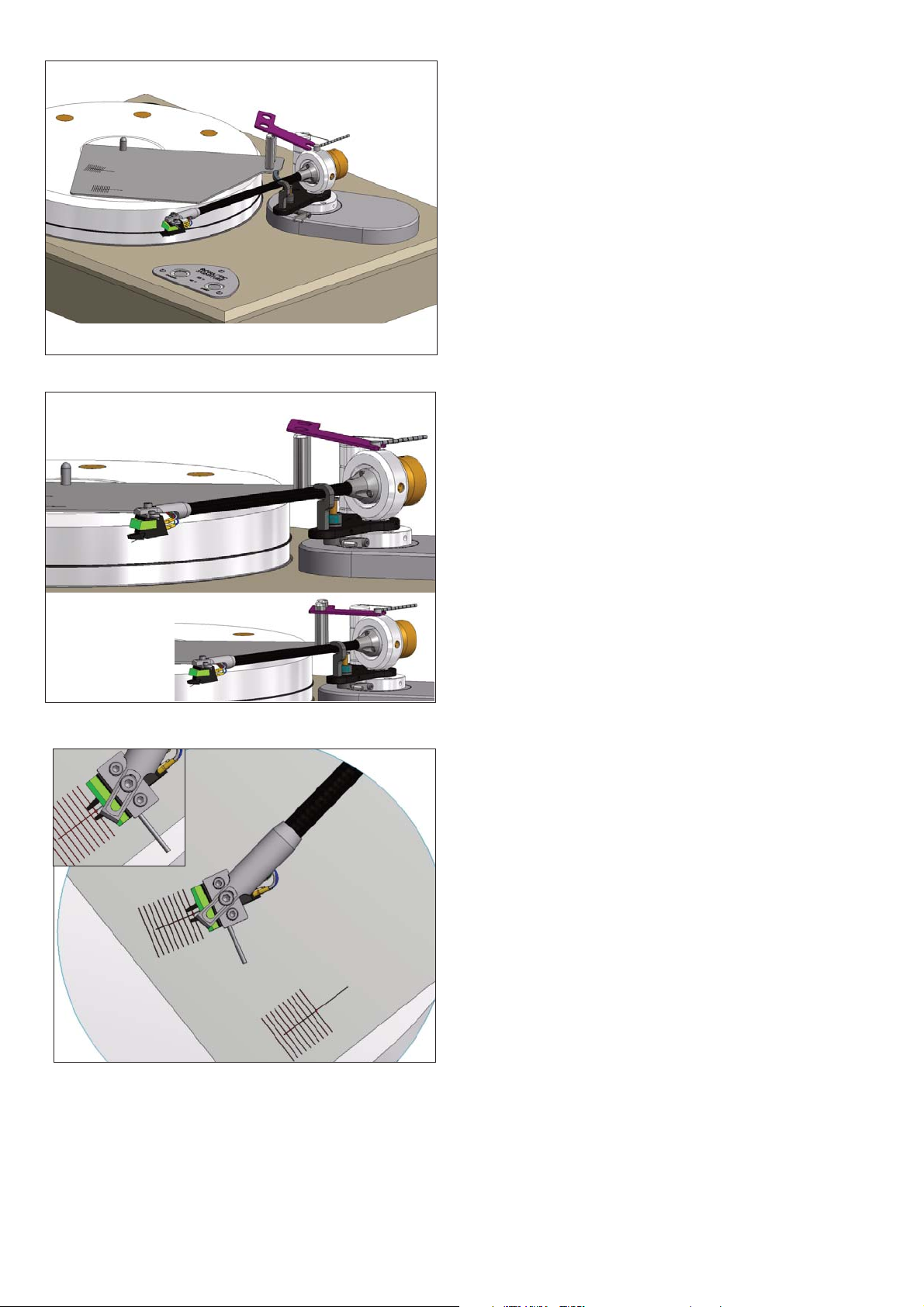

3.1 Antiskating

To ensure that depending on your needed Anti Skating force the

string is moving straight the Antiskating Tower can be moved

forward and backward. For low antiskating value up to 1gr. we

suggest to have the Tower in a more front position. Higher values

require a position in the midle or on the back end of the arm.

By opening the screw on the bottom the tower can be moved.

Please check with your cartridge manual for the right value.

.......................................................

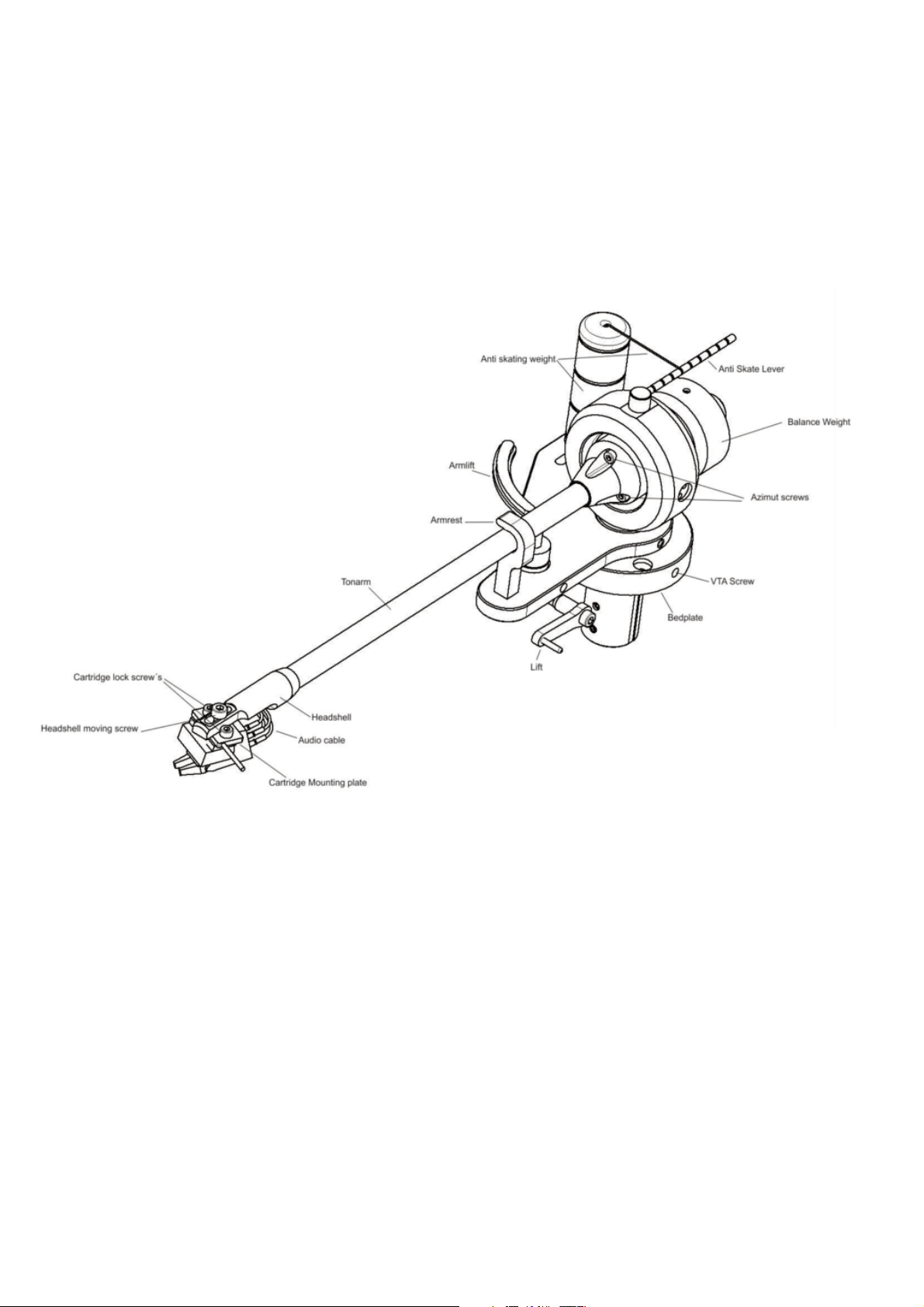

4. Mounting the cartridge

Please take a look at the assembly drawing to mount your car-

tridge to the tonearm. We use a cartridge mounting plate to

mount your cartridge on. Use the provided screw´s of the car-

tridge or the 2 M2.5 screws we supply with the tonearm. Mount

your cartridge to the plate and then connect the audio cable pin´s

to your cartridge.Take care for the correct color. Then use the

provided M3 Screw to attach the assembly to the head-shell.

5. Prepare adjusting the cartridge

Before we start aligning the cartridge we we need to pre adjust

the Tracking force and the height of the tonearm. Tracking force

will be adjusted by moving the counter weight forward (more

weight) or backward (for less weight). Search the manual of your

cartridge for the right value and adjust it by using a weight scale

(not provided).