ACO FUNKI A/S ∙ Kirkevænget 5 ∙ DK-7400 Herning ∙ Tel. +45 97 11 96 00 ∙ Fax. +45 97 11 96 77 ∙ www.acofunki.com

M-1040_GB

2/24

Manufacturer and product data

Manufacturer: ACO Funki A/S

Kirkevænget 5, Gjellerup

DK-7400 Herning

Denmark

Tel. +45 97 11 96 00

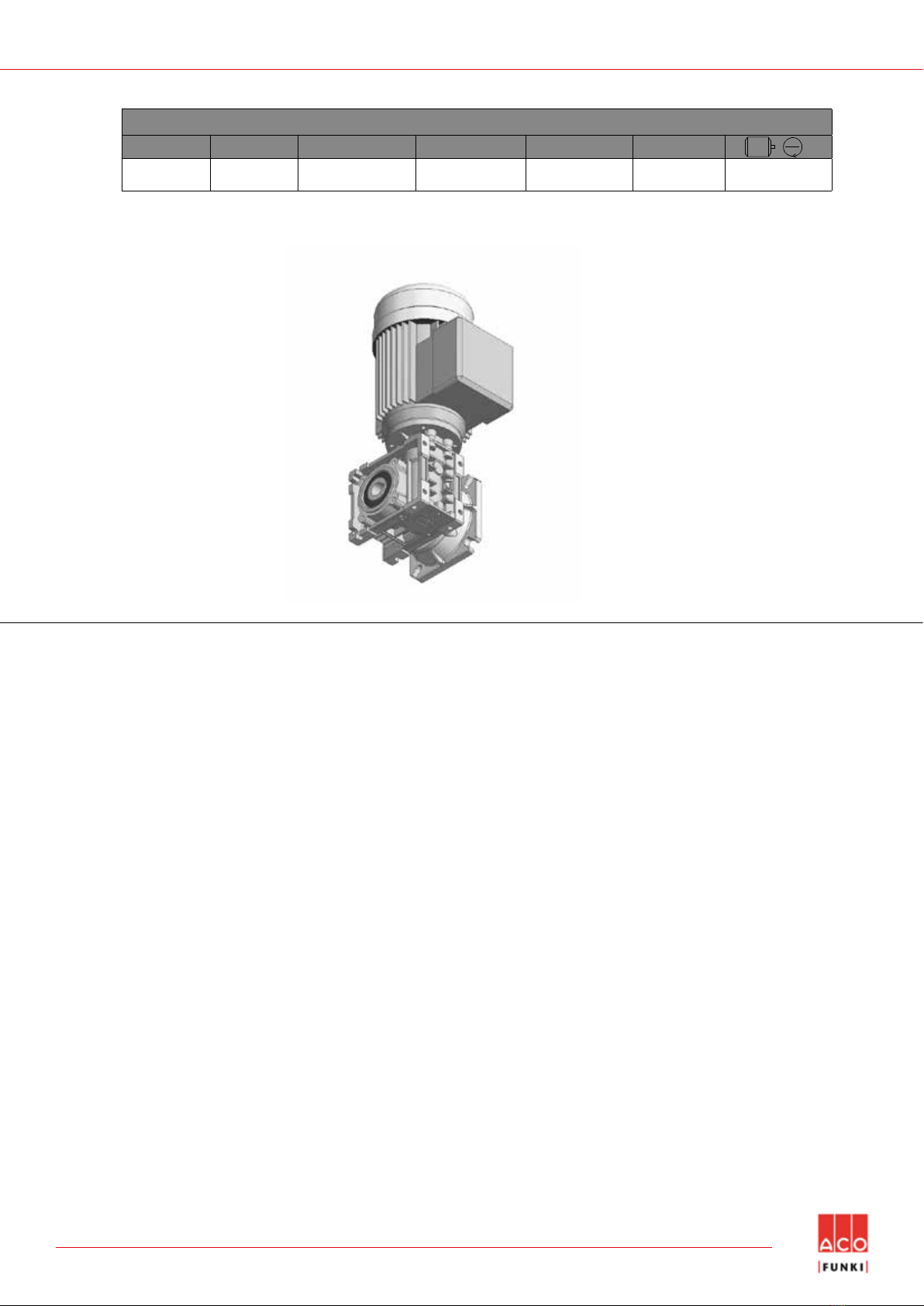

Product type: Reception unit, type M

Every effort has been made to ensure that the contents of this manual are correct. However, should you discover any er-

rors, please inform ACO Funki A/S immediately so that they can be corrected.

Despite our efforts, ACO Funki A/S accepts no liability whatsoever for possible errors in the manual or for the consequenc-

es of such errors.

ACO Funki A/S reserves the right to change the contents of the manual without prior notice.

1.1 General safety instructions

This product has been designed and manufactured in accordance with the latest engineering standards and acknowledged

safety regulations, making it highly reliable. The product may, however, be dangerous for operators or third parties and

may cause material damage if operated by unqualied persons or for purposes other than that described in section 5.1.

The following safety instructions must therefore be carefully read and observed.

• The product must only be used for its intended purpose, as described in section 5.1. The general instructions re-

garding safety and accident prevention must be observed at all times.

•

Qualied personnel are persons who by reason of their training, experience or instruction and their knowledge of rel-

evant standards and regulations, accident prevention instructions and operating conditions have been authorised by

the person responsible for the safety of the machine to perform appropriate everyday activities, including the identi-

cation and prevention of potentially hazardous situations (IEC 364).

• The machine must only be operated by trained personnel. Children may only operate the machine if over 16 years

of age, supervised by a qualied adult and where such operation forms part of their training/education.

• To ensure personal safety and reliable operation, only original accessories and spare parts from ACO Funki A/S must

be used.

• For safety reasons, unauthorised machine alterations are not permitted.

• Maintenance and repair (of electrical parts in particular) must only be performed by qualied and trained personnel.

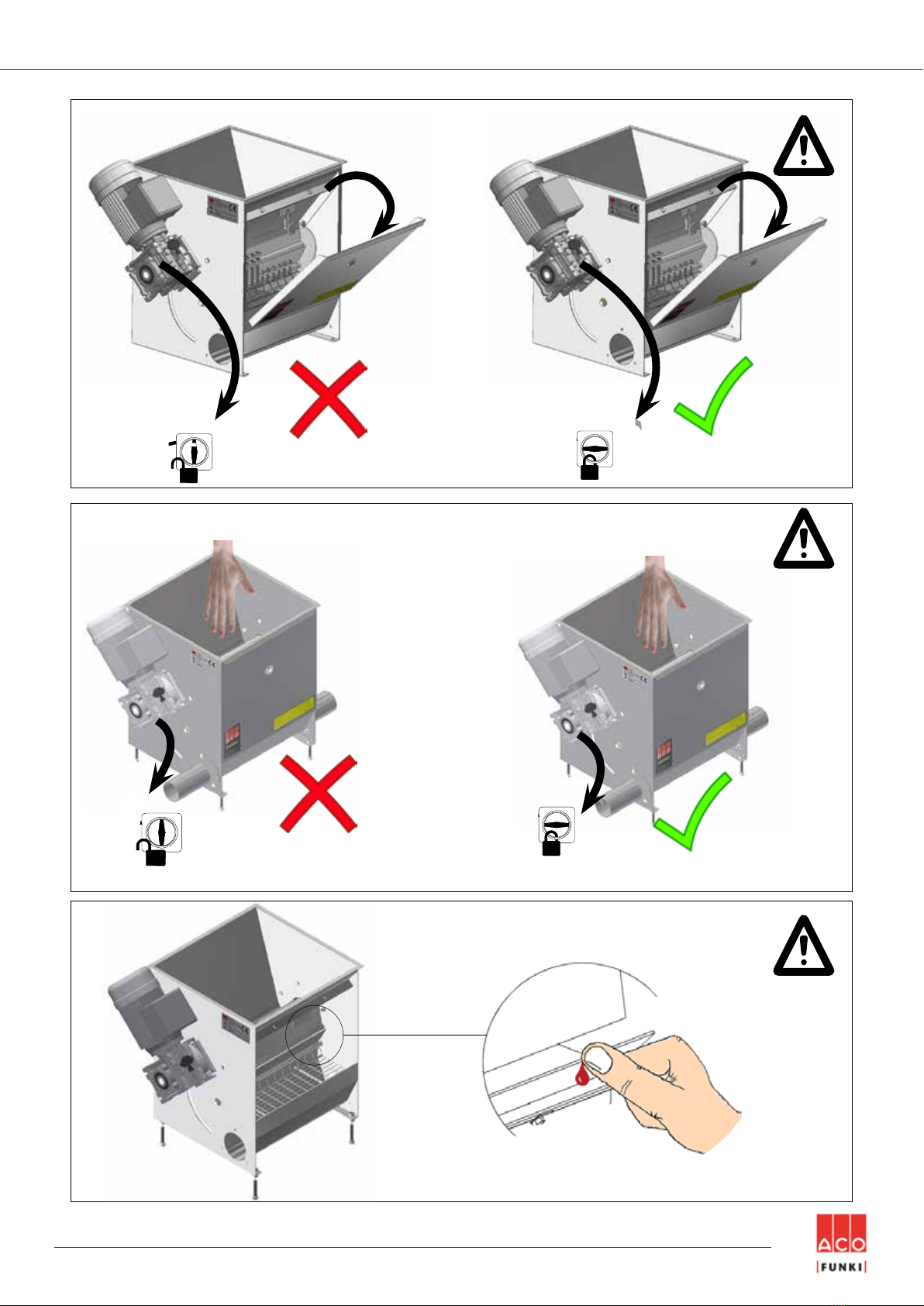

• Voltage-carrying, pressure-activated and rotating or in any other way moving machine parts may cause serious or

fatal injury if operated incorrectly or if safety instructions are not observed.

• Protection devices must never be disconnected during operation and must never be altered or weak ened in

relation to their intended effect.

• Current national and international guidelines and regulations regarding accident prevention must be observed at all

times, as must general safety requirements.

NOTE: THE DANISH VERSION IS THE ORIGINAL SAMPLE, ALL OTHER LANGUAGE VERSIONS REFER TO THE

ORIGINAL SAMPLE.

GENEREL INFORMATION