2 / 19

2 Functional characteristics

2.1 AIM-T500L insulation monitor

■Monitor resistance of IT system real time, warning or alarm when the resistance exceeds the limit;

■Relay alarm output, LED alarm output and other fault indication modes;

■SOE function, convenient for staff to check and analyze the failure type and occurrence time, and

judge the operation status of the system;

■Self-check function, which can realize fault self-check of instrument hardware circuit;

■ Disconnect monitoring, real-time monitoring of PE/KE function grounding wire connection status;

■ RS485 interface, standard Modbus-RTU protocol;

■ CAN interface, custom protocol, used to interact with signal generator and fault locator;

■ Support manual/automatic reset modes;

■ Wide range of applications, suitable for AC, DC and AC-DC hybrid IT systems.

2.2 ASG200 test signal generator

■ Generate positioning signals and inject them into the ungrounded system;

■Indicate the phase line where the fault is;

■Manual startup positioning is supported;

■CAN bus technology is adopted to facilitate data interaction with other devices in the system.

2.3 AIL200-12 insulation fault locator

■ Locate and indicate the loop where the fault is;

■ A single AIL200-12 can locate up to 12 loops;

■ Each IT system can be connected to a maximum of 90 locators, with a total of 1080 loops;

■CAN bus technology is adopted to facilitate data interaction with other devices in the system.

2.4 AKH-0.66L series current transformer

■Rated current ratio 5A:5mA , select model according to the rated current of the loop;

■Coordinate with AIL200-12 insulation fault locator to achieve fault location.

3 Technical parameters

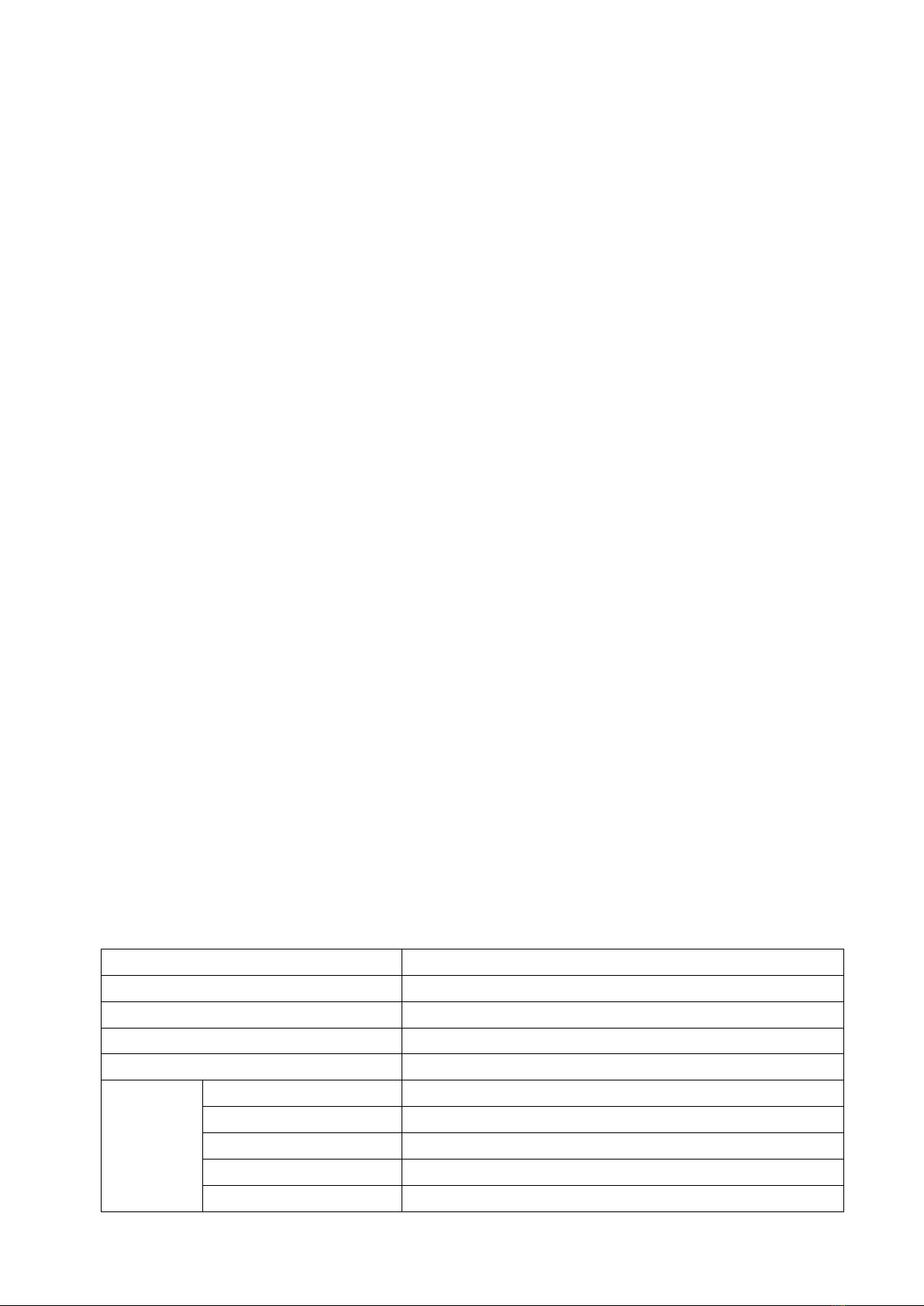

3.1 AIM-T500L insulation monitor