Acorn Safety S0S60 Manual

Revised: A-07/09/2021Part #: 7109-111-001

PORTABLE EYE WASH

TECHNICAL ASSISTANCE TOLL FREE TELEPHONE NUMBER

1.800.591.9360

TECHNICAL ASSISTANCE FAX: 1.626.855.4894

WWW.ACORNSAFETY.COM

INSTALLATION, OPERATION AND MAINTENANCE INSTRUCTIONS

P.O. BOX 3527

ACORN SAFETY

UNITED STATES OF AMERICA

CITY OF INDUSTRY, CA 91744-0527

LIMITED WARRANTY

2. Please read this entire booklet before beginning the installation.

NOTES TO THE INSTALLER:

1. Please leave this documentation with the owner of the fixture when finished.

Acorn warrants that all of its products are guaranteed against defective material or poor workmanship for

a period of one year from date of shipment. Acorn’s liability under this warranty shall be discharged by

replacing without charge F.O.B. City of Industry, California, any goods, or part thereof, which appear to

the company upon inspection to be of defective material or not of first class workmanship, provided that

claim is made in writing to the company within reasonable period after receipt of the product. Where

claims for defects are made, the defective part or parts shall be delivered to the company, prepaid, at City

of Industry, California for inspection. Acorn will not be liable for the cost repairs, alterations or

replacement, or for any expense connected therewith made by the owner or his agents, except upon

written authority from the Acorn City of Industry office. Acorn will not be liable for any damages caused by

defective materials or poor workmanship, except for replacements, as above provided. Buyer agrees that

Acorn has made no other warranties either expressed or implied in addition to those above stated, except

that of title with respect to any of the products or equipment sold hereunder and that Acorn shall not be

liable for general, special or consequential damages claimed to arise under the contract of sale. All

designs are subject to change without notice. Unless stated in the order, material will be furnished of the

design in effect at the time the order is filled.

UNITED STATES AND CANADA

Acorn Safety a division of Acorn Engineering Company™

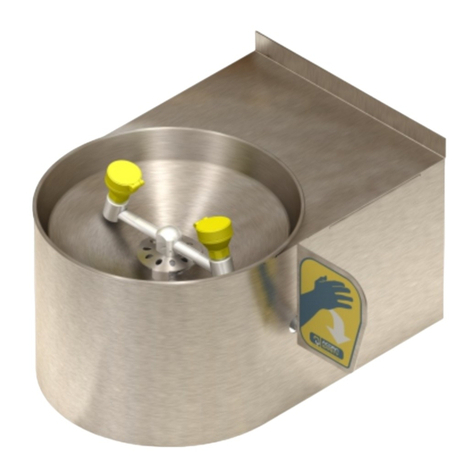

Model Shown: S0S60 Model Shown: S0S61

Revised: A-07/09/2021Part #: 7109-111-001 Page 2 of 4

Installation & Operation Manual

Acorn Safety a division of Acorn Engineering Company™

NOTES:

4. 2” HIGH POLISH QUICK CLAMP

6. (MODEL S0S61) DRENCH HOSE

ASSEMBLY

2. EYE WASH/ VALVE ASSEMBLY

3. 1/4” OD STAINLESS STEEL TUBE

1. KEG WITH LABEL ASSEMBLY

5. 2” TRI-CLAMP GASKET

TECHNICAL DETAIL AND INSTALLATION

DRENCH HOSE;

PROVIDED ON

S0S61 MODELS

C - S0S61 MODELS: ATTACH DRENCH HOSE ASSEMBLY

TO THE AIR INTAKE VALVE.

A - ASSEMBLE EYE WASH/ VALVE ASSEMBLY , AND

ATTACH 1/4” STAINLESS STEEL TUBE USING

APPROPRIATE PIPE SEALANT.

B - PLACE 2” TRI-CLAMP GASKET TO ENSURE

PROPER SEAL, AND SECURE 2” QUICK CLAMP TO

THE BASE OF EYE WASH/ VALVE ASSEMBLY AND TO

THE OPENING OF THE KEG ASSEMBLY .

ASSEMBLY INSTRUCTIONS:

1

3

2

5

4

2

6

TOP VIEW

151

2"

[394]

231

4"

[591]

41 1

4"

[1072]

FRONT VIEW

2

4

5

3

6

1

Revised: A-07/09/2021Part #: 7109-111-001 Page 3 of 4

Operation

4. When finished return the push paddle to the

vertical or fully “OFF” position. Flushing fluid

should stop. Once flushing fluid has stopped

flowing, return spray nozzle lids to the closed

position to protect from airborne contaminates.

1. To start the Eye Wash, push the paddle forward

to the horizontal or fully “ON” position. Flushing

should start, popping the spray nozzle caps

open.

2. Lower both eyes into flow. Both eyes should be

flushed to prevent contamination from one eye

from being delivered to unaffected eye.

Personnel who wear contact lenses should

remove them immediately prior to or during the

flush to prevent the contamination from

remaining against the cornea possibly causing

unnecessary damage or pain.

3. Using thumb and forefingers, fully open eyelids

and flush eyes thoroughly for approximately 15

minutes or until medical personnel arrive. Be

prepared to let the doctor know what type of

contamination has entered the eye.

1. Check for obvious signs of wear, broken or

defective equipment. Re-paint if necessary.

Replace missing or defective equipment such as

broken push paddles, missing signs and

inspection tags.

Maintain and inspect in accordance with ANSI

Z358.1-2014

2. Operate Eye Wash nozzles using the push

paddle to place ball valve in the fully “ON”

position checking for smooth operation of valve

push paddle mechanism at the same time

ensuring that the Eye Wash spray nozzle caps

pop off immediately when actuated. If the ball

valve does not operate smoothly check the

actuating assembly for binding or missing parts.

If the Eye Wash spray nozzle caps do not pop

off immediately when actuated check for correct

supply inlet pressure.

4. Return push paddle to vertical or fully “OFF”

position and swing back to stand by position. To

prevent Eye Wash spray nozzles from becoming

contaminated, always close nozzle lids after

each use.

3. While in operation, inspect spray nozzles for

clogs or debris correct or replace as required.

Installation & Operation Manual

Acorn Safety a division of Acorn Engineering Company™

4. Reassemble Eye Wash/ Valve Assembly to keg

with the necessary attachments to secure unit.

Pressurize tank to 80 PSI using a compressor or

related device.

A waterproof Test Card to record the date and

inspector's name is provided. It is recommended

that the eyewash be visually inspected weekly for

inadequate water level. Inspections which give

evidence of any “particulate matter” or

discoloration suggest the water be replaced

immediately.

Employees who work with hazardous materials

should become familiar with the location and

operation of the nearest emergency plumbing

station. Portable emergency plumbing stations are

simple to use and require hands free operation

once the station is activated. Regular instruction

regarding proper care and use will increase

confidence that the units are accessible and

function properly.

The route and area surrounding the Eye Wash

should be clear and unobstructed; the sooner eyes

are flushed, the less likelihood of damage.

Portable Eye Wash stations should be located in

close proximity to the hazard and take no more

than 10 seconds to reach. In the case of severe

eye contamination the victim may require

assistance to the Eye Wash station and help

flushing their eyes.

To operate unit, fill with 10 gallons clean potable

water and add water preservative (by others).

Preservative protects against growth of bacteria,

fungus and algae. After filling with water,

pressurize unit to 80 PSI. Unit should be visually

inspected weekly and water should be changed at

least once every six months.

Filling the Tank

1. Relieve pressurized keg by pulling the ring

attached to the pressure relieve valve until

pressure gauge reads 0 PSI.

2. Remove Eye Wash/ Valve Assembly and set

aside, then dump remaining contents of keg. If

necessary, clean the inside of the tank using

warm water and mild soap. Rinse thoroughly

with warm water.

3. Refill keg with 10 gallons of potable water and

add water preservative (recommended).

OPERATION INSTRUCTIONS:

Weekly Inspection

OPERATION AND MAINTENANCE

Revised: A-07/09/2021Part #: 7109-111-001 Page 4 of 4

ITEM PART NUMBER DESCRIPTION

1

6410-208-000

CHROME PIPE NIPPLE, 3/8” NPT X 10” LG.

2 7101-004-000 YOKE PIPE, BRASS, 1/4” NPT

3

7101-100-001

SPRAY HEAD ASSY, EYE WASH

4 7101-232-001 1/2" CHROME VALVE/ ACTIVATOR SUBASSY

5

7101-905-001

KEG WITH LABEL ASSEMBLY

6 7101-934-199 AIR INTAKE VALVE BODY

7

7101-935-199

1/2” NPT IN-LINE NEOPERL FLOW X 3/8” NPT FEMALE

8 7101-936-199 304 S/S TUBE 20.250L

9

7101-941-000

2” HIGH-POLISH QUICK CLAMP SANITARY

10 7101-942-000 2” TRI-CLAMP GASKETS

11

7101-943-000

1/8” NPT PRESSURE RELIEVE VALVE

12 7101-944-000 PRESSURE GAUGE

13

7104-122-199

1/4”x1/4”x3/8” TEE, E/F WASH, CHROME PLTD

14 7105-051-001 EYE/FACE WASH DRENCH HOSE ASSY (MODEL S0S61)

Installation & Operation Manual

Acorn Safety a division of Acorn Engineering Company™

4

3

2

5

6

1

11

10

9

12

13

7

PARTS BREAKDOWN

PROVIDED ON

S0S61 MODELS

DRENCH HOSE;

14

8

This manual suits for next models

1

Other Acorn Safety Washer manuals