1.3.4.2 Factory Assigned Display Modes

There are 17 factory pre-set frequency video

modes. These modes have a factory pre-set for all

characteristics affecting front-of-screen

performance. When the system is powered-

on,previously stored screen parameters for a pre-

defined mode will be recalled if the operating

mode is one of those stored in memory. If the

operating mode is not one of those stored in

memory, the monitor CPU will select the PRESET

timing for a mode that is the next lowest in

horizontal scanning frequency to the mode being

currently used. The screen parameters may be

adjusted by the use of the front bezel controls and

then may be saved as a user defined mode. The

monitor shall include all the preset video timings

shown in the following page.(Please see Note.(3) )

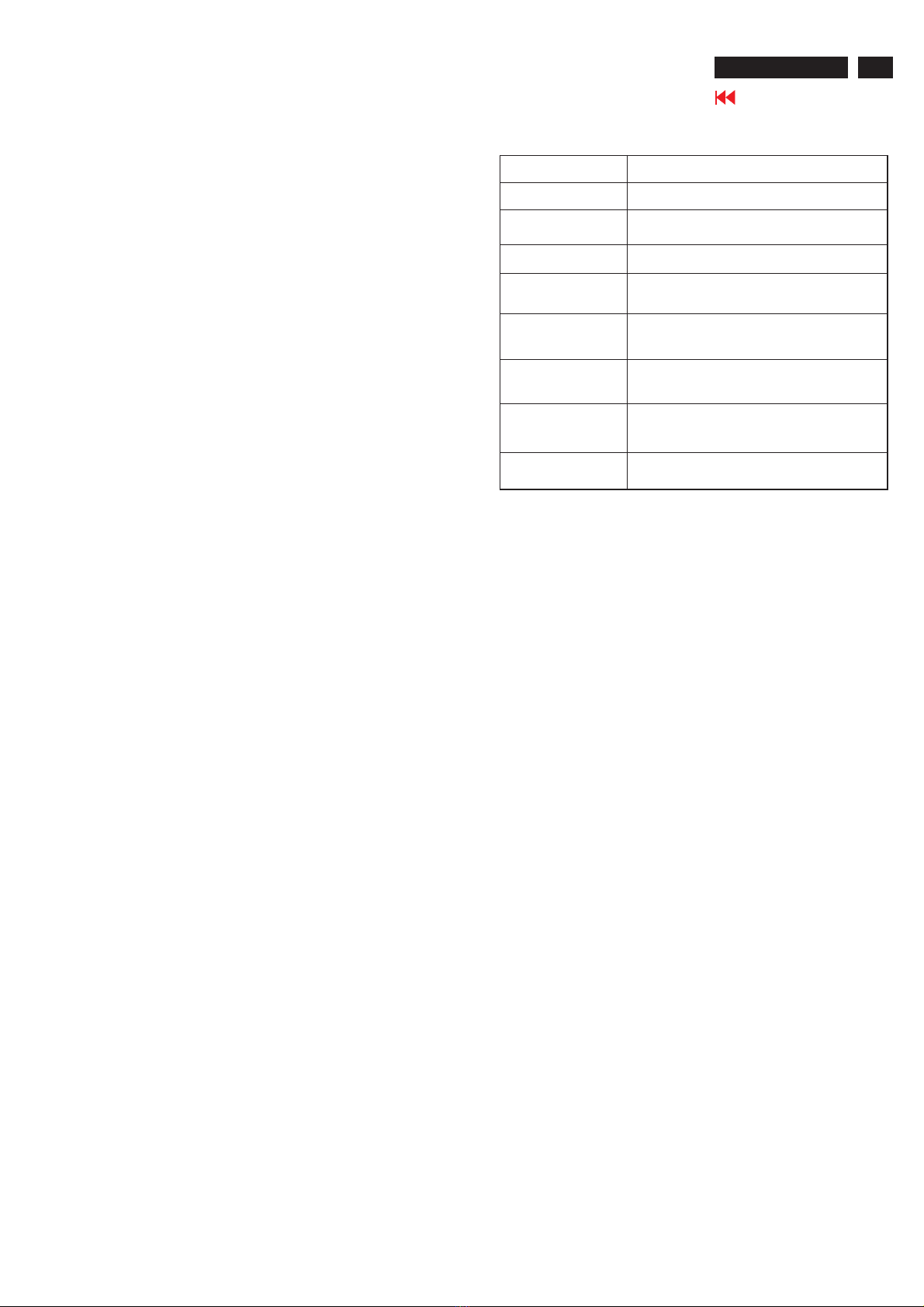

1.3.3.4 OSD adjustment

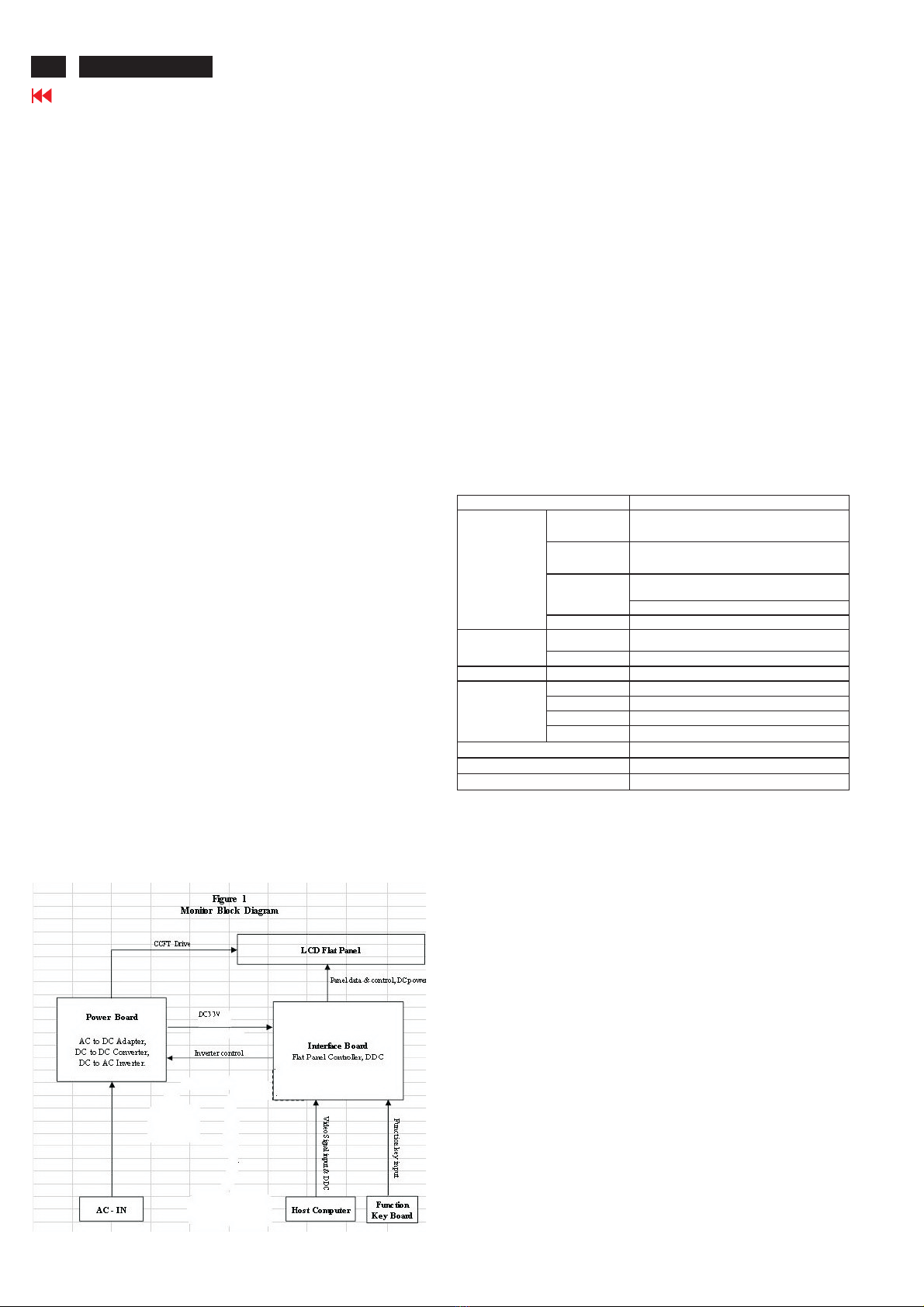

1. Product Specification (continued)

1.3.3.3 On-Screen Display

The Lite-ON On Screen Display system shall be

used , controlled by a Menu button. If the buttons

remain untouched for OSD turn off time while

displaying a menu , the firmware shall save the

current adjustments and exit. Also, if the video

controller changes video mode while the OSD is

active, the current settings shall be saved

immediately, the OSD turn off, and new video

mode is displayed.

ITEM CONTENT

AUDIO VOLUME To increase or decrease the sound level

BRIGHTNESS Back light Luminance of the LCD panel is adjusted.

CONTRAST A gain of R , G and B signal is adjusted.

AUTO CONTRAST A gain of R , G and B signal auto adjust.

CLOCK The ratio of dividing frequency of the dot clock is adjusted.

PHASE The phase of the dot clock is adjusted.

H-POSITION The indication screen is horizontally moved right and left (1 Pixels pitch).

V-POSITION The indication screen is vertically moved up and down (1 Pixels pitch).

AUTO ADJUST Clock system auto adjustment, about under 8 sec.

COLOR BALANCE Select three kinds of modes. ( USER /6500 / 9300 ).

OSD POSITION The OSD indication position can be adjusted.

OSD LANGUAGE Select the language used for the OSD menu among English , French ,

Italian , Deutsch and Spanish.

RECALL DEFAULTS All data copy from factory shipment data.

OSD DURATION Adjust OSD menu off time range from10~120 second.

POWER-SAVE Back light of the LCD panel is cut when the signal is not input (AC line

power consumption 2W or less).

INFORMATION The frequency of the horizontal / vertical synchronizing signal under the

input is indicated.

※NOTE : OSD MENU SEE APPENDIX A

Key When no OSD display OSD Displayed

1. To display the OSD menu on the screen.

2. To select the OSD sub-Menu

>Speaker Volume/Minus

(with Audio)

1. Back-forward selection of the OSD menu.

2. Decrease the value after sub-menu selected.

<Speaker Volume/Plus

(with Audio)

1. Forward selection of the OSD menu.

2. Increase the value after sub-menu selected.

Menu or sub.menu EXIT/Scenario mode

Auto Auto Adjust Function

Description

MENU Menu Display

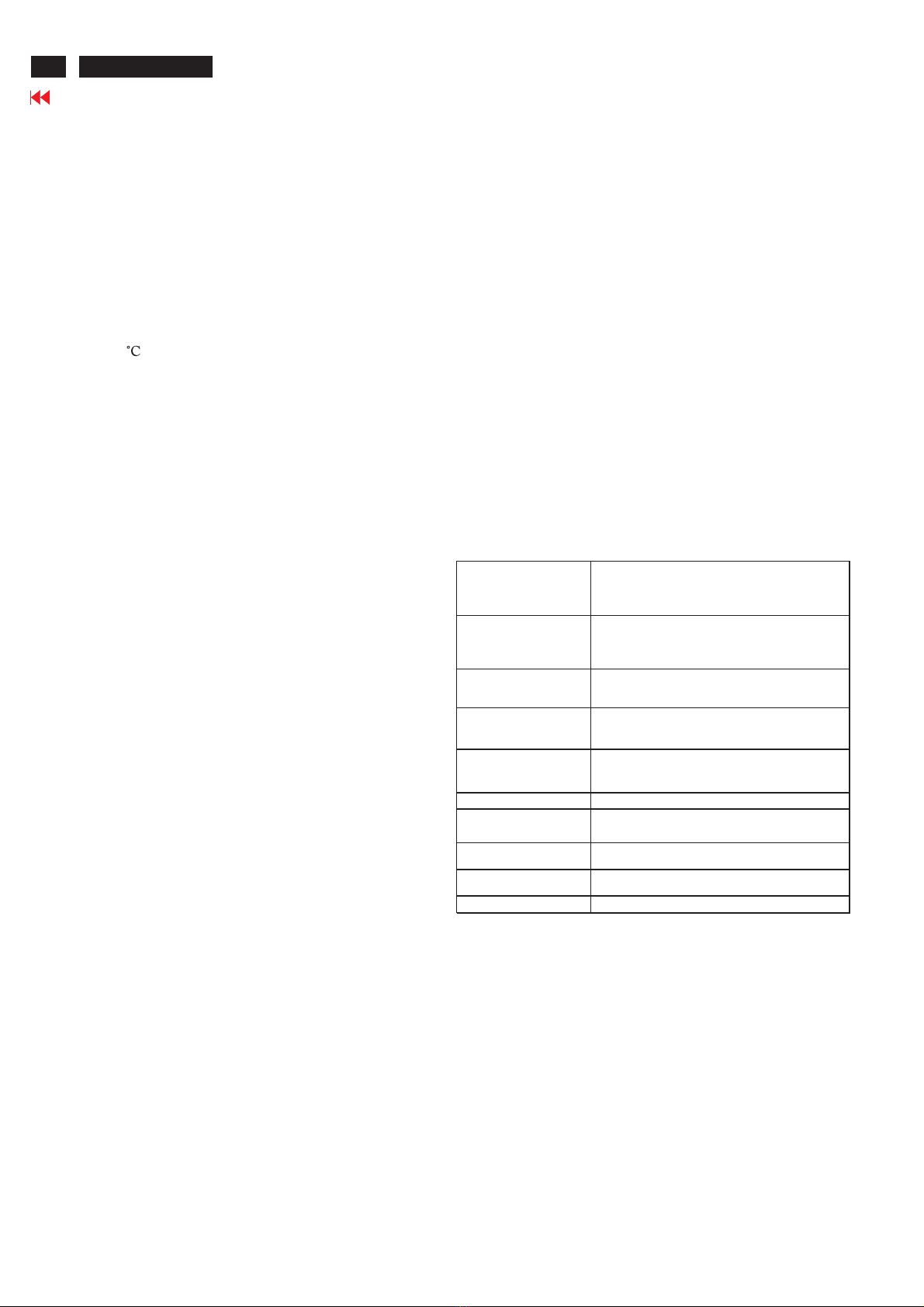

1.3.4 Monitor Modes and Timing Capability

1.3.4.1 Format and Timing

The monitor shall synchronize with any vertical

frequency from 55 to 81K Hz , and with any

horizontal frequency from 30 to 94KHz. If the input

frequency is out of the above – specified range, the

monitor shall display a warning screen indicating

that the input frequency is out of range. Under no

circumstances shall any combination of input

signals cause any damage to the monitor .

1.3.4.4 User Display Modes

In addition to the factory pre-set video modes,

provisions shall be made to store up to 9 user

modes. If the current mode is a user mode, the

monitor shall select its previously stored settings.

If the user alters a setting, the new setting will be

stored in the same user mode. The user modes

are not affected by the pre-set command. If the

input signal requires a new user mode, storage of

the new format is automatically performed during

user adjustment of the display (if required, please

see Note.(4) )

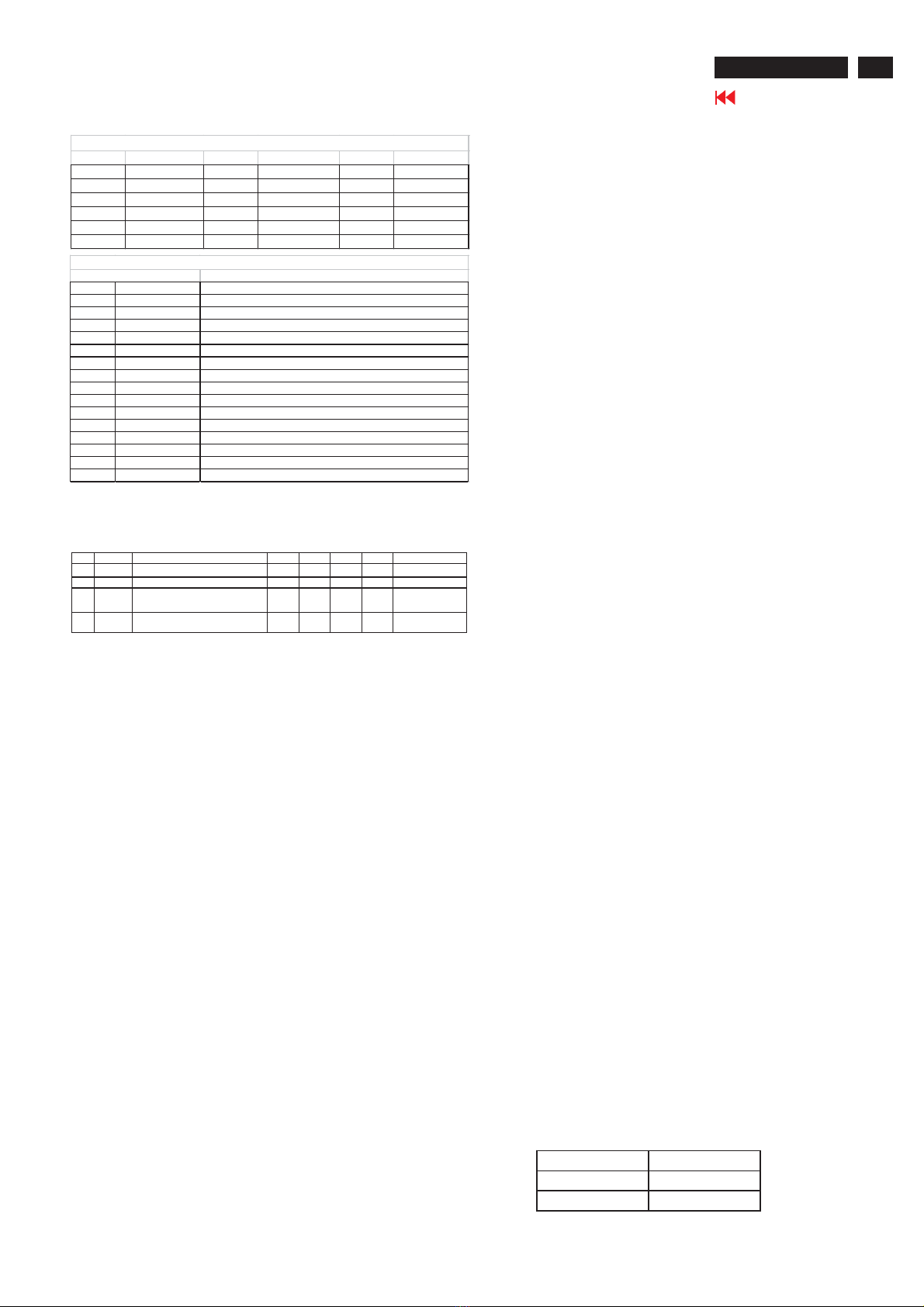

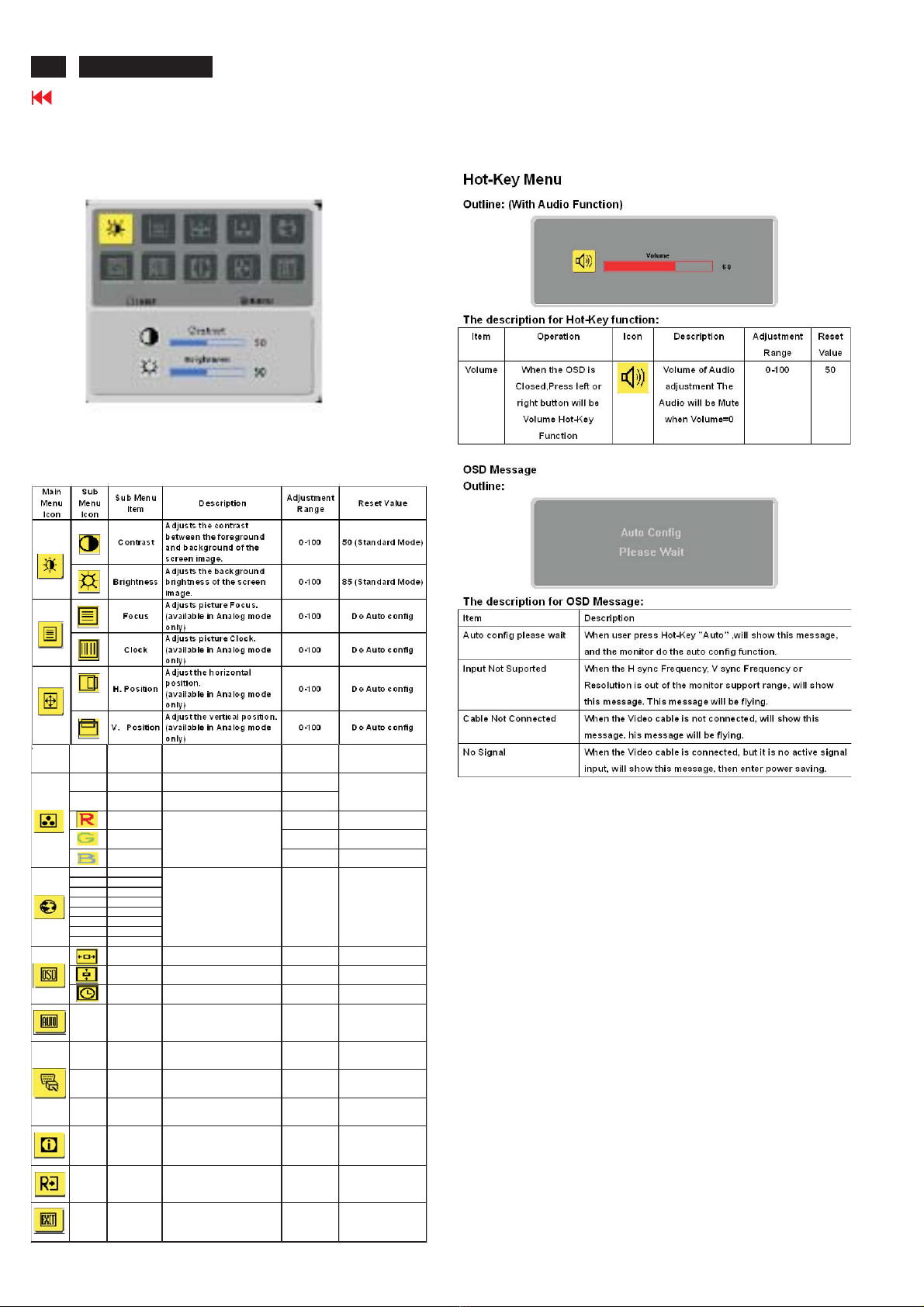

Preset timing Chart

1.3.4.3 Mode Recognition Pull-in

The monitor shall recognize preset modes within a

range of +/-1KHz whichever is less for horizontal ;

and within +/-1Hz for vertical.

H-Sync Band Width

(KHz) (MHz) H V

1 102 720 x 400 (70Hz) 31.469 28.322 - +

2 103 640 x 480 (59.94Hz) 31.469 25.175 - -

3 109 640 x 480 (75Hz) 37.5 31.5 - -

4 116 800 x 600 (60Hz) 37.879 40 + +

5 110 800 x 600 (75Hz) 46.875 49.5 + +

6 118 1024 x 768 (60Hz) 48.363 65 - -

7 141 1024 x 768 (75Hz) 60.023 78.75 + +

8 1280x800(60Hz) 49.306 71 + -

NOTE : (1) 76 ≦FV ≦86 : monitor can display but doesn't guarantee.

(2) fV < 55, or fV > 86 : warning invalid mode.

(3) Factory model :

After we first burn the code into the flash, every preset-model we run first must do auto-adjusting.

Then it'll not do auto-adjust again when we changed preset-mode back including AC on/off DC on/off.

The only way that preset-mode do auto-adjust again is press '' Internal Factory Reset''.

(4) User mode :

The code should memorize 9 timing mode exclusive of preset-modes as use mode and do auto-adjusting.

When user set a new mode that is not among previously. It'll do auto-adjusting then be solved to user modes.

The new mode will overwrite the first memorized user modes.

The user modes be cleared is same as Factory mode. Just do '' Internal Factory Reset''.

(5) Internal Factory Reset and OSD Factory Reset behavior.

Preset Timing Chart

Polarity

Item No Resolution

4

Go to cover page

ACER AL1516W