- 1 -

1

1

1

1 Overview

Overview

Overview

Overview

The ARD3M intelligent motor protector (hereinafter referred to as the protector) is suitable for

low-voltage motor circuits with rated voltage up to 660V and integrates protection, measurement,

control, communication, operation and maintenance.Its perfect protection function ensures the

safe operation of the motor, with logic programmable function, can meet a variety of control

methods.Different communication modules can be selected to meet the needs of field

communication.

Product Implementation standards:

—— GB 14048.4-2010 Low-voltage switchgear and controlgear -- Part 4-1: Contactors and

motor starters -- Electromechanical contactors and motor starters (including motor protectors);

—— JBT 10736-2007 Low voltage motor protector.

2

2

2

2 Product

Product

Product

Product Features

Features

Features

Features

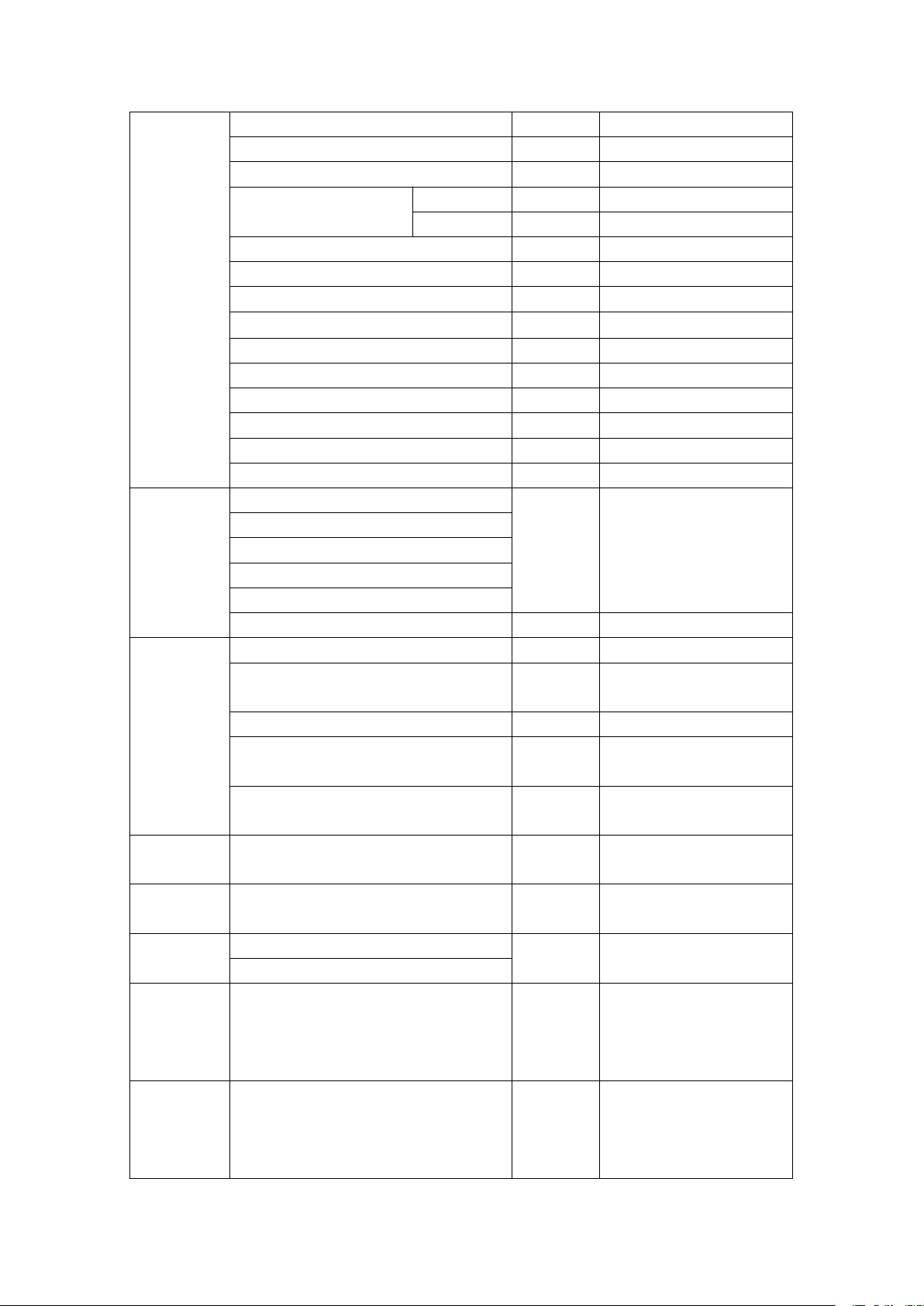

■ The auxiliary power type is optional. The AC220V power module supports the power range of

AC85-265V/DC100-300V and the AC380V power module supports the power range of

AC/DC100-415V.

■ Support fundamental and full-wave power parameter measurement (U, I,

P,

Q, S,

PF,

F,

EP,

EQ), voltage and current imbalance degree, voltage and current positive sequence, negative

sequence, zero sequence component, three-phase voltage phase a ngle, residual current, voltage

and current 2-63 sub-harmonic measurement, sub-harmonic inclusion rate and total harmonic

distortion rate.

■ Protection functions include overload inverse time, overload definite time, grounding, starting

a timeout, leakage, under load , locked-rotor, obstruction, short circuit, phase, overflow, imbalance

(current, voltage, power, less power, overvoltage, undervoltage, phase sequence, temperature, time,

external fault, tE starting number, running time, alarm, fault alarm.

■ 10 channels programmable DI input, the default use of DC24V power supply, or external

active wet contact can be selected (see the selection table).

■ 6 channels programmable DO output, to meet the direct starting,

Y

-△starting,

auto-transformer starting, and other starting modes, can be through the communication bus to

achieve the master station to the motor remote control "start/stop".

■ Optional anti-shaking function: support immediate restart of shaking power and restart of

voltage loss.

■ 2 MODBUS_RTU communication channels are standard, and PROFIBUS DPV1, Ethernet

and P rofinet communication modules are available for selection.

■ Optional 2 channels DC 4-20 m

A

analog output interface, connected with DCS system, can

realize the monitoring of field equipment.

■ With fault record, start record, stop record, DI displacement record, restart record and other

records of various events, you can view a number of motor operation and maintenance

information, and can record the motor operation record for 1-5 hours at the same time.

■ The display interface supports Chinese/English liquid crystal display

■ It supports exporting waveform record and event record data on usb flash disk, and can open

exporting event record file with EXCEL 。