7369053-0SIBC VI.HB.C1.00 © Danfoss 5/02 1

Instructions

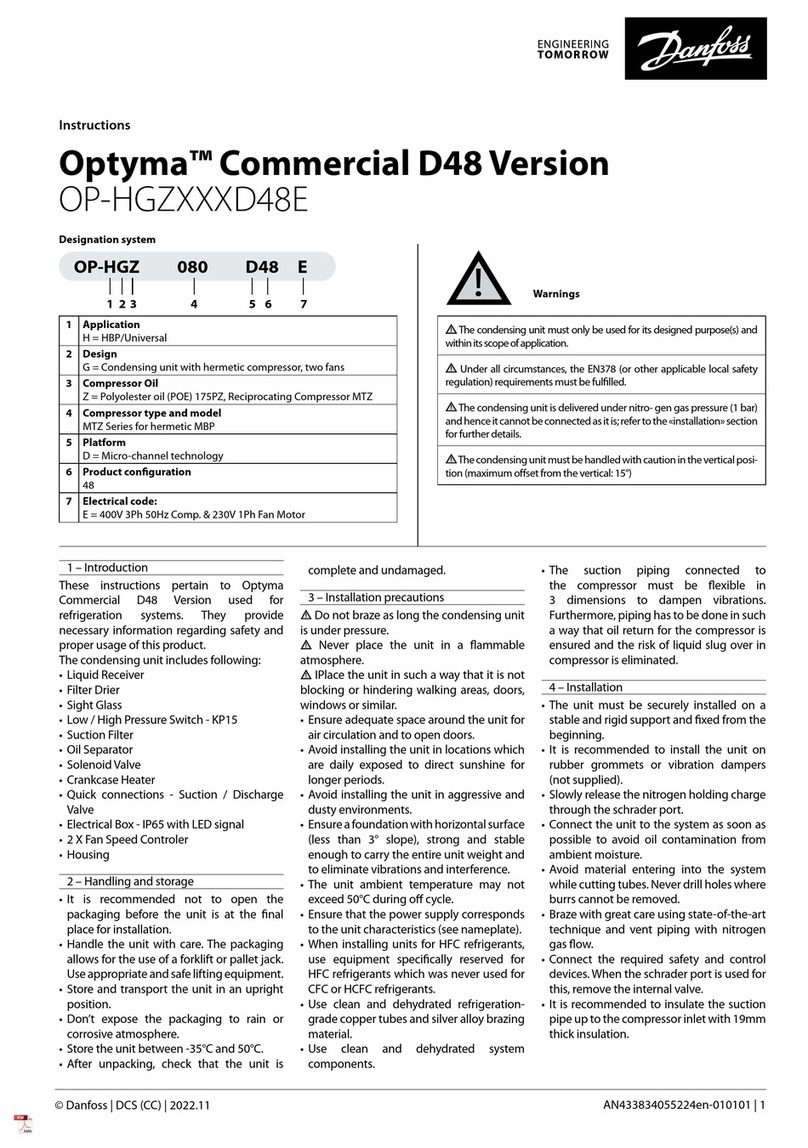

VM2, VB2 2-way

065R9074

065R9074

DN L(mm)

15 65

20 70

25 75

32 100

40 110

50 130

DN L1(mm)

15 131

20 142

25 159

32 196

40 196

50 228

DN L2(mm)

15 139

20 154

25 159

32 184

40 294

50 330

DN L3(mm)

15 69

20 74

25 79

32 104

40 114

50 134

VM2 VB2

Manual override

Instructions

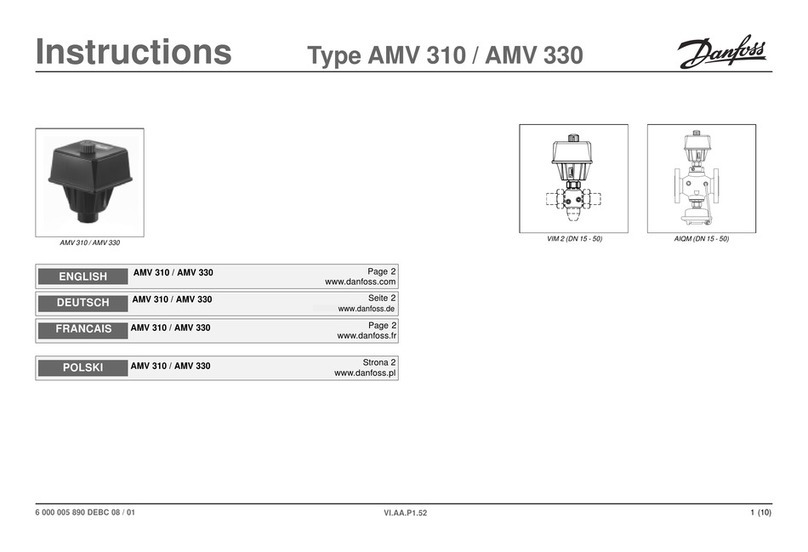

AVQM, AVQMT – PN 16, 25 / DN 15-50

73695050DH-SMT/SI VI.DB.T2.1N©Danfoss 09/2009 1

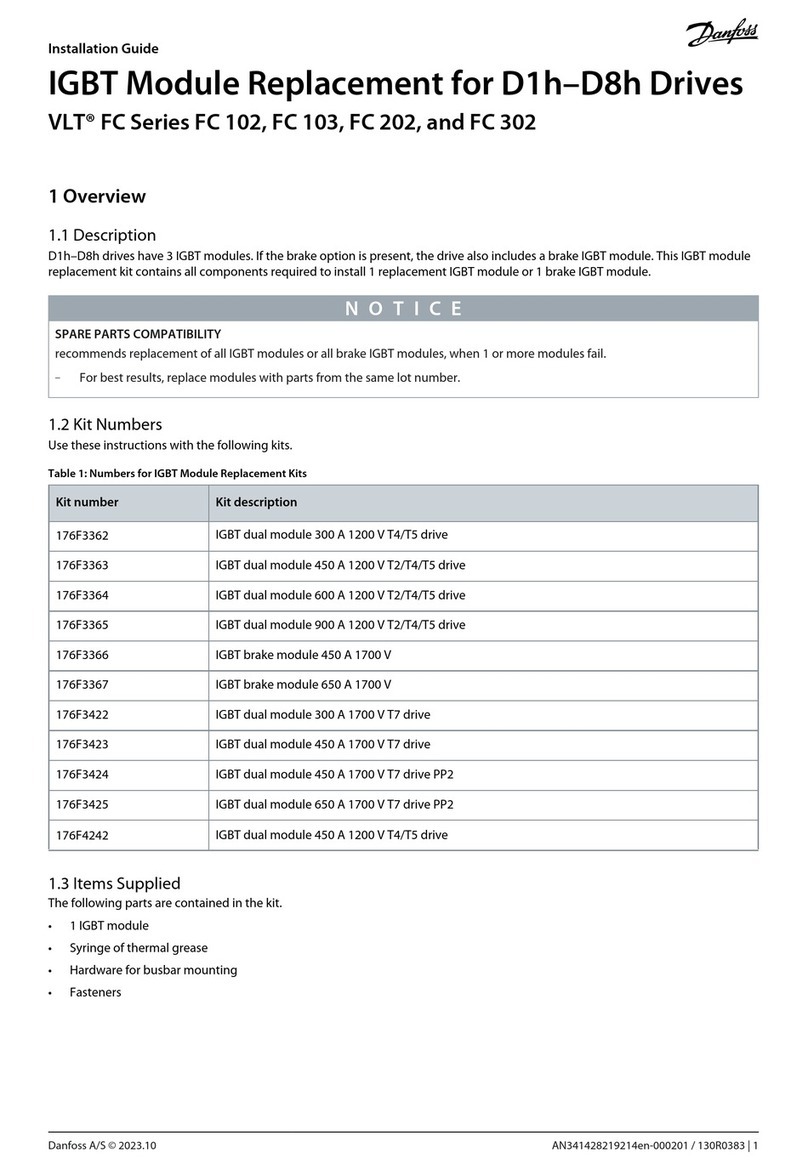

DN 15-3 2 DN 15- 50 DN32-50 DN 15-5 0 DN32-50 DN 15-5 0 D N 32-50

∆p= 0.2 ∆p = 0.2 ∆p = 0.2 ∆p= 0. 2 ∆p= 0.2 ∆p = 0.2 ∆p = 0.2

AVQM (PN 16) AVQM(PN 25) AVQMT(PN 25) AVQMT/AVT(PN 25)

ENGLISH Flow(and temperature) controller with integr ated control

valve AVQ M, AVQMT www.danfoss.com Page 7

DANSK Flow- (og temperatur-)regulatorme d indbygget motorventil

AVQM, AVQM T www.danfoss.dk Side 9

DEUTSCH Volumenstrom(und Temperatur-) Regler mit Motorstell ventil

AVQM, AVQM T www.danfoss.de Sei te 11

ESPAÑOLRegulad or de caudal (y temperatura) con válvula de control

integradaAVQM, AVQMT www.danfoss.es Página13

SLOVENŠČINA Regulatorpretok a (in temperature)z re gulacijskim ventilom

AVQM, AVQM T www.danfoss.si Str an 15

POLSKI Regulator przepływu (i temperatur y)z z aworem

regulacyjnym AVQM, AVQMT www.danfoss.pl Str ona 17

MAGYAR Térfogatáram(éshőmérséklet)szabályozó, motoros

szabályozó-szeleppel egybeépítve AVQM, AVQMT ww w.danfoss.hu Oldal19

SRPSKI Uputstvo AVQM, AVQMT-PN16, 25/DN 15-50 grejanje.danfoss.com Strana21

Alternative actuator

AMV150 and valve

housing VS2

99

Instructions for installation and use S 22

Danfoss District Energy VI.IE.D1.02 DKDHR

General information

PLEASE NOTE! Some models may have a slightly dierent appearance,

but the control function is in principle the same as described below.

Commissioning

Commission the unit in accordance with instructions on page 6 -7.

Filling the system

Filling of water to the heating system must be done according to the

instructions on page 6 (item 5 - GETTING STARTED).

Check and tighten all connections before adding water to the system,

as vibrations during transport may have caused leaks. After having

added water to the system, tighten all the connections before per-

forming leak test.

Then heat up the system, check the connections and tighten once

again if necessary.

Before adding water to the system and rst start-up, check if:

- pipes are connected according to the circuit diagram,

- heat meter is mounted,

- shut-o valves are closed,

- threaded and anged connections are tightened.

Dierential pressure controller (common return pipe

- only Application A266)

The dierential pressure controller, Danfoss AVP-F reduces the high

uctuations in pressure in the district heating network, ensuring a

small and constant operating pressure across the unit. This ensures

optimum operating conditions for the control equipment.

The dierential pressure controller closes on rising dierential

pressure.The dierential pressure controller is preset to a xed value

from factory and should not be adjusted afterwards.

Please refer to enclosed producer instructions for further information.

Instructions AVP-F

Danfoss ECL Comfort 310

The substation is supplied with an Danfoss ECL 310 controller. The ECL

controller is supplied with an ECL Application Key A266.The application

Key contains information about application, language and factory set-

tings, adapted to the type of system, for which it is ordered.

Note! Various applications can be loaded.

The controller is factory-set for local language and the running time for

the actuator (heating circuit) is preset for the actual application.

General controller settings such as “Time and Date” must be entered

during commissioning of the controller. And also the desired supply

ow temperature must be set.

Please refer to enclosed manufacturer instructions for the ECL 210/310

controller to set the required temperature for the heating circuit:

ECL Application Key Box with ECL Comfort 210/310 user guide and

mounting guide, for further information.

We recommend that your order commissioning of the controller with your

local Danfoss representative.

Note, in systems that feature only oor heating it is important that the

supply temperature does not exceed 35°C, and ALWAYS check the in-

structions from the oor supplier ( typically for wooden oors).

Actuator + valve, unit with control of heating- and DHW circuits,

Application A266

For controlling the heating circuit the S 22, A266 is supplied with a

Danfoss AMV 10 actuator with Danfoss valve type VM2, placed on the

primary return ow pipe. The AMV actuator is electrically wired to the

controller from factory.

Please refer to enclosed producer instructions for further information.

Instructions AMV10

Factory setting

The actuator has undergone a functional test and is preset from factory.

In the event of operating disturbances the actuator can be shut o man-

ually in accordance with enclosed instructions, by turning the manual

override knob on top of the actuator clockwise. Please note that the

knob can be“tight”to turn.

8. Adjustment and commissioning, heating circuit