Acrobat M5 User manual

HYDRAULIC TAPPING MACHINE (M5- M36) MANUAL

2

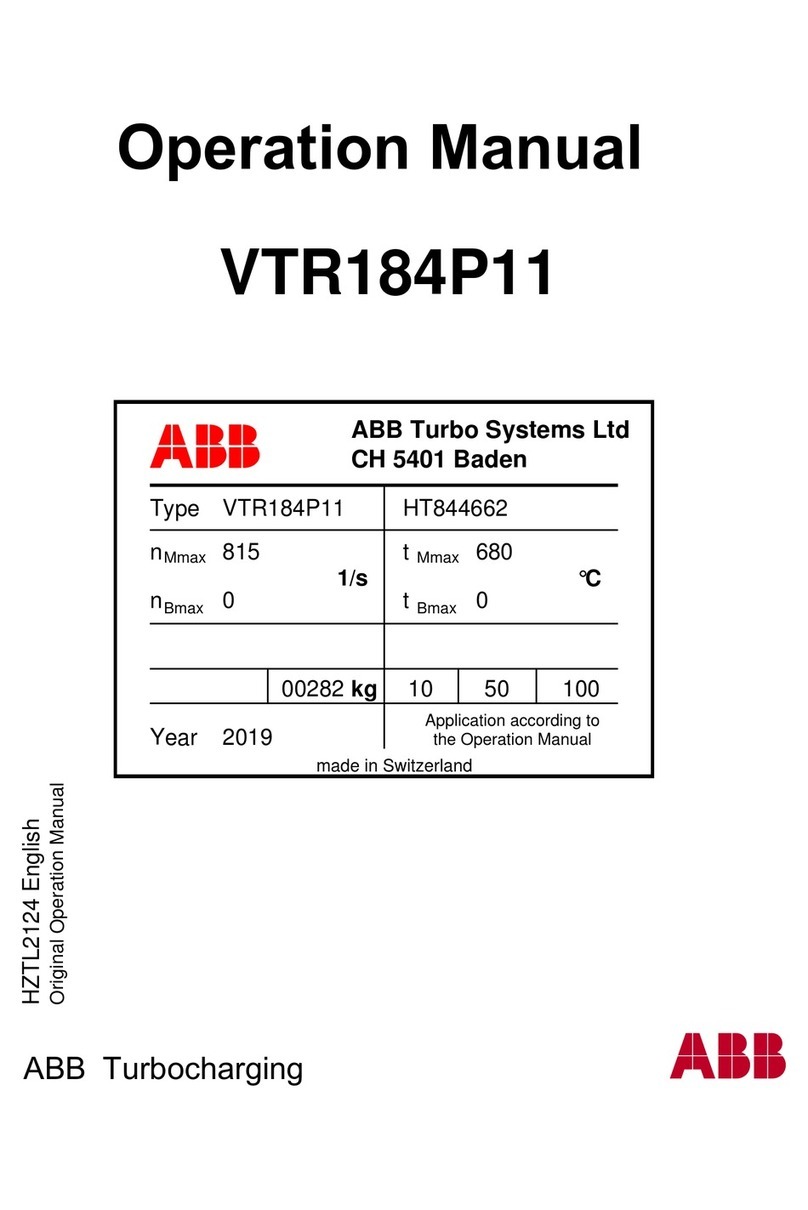

Hydro Motor

Hydraulic Hose

Handle

Ring

Front Paralel Arm

Piston Adjustment Handle

Piston

Piston

Adjustment

Handle

Level and

Heat

İndicator

Wheel

Dimmer

Pressure

indicator

Ventilation fan

Electric

panel

Start /

Stop

Pacco

Switch

3

CONTENTS

1- Safety Rules - - - - - - - - - - - - - - - - - - - - - - - - - - - - - Page 4- 5 –6

2 - Machine’s Usage - - - - - - - - - - - - - - - - - - - - - - - - - - Page 7

3 - Technical Properties - - - - - - - - - - - - - - - - - - - - - - - - Page 7

4 - Standard Accessories - - - - - - - - - - - - - - - - - - - - - - - Page 7

5 - Optional Accessories - - - - - - - - - - - - - - - - - - - - - Page 7

6 - Machine’s Assmebly - - - - - - - - - - - - - - - - - - - - - - - - Page 8

7 - Operation of Machine - - - - - - - - - - - - - - - - - - - - - - Page 9 - 10 - 11

8 - Maintenance of Machine - - - - - - - - - - - - - - - - - - - - - - - Page 12

8-1 - Filling Hydraulic Oil - - - - - - - - - - - - - - - - - - - Page 12

9 - Maintenance Control List - - - - - - - - - - - - - - - - - - - - - - - Page 13

10 - Safe Tap Holder System - - - - - - - - - - - - - - - - - -Page 13

11 - Control Circuit - - - - - - - - - - - - - - - - - - - - - - - -- - - Page 14

12 - Power Cycle - - - - - - - - - - - - - - - - - - - - - - - - - - - -- - - Page 15

13 - Drawing Diameters - - - - - - - - - - - - - - - - - - - - - - - -- -- - - Page 16

14 - Spindle—Part List - - - - - - - - - - - - - - - - - - - - - - - -- -- - - Page 17

4

1- Safety Rules

Your machine works at 380 V.

Machine will not work when phases are connected inverse, because there is phase protection relay at the

machine.

DEFINING SAFETY INFORMATION

Possible dangers may be prevented by reading explanations carefully. Keep people (especially children)

away from working eld during tapping process, except for the operator.

UNDERSTANDING SAFETY WARNINGS

Read manual carefully.

Use your machine at a suitable working environment. Unsuitable modications will aect safe operation

and long life of your machine negatively.

HAVE ELECTRIC INSTALLATION CONNECTED BY A COMPETENT ELECTRICIAN

Do not work the machine before putting oil into machine's hydraulic unit. Make sure hydraulic hose ttings

are rmly tightened.

WARNING! THERE IS HIGH PRESSURE IN THE MACHINE

PRESSURED OIL MAY HARM YOUR BODY

Metal parts may jump out when tapping. To prevent injuries arising from this reason, you have to wear

protective eye glasses for job, with edge protection

SPREADING METAL PARTS MAY HARM YOUR EYES

Heat will occur because of tap's friction to material. Do not touch hot parts with bare hands.

HOT PARTS MAY CAUSE BURNS

5

1- Safety Rules

Placing any part of the body on the machine while the machine is turned on is prohibited. It is also

prohibited to place on the machine or near the machine materials that are not mounted on the machine for

processing. These materials may be under the inuence of a working machine vibrations and cause a threat

to the health of people in the vicinity.

It is forbidden to operate the machine by people who are not familiar with the manual.

The user is required to secure the area around the machine to protect bystanders from being hit by a

moving part of a machine or workpiece`s splinter.

The machine must be operated by no more than one person (the operator) at a time.

Operate wearing clothes with narrow buttoned cus.

Long hair should be tied up.

If you notice irregularities in the operation of the machine immediately stop the operation and contact your

service representative.

It is forbidden to operate the machinery while intoxicated.

Children can not approach the machine.

When the machine is running, stay clear of the rotating tap

It is forbidden to leave the machine running unattended.

When the machine is running do not perform any operations in its surrounding area.

Never service the machine with motor on.

Never operate, service, repair or adjust machine without proper instruction from your supervisor and

without reading and understanding the instruction manual. It is the employer's responsibility to implement

the above instructions and to provide proper safety measures necessary for each particular use, operation,

setup or service of the machine.

Do not remove the labels from machine for any reason.

Heat will occur because of tap's friction to material. Do not touch hot parts with bare hands.

This is a very important chapter because in the past purchasers of ACROBAT tapping machines used it in a

manner that endangered the persons in the vicinity of the machine and the environment in which the

machine was located.

The machine is built mainly of steel and can not be used for combustible materials and harmful. The

customer must check whether the processed materials meet these requirements and do not pose a threat

to people living in the vicinity.

6

1- Safety Rules

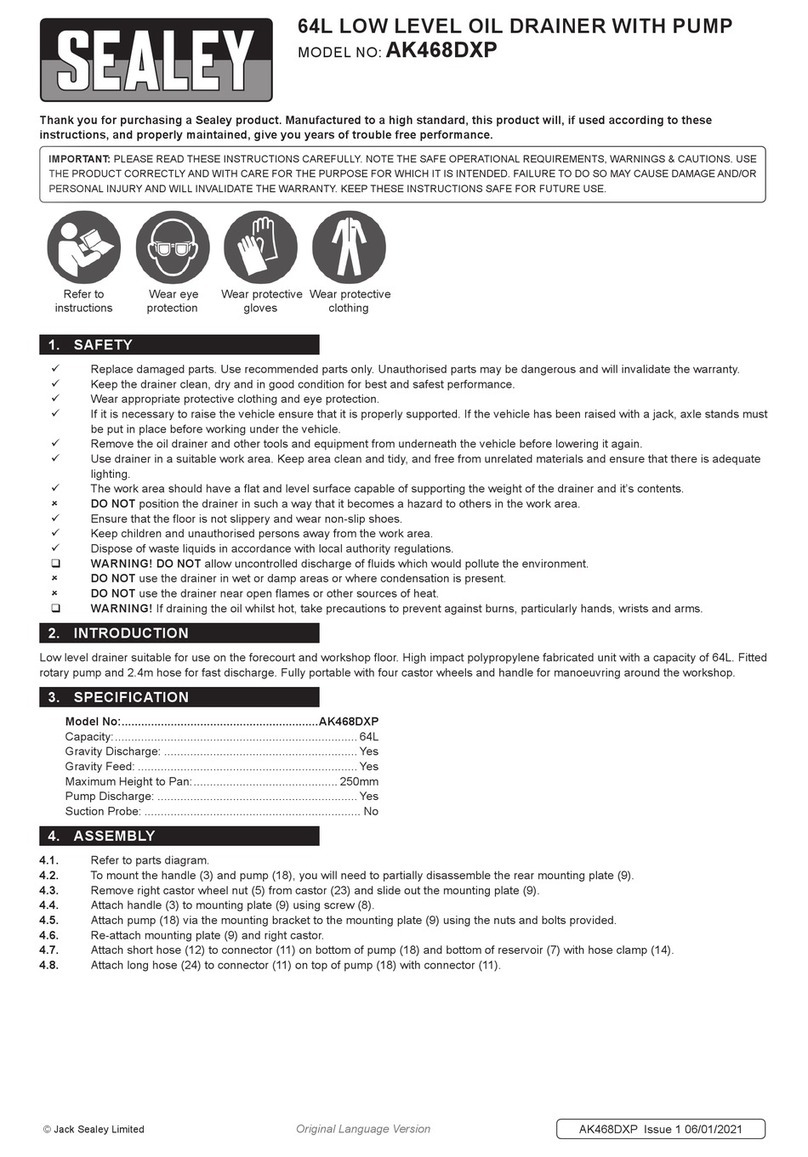

C

AE

D

B

NOISE EMITED BY THE MACHINE

The device properties used to measurement.

Model : Delta Ohm HD2110

Serial Number : 14000044R

The measurement condition was made as below :

15 °C and % 55 Rh

Results of measuArement

A point 72,2 dB(A)

B point 72,5 dB(A)

C point 71,5 dB(A)

D point 70,5 dB(A)

E point 70,0 dB(A)

7

2– Machine’s Usage

Acrobat M36 Hydraulic tapping machine is designed to help you perform your tapping works easily,

quickly and economically. It provides you with fast tapping possibility thanks to special hydraulic system

with high torque.

Connection is vertical to ground thanks to its acrobatic arm, horizontal operation is possible if you desire.

Prevents the breakage of tap thanks to safe type tap holders, and provides savings for you.

3– Technical Properties

Working Pressure : 60 Bar - 120 Bar

Power : 5.5 kw

Speed: 0– 125

Machine Wight : 260 Kg

Reaching Capacity : 2050 mm

Elevation Capacity : 920 mm

Rotating Capacity : 360 degree

Table Height : 900 mm

Widht of Table : 700 mm

Lenght of Table : 900 mm

4– Standard Accessories

5– Optional Accessories

1– Angle head system

2– Connection bolts

3– Tap holder placement socket

4– Hydraulic system

1– Tap holders with or without safety

2– Fixed head system

3– Mobile table at any size

8

6– Machine Assembly

Place the base ange of machine in such a way to t table connection holes. Make sure you tighten bolts

after you place them with suitable Allen wrench.

WARNING! Make sure the connection surface of table is clean.

The smallest defect here (burr, small metal pieces) will prevent your machine to work vertically to ground.

After you place the bolts, remove package bands and uncover the machine.

To make machine adjustment for 90 degrees (See Picture-1) loosen bolts with number 1 and number 2 as in

the picture (2 bolts facing each other). So that front head group will become free.

Press the mouth to which safe tap holder is connected,rmly on the surface you want to carry out tapping.

(PICTURE 4/ 90 degrees of leaning mouth) Tighten bolts with number 1 and number

2 again after surface leans. Make sure surface leaning does not change during the process of tightening

bolts. In that way 90 degrees adjustment of your machine will be done.

4

Picture –1

Hardness adjustment mechanism which allows lifting its weight is available on the acrobatic arm.

[See Picture 1) Front parallel arm group hardness adjustment can be done via handle with number 3 as

seen on the picture, and handle with number 4 is used for rear parallel arm group's hardness adjustment.

9

7– Operation Of Machine

Machine includes a 5.5 kw electric motor. Firstly measure the currents coming to plug you will use before

connecting your machine to plug and operating it. It must be 380 V between the phases and 220 V

between phase-neutral. If alternating current is reaching to system, it will damage electrical system of

your machine. In this situation, use a regulator to balance phases before operating the machine.

WARNING! Otherwise electric faults which may occur will not be in scope of guarantee.

Electric installation has phase protection relay. So that when phase with reverse order reaches to electric

motor, phase protection relay activates and prevents the reverse operation of electric motor and

hydraulic pump which is connected to motor from working in reverse direction, and protects the system.

(See Picture 2) In such a situation if the machine is not working, remove machine's three-phase electric

cable and connect to another suitable three-phase socket. When the phase coming to motor is correct,

system will activate.

To start the machine open pacco switch on unit and press on motor start button (green button) after

waiting for 5 seconds. (See Picture 3) And hydraulic system will become activate

MOTOR

STOP

MOTOR

START

PACCO

SWITCH

Picture –3

When the lamp is o

REVERSE PHASE

When the lamp is 0n

FLAT PHASE

Picture –2

10

7– Machine’s Operation

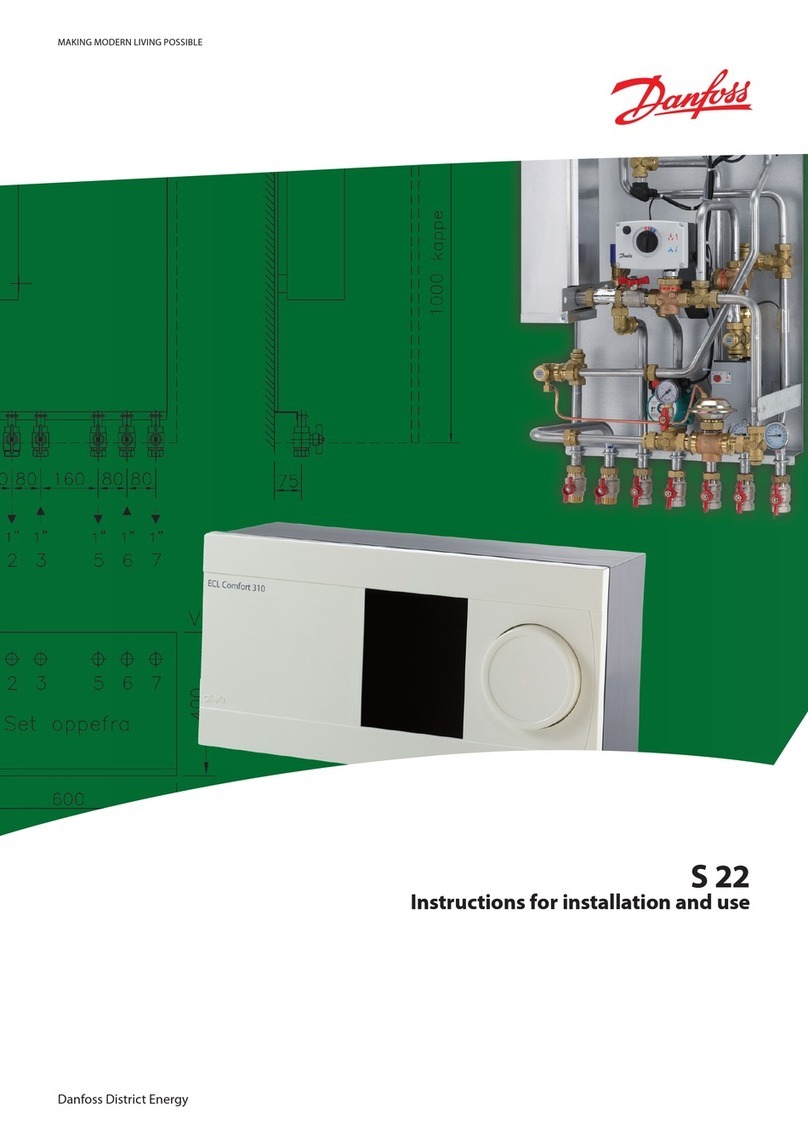

Button on handle at the end of acrobatic arm (See Picture 4) adjusts machine's spindle rotation direction.

Button stays at middle position automatically when machine is not used and spindle does not rotate. To be

able to turn spindle clockwise, press and hold the button to left. In that way spindle will rotate clockwise.

When you press and hold the button to right, spindle will rotate counter-clockwise.

Handle

Left Button

Attach the tap you want for tapping to tap holder with suitable metric according to your tap. If the tap

you will use is attached to a tap holder of dierent metric, your tap may break because of torque

disagreement. Place the teeth near tap holder in such a way to t teeth sockets at the end of module, by

pushing the ring on module at the end of spindle upwards, and release the ring; locking mechanism will

work automatically and x the tap holder. ( See Picture 4)To remove tap holder from its place, it will be

enough to lift ring on module upwards.

Bring the tap (which is suitable for the hole you drilled beforehand, or which you will tap) on the hole and

press slightly and provide mouthing (diameters of holes to be drilled according to taps for tapping can

be found at the end of guide).

Then by pressing button to left side, make spindle turn clockwise. This way tapping tool will begin

process of tapping for hole. When the process is done, by holding button pressed to the right, make the

spindle turn counter-

clockwise. In that way tap tool will come back from tapped hole. If you lubricate the tap with suitable

grease before contacting with the material it will increase cutting speed and extend the life of the tap.

Picture 4

Safe Tapping Holder

Ring

90 Degree

Damping Surface

Right Button

11

7– Machine’s Operation

Huk 2000 Rh (M5-M36) hydraulic tapping machine works at 100 rpm speed for tapping processes between

M5 and M36. İt is possible to adjust spindle cycle at speed adjustment dimmer, according to size of teeth

you will tap. You can use it at any speed by reducing cycle by using accurate speed adjustment dimmer

for bigger teeth; and increase cycles with accurate speed adjustment for smaller teeth. Huk 2000 Rh

Hydraulic tapping machine can carry out tapping horizontally.

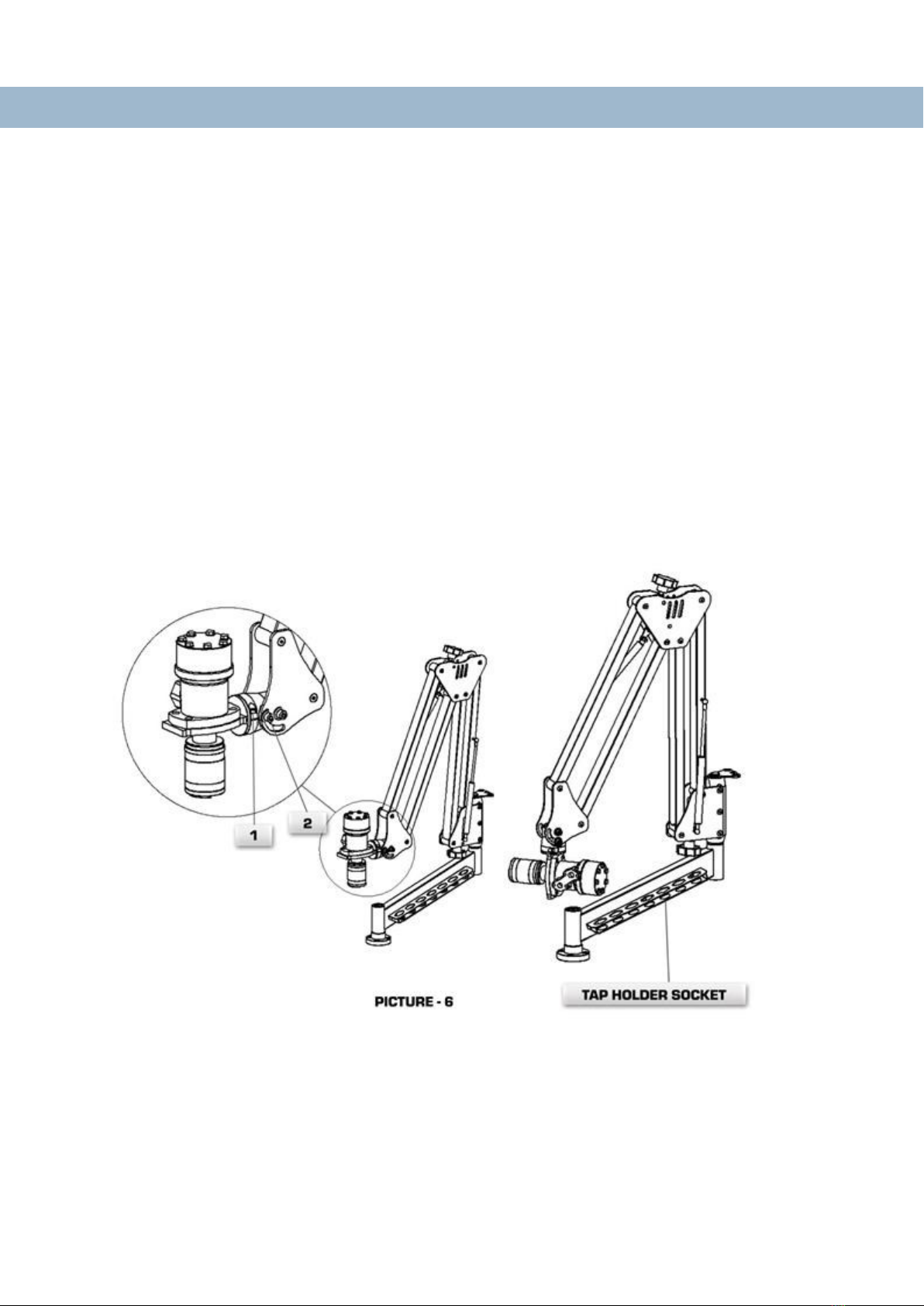

When you want to carry out tapping (See Picture 6) slightly loosen bolts with number 1 and number 2 as

seen on the picture ( two bolts looking at each other). This way the front head will turn to horizon and

tapping head will be able to rotate 360 degreess.

Then only tighten bolts with number 2 and leave bolt with number 1 loose. Because head group needs to

be free during horizontal tapping process. It is to ensure that head and related tap move easily at the axis

of hole you drilled during horizontal tapping , and being able to adjust itself according to angle.

Your machine is ready for horizontal tapping proccess.

If you put tap holders whose job nished to the tap holder sockets at sides you can prevent possible

accidents.

When you job ends with the machine, press the motor stop (red button) button at the unit and close

pacco switch. Keep acrobatic arm at closed condition when you are not working with the machine.

Picture 5

12

8– Maintance of Machine

Fill oil tank in the table with minimum 90 lt, maximum 100 It with hydraulic oil (grade 46).

Periodically change hydraulic oil after 2500 hours of usage to use hydraulic motor and machine at desired

performance with long life.

Track oil level with indicator at certain periods. Clean the inside of safe tap holders with pressured air at

certain periods. Otherwise there may be breakage possibility for the taps.

Thin machine oil and grease shall be applied to suitable grease ttings at transmission unit at certain

periods depending on machine's operation frequency.

To change hydraulic oil, open blind plug at the bottom of machine and evacuate hydraulic oil. After

hydraulic oil is completely emptied, tighten blind plug again at its place.You can ll hydraulic oil (grade

46) with funnel (minimum 90 It, maximum 100 It) by opening storage cover.

8–1 Filling Hydraulic Oil

When you want to ll machine with hydraulic oil, you can ll hydraulic oil (grade 46) at minimum 90 It,

maximum 100 It with the help of funnel by opening storage cover as in the picture (See Picture-7).

STORAGE

COVER

Picture 7

13

9 – Maintenance Control List

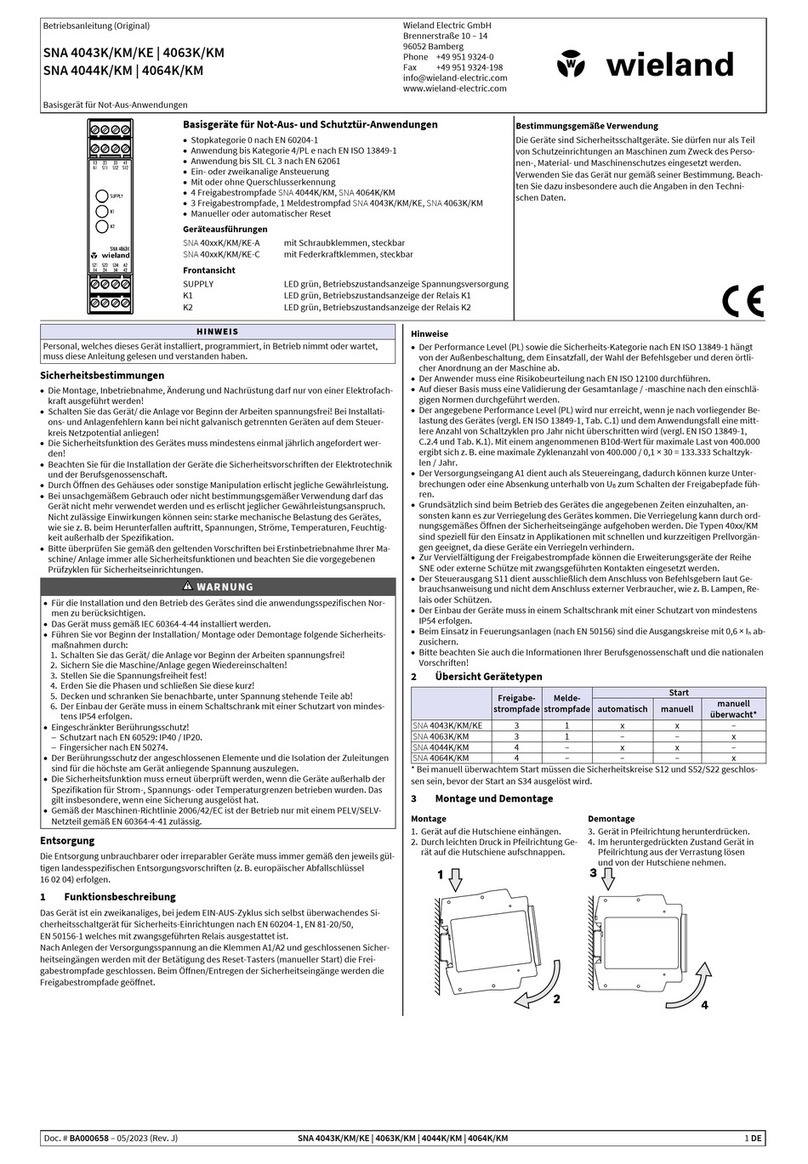

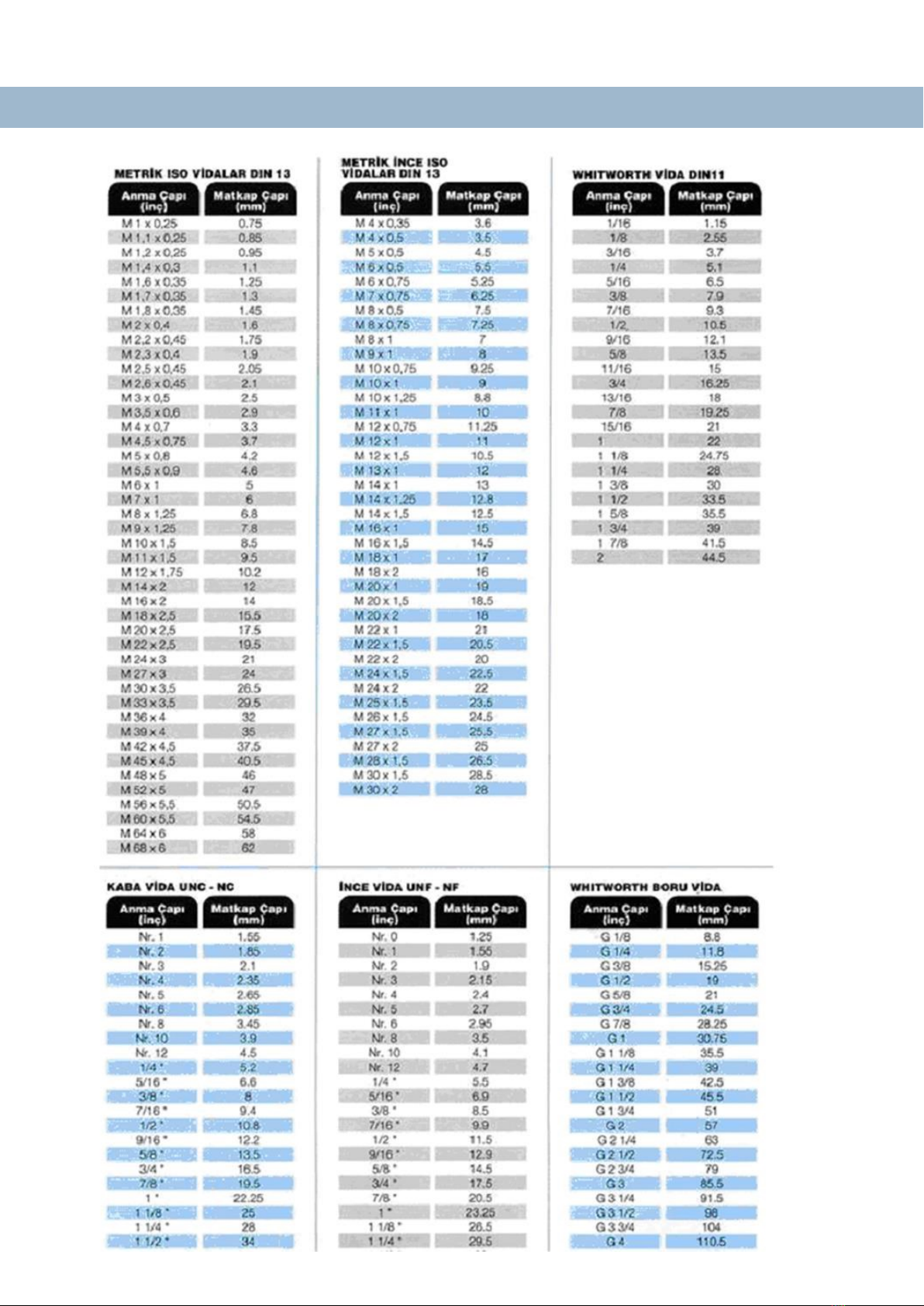

Safe type tap holders are produced separately for each metric tooth and they have a torque-adjusted

system inside of them. This system is adjusted by producing company according to torque values which

prevent breakage of tap you use, and prevents being exposed to too much force. It reduces tap breakage

risk to minimum. If the hole you use for tapping is a blind hole and if tap reached to bottom or if tap cannot

move because of the jamming of burr created during tapping process or similar reasons, this torque-

adjusted safe tap holder will become activated and even if you continue working for tapping, the machine's

spindle will turn but will not rotate the tap and tap will not move. So that tap breakage risk will be reduced

to minimum. Also decay of tapped part and tap tool costs will be minimum.

According to variety of the tap you use and the hardness of part for which you are carrying out tapping,

torque values of tap holders can be adjusted manually. Torque hardness of safe tap holder can be

increased or reduced. If your tap breaks before tap holder is activated remove wire segment at the front

side of tap holder (See Picture 8) as seen in the picture, rotate interior hub of holder one grade in counter-

clockwise direction in such a way to t wire segment entrance holes on the hub, and place wire segment

again to its place. In that way torque value of your tap holder will be reduced and your tap will not break

with the activation of safe torque system before your tap

breaks. To operate safe torque system at later and higher torque values, apply the above mentioned

process by rotating clockwise. In that way torque value of tap will be increased and torque system will be

activated later.

WARNING! Attention must be paid at this process because the breakage risk of tap will increase as it will be

exposed to bigger force

10 - Safe Tap Holder System

CONTROL POINTS

HYDRAULIC OIL LEVEL CONTROL

HYDRAULIC OIL LEAKAGE CONTROL

HYDRAULIC OIL REPLACEMENT

GENERAL CLEANING

CONTROLLING CONNECTION BOLTS

CONTROLLING ELECTRIC CONNECTIONS

CLEANING TAP HOLDERS

15 DAY

MONTHLY

EVERY 2500 H

WIRE SEGMENT

THE SOCKET WHERE WIRE SEGMENT IS

PLACED AND CHANNEL SHOWN WITN

ARROW MUST COINCIDE WITH EACH

OTHER

Picture 8

14

11– Control Circuit

15

12– Power Cycle

16

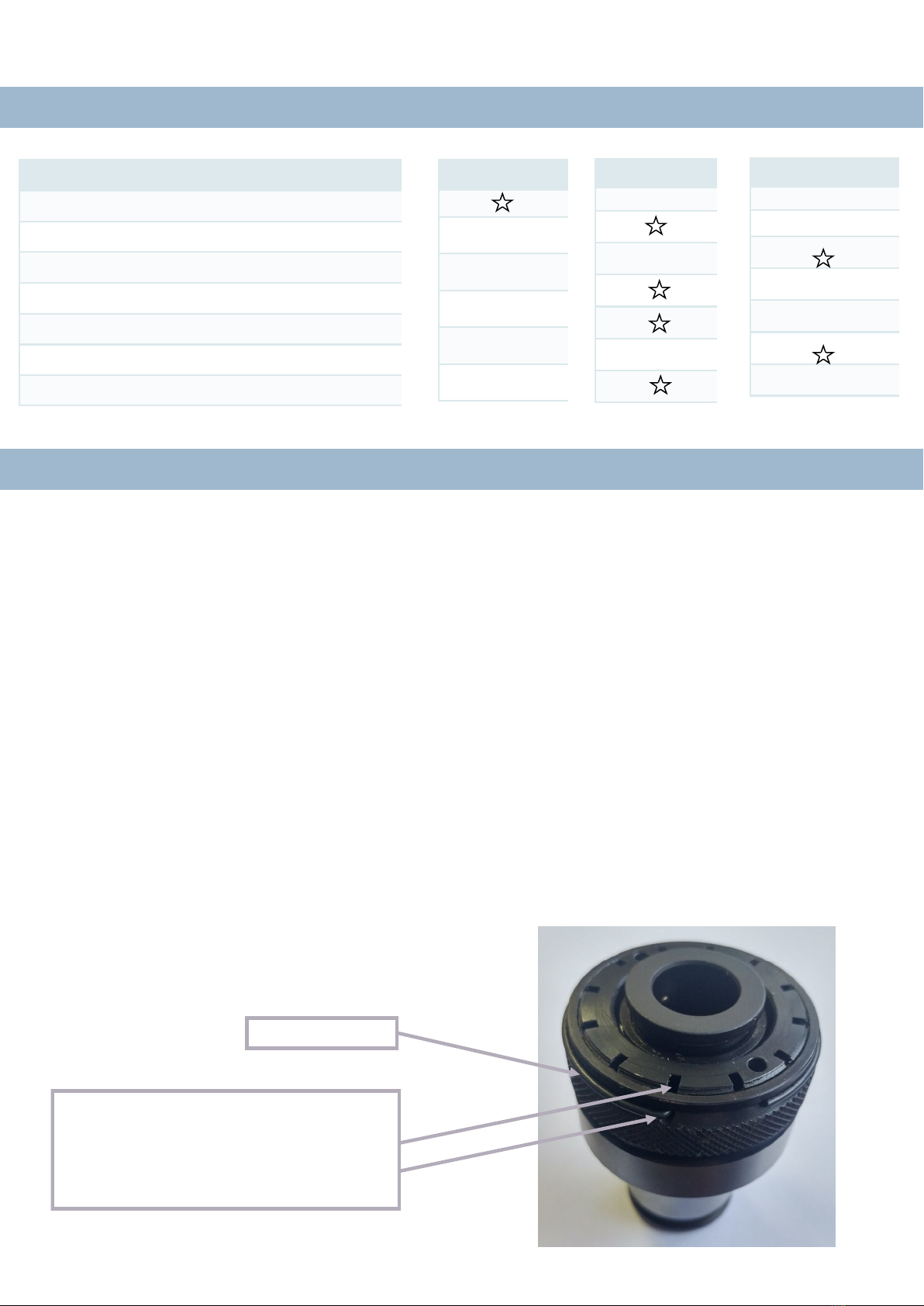

13– Drawing Diameters

17

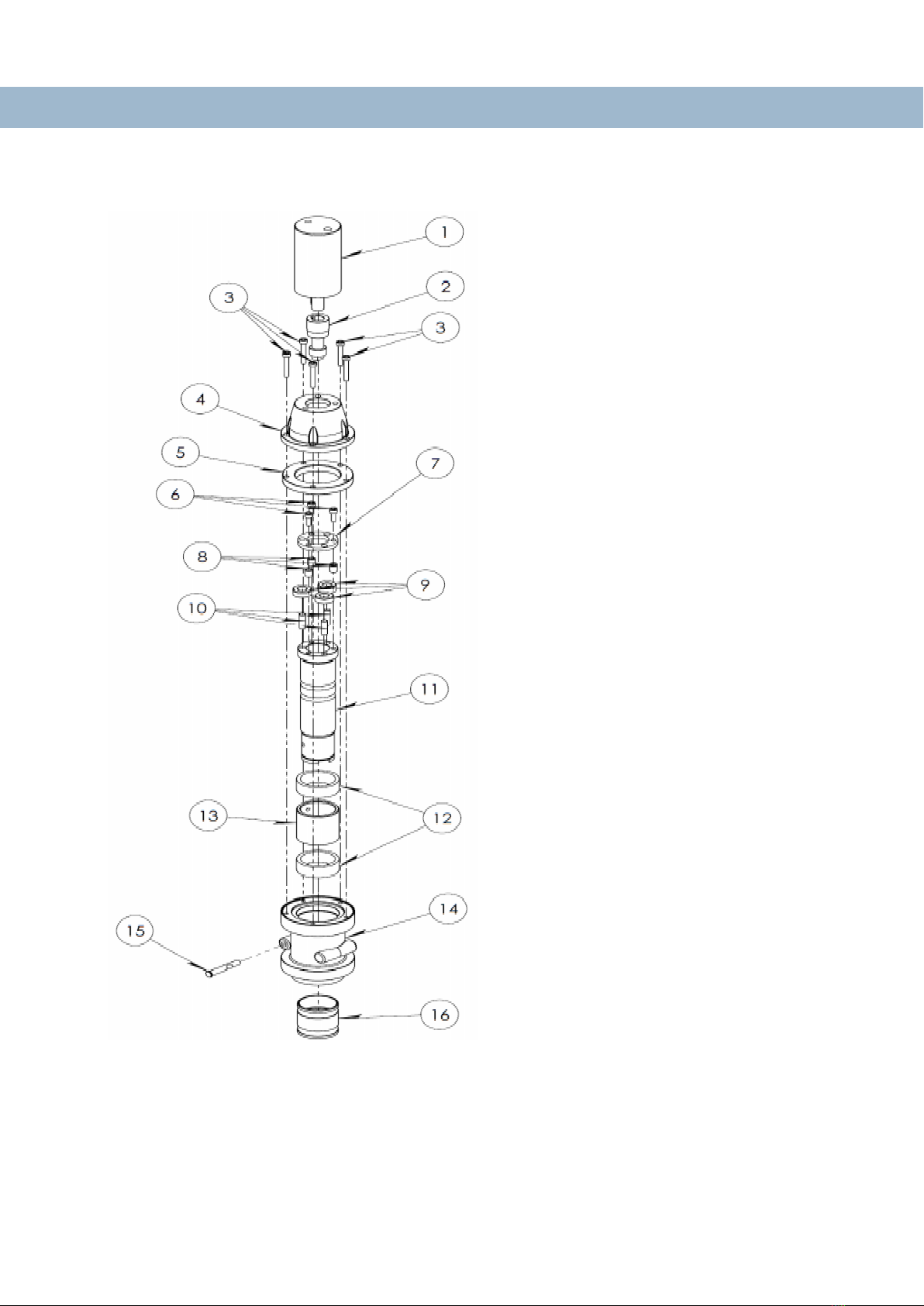

14– Spindle – Part List

1. HYDRAULIC MOTOR

2. PINION GEAR

3. M6 X 40 BOLT

4. HYDRAULIC MOTOR

FLANGE

5. OUT SUN GEAR

6. M6 X 25 BOLT

7. GEAR FLANGE

8. NEEDLE BEARING

9. PLANET GEAR

10. PLANET GEAR PIN

11. SPINDLE

12. SPINDLE BEARING

13. SPINDLE RING

14. SPINDLE MAIN BODY

15. SPINDLE LOCKING PIN

16.TAP COLLET LOCKING

RING

Other manuals for M5

1

This manual suits for next models

1

Table of contents

Other Acrobat Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

RINGSPANN

RINGSPANN FRS Series Installation, Lubrication, Maintenance Instructions

Pepperl+Fuchs

Pepperl+Fuchs PGV100RS-F200-B16-1,5M manual

Bühler technologies

Bühler technologies GAS 222.30 Assembly, installation and operation instructions

Yamaha

Yamaha SIGMA-G5SII Service information

ABB

ABB HT611632 Operation manual

evoheat

evoheat EVO Fusion-i Series manual