HG H1000 HIGH TIP User manual

User Manual HG H1000 HIGH TIP

Side 1

User Manual

HG H1000 HIGH TIP

SUPER SKUB

User Manual HG H1000 HIGH TIP

Side 2

Table of Contents

User Manual ................................................................................................................................................................ 1

Introduction........................................................................................................................................................... 3

1.Safety................................................................................................................................................................. 4

1.1 Read the manual ........................................................................................................................................ 4

1.2 Education...................................................................................................................................................5

1.3 The most frequent causes of accidents:..................................................................................................... 5

1.4 Preparation................................................................................................................................................. 5

1.5 Noise and vibration level ............................................................................................................................ 6

1.5.1 Vibration level.......................................................................................................................................... 6

1.6 Operation.................................................................................................................................................... 7

1.7 Maintenance............................................................................................................................................... 9

1.8 Transport & Towing .................................................................................................................................. 10

1.9 Disposal & dismantling ............................................................................................................................. 10

2. Function description........................................................................................................................................ 11

2.1 Control panel ............................................................................................................................................ 11

2.2 Machine's operating units......................................................................................................................... 12

3. Precautions before starting............................................................................................................................. 13

4. Driving............................................................................................................................................................. 15

5. Maintenance................................................................................................................................................... 17

5.1 Overview of maintenance......................................................................................................................... 17

5.2 Towing and tipping in case of engine failure............................................................................................ 18

5.3 Maintenance Points.................................................................................................................................. 19

6. FAQ............................................................................................................................................................. 24

7. Hydraulic program .......................................................................................................................................... 25

8. Technical specifications.................................................................................................................................. 26

9. Warranty provisions........................................................................................................................................ 27

10. EU declaration of conformity ........................................................................................................................ 28

User Manual HG H1000 HIGH TIP

Side 3

Introduction

The HG H1000 High Tip

is a high-quality dumper with an

added benefit –the ability to

unload directly over the rim and

into containers and trailers. It is still

user-friendly and comes with a

low total cost of ownership.

The high-tip function is particularly

popular for work sites in tight spaces,

such as cities, among rental

companies, landscapers, contractors,

and demolition companies.

The HG dumper has total safety

measures that ensure the highest

safety standards for users while

being able to load up to 1000 kg.

Manufacturer:

HG Machines ApS

Vejlevej 15, 8722

Hedensted, Danmark

Bredgade 63 A

1260 København K, Danmark

+45 75 89 12 44

hello@hg-machines.com

www.hg-machines.com

HG Poland Sp. z.o.o

Ul.Prosta 34 Lozienica

Pl-72-100 Goleniów

NIP: PL 7010040430

+48 (91) 885 23 04

Find out more at:

www.hg-machines.com

• Minimal maintenance - built to last

• Increases on-site efficiency

• User-friendly and simple machine

• Excellent maneuverability and versatility

• High quality and low total cost of ownership

• Hydraulic high-tip enables container unloading

User Manual HG H1000 HIGH TIP

Side 4

1.Safety

1.1 Read the manual

Please read this manual carefully and make

sure that it is also read by other potential

users of the machine. A hazardous situation

may arise if the user is unaware of certain

details about the machine.

If one of the warning labels is peeling off,

worn or damaged, making the symbol

illegible, replace the label.

WARNING!

Next to a piece of text in the manual indicates a

risk of personal injury if the instructions are not

observed.

WARNING!

Hot parts

Do not touch the engine or exhaust pipe during

operation or immediately after the engine has

stopped. Hot parts can cause serious burns.

WARNING!

Noise

We recommend the use of hearing protectors.

Long-term exposure to noise damages your the

hearing.

WARNING!

Poisonous gases

Do not let the engine run

without

adequate ventilation and

never indoors, as the machine's exhaust

poisonous carbon monoxide.

Manuals, parts lists and instructional videos can

be found at www.hg-machines.com

WARNING!

Crushing risk

Do not touch the machine's moving parts. This

applies to fingers and clothing as it

may result in a loss of limbs.

WARNING!

Explosive liquid

Petrol is highly flammable and explosive, and

may cause serious injury during filling.

We recommend stop the machine and keep it

that you away from heat,

sparks and flames, remove

any spills immediately and

fill it with petrol outdoors.

WARNING!

Danger

When servicing and parking the machine, the

engine must be switched off and ignition key

removed.

User Manual HG H1000 HIGH TIP

Side 5

1.2 Education

•Read the instructions carefully. Please

familiarize yourself with all controls,

switches etc. and how to use the

equipment correctly.

•Operators of the motorized wheelbarrow

must be over 18 years of age and have

normal mental and physical capabilities.

National or local legislation may

prescribe a different age limit for persons

authorized to operate the motorized

wheelbarrow in a given situation.

•Remember that the operator is

responsible for accidents or hazardous

situations involving other people or their

property.

•The operator should be properly

instructed in the use of the motorized

wheelbarrow. These instructions should

focus on the following:

- 1) The operator must be careful and

concentrated when working with self-

propelled machines.

- 2) The operator must be aware of

what is going on in front of/behind the

vehicle, particularly in areas where

people may be moving about.

1.3 The most frequent

causes of accidents

1. Lack of overview

2. The operator's knowledge of the vehicle

is insufficient

3. Too steep terrain conditions

4. Substrate does not have sufficient

stability

5. The vehicle is used in insufficient space

1.4 Preparation

1. Do not wear loose-fitting clothing when

operating the vehicle.

2. Store fuel in canisters approved for this

purpose and keep out of reach of

children and unauthorized personnel.

3. Fuel fill is only permitted outdoors.

Smoking is prohibited during filling.

4. Fill fuel before starting the engine. Never

remove the fuel tank cover or fill fuel

while the engine is running or hot.

5. In case of fuel spills, do not attempt to

start the engine, but remove the

motorized wheelbarrow from the location

of the spill to avoid igniting it.

6. If you spill fuel on the exhaust pipe or the

engine, wait until the fuel has evaporated

due to the risk of fire.

User Manual HG H1000 HIGH TIP

Side 6

7. If petrol or oil comes into contact with

your skin, wash your skin thoroughly with

soap.

8. Inhalation of fuel vapors or oil mists is

harmful to health.

9. Ingestion of fuel or oil is life-threatening.

1.5 Noise and vibration level

When tipping with an empty tray and maximum

revolutions, the highest energy-equivalent sound

pressure level at the operator's position has

been measured at 88 dB (A) in accordance with

ISO 6396.

Under simulated operating conditions involving

combined driving and tipping,

the highest energy-equivalent

sound pressure level at the

operator's position has been

measured at 87 dB (A) in

accordance with ISO 6396.

The uncertainty of the measurements stated

above is ±2 dB. HG recommends the use of

hearing protectors, even though the noise level

is below the limit where hearing protection is

required.

1.5.1 Vibration level

When tipping with an empty tray and maximum

revolutions, the maximum weighted arm-hand

vibration level at the operator's position has

been measured in accordance with ISO 1032 at:

ahv = 5.0 m/s2.

Under simulated operating conditions involving

combined driving and tipping, the maximum

weighted arm-hand vibration level at the

operator's position has been measured in

accordance with ISO 1032 at:

ahv = 3.0 m/s2.

The uncertainty of the measurements stated

above is ±25%.

User Manual HG H1000 HIGH TIP

Side 7

1.6 Operation

WARNING!

Failure to observe the following operating

instructions may result in injury:

•When driving indoors, make sure you

observe the rules and instructions in force on

site.

•Do not use the machine in places with

flammable dust or explosive gases.

•As far as possible, only use the motor

barrow in daylight or in good artificial

lighting.

Do not drive on

slopes exceeding 5%

(4,5 degrees).

Do not drive across

slopes exceeding: 10°

(10 degrees) on hard

surfaces such as

concrete and asphalt.

5° (4,5 degrees) on

compacted ground

such as gravel and

grass.

•In case of overturning, let go of the

machine and keep your distance. Never

try to hold onto the machine.

•Be aware that the driving characteristics

of the motor barrow change significantly

between an empty and a full skip, as the

center of gravity of the motor barrow is

higher when the skip is full.

Do not use the motor

barrow with insufficient

ceiling height.

NEVER drive on slopes

with an empty or full

container when HIGH TIP

is activated.

Only drive on horizontal

and stable ground when

the HIGH TIP has been

driven out.

Do not drive and unload

close to excavations and

unstable edges.

•Unloading of frozen loads or highly adhesive

materials such as clay must not be

performed by tipping, as the machine may

tip over.

•Driving on soft, loose and uneven surfaces is

prohibited, as the operator may be exposed

to inappropriate loads on the body when

operating the machine.

User Manual HG H1000 HIGH TIP

Side 8

•When leaving the motor barrow, remove the

ignition key and turn off the main switch.

•Always turn off the ignition and main switch

before carrying out any service or repair

works.

•Always turn off the ignition and main switch

before charging the machine.

•Do not touch the motor or other electrical

parts when the machine is on and/or

running.

•The machine may only be used for

transporting materials.

When reversing, the

operator must pay

special attention to

uneven surfaces and

objects that the

operator may fall

over or drive into.

The operator must be

aware of persons in the

area so that they are

not crushed under the

truck bed when it is

being lowered.

•The area around the machine must be

kept tidy to avoid accidents caused by

falling.

User Manual HG H1000 HIGH TIP

Side 9

1.7 Maintenance

Each time the machine is used, visual inspection

and inspection must be performed to ensure:

•That there are no leaks in the hydraulic

system by hoses, tank etc.

•That there are no worn or damaged cables.

•That bolts, nuts, etc. are properly tightened.

•That the radiator grille and radiator fins on

the motor are free of dirt.

•That no hydraulic oil has been spilled on or

around the machine.

•That the motor barrow is stationary when the

propulsion lever is not activated.

•That the safety plate activates forward

movement when activated.

•That the tires have the correct pressure and

are lubricated.

WARNING! Always fit the safety bracket of the

tipping cylinder before starting the inspection

work.

User Manual HG H1000 HIGH TIP

Side 10

1.8 Transport & towing

To tow the machine without starting the engine,

activate the coasting button on the left-hand

side. This will disengage the drive wheels,

allowing the machine to be moved.

When lifting the machine, use the three lifting

points in front and on the control panel.

Ensure sufficient stability during lifting to prevent

disconnection.

The machine may ONLY be lifted when the tray

is empty.

The machine may only be

transported using a

vehicle with sufficient

headroom as there is a

risk of serious injury and

damage to the operator,

machine and transport vehicle.

During transport, make sure that the machine is

securely fastened to the tray or in a cargo

compartment in accordance with the applicable

regulations.

1.9 Disposal & dismantling

When, many years from now, the motorized

wheelbarrow is worn out and must be disposed

of, Hedensted Gruppen will carry out the

dismantling work by arrangement, as this work

must be carried out in an environmentally

friendly manner. During the dismantling process,

the parts are sorted according to type of

material. This means that steel parts are classed

as steel, rubber seals as rubber and so forth.

The various materials are then disposed of

according to the regulations

in force at any time.

User Manual HG H1000 HIGH TIP

Side 11

2. Function

description

2.1 Instrument panel

1) Operating handle for tipping the vessel.

Press up to tip off and down to lower the bed.

2) Control handle for High tip function. Press up

for the container to lift. Press down for the

container to lower

3) Control handle for choke.

The handle is pressed down to activate the

choke.

4) Free coupling of propulsion.

Turn the knob counterclockwise to disengage

the wheels so the machine can be pushed. The

propulsion is switched on again by pressing the

button in and turning clockwise.

5) Emergency stop/safety plate.

When the plate is affected, forward travel is

activated, so that the operator does not run the

risk of being trapped.

6) Control handle for driving backwards.

The handle is clamped up against the

handlebar. The more the lever is squeezed, the

higher the speed.

7) Control lever for throttle (engine revolutions).

The handle is pressed down to give the engine

gas.

8) Control handle for driving forward.

The handle is clamped up against the

handlebar. The more the lever is squeezed, the

higher the speed.

User Manual HG H1000 HIGH TIP

Side 12

2.2 The functional units of

the machine

9. Petrol filling –92 octane unleaded.

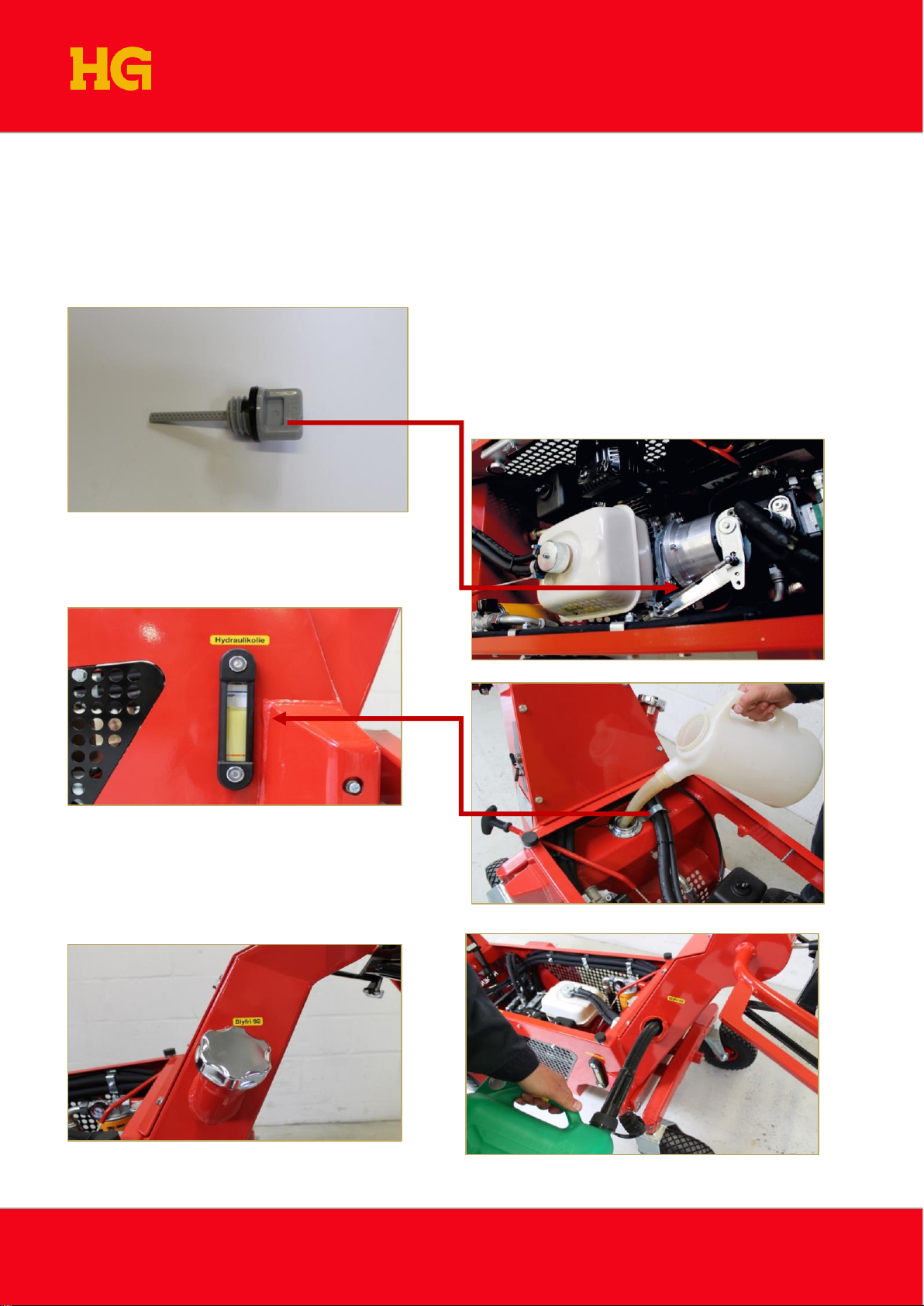

10.Sight glass for checking hydraulic oil

level.

11.Tip protection for the tub's hydraulic

cylinder.

12. Control and engine oil fill.

13.Hydraulic filter with service indicator.

14.Key start.

Used to start and stop the engine.

15. Recoil start.

Used to start in the event of a power failure.

16.Filling of hydraulic oil

Releaser. If the release lever is pushed down,

the motor is disconnected and the machine can

be pushed. If the handle is pushed up, the motor

is switched on and the machine can be operated

via the control handles.

User Manual HG H1000 HIGH TIP

Side 13

3. Precautions before

starting

Check engine condition

Oil must be visible on the dipstick or top up with

type SAE 15W-40 engine oil, if necessary.

Check hydraulic oil level:

WARNING! Fit the tipping protection.

Top up with type Q8 Handel 46 hydraulic oil or

similar, if necessary

Petrol fill

Use unleaded petrol, 92 octane or higher.

WARNING!

Petrol is a highly flammable and explosive liquid.

Leave the machine to cool for at least 10 min.

before filling and keep it away from ignition

sources.

Seek medical attention if you have inhaled

vapors or swallowed petrol.

User Manual HG H1000 HIGH TIP

Side 14

Tyre pressure and retightening:

All tyres must have the right air pressure in order

to ensure optimum ergonomics.

Tyre pressure, drive wheel: 85 psi/8.5 bar

Tyre pressure, guide wheels: 71 psi/7.1 bar

Retighten the wheels once a week.

Torque: 100 Nm.

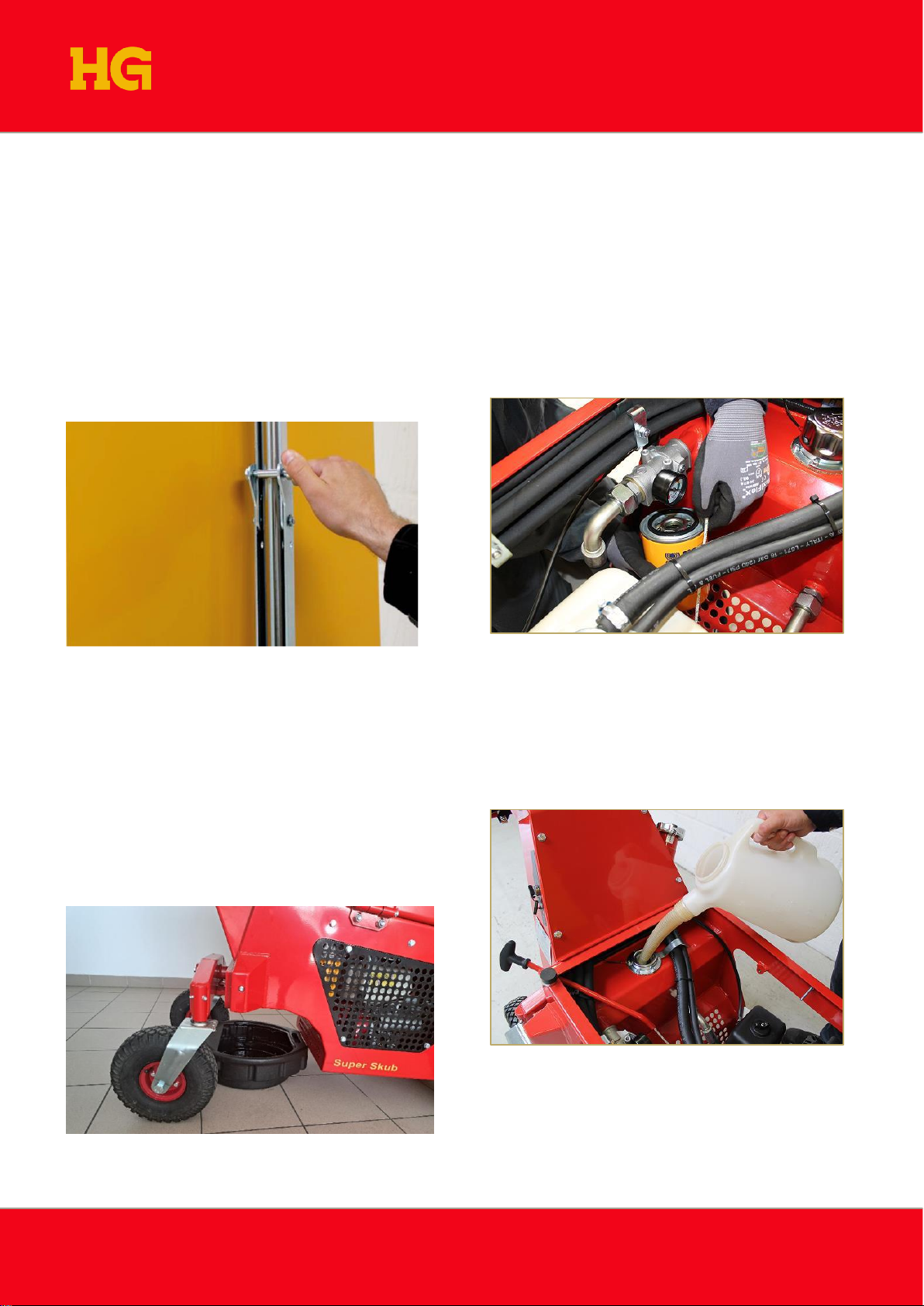

Service indicator on hydraulic filter

The indicator gauge on the hydraulic filter

indicates whether the filter needs servicing or

replacing.

Apply full throttle, and check the indicator. If the

indicator is in the red area, the machine needs

servicing.

Safety plate test

Pressing the safety plate should move the

machine forward, preventing the operator from

being trapped during reverse.

Check the plate when the machine is switched

on.

Press the plate, and check that the machine is

moving forward.

The system must be undamaged and be able to

move effortlessly.

The system must be undamaged and able to be

moved without difficulty.

User Manual HG H1000 HIGH TIP

Side 15

4. Driving

Start the machine by activating the choke when

the engine is cold and then turning the ignition

key clockwise. When the engine is running,

release the key and adjust the choke until the

engine is running smoothly. Adjust the throttle to

the desired engine revolutions.

The choke is deactivated after a while.

If the engine is warm, it is not necessary to use

the choke.

Place both hands on the handle bar so that your

fingers can reach the forward handle. Pull up the

hand lever on the right to move the machine

forward and release to stop. Pull up the hand

lever on the left to reverse.

Before reversing, check for people and

obstacles behind you.

The direction of the machine is controlled by

pulling the handle bar to the right or left while the

machine is moving forward. Do not attempt to

control the direction, while the machine is

standing still as this will put considerable strain

on the body.

WARNING!

The machine should stop immediately and come

to a complete standstill when releasing the

forward and reverse handles. If the machine

'crawls' slightly, it must be taken out of service

immediately, and the fault repaired.

To tip the tray, push the tipping lever up with

your left hand, while keeping your right hand on

the handle bar. Use the lever to adjust the

speed: the more you push it, the greater the

speed.

Before lowering the tray, the operator must

check that no people are within the machine's

range. Lower the tray by pushing down the

User Manual HG H1000 HIGH TIP

Side 16

tipping lever with your left hand, while keeping

your right hand on the handle bar. Wait until the

tray is lowered completely, and place both

hands on the handle bar before pulling

the forward handle.

WARNING!

If the machine tips over, let go of the machine

and step away from it. Never attempt to keep the

machine steady.

Before leaving the machine, make sure the tray

is lowered completely, the throttle hand lever is

in the uppermost position and the engine is

switched off with the key. Remove the key from

the machine before leaving the machine for an

extended period of time.

Operation of the High Tip function

The container is operated by pressing the

handle up or down, while the right hand is still

kept on the control handle. Before activating the

functions, the operator must inform and ensure

that no one is within the machine's range of

motion.

When activating the handle, the right hand must

remain on the control handle. Wait until the

container is completely down and place both

hands on the control handle before activating

propulsion.

•High Tip lift: Press handle up, the entire

container will now rise up, when the

container cannot rise right, release the

switch again.

•High Tip lower: Press handle down, the

entire container will now lower to normal

position, when the container cannot be

lowered any further, release the contact

again.

•Tip container up: Press handle up, the

entire container will now tip, when the

container cannot be tipped right up,

release the switch again.

•Tip container down: Press handle down,

the entire container will now tip down,

when the container cannot be tipped

down any further, release the switch

again.

WARNING!

In case of overturning, release the machine and

take a distance. Never try to hold the machine.

Before the operator leaves the machine, the

container must be down and the machine

switched off at the key switch. If the machine is

left completely, the key must be removed from

the machine and the main switch placed in the

broken state.

User Manual HG H1000 HIGH TIP

Side 17

5. Maintenance

5.1 Overview of maintenance

Activity

For each xx operating hours

Daily

3 m.

20

hours

50

hours

100

hours

300

hours

Check

Hydraulic oil level

x

Engine oil level

x

Air filter (in a very dusty

environment)

x

Wheel air pressure

x

Function of the safety plate

x

Leaks

x

Coasting valve

x

Bolts and nuts are tightened

x

Adjustment

Spark plug

x

Release button

x

Safety plate

x

Lubrication

Pendular suspension

x

Wheel

x

Re-tightening

Wheel

x

Cleaning

Spark plug

x

Sediment in carburettor

x

Air filter

x

x

Replacement

Air filter

x

Engine oil

First

x

Engine oil filter

First

x

Hydraulic filter

First

x

Hydraulic oil

First

x

Warning signs as needed

x

Spark plug

First = replaced when the machine has run 20 hours.

Components must be checked as recommended by the

supplier. Hedensted Gruppen requires that a

comprehensive service inspection of the machine be

carried out by an authorized service technician at least

once a year. Safety features such as the release button

and safety plate must be inspected every three months. All

maintenance must be carried out by a trained mechanic,

service technician or similar professional.

User Manual HG H1000 HIGH TIP

Side 18

5.2 Towing and tipping in

case of engine failure

The coasting button is used to disengage the

drive wheels, allowing the motorized

wheelbarrow to be moved when the engine is

off. Turn the button counter-clockwise to

disengage. Push the button and turn clockwise

to re-engage the engine.

WARNING!

The machine's parking brake cannot be

operated when disengaged. Place a suitable

object on both sides of the wheels when leaving

the machine.

HG does not recommend

leaving the machine in

disconnected mode.

With the help of two people,

the container can be tipped

to the side. High Tip does

not need to be raised as

shown in figure pos. 24.

Alternatively, the machine's

container can also be tipped

without High Tip being

activated figure pos. 27 and

28.

The advantage of an

activated high tip or only

tipped container is that the

container can thereby be

placed directly on the

surface on which the

machine stands. See figure

pos. 23

If the high tip is not

activated, the container,

when it is tipped to the side,

must be supported by a

suitable stable object, which

may be support trestle with

an approved carrying

capacity of at least 200kg. See figure pos. 25

User Manual HG H1000 HIGH TIP

Side 19

WARNING!

In this case, it must always be ensured that the

container is tipped at least 125* degrees above

the horizontal surface where the container has

its normal position, precisely to avoid the

container falling back.

5.3 Maintenance Points

Safety fittings

Mount the safety fitting on the tipping cylinder

before carrying out maintenance. Loosen the

two finger screws, and remove the fitting from

the inside of the machine. Remove the large

finger screw, and fold out the fitting. Place it over

the cylinder rod, and screw on the finger screw

to lock.

Draining hydraulic oil

Place a suitable container under the hydraulic oil

tank and remove the plug. The tank must be

able to hold 17 liters. Clean and refit the plug

when the oil has been drained from the tank.

WARNING!

Be careful as the oil may be very hot!

Replacing the hydraulic filter

Place a suitable container under the machine

near the filter. Loosen the filter, and unscrew it.

Lubricate the gasket on the new filter with oil,

and screw it on. Tighten the filter firmly by hand.

Hydraulic oil fill

Using a clean oil can, add approximately 17

liters of type Q8 Handel 46 hydraulic oil or

similar. Check the oil level in the sight glass on

the left-hand side of the machine.

User Manual HG H1000 HIGH TIP

Side 20

Changing the engine oil

Place a suitable container under the hydraulic oil

tank and remove the plug. Clean the plug,

replace the gasket and refit the plug when the oil

has been drained from the tank.

Using a clean oil can, add approximately 0.6

liters of type SAE 15W-40 engine oil. The oil

level must reach the top of the thread. Check the

oil level with the dipstick.

WARNING!

Be careful as the oil may be very hot!

Sediment in the carburetor

Place a suitable container under the machine

near the carburetor. Close the fuel tap, and

remove the drain plug on the side of the float

bowl. Replace the gasket and refit the plug.

Open the fuel tap again.

Air filter

Remove the cover and filter by loosening the

two finger nuts.

Clean the foam filter and paper filter with

compressed air or replace them. Refit the foam

filter around the paper filter and then mount it on

the engine with the metal nut. Mount the cover

with the plastic nut.

Replacement of spark plugs

Remove the spark plug with a 21 mm spanner

by turning counter-clockwise. Clean the spark

plug and adjust the electrode distance to 0.70-

0.80 mm. Replace the spark plug if necessary.

Always screw on the spark plug by hand. If a

new spark plug is fitted, tighten it another half

turn to seal the gasket. If a used spark plug is

fitted, only tighten it another one-eighth to one-

quarter turn.

Table of contents

Other HG Farm Equipment manuals

Popular Farm Equipment manuals by other brands

LELY

LELY HIBISCUS 1525 Master Operator's manual

Horizont Agrar

Horizont Agrar EQUISTOP M3 Operating instruction

Prointegra

Prointegra Meteobot user manual

Gaspardo

Gaspardo HCS USE AND ASSEMBLY INSTRUCTIONS / SPARE PARTS

Poettinger

Poettinger ALPINTOP 300 U Operator's manual

SaMASZ

SaMASZ KDT 220 Operator's manual