Acorn Computers Limited BBC A Installation instructions

1

A Hardware Guide

For The BBC

Microcomputer.

Written By:

A. D. Derrick. B.Sc.

D. S. Harding. B.Sc.

S.D. Middleton.

M. P. Smith.

Edited and Published by:

Wise Owl Publications

Printed by Queenprint Ltd.; 64/74 Holderness Road, Hull HU9 lEQ. Telephone (0482) 224935.

2

Published in the United Kingdom by:

Wise-Owl Publications,

Hull Innovation Centre.

Guildhall Road,

Queens Gardens

Kingston-upon-Hull, England.

Copyright © 1983 Wise-Owl Publications.

All rights reserved.

No part of this publication may be produced or transmitted, in any form or by any means, without the prior

written permission of the publishers.

First Published 1983.

The Authors would like to thank Dr. W. K. Donaldson, Ian Halstead, Instruments and Controls (Hull),

Bernadette, Catherine and Julie for their assistance in the production of this book.

The information contained within this book is given in good faith and is believed to be correct at the time

of writing. However, neither the Authors or the Publishers take any responsibility for omissions or errors.

No liability is assumed for any damages or injury whatsoever resulting from the use of information

contained within this publication.

All references to the BBC Microcomputer in this publication refer to the microcomputer produced for the

British Broadcasting Corporation by Acorn Computers Ltd.

CP/M is a registered trademark of Digital Research Corporation.

It should be noted that the terms "Econet" and "Tube" are registered trademarks of Acorn Computers Ltd.

The Authors thank the following manufacturers for granting permission to publish the data sheets given in

Appendix 1 of this book:

Hitachi

Intel Corporation

Motorola Ltd.

Mullard Ltd.

NEC Microcomputers Inc.

Rockwell International.

Texas Instruments Ltd.

RS Components Ltd.

The data sheets printed in Appendix 1 remain the copyright of the respective manufacturers.

Manufacturer’s disclaimers given within these data sheets should be strictly observed.

ISBN 0 946949 00 X

3

Preface

The BBC Microcomputer, manufactured by Acorn Computers Limited, was commissioned by the BBC as

part of its Computer Literacy Project. As such the machine is an educational tool, which is capable of

being expanded into a very sophisticated computer with computational powers to rival those of present

day mini-computers.

As with any complex machine it makes sense to understand something of how it works, what goes where

and how to obtain the best from it. A computer is no different and a working knowledge of the internal

functions and layout will boost your confidence in computing.

This Hardware Guide delves inside the computer to reveal some of the many modifications, upgrades

and circuit changes that can be performed. Some modifications only require extra components to be

inserted whilst others require careful work with a soldering iron on the main printed circuit board. For

those who prefer only to peek inside the lid, photographs and circuit layouts have been provided to

identify the various integrated circuits and work areas on the main board. Some handy tips, such as

getting rid of that annoying buzz found on many computers, introduce the beginner to electronics

stimulating his or her interest in both spheres of activity.

For the more advanced reader, system fault finding, further expansion and the inclusion of manufacturers

data sheets and detailed descriptions of complex circuitry make this manual a necessary adjunct to the

existing publications available.

4

SUPPLIERS ADDRESSES AND CODES.

Below are the names and addresses of suppliers, which are identified within the book by the following

codes. These are given as examples to assist the reader, not as recommendations.

Code A:

Acorn Computers Ltd.

Fulbourn Road, Cherry Hinton, Cambridge. CB1 4JN.

Tel: 0223 245200

Code B:

W. Broady & Son Ltd.

English Street, Kingston-Upon-Hull. HU3 2DU.

Tel: 0482 29894

Code F: Farnell Electronic Components Ltd.

Canal Road, Leeds L512 2TU.

Tel: 0532 636311

Code RR:

The Radio Resistor Co. Ltd.

St. Martins Way Industrial. Estate, Cambridge Road, Bedford. MK42 0LF.

Te1: 0234 47188

Code RS:

RS Components Ltd. (TRADE ONLY)

P. O. Box 427,

13/17 Epworth Street, London.

EC2P 2HA.

Tel: 0l 253 3040

0l 250 3131

Code T:

Technomatic Ltd.

17 Burnley Road, London.

NW10 1ED.

Tel: 0l 452 l500

01 450 6597

Code W:

Watford Electronics.

34/35 Cardiff Road,

Watford. Herts.

Tel: 0923 40588

5

Contents

CHAPTER 1 : INTRODUCTION.

CHAPTER 2 : ATTITUDES TO WORK AND DISCIPLINES REQUIRED.

2.1 Attitudes to Work and Working Environment.

2.2 Anti-Static Precautions.

2.3 Tools and equipment Required.

2.4 Soldering.

2.5 Desoldering.

2.6 Defluxing.

CHAPTER 3 : COMPLETE CIRCUIT DESCRIPTION

3.1 The Power Supply Unit.

3.2 The Microprocessor (MPU)

3.3 The Clock Circuitry.

3.4 Memory Devices.

3.5 Random Access Memory.

3.6 The Video Generating Circuitry.

3.7 The Video Driving Circuitry.

3.8 Cycle Stretching.

3.9 The "Econet" Circuitry.

3.l0 The Keyboard Circuitry.

3.11 The Cassette and R5423 Serial Interfaces.

3.12 The Floppy Disc Interface.

3.13 The User and Printer Ports.

3.14 The Reset Circuitry.

3.15 The Analogue Port.

3.16 The Voice Synthesiser.

3.17 The Sound Generator and Audio Amplifier.

3.18 The 1MHz Bus Interface.

3.19 FRED.

3.20 Glitches.

3.21 Double Accessing.

3.22 NPGFD (JIM)

3.23 General Guidelines For Use of the 1MHz Bus.

CHAPTER 4 : LINK SETTINGS AND FUNCTIONS.

4.1 Keyboard PCB Removal.

4.2 Removing the Main PCB.

4.3 Re-Assembling the Machine.

4.4 Link Functions.

6

CHAPTER 5 : MACHINE UPGRADING.

5.10 Upgrading a Model "A" Machine to a Model "B" Machine.

5.11 Insertion of IC's Into Sockets.

5.12 Connectors.

5.13 Adding the User/Printer Port.

5.14 The RS423 Interface.

5.15 The Analogue to Digital Converter (ADC) Upgrade.

5.16 Testing the Analogue Input Port.

5.17 The RGB (Red, Green, Blue) Primary Colour Output.

5.18 The "Tube" Interface.

5.19 Memory Upgrade.

5.20 Sideways ROM Selection Upgrade.

5.21 The 1MHz Bus.

5.22 Further Expansions.

5.23 The Floppy Disc Expansion.

5.24 The Speech Expansion.

5.25 The "Econet" Expansion.

5.26 The Second Processor Add-Ons.

I

CHAPTER 6 : HINTS, TIPS AND MODIFICATIONS.

6.1 The Cassette Interface.

6.2 Sound Output From the BBC Microcomputer.

6.3 Video Modifications and Hints.

6.4 Speech Synthesiser Tips and Modifications.

6.5 Analogue Port Modifications.

6.6 Printer Modifications and Tips.

6.7 Keyboard Hints.

6.8 Sideways ROM Socket.

6.9 Disc Interface Modifications.

6.10 R5423 Hint.

INDEX.

APPENDIX 1: MANUFACTURERS DATA SHEETS FOR MAIN INTEGRATED

CIRCUIT DEVICES USED IN THE BBC MICROCOMPUTER.

7

CHAPTER 1 :- INTRODUCTION.

It is the intention of the authors to provide the reader with detailed information on the hardware aspects of

the BBC Microcomputer. Some of this information has appeared in magazines but these articles usually

just give sufficient information to explain a particular project. This book goes further, giving both the

enthusiast and advanced user a detailed understanding of the internal workings of the BBC

Microcomputer, thus making it a very useful reference manual, whether undertaking projects of your own

or elaborating on projects found in magazines. There is a comprehensive link survey and a large number

of hints, tips and modifications which can be undertaken.

Servicing is a task that is best entrusted to an approved Acorn service centre. It should be pointed out

that modifying the machine yourself could invalidate the manufacturers guarantee. Further, it is possible

that you may discover a fault outside the scope of this book, or one you prefer not to tackle yourself. In

either case it would be worth consulting your local Acorn dealer first who will probably have access to

diagnostic test equipment. This should be either a Progressive Establishment Tester (PET), or Final

Inspection Tester (FIT). Both of these diagnostic and test devices are produced by Acorn Computers Ltd.

and are presently only available to official Acorn dealers.

Until late 1983 the machine was available in two options, model A and model B, both having the same

main printed circuit board, case, and keyboard. The main differences being that the model A version had

fewer IC's and connectors fitted. The BBC Microcomputer has a maximum available on-board Random

Access Memory (RAM) of 32 Kilobytes, (one kilobyte = 1024 bytes). However only half of this RAM (16K)

is fitted to the model A machine. The model B machine has the full 32K.

There is a requirement for a minimum of two Read Only Memories (ROMs) in the Machine (both A and

B), one houses the Machine operating System, (MOS) the other houses the Basic Interpreter and 6502

Assembler. There are three additional internal sockets for other ROMs (e.g. Word Processors, Filing

systems and other languages etc.). A number of hardware add-ons are available to allow a further 13

ROMs to be installed in the machine.

The Computer has a UHF output, to connect to the aerial socket of a standard television set tuned into

channel 36. In addition to this there is a composite video output and a Red, Green and Blue, (RGB)

output (model B only), to drive a black and white, or colour monitor respectively. These outputs give a

much clearer and sharper display, since they eliminate the need to modulate and demodulate the signal

on to a UHF carrier.

8

The Computer has eight different formats for the screen layout these are called screen modes and are

numbered 0 to 7, each giving different resolutions and colour availability. The screen display is stored

within the machines RAM, the amount required being dependant upon which particular screen mode is

selected. The highest resolution modes require 20K of RAM. Mode 7 is unique, in that it uses a special

teletext character generator IC. The advantages of using this method of character generation are that

high quality text and easy to use graphics are available using only 1K of memory.

The two most common mass storage mediums used with the microcomputer are an audiocassette

system, (models A and B), or a floppy disc system (with the relevant upgrade). The cassette interface is

very tolerant with regard to the quality of the signal and the cassette storage system. Although the

cassette interface used within the BBC Microcomputer is very reliable it still only represents a good

compromise for a data storage and retrieval system. If you intend to use the machine for any serious

work then you will probably find the cassette system rather inadequate. A floppy disc or "Econet" system

will provide a much more suitable solution.

A single floppy disc can store between 100 and 300 Kilobytes of information with a 100-fold decrease in

access time over a cassette based system.

The BBC Microcomputer has an on-board sound generator which provides four independent sound

channels. Three of these channels can be used for music synthesis each one having full envelope

control, attack, sustain, decay and release. The fourth channel is a white noise generator and uses the

same envelope control features as the other three channels.

The machine also has the capability to interface to a great variety of other equipment, through its

numerous Ports, the connectors for which are mainly situated on the underside of the case. These are as

follows: -

Floppy Disc Interface (5 ¼ and 8 inch).

A Centronics type parallel printer interface.

1 MHz Bus Extension I/O.

The Acorn "Tube" second processor port.

An 8-bit parallel "User Port".

The Cartridge ROM system.

The Acorn "Econet" local area network system.

The analogue-to-digital converter.

RS423 (RS232C compatible) serial interface.

9

The parallel printer port can interface with a large number of different printers, including Epson, NEC, and

Seikosha.

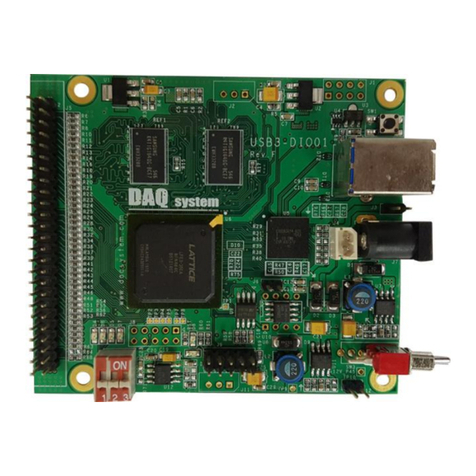

The 1MHz bus is used to interface the microcomputer to a whole range of slower peripheral devices such

as EPROM programmers, input output rack systems, data acquisition systems etc.

The "User Port" provides the machine with an eight bit wide input/output connection which can be used to

control external equipment such as robots and relays etc.

The Acorn "Tube" interface is used to allow the BBC Microcomputer to access a second high-speed

microcomputer called a second processor. By adding a second processor to the standard machine the

overall computing power can be greatly enhanced. The resulting improvement will depend upon the

particular second processor. At the present time there are only two second-processor boards available

these are the Z80 and a 3MHz version of the 6502. The Z80 processor will enable the BBC

Microcomputer to use the C/PM operating system and thus enable the machine to run an extremely wide

range of currently available software.

The Acorn "Econet" network feature enables up to 255 BBC Microcomputers to be connected together

and each microcomputer can have access to a central information storage and retrieval device. This

system enables a large number of users to share expensive peripheral devices and also provides each

one with the facility to communicate with any other user in the network. The "Econet" system finds most

use in schools and colleges.

The analogue port, which is located at the rear of the machine, (model B only) allows the user to connect

up to four analogue signals into the computer. These signals could be derived from all manner of

transducers thus enabling the machine to measure and record real physical quantities. This feature will

enable the machine to be used for monitoring signals in experimental or perhaps industrial applications.

The RS423 port situated at the rear of the machine (model B only) enables the microcomputer to

communicate with other pieces of equipment. This equipment could be peripheral devices such as serial

printers or perhaps other computers. In most cases the RS423 port can interface with other equipment

which uses the more common RS232C (V24) serial interface standard, although this is not always the

case. The BBC Microcomputer does not provide all of the signals necessary for a full implementation of

the RS423 standard but the main signal lines are provided. The machine’s operating system enables the

port to be configured for a whole range of baud rates ranging from 75 to 19200 although the integrity of

the data is not guaranteed at 19200 baud.

10

To complement the impressive graphics features of the BBC Microcomputer the model B machine is fitted

with a primary colour drive RGB output. This can be used to connect the machine directly to primary

colour drive monitors. The display produced on good quality RGB monitors is far superior to that

produced by connecting the machine to a domestic television receiver.

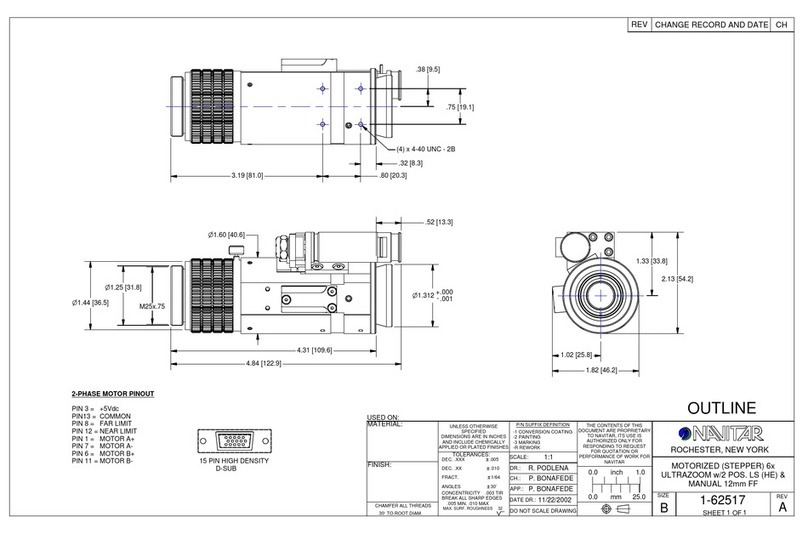

Figure 1.1 is an overview of the BBC Microcomputer system showing the numerous expansions that can

be added to the machine. It can clearly be seen from this diagram that the machine is capable of being

considerably expanded.

The authors of this book have endeavoured to cover all of the hardware aspects of the machine in the

hope of assisting people to understand the inner workings of what otherwise might be considered as a

“magic black box" (cream box ?). It has been our aim throughout the book to simplify, wherever possible,

the descriptions and explanations of the internal circuitry of the machine. In some instances it has been

extremely difficult to describe in simple terms what is in fact a very complex process and the casual

reader may, therefore, find certain sections difficult to understand. The manufacturers data sheets

included in appendix 1 may be of help in such instances.

Wise Owl Publications have produced a further book on the hardware aspects of the BBC

Microcomputer. This book contains a full set of manufacturers data sheets on all of the TTL 7400 and

CMOS 4000 series devices used in the machine together with data sheets on all of the devices that are

not given in appendix 1. In addition to this book Wise Owl also produce a range of hardware "add-ons" for

the BBC Microcomputer including digital-to-analogue converters and an automatic stop/start scroller

called the "Owl-Scroll". For details on any of the above items send an S.A.E. to:

Wise-Owl

Hull Innovation Centre,

Guildhall Road,

Queens Gardens,

Hull.

HUl 1HJ.

11

<p11 intentionally left blank for diagram>

12

<p12 intentionally left blank for diagram>

13

CHAPTER 2 :- ATTITUDES TO WORK AND DISCIPLINES REQUIRED.

This chapter is intended to provide the less experienced reader with some of the information which he or

she may require in order to carry out some of the more advanced upgrades and modifications described

within this book. Those readers who already have some practical experience with a soldering iron may

find some of what follows a little tedious, although they should still read the sections on anti-static

precautions and perhaps de-fluxing.

2.1 Attitudes To Work And Working Environment.

Before going on to describe the precautions that should be taken when handling certain integrated

circuits it is prudent to spend a little time considering the environment in which any work on the BBC

Microcomputer should be carried out.

If you do intend to carry out any work on the circuitry within the microcomputer, whether to simply plug in

additional chips or to perform soldering operations, you must first of all give some thought to the manner

and place in which the work should be carried out.

You must have a solid work surface, which should ideally have a free area of no less than one metre

square. It should be set at a comfortable height such that you can sit down whilst working. It is advisable

to use a conductive cover placed over the surface of the workbench, the reasons for this are detailed in

the section below on anti-static precautions.

There should be plenty of light, a desk top lamp fitted with the highest wattage bulb that it can safely hold

is an ideal light source since it can be adjusted into position above the work. For some of the more

delicate work a magnifying glass or eye glass may be required, these can be of great help when working

on small or delicate parts. The best place to obtain a suitable magnifying glass would probably be your

local philatelists or hobby shop.

Before commencing work on the machine, be sure that you fully understand exactly what it is you are

doing. This is especially true if you have not tackled this type of work before. You should be totally familiar

with the particular section in the book that deals with the work you are doing, if you are less experienced

this will involve reading the section a number of times. All of the tools, integrated circuits, sockets and

connectors etc, which you require for the work should be on hand ready. It is advisable to check that you

do in fact have the correct devices before fitting them, this is especially true if the parts were purchased

by mail order since more mistakes seem to occur when parts are bought in this way.

14

It is important to allow yourself plenty of time in which to carry out the work. Do not be tempted to rush

because this usually results in poor quality workmanship. Also if you rush work of this type it is very likely

that mistakes will be made and these could turn out to be costly.

A systematic and orderly approach should be adopted since this will minimise the likelihood of doing

something incorrectly or omitting something. In practise this will mean planning ahead by mentally going

through the procedure before you commence work. Try to keep the workbench tidy and do not clutter the

space up with unnecessary objects, leave yourself plenty of room in which to work.

It is also important to seat yourself in a comfortable position at the workbench. If you are not comfortable

whilst you are carrying out the work you will be tempted to rush the job and hence run a higher risk of

making mistakes. If you do rush the work the end result will probably not be of a good standard.

Make sure that you have plenty of light on the work area, a strong light will make most of the work that

you will be carrying out on the machine far easier.

Once you have completed the work on the printed circuit boards it is essential that you conduct a detailed

visual inspection of both the work which you have carried out and the remaining areas of the PCB. It is

quite likely that small pieces of wire etc., will have fallen onto the PCB whilst you were working on it.

Under no circumstances should you reassemble and switch on the machine without having carried out

this inspection, in fact it is advisable to inspect the board at least twice using a strong light and an

eyeglass. As mentioned in chapter 5, be sure to check that the heat sink on IC6 (Video Uncommitted

Logic Array) is firmly seated and that non of the resistors and capacitors have become bent over and

shorted. The importance of this inspection cannot be over emphasised.

2.2 Anti-Static Precautions.

Many of the integrated circuits used within the BBC Microcomputer are either Negative Metal Oxide

Semiconductor (NMOS) or Complementary Metal Oxide Semiconductor (CMOS) types. These types of

IC's are susceptible to damage by static discharge and special precautions are, therefore, necessary

when handling these devices.

Opinions on exactly what precautions should be observed when handling the devices seem to differ but

the procedures outlined below, if observed, will ensure that the risk of damage to the IC's is very minimal.

Although many people believe that with present day MOS devices the possibly of damage due to static

15

discharge is hardly worth considering recent research has proved otherwise. Recent investigations have

revealed that damage caused to MOS and CMOS integrated circuits may not be immediately apparent,

that is to say that the device may function perfectly satisfactorily but will fail after only a relatively short

time in service.

The number of MOS devices which you will be handling whilst upgrading or modifying your machine does

not warrant the expense involved in purchasing any sophisticated anti-static handling equipment but a

few simple precautions should be observed;

i) Avoid wearing any static generating materials such as Nylon.

ii) Do not have monitors or televisions switched on in close proximity to where you are working. There is

a very high electrostatic field produced in the vicinity of the screen.

iii) Before commencing work touch some metal object that is known to be at Earth potential. The chrome

portion of a central heating radiator valve or water tap are ideal.

iv) If possible, you should carry out the work on a conductive surface. This work surface should be

connected to the mains EARTH via a 1 Megohm resistor. Do not on any account connect the work

surface anything other than EARTH. Whilst handling the PCB's or integrated circuits keep them

positioned on the conductive surface and try to keep part of your body in contact with the surface. The

forearms are generally most easily kept in contact with the working surface.

v) Make sure that you use a low leakage soldering iron with an earthed bit. The ideal type is one which

operates via a low voltage transformer (usually 24 volts) although these tend to be rather expensive. A

mains operated iron with an earthed bit is generally suitable. The section below on soldering gives more

details on soldering irons.

vi) If at all possible you should avoid carrying out the work in warm dry atmospheres since these usually

produce high static charge levels.

16

2.3 Tools and Equipment Required.

In order to carry out many of the modifications described in subsequent chapters, certain basic tools are

required. If possible, obtain good quality tools, as these should last a lifetime if treated with care.

The following list of tools will allow the reader to carry out all of the hardware upgrades and modifications

that are described in this book:

No.2 cross-point screwdriver.

No.3 cross-point screwdriver.

Flat bladed terminal screwdriver.

Pair of thin nosed pliers.

Pair of oblique cutters.

Soldering iron, preferably temperature controlled (see section 2.4).

Desolder pump (see section 2.5).

Solder-22 S.W.G. rosin cored, 60/40 tin/lead alloy.

Bench lamp (e.g. "Anglepoise" lamp).

2.4 Soldering.

Many newcomers to electronics and computing are under the misconception that the soldering of

components to delicate printed circuit boards is a very difficult technique to master. Although good quality

soldering does require practice and patience, it is a task that should be mastered fairly easily by the

majority of readers. This is especially the case if the

general guidelines that follow are carefully observed.

A good quality soldering iron is, of course, a necessary requirement. Poor quality soldering irons can

easily cause damage to the main PCB of the BBC Microcomputer, since the board has fine copper tracks

on both sides as well as through-hole plating. Ideally, a temperature controlled iron which is fitted with a

fine pencil" tip, should be chosen. This type of iron may have a heating element power of up to 50 watts,

the higher wattage types having a much faster temperature recovery than the lower wattage types.

Temperature controlled soldering irons are, however, relatively expensive and if the price is considered to

be excessive, then a good quality "thermally balanced" type is an inexpensive be alternative. This type of

iron is designed such that the heating element and tip assembly combination is only capable of attaining

a certain maximum tip temperature, in the steady be state condition. For work on the BBC

Microcomputer, a thermally balanced soldering iron of power between 15 and 25 watts should be chosen.

17

Before the soldering iron is used to make a joint, the heated tip should be thoroughly cleaned on a damp

sponge and then "tinned" using rosin cored solder. For soldering delicate PCB assemblies, such as the

main PCB of the BBC Microcomputer, a good quality, rosin flux cored, 60% tin, 40% lead solder of 22

SWG should be used for both tinning the bit and soldering the components. To solder a joint, place the

fully heated tip of the soldering iron into position and allow the area to heat up for approximately two

seconds, before "feeding" in the cored solder. When the solder has flowed uniformly around the joint,

stop feeding in the solder and then remove the soldering iron. After the soldered joint has cooled, inspect

it to see that the solder has formed a good quality joint, which has a bright, shiny appearance. Dry-joints,

which are usually caused by insufficient heating of the joint or contaminants on the component leads, can

quite often be identified by their dull, matt appearance.

When soldering multi-leaded components such as integrated circuit sockets and some types of

connector, it is recommended that soldering is alternated between diagonally opposite pins, so that

localised overheating of the component and PCB is avoided.

2.5 Desoldering.

Occasionally, it will be necessary to desolder components or clear PCB holes which are blocked with

solder. This task can be successfully performed using a desolder pump, which should be available from

most electronic component stockists. Most desolder pumps consist of a spring loaded plunger inside a

cylindrical barrel. The spring is held compressed by a catch, which when released causes the plunger to

travel rapidly along the barrel, thus sucking the molten solder through the fine, heat resistant plastic

nozzle.

To remove excess solder using a desolder pump, firstly "arm" the pump by depressing and locking the

spring loaded plunger. Position the nozzle of the pump close to the solder to be removed and whilst

keeping your thumb positioned over the trigger button, melt the solder using a soldering iron. When the

solder is fully molten, depress the trigger button such that solder is sucked up into the barrel of the

desolder pump. The molten solder forms a pellet inside the barrel, which should be discarded by re-

arming the pump. This operation should not be carried out whilst the desolder pump is positioned over

the PCB, since the solder pellet or any solder flakes which have been formed can easily fall onto the

board, thus bridging tracks.

18

2.6 Defluxing.

After soldering, flux deposits will be left on the printed circuit board, which look unsightly as well as

possibly causing high impedance tracks between soldered joints. These deposits can be easily removed,

using a proprietary defluxing solvent (e.g. RS stock number 555-134), which should be applied using a

stiff brush. It is recommended that the manufacturers instructions supplied with the defluxing fluid are

carefully read and understood, since the solvents used can be harmful, are particularly if defluxing is not

carried out in a well ventilated area. It is also important to ensure that the point solvent does not come

into contact with the bodies of the components on the PCB, since the solvent may dissolve certain types

of component marking and some thermoplastic.

19

CHAPTER 3 :- COMPLETE CIRCUIT DESCRIPTION.

3.1 The Power Supply Unit.

The power supply unit fitted to the BBC Microcomputer is a switch mode type. This unit produces +5 volts

at 3.75 amps and -5 volts at 0.l amps, which are supplied to the main printed circuit board (main PCB) via

seven flying leads. These leads are connected to the main PCB using 0.ll" blade type push-on

receptacles. The three red leads carry +5 volts to various points on the board, which are all connected

together electrically by copper tracks on the underside. The reason for this is to overcome the need for

large, high current carrying, copper tracks on the printed circuit board. The mauve coloured lead carries

the -5 volt supply and the three black leads connect the zero volt line to the board. Note on the early,

linear type, supply the -5V lead is coloured brown.

A six pin connector, which is mounted on the case of the power supply unit on the underside of the

microcomputer (see photograph chapter 5), provides auxiliary power for accessories such as a floppy

disc drive unit. This socket provides a +12 volt supply in addition to the supplies carried to the main PCB.

Details of the connections to this socket are given in chapter 5 (fig 5.2).

Early BBC Microcomputers, mainly issues 1 and 2, were fitted with a linear type power supply unit which

employed a conventional mains transformer and bridge rectifier, the regulation of the voltage being

performed by several 7800 series voltage regulators. These power units tend to get rather hot, even in an

unexpanded model A machine and do not provide any auxiliary power. The linear supply can be

distinguished from the later switch mode type by its black painted case and the absence of an auxiliary

power socket.

Both types of supply contain no user-serviceable components and should therefore be exchanged if they

are found to be faulty. The early linear supply should be exchanged for a switch mode type if it overheats

or is faulty.

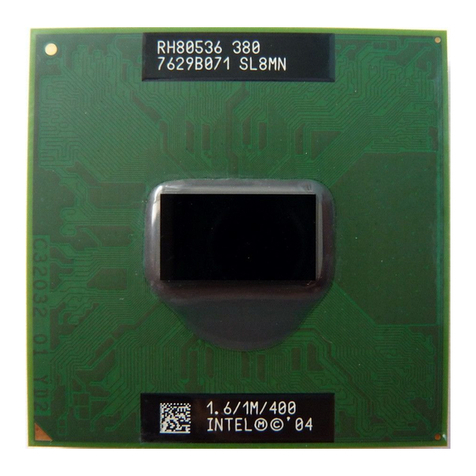

3.2 The Microprocessor (MPU)

The Microprocessor Unit (MPU) used in the BBC Microcomputer is the 6502A, which is a 2 MHz version

of the popular 8 bit 6502, introduced by MOS Technology in 1975. Although a 2 MHz device is used, and

indeed many devices such as the Random Access Memory (RAM) are accessed at this speed, the MPU

does in fact run at 1MHz when addressing slow devices within the computer. Examples of these 1MHz

devices are the Versatile Interface Adapters (VIA's) and the Analogue-to-Digital (A to D) converter.

3.3 The Clock Circuitry.

The microcomputer uses a master clock frequency of 16MHz, which is generated by a crystal controlled

oscillator. The oscillator circuitry is designed around a high speed TTL hex inverter type 74S04 (IC43).

Two of the inverters within IC43 form an RC oscillator which is forced to run at 16 MHz by a 16MHz

crystal (X1). The output of this oscillator is buffered by one of the remaining inverters within IC43 before

being conditioned by a high-speed NAND gate, part of IC40. This provides the 16 MHz clock signal for

both the video ULA, the floppy disc circuitry and the serial ULA.

One section of the video ULA is used to subdivide the 16MHz clock into four in-phase signals of 1,2,4 and

8 MHz, thus providing the required clock signals for the remaining circuitry within the microcomputer.

A 6MHz clock is required by the SAA5050 Teletext character generator (IC5) and also the "Econet"

circuitry on early versions of the machine. This is produced in a rather unique way using the 4MHz and

8MHz clock signals. A set-reset (SR) bistable is formed using two cross coupled NAND gates (part of

IC40) and two inverters (part of ICs 37 and 43) The 8MHz signal is inverted by part of IC37 (74LS04) and

20

fed to one input of the cross-coupled NAND gates. Similarly, the 4MHz signal having been inverted by

part of IC43 is coupled via a capacitor/resistor network (C41 and R94) to the other input of the cross-

coupled NAND gates. This CR network delays the reset action of the bistable thus producing a modified

4MHz waveform (see figure 3.1).

The phase-modified 4MHz waveform produced by the bistable is exclusively ORed (using part of IC38)

with the 2MHz clock to produce a 6MHz clock which is "phase-locked" to the master clock. This 6MHz

signal contains erroneous pulses which are removed by a CR network coupled to the input of an inverter

(IC37, 74LS04)

This manual suits for next models

1

Table of contents

Other Acorn Computers Limited Computer Hardware manuals