Contents

Preface ............................................................................... 3

Introduction ....................................................................... 3

Safety ................................................................................ 4

Planning the location of the feeding system ...................... 5

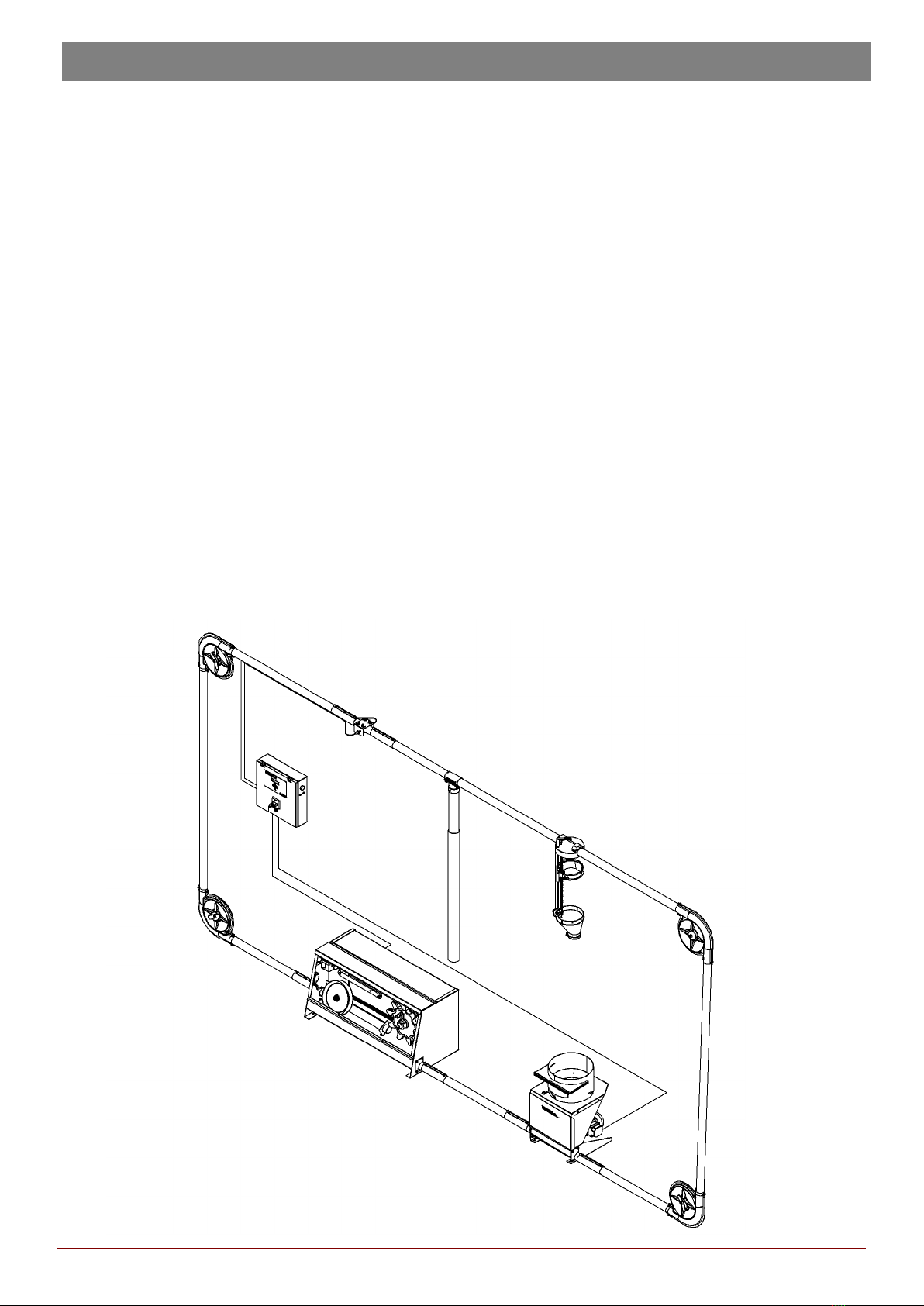

Installation height ............................................................. 5

Bends ................................................................................. 6

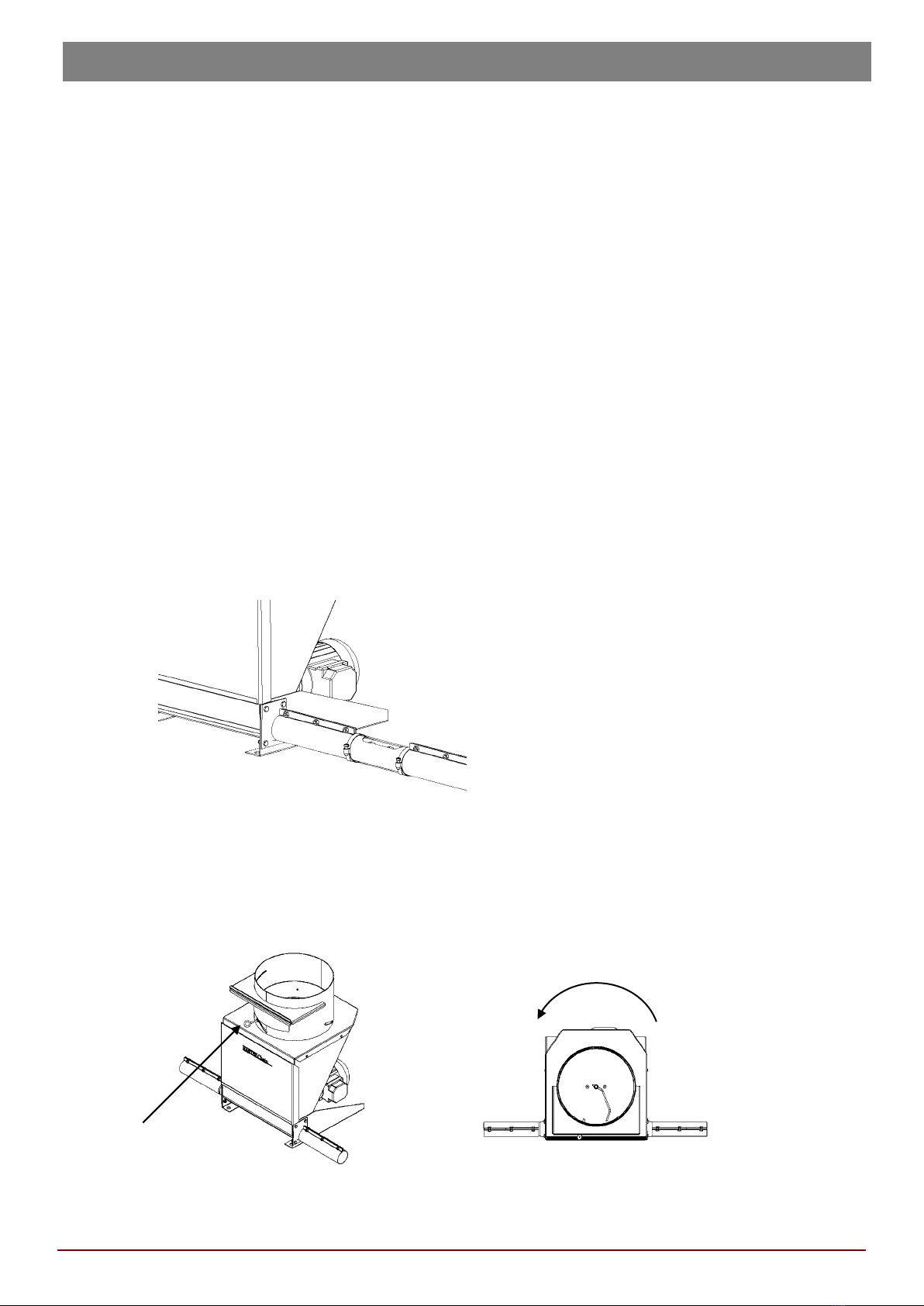

Loading hopper .................................................................... 6

Drive unit ............................................................................ 7

Sensor switch ...................................................................... 7

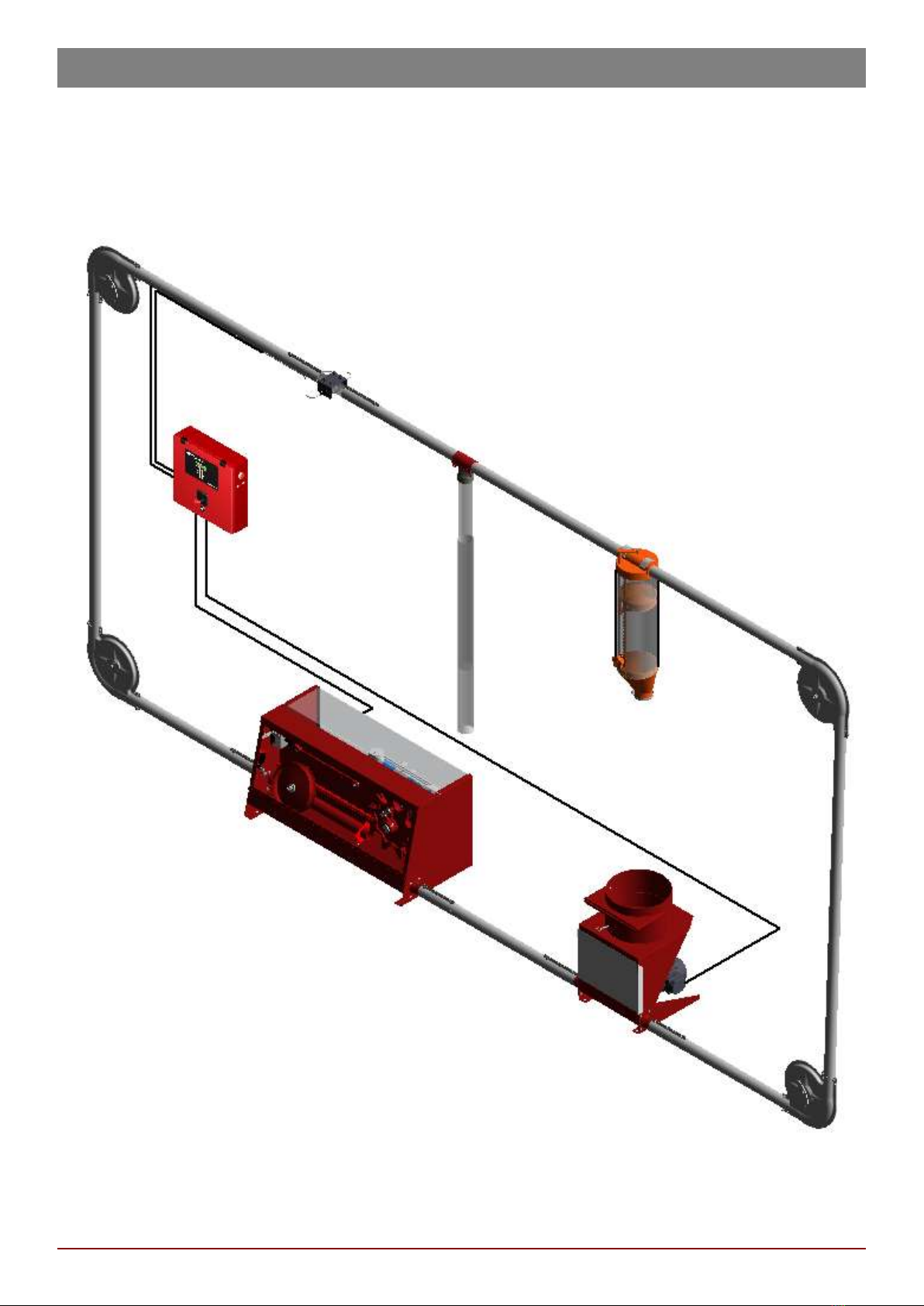

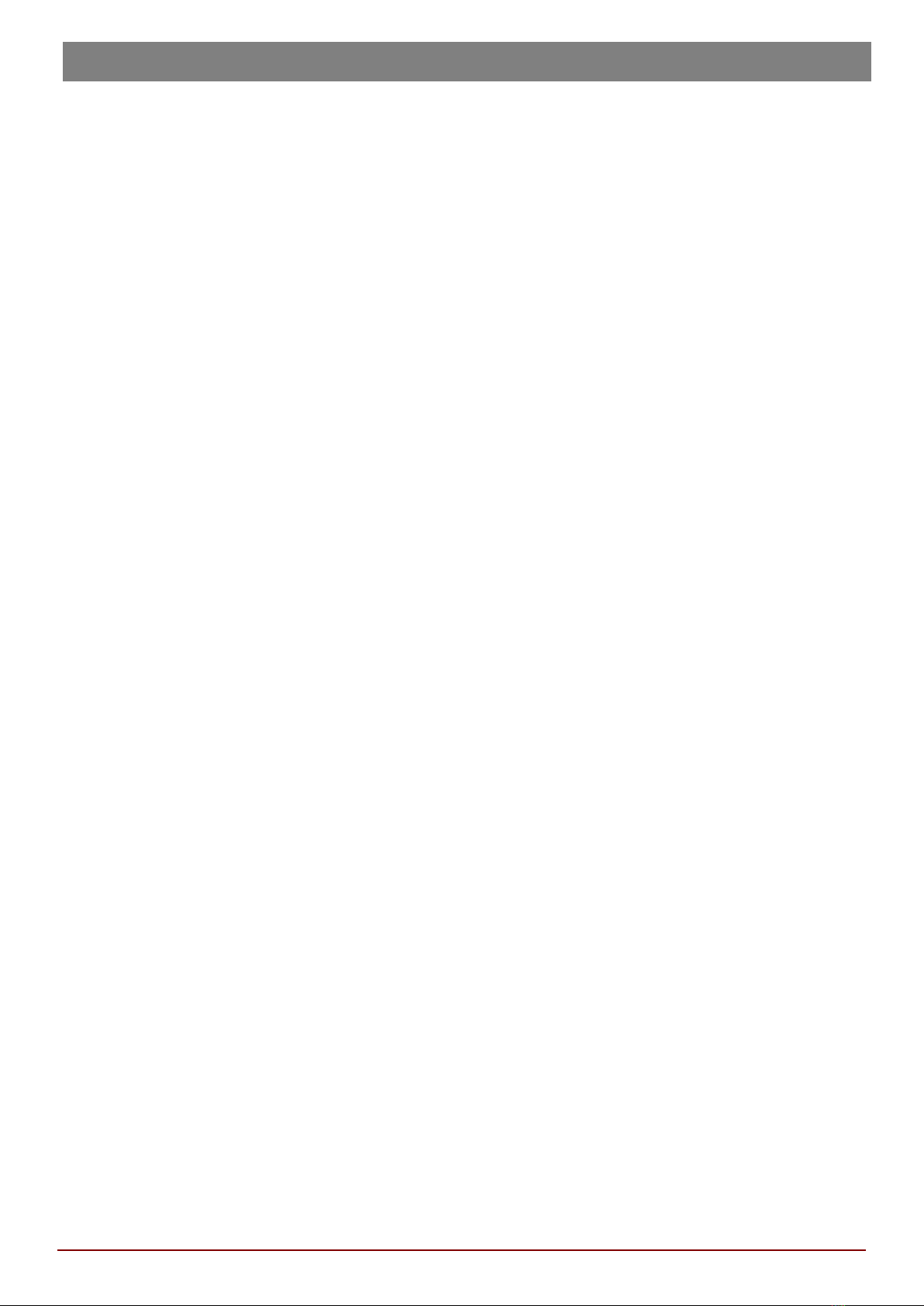

Assembly ........................................................................... 8

Loading hopper .................................................................... 8

Adjustment ......................................................................... 8

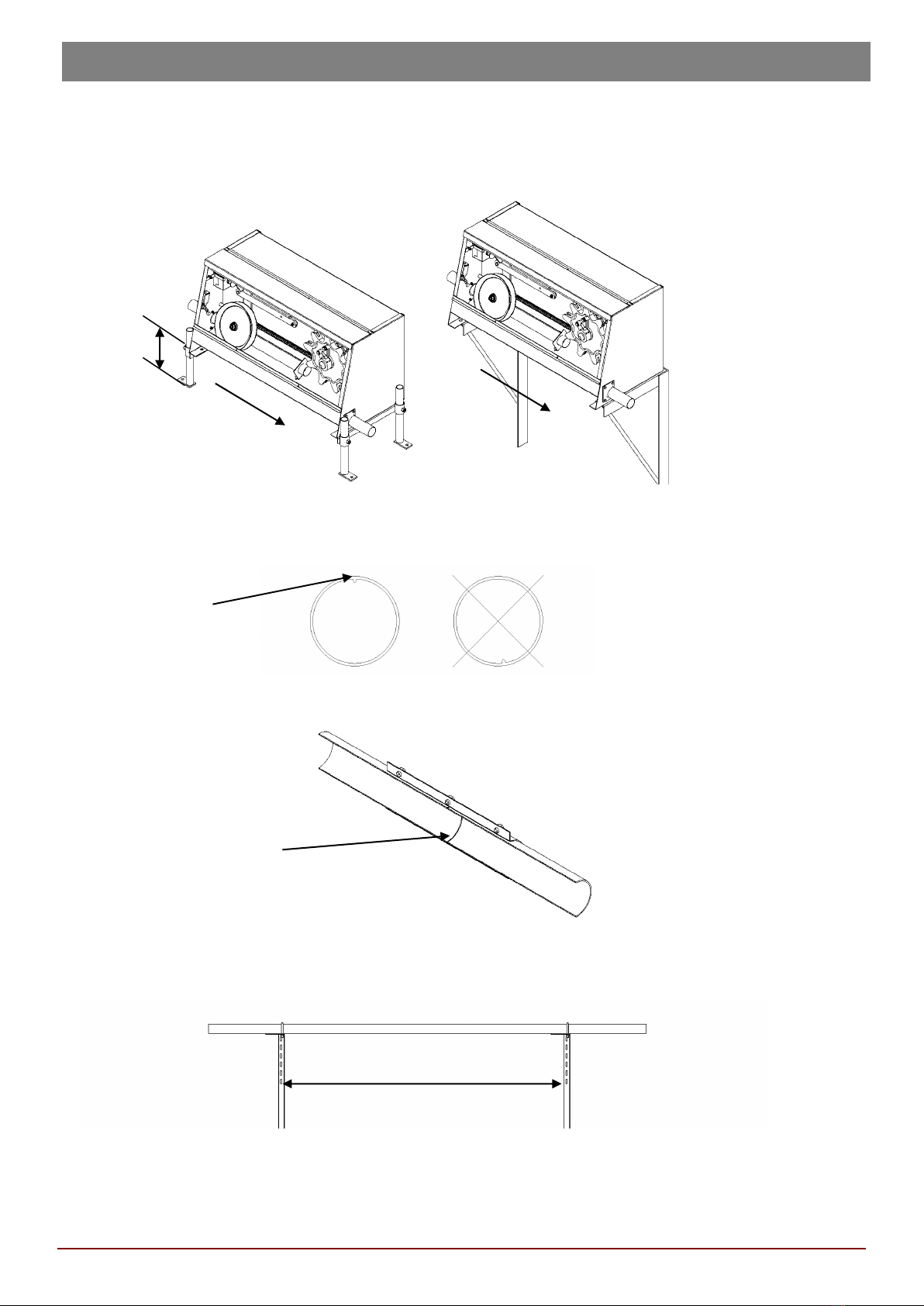

Drive unit ............................................................................ 9

Feed pipes .......................................................................... 9

Splicing sleeves ..................................................................10

Bends ................................................................................10

Feed outlet .........................................................................10

Plastic feed dispensers .........................................................11

Sensor switch .....................................................................11

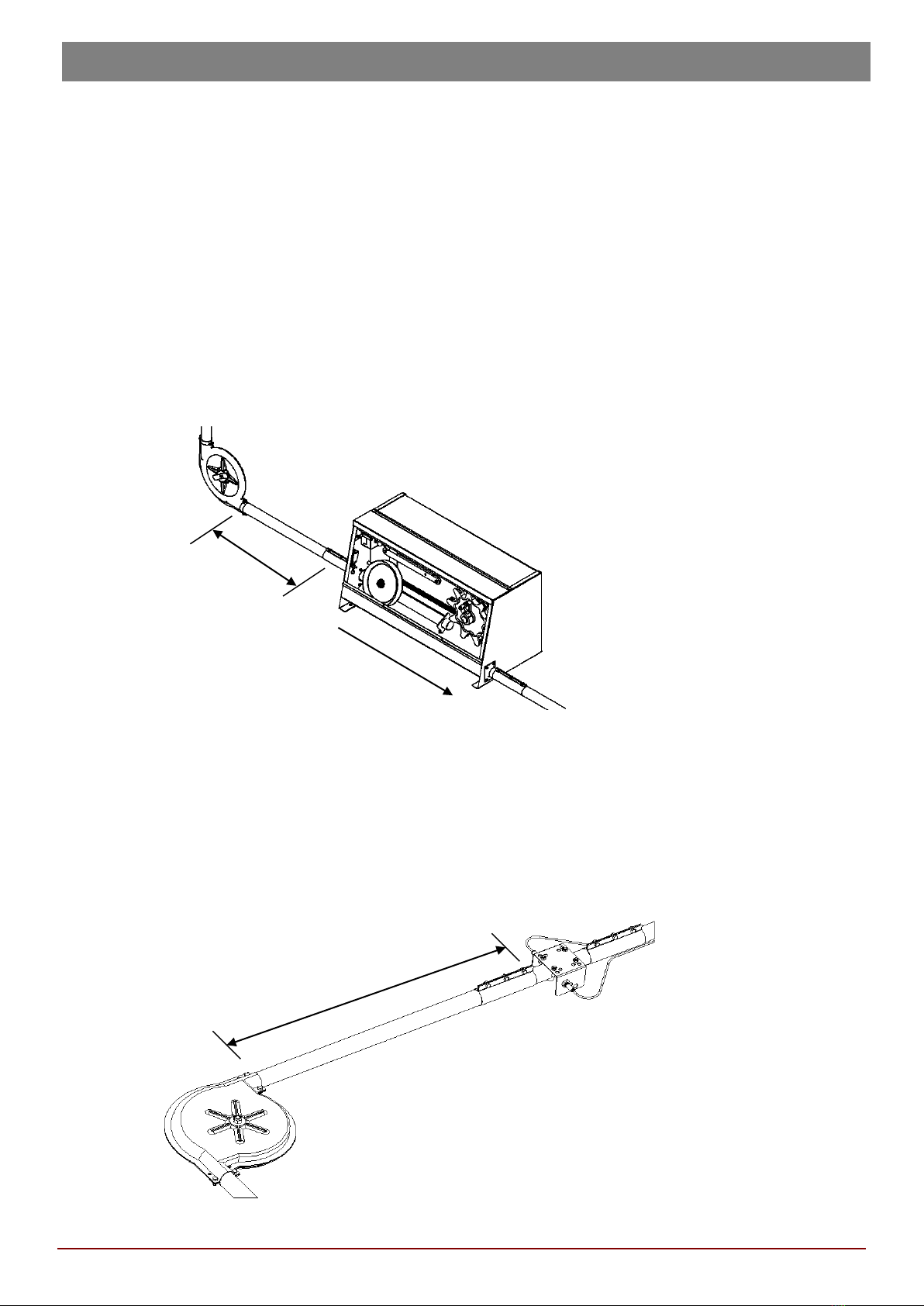

Feed wire ...........................................................................12

Feed chain .........................................................................13

Opening system for plastic feed dispensers ............................14

Mounting the opening system ...............................................14

Adjusting the opening device ................................................15

Technical data ...................................................................16

Drive unit ...........................................................................16

Accessories ........................................................................18

Loading hopper ...................................................................18

Opening motor ...................................................................20

Maintenance ......................................................................21

Troubleshooting .................................................................22