

prevenlative

mainlenance.

2, Vacuum

Molors

areavailable

fromthe

factoryby

ordering

PartNo.65001.These

motorsare

thermally

protecled

byanaulomatic

reselthermal

circuilbreaker

andwillshutdo\*n

if theyareovefpaled dueto lackot

airflow

or lockedrctorcondition.

DOI{OTREPLACETHESE

MOTORSWITH

A MOTOR

THATDOESNOT

HAVEATHERMAL

OVERLOADI

REPAIR

PARTS

'1)

lvlotorWscrews-...........-

...................

. . - 65001

2)[,lotorGasket..............-....................................65002

3)RubberLatch.-.......-..............-......

... 65003

4)Clogged

FilterIndicalot

1i9h1............

. .. . .. 65004

5)ON/OFFToggle

Switch............

.. . . 65005

6)DifferentialPressureSwitch.....................

.65006

7)Motorbrushes.....-.......-.............--....

.. - ... 65077

ACCESSORIES

Thefollowiogaccessories

and

attachments

areavailable

faomthefactoryorfiom youtACEdealer:

FlexTube....... " - 65012

MagnelicBase-...-....................

. ...-.-..- . 65014

8"DiameterRound

Nozzle.

.. . .........-.........

..- .65015

4"SuctionCup

Base...-.......................

...

. . ... ...

65016

10'ExtensionHose

&Coup|ing....

.. . ... .. 65017

3"CastertobilityKit...........-................-.......-.

. .65018

StotNozzle._...._..........................-

. .......................65019

20'SlolNozzle

...........................

..-

.- . .. .. .. 65036

MobiteCart....._.._......-...-..........

. ........................--..

65038

'T'Adapter..................................

....

.. ...

.. .. .65040

Reducer,1-1/4'(Smoke

Exlractrng

Gun)-

.-. ..65041

Reducer,1-112'

(Smoke

Enracting

Gun). - .. ..65043

PoweFMaticInduclive

switch

. ........

.. ... .. 99-800

ACEINDUSTRIAL

PRODUCTS

A Division ofi

AssociatedEqulpment

Corporation

5043Farlin

Avenue

St.

Louis,MO63115

Tel.

(314)

3€t5178

Fax.

(314)

385'3254

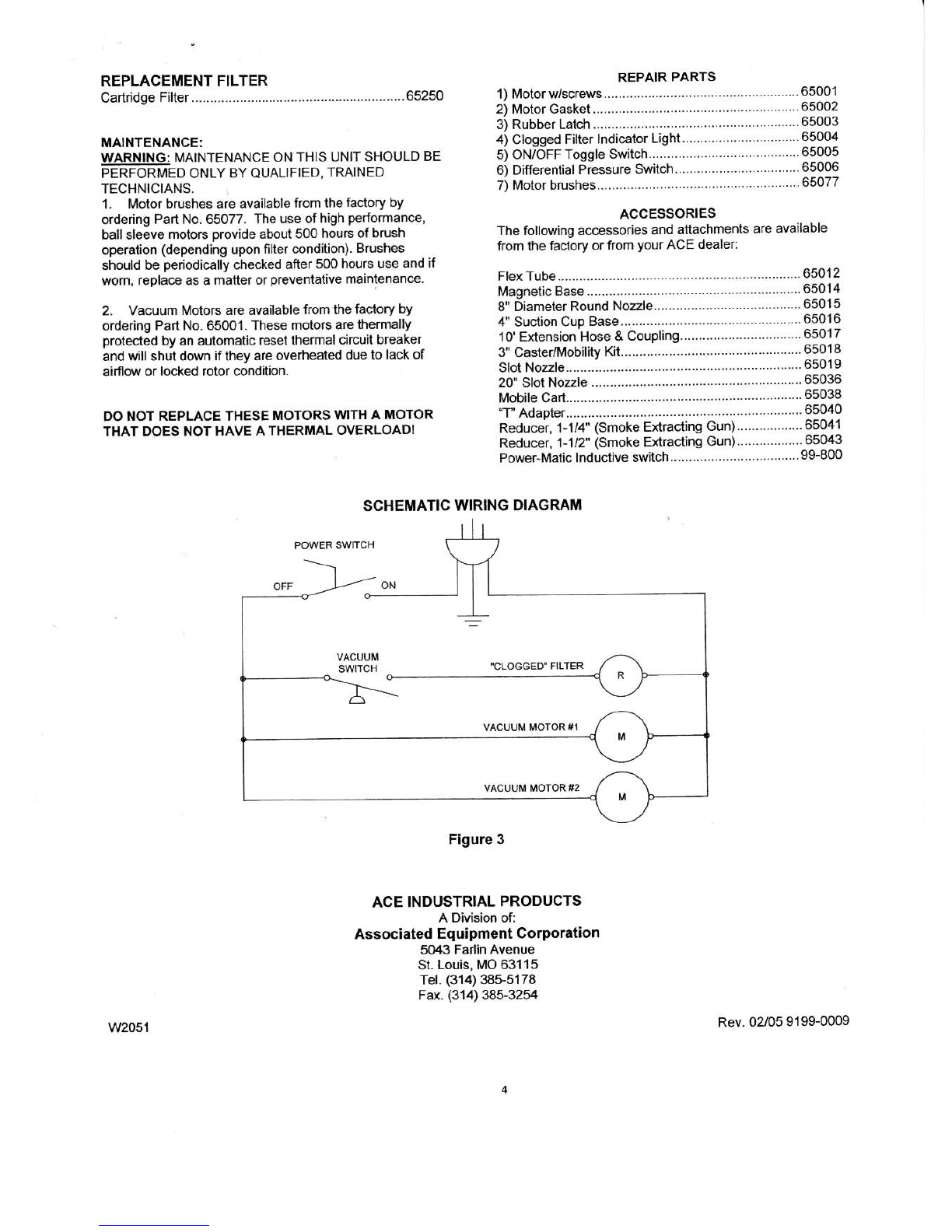

SCHEi'ATIGWIRING

DIAGRAM

Figure

3

w2051 Rev.

020591

990009