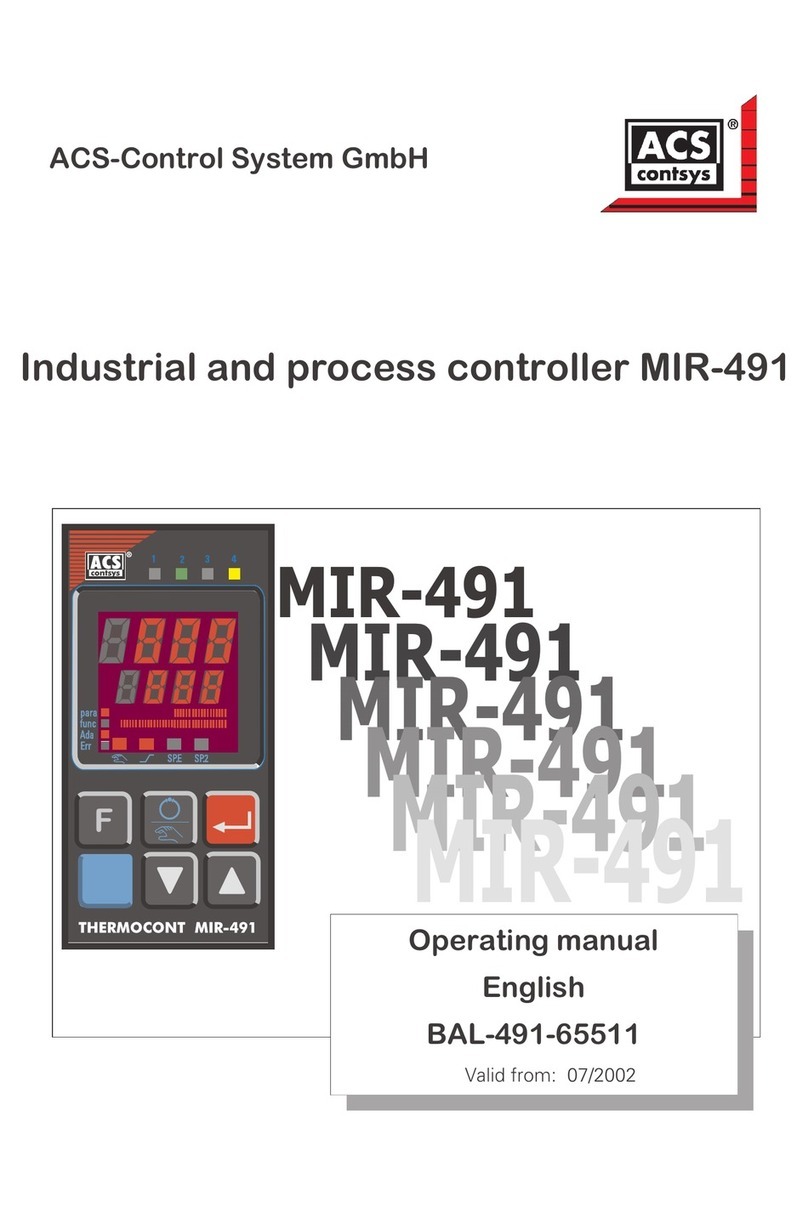

ACS contsys MIR-491 User manual

Operating Instructions

MIR-491 and MIR-492

Industrial- and process controller

MIR-491

MIR-492

ACS-CONTROL-SYSTEM GmbH l Lauterbachstr. 57 l D-84307 Eggenfelden l www.acs-controlsystem.de l [email protected]

2

© PMA Prozeß- und Maschinen-Automation GmbH •Printed in Germany

All rights reserved. No part of this document may bereproduced or published in any form

or by any means without prior written permission from the copyright owner.

A publication of PMA Prozeß- und Maschinen Automation

P.O.Box 310229

D-34058 Kassel

Germany

ûBlueControl

More efficiency in engineering,

more overview in operating:

The projecting environment for the BluePort®controllers

ATTENTION!

Mini Version and Updates on

or on PMA-CD

www.pma-online.de

Description of symbols

in the text: on the device:

gGeneral information aFollow the operating instructions

aGeneral warning

lAttention: ESD-sensitive devices

© PMA Prozeß- und Maschinen-Automation GmbH •Printed in Germany

All rights reserved. No part of this document may bereproduced or published in any form

or by any means without prior written permission from the copyright owner.

A publication of PMA Prozeß- und Maschinen Automation

P.O.Box 310229

D-34058 Kassel

Germany

ûBlueControl

More efficiency in engineering,

more overview in operating:

The projecting environment for the BluePort®controllers

ATTENTION!

Mini Version and Updates on

or on PMA-CD

www.pma-online.de

Description of symbols

in the text: on the device:

gGeneral information aFollow the operating instructions

aGeneral warning

lAttention: ESD-sensitive devices

ACS-CONTROL-SYSTEM GmbH l Lauterbachstr. 57 l D-84307 Eggenfelden l www.acs-controlsystem.de l [email protected] 3

KS 90-1 / KS 92-1 3

Contents

1Mounting.............................. 5

2Electrical connections . . . . . . . . . . . . . . . . . . . . . . . 6

2.1 Connecting diagram . . . . . . . . . . . . . . . . . . . . . . . 6

2.2 Terminal connection . . . . . . . . . . . . . . . . . . . . . . . . 7

3Operation............................. 11

3.1 Frontview ............................ 11

3.2 Behaviour after power-on . . . . . . . . . . . . . . . . . . . . . 12

3.3 Operatinglevel .......................... 12

3.4 Error list / Maintenance manager . . . . . . . . . . . . . . . . . 13

3.5 Self-tuning............................. 16

3.5.1 Preparation for self-tuning . . . . . . . . . . . . . . . . . . . 16

3.5.2 Optimization after start-up or at the set-point . . . . . . . . . 17

3.5.3 Selecting the method ( ConF/Cntr/tunE).........17

3.5.4 Step attempt after start-up . . . . . . . . . . . . . . . . . . 18

3.5.5 Pulse attempt after start-up . . . . . . . . . . . . . . . . . . . 18

3.5.6 Optimization at the set-point ..................18

3.5.7 Optimization at the set-point for 3-point stepping controller. . 20

3.5.8 Self-tuning start . . . . . . . . . . . . . . . . . . . . . . . . . 21

3.5.9 Self-tuning cancellation. . . . . . . . . . . . . . . . . . . . . 21

3.5.10 Acknowledgement procedures in case of

unsuccessful self-tuning . . . . . . . . . . . . . . . . . . . . 22

3.5.11 Examples for self-tuning attempts . . . . . . . . . . . . . . . 23

3.6 Manualself-tuning......................... 24

3.7 Second PID parameter set . . . . . . . . . . . . . . . . . . . . . 25

3.8 Alarmhandling .......................... 26

3.9 Operating structure . . . . . . . . . . . . . . . . . . . . . . . . 28

4Configurationlevel........................ 29

4.1 Configuration survey . . . . . . . . . . . . . . . . . . . 29

4.2 Configuration parameters . . . . . . . . . . . . . . . . . . . 30

4.3 Set-point processing . . . . . . . . . . . . . . . . . . . . . . . . 44

4.3.1 Set-point gradient / ramp . . . . . . . . . . . . . . . . . . . . 44

4.4 Switching behaviuor . . . . . . . . . . . . . . . . . . . . . . . . 45

4.4.1 Standard ( CyCl=0).....................45

ACS-CONTROL-SYSTEM GmbH l Lauterbachstr. 57 l D-84307 Eggenfelden l www.acs-controlsystem.de l [email protected]

4

4 KS 90-1 / KS 92-1

4.4.2 Switching attitude linear ( CyCl=1).............45

4.4.3 Switching attitude non-linear ( CyCl=2) ..........46

4.4.4 Heating and cooling with constant period ( CyCl=3) . . . . 47

4.5 Configuration examples . . . . . . . . . . . . . . . . . . . . . . 48

4.5.1 On-Off controller / Signaller (inverse) . . . . . . . . . . . . . 48

4.5.2 2-point controller (inverse) . . . . . . . . . . . . . . . . . . . 49

4.5.3 3-point controller (relay & relay) . . . . . . . . . . . . . . . . 50

4.5.4 3-point stepping controller (relay & relay) . . . . . . . . . . . 51

4.5.5 Continuous controller (inverse) . . . . . . . . . . . . . . . . . 52

4.5.6 Y - Off controller / 2-point controller with pre-contact . 53

4.5.7 Continuous controller with position controller . . . . . . . . 54

4.5.8 Measured value output . . . . . . . . . . . . . . . . . . . . . 55

5Parameter setting level . . . . . . . . . . . . . . . . . . . . . . 56

5.1 Parametersurvey ....................... 56

5.2 Parameters............................. 57

5.3 Inputscaling............................ 60

5.3.1 Input Inp.1 and InP.3...........60

5.3.2 Input InP.2 ..........................60

6Calibrationlevel......................... 61

7Specialfunctions......................... 64

7.1 DAC®– motor actuator monitoring ...............64

7.2 O2measurement.......................... 66

7.2.1 Connection...........................66

7.2.2 Configuration:..........................67

7.3 Linearization............................ 68

7.4 Loopalarm............................. 69

7.5 Heating current input / heating current alarm . . . . . . . . . . . 69

7.6 KS9x-1 as Modbus master. . . . . . . . . . . . . . . . . . . . . 70

7.7 Back-up controller (PROFIBUS) . . . . . . . . . . . . . . . . . 70

8BlueControl............................ 71

9Versions.............................. 72

10 Technical data .......................... 74

11 Safetyhints............................ 78

11.1 Resetting to factory setting, . . . . . . . . . . . . . . . . . . . . 80

MIR-49x as Modbus master.

ACS-CONTROL-SYSTEM GmbH l Lauterbachstr. 57 l D-84307 Eggenfelden l www.acs-controlsystem.de l [email protected] 5

1Mounting

aFix the instrument only at top and bottom to avoid damaging it.

Safety switch:

For access to the safety switch, the controller must be withdrawn from the hou-

sing. Squeeze the top and bottom of the front bezel between thumb and forefinger

and pull the controller firmly from the housing.

1Factory setting 2Default setting: display of all levels

suppressed, password PASS =OFF

lCaution! The unit contains ESD-sensitive components.

Mounting

KS 90-1 / KS 92-1 5

%

max.

95% rel.

max. 60°C

0°Cmin.

96 (3.78")

48 (1.89")

Loc

min.48 (1.89")

10 (0.4")

1..10

(0.04..0.4")

118 (4.65")

45 +0,6

(1.77" )

+0.02

92

+0,8

(3.62" )

+0.03

Ü

*

KS 90-1

advanced

1 2 3

è

1200

1199

°C

°F

SP.2

SP.E

para

func

Ada

Err

4

1200

1199

°C

°F

SP.2

SP.E

para

func

Ada

Err

1234

F

KS 92-1 advanced

F

92+0,8

92

+0,8

96

96

10

118

1234

KS 92-1 advanced

F

SP.E

SP.2

run

920.1

921.2

C

para

func

Ada

Err

SP.E

SP.2

run

o

locking switch

Loc open Access to the levels is as adjusted by means of BlueControl(engineering tool) 2

closed 1all levels accessible wihout restriction

1Mounting

aFix the instrument only at top and bottom to avoid damaging it.

Safety switch:

For access to the safety switch, the controller must be withdrawn from the hou-

sing. Squeeze the top and bottom of the front bezel between thumb and forefinger

and pull the controller firmly from the housing.

1Factory setting 2Default setting: display of all levels

suppressed, password PASS =OFF

lCaution! The unit contains ESD-sensitive components.

Mounting

KS 90-1 / KS 92-1 5

%

max.

95% rel.

max. 60°C

0°Cmin.

96 (3.78")

48 (1.89")

Loc

min.48 (1.89")

10 (0.4")

1..10

(0.04..0.4")

118 (4.65")

45 +0,6

(1.77" )

+0.02

92

+0,8

(3.62" )

+0.03

Ü

*

KS 90-1

advanced

1 2 3

è

1200

1199

°C

°F

SP.2

SP.E

para

func

Ada

Err

4

1200

1199

°C

°F

SP.2

SP.E

para

func

Ada

Err

1234

F

KS 92-1 advanced

F

92+0,8

92

+0,8

96

96

10

118

1234

KS 92-1 advanced

F

SP.E

SP.2

run

920.1

921.2

C

para

func

Ada

Err

SP.E

SP.2

run

o

locking switch

Loc open Access to the levels is as adjusted by means of BlueControl(engineering tool) 2

closed 1all levels accessible wihout restriction

MIR-491 MIR-492

ACS-CONTROL-SYSTEM GmbH l Lauterbachstr. 57 l D-84307 Eggenfelden l www.acs-controlsystem.de l [email protected]

6

2Electrical connections

2.1 Connecting diagram

gDependent of order, the controller is fitted with :

wflat-pin terminals 1 x 6,3mm or 2 x 2,8mm to DIN 46 244 or

wscrew terminals for 0,5 to 2,5mm²

On instruments with screw terminals, the insulation must be stripped by min.

12 mm. Choose end crimps accordingly!

Electrical connections

Connecting diagram 6 KS 90-1 / KS 92-1

1

3

4

5

6

7

8

9

10

11

12

13

14

15

17

(2)

(16)

mA

(mV)

(mV)

Volt

mA

INP2

INP3

INP1

di2

di1

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

Option

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

17

(16)

OUT1

OUT2

OUT3

OUT4

90...250V

24 V UC

0%

100%

V

V

mA

HC

KS90-1. -2

5

...

KS90-1. -4...

KS90-1. -5...

KS90-1..-.1...

di2

di3

UT

RXD-B

GND

RXD-A

TXD-B

TXD-A

RS485 RS422

Modbus RTU

RGND

DATA B

DATA A

9

0

8

3

2

17

6

5

4

abc d e

f

g

a

bc

d

e

+24V DC

24V GND

OUT5

OUT6

!

VP (5V)

DGND

RxD/TxD-N

RxD/TxD-P

PROFIBUS-DP

Schirm/

Screen

5

9

4

8

3

7

2

6

1

5

9

4

8

3

7

2

6

1

390 [

390 [

220 [

DGND

VP (5V)

max.

1200m

Adapter

Profibus DP

MIR-49x-1.4...

MIR-49x-1.5...

MIR-49x-1.2...

MIR-49x-1...-1...

ACS-CONTROL-SYSTEM GmbH l Lauterbachstr. 57 l D-84307 Eggenfelden l www.acs-controlsystem.de l [email protected] 7

2.2 Terminal connection

Power supply connection 1

See chapter "Technical data"

Connection of outputs OUT1/2 2

Relay outputs (250V/2A), potential-free

changeover contact

Connection of outputs OUT3/4 3

arelay (250V/2A), potential-free

changeover contact

universal output

bcurrent (0/4...20mA)

cvoltage (0/2...10V)

dtransmitter supply

elogic (0..20mA / 0..12V)

Connection of input INP1 4

Input mostly used for variable x1 (pro-

cess value)

athermocouple

bresistance thermometer (Pt100/ Pt1000/ KTY/ ...)

ccurrent (0/4...20mA)

dvoltage (0/2...10V)

Connection of input INP2 5

fheating current input (0..50mA AC)

or input for ext. set-point (0/4...20mA)

gpotentiometer input for position

feedback

Connection of input INP2 5

aHeating current input (0...50mA AC)

or input for ext. Set-point (0/4...20mA)

bPotentiometer input for position

feedback

Connection of input INP3 6

As input INP1, but without voltage

Connection of inputs di1, di2 7

Digital input, configurable as switch or

push-button

Electrical connections

KS 90-1 / KS 92-1 7 Terminal connection

6

9

10

11

12

13

14

15

1

2

3

4

5

6

7

8

9

10

11

12

13

14

17

(16)

L

N

+

5

43

2

1

8

7

15

2OUT1/2 heating/cooling

L

N

+

_

SSR

3

4

5

6

9

10

11

12

13

14

15

1

2

3

4

5

8

9

10

11

12

13

14

15

17

(16)

2

1

8

7

6

7

Logik

5INP2 current tansformer

ACS-CONTROL-SYSTEM GmbH l Lauterbachstr. 57 l D-84307 Eggenfelden l www.acs-controlsystem.de l [email protected]

8

Connection of inputs di2/3 8(option)

Digital inputs (24VDC external), galvanically isolated, configurable as switch or

push-button

Connection of output UT9(option)

Supply voltage connection for external energization

Connection of outputs OUT5/6 0(option)

Digital outputs (opto-coupler), galvanic isolated, common positive control volta-

ge, output rating: 18...32VDC

Connection of bus interface !(option)

PROFIBUS DP or RS422/485 interface with Modbus RTU protocol

gAnalog outputs OUT3 or OUT4 and transmitter supply UTare connected to

different voltage potentials. Therefore, take care not to make an external galvanic

connection between OUT3/4 and UTwith analog outputs!

Electrical connections

Terminal connection 8 KS 90-1 / KS 92-1

13

14

15

Option

17

(16)

1

3

4

5

6

7

8

9

10

11

12

13

14

15

17

(2)

(16)

+24VDC

5mA

5mA

0V

1

2

3

K

+

-

+

-

17,5V

22mA

14

13

+

-

15

OUT3

10

11

12

J

J

8 9 di2/3, 2-wire transmitter supply

ACS-CONTROL-SYSTEM GmbH l Lauterbachstr. 57 l D-84307 Eggenfelden l www.acs-controlsystem.de l [email protected] 9

* Interface description Modbus RTU in separate manual: see page 72.

Electrical connections

KS 90-1 / KS 92-1 9 Terminal connection

1

2

3

K

+

-

+

-

13V

22mA

13

14

15

11

12 13

17

(16)

14 15

12

11

10

3OUT3 transmitter supply

1

3

4

5

6

7

8

9

10

11

12

13

14

15

17

(2)

(16)

option

1

3

4

5

6

7

8

9

10

11

12

13

14

15

17

(2)

(16)

option

1

3

4

5

6

7

8

9

10

11

12

13

14

15

17

(2)

(16)

option

11

12

13

14

15

10

11

12

13

14

15

10

11

12

13

14

15

RGND RGND RGND

RT

RS485-RS232

converter

PC

DATA A

DATA B

DATA A

DATA B

DATA A

DATA B

J

max. 1000m

"Twisted Pair” cable

10

RT

R=100 Ohm

RGND connection optional

R = 120...200 OhmT

R = 120...200 OhmT

9RS485 interface (with RS232-RS485 interface converter) *

ACS-CONTROL-SYSTEM GmbH l Lauterbachstr. 57 l D-84307 Eggenfelden l www.acs-controlsystem.de l [email protected]

10

KS9x-1 connecting example:

aCAUTION: Using a temperature limiter is recommendable in systems where

overtemperature implies a fire hazard or other risks.

Electrical connections

Terminal connection 10 KS 90-1 / KS 92-1

12

+

_

SSR

+

_

SSR

+

_

SSR

Series connection

Parallel connection

+

_

SSR

+

_

SSR

4V

4V

4V 12V

I =22mA

max

I =22mA

max

12V 11

10

10

11

12

Logic

3OUT3 as logic output with solid-state relay (series and parallel connection)

+

_

L1

L2

N1

N2

Fuse

1

2

3

4

7

5

8

6

9

10

11

12

13

14

15

Fuse

1

Fuse

SSR

Reset-

key

Contactor

Heating

1TB 40-1 Temperaturelimiter

Standard-version (3 Relays):

TB40-100-0000D-000

further versions on requestr

++

3

4

5

6

7

8

9

11

13

14

15

1

2

3

4

5

6

7

8

9

10

11

12

13

14

17

(16)

15

2

1

12

10

Logik

KS90-1

TB 40-1

Temperaturelimiter

KS9x-1 connecting example:

aCAUTION: Using a temperature limiter is recommendable in systems where

overtemperature implies a fire hazard or other risks.

Electrical connections

Terminal connection 10 KS 90-1 / KS 92-1

12

+

_

SSR

+

_

SSR

+

_

SSR

Series connection

Parallel connection

+

_

SSR

+

_

SSR

4V

4V

4V 12V

I =22mA

max

I =22mA

max

12V 11

10

10

11

12

Logic

3OUT3 as logic output with solid-state relay (series and parallel connection)

+

_

L1

L2

N1

N2

Fuse

1

2

3

4

7

5

8

6

9

10

11

12

13

14

15

Fuse

1

Fuse

SSR

Reset-

key

Contactor

Heating

1TB 40-1 Temperaturelimiter

Standard-version (3 Relays):

TB40-100-0000D-000

further versions on requestr

++

3

4

5

6

7

8

9

11

13

14

15

1

2

3

4

5

6

7

8

9

10

11

12

13

14

17

(16)

15

2

1

12

10

Logik

KS90-1

TB 40-1

Temperaturelimiter

MIR-49x

Anschlussbeispiel MIR-49x:

ACS-CONTROL-SYSTEM GmbH l Lauterbachstr. 57 l D-84307 Eggenfelden l www.acs-controlsystem.de l [email protected] 11

3Operation

3.1 Front view

1Statuses of switching outputs OuT.1... 62Process value display

3Setpoint or correcting variable display 4°C or °F display signalling

5Signals ConF- and PArA level 6Signals activated function key

7Selft-tuning active 8Entry into the error list

9Bargraph or plain text display 0Setpoint SP.2 is effective

!Setpoint SP.E is effective "Setpoint gradient is effective

§Manual-automatic switchover: Off: automatic On: manual mode (adjustment possible)

Blinks: manual mode (adjustment not possible (rConF/Cntr/MAn))

$Enter key: call up extented operating level / error list

%Up/ down keys: changing setpoint or correcting variable

&automatic/manual or other functions ( rConF/LOGI)

/freely configurable function key with pure controller operation

(PC connection for BlueControl (engineering tool)

LED colours: LED 1, 2, 3, 4: yellow, Bargraph: red, other LEDs: red

gIn the upper display line, the process value is always displayed. At parameter,

configuration, calibration as well as extended operating level, the bottom display

line changes cyclically between parameter name and parameter value.

Operation

KS 90-1 / KS 92-1 11 Front view

123 4

F

SP.E

SP.2

920.1

921.2

C

para

func

Ada

Err

SP

.E

SP

.2

o

1200

1199

°C

°F

SP.2

SP.E

para

func

Ada

Err

F

1 2 3 4

A

(

1

2

3

4

5

6

$

7

8

%

&

(

/

p

f

9

0

!

§ "

!

2

5

3

4

C

9

0

!

!

§ "

Err

7

8

$

%

&

/

(

6

5

5

6

1

2

3

ACS-CONTROL-SYSTEM GmbH l Lauterbachstr. 57 l D-84307 Eggenfelden l www.acs-controlsystem.de l [email protected]

12

3.2 Behaviour after power-on

After supply voltage switch-on, the unit starts with the operating level.

The unit is in the condition which was active before power-off.

If the controller was in manual mode at supply voltage switch-off, the controller

will re-start with the last output value in manual mode at power-on.

3.3 Operating level

The content of the extended operating level is determined by means of BlueCon-

trol (engineering tool). Parameters which are used frequently or the display of

which is important can be copied to the extended operating level.

Operation

Behaviour after power-on 12 KS 90-1 / KS 92-1

Ò

Ò

Ù

Ù

Ù

Ù

Automatic

Extended operating level

Manual

i

i

only

display

switching

Display

Error list (if error exists)

Y 21

1199

1200

1199

È

Ì

È

Ì

Y 21

1199

1200

1199

È

Ì

FbF.1

126

Err

2

126

Err

time

out

time

out

time

out

ACS-CONTROL-SYSTEM GmbH l Lauterbachstr. 57 l D-84307 Eggenfelden l www.acs-controlsystem.de l [email protected] 13

3.4 Error list / Maintenance manager

With one or several errors, the extended operating le-

vel always starts with the error list. Signalling an ac-

tual entry in the error list (alarm, error) is done by the

Err LED in the display. To reach the error list press

Ùtwice.

Error list:

Operation

KS 90-1 / KS 92-1 13 Error list / Maintenance manager

1200

1199

°C

°F

SP.2

SP.E

para

func

Ada

Err

Err LED status Signification Proceed as follows

blinks

(status 2)Alarm due to

existing error - Determine the error type in the error list

- After error correction the unit changes to status 1

lit

(status 1)Error removed,

alarm not

acknowledged

- Acknowledgethealarmintheerrorlistpressingkey ÈorÌ

- The alarm entry was deleted (status 0).

off

(status 0)No error, all alarm

entries deleted - -Not visible except when acknowledging

Name Description Cause Possible remedial action

E.1 Internal error,

cannot be

removed

- E.g. defective EEPROM - Contact PMA service

- Return unit to our factory

E.2 Internal error,

can be reset - e.g. EMC trouble - Keep measurement and power supply

cables in separate runs

- Ensure that interference suppression

of contactors is provided

E.3 Configuration

error,

can be reset

- wrong configuration

- missing configuration

- Check interaction of configuration /

parameters

E.4 Hardware error - Codenumber and hardware

are not identical

- Contact PMA service

- Elektronic-/Optioncard must be

exchanged

FbF.

1/2/3Sensor break

INP1/2/3 - Sensor defective

- Faulty cabling

- Replace INP1/2/3 sensor

- Check INP1/2/3 connection

Sht.

1/2/3Short circuit

INP1/2/3 - Sensor defective

- Faulty cabling

- Replace INP1/2/3 sensor

- Check INP1/2/3 connection

POL.

1/2/3INP1/2/3

polarity error - Faulty cabling - Reverse INP1/2/3 polarity

HCA Heating current

alarm (HCA) - Heating current circuit

interrupted, I< HC.A or

I> HC.A (dependent of

configuration)

- Heater band defective

- Check heating current circuit

- If necessary, replace heater band

- Service kontaktieren

- Gerät einschicken

- Service kontaktieren

ACS-CONTROL-SYSTEM GmbH l Lauterbachstr. 57 l D-84307 Eggenfelden l www.acs-controlsystem.de l [email protected]

14

gSaved alarms (Err-LED is lit) can be acknowledged and deleted with the digital

input di1/2/3, the è-key or the Ò-key.

Configuration, see page 37: ConF /LOGI /Err.r

gIf an alarm is still valid that means the cause of the alarm is not removed so far

(Err-LED blinks), then other saved alarms can not be acknowledged and deleted.

Operation

Error list / Maintenance manager 14 KS 90-1 / KS 92-1

Name Description Cause Possible remedial action

SSr Heating current

short circuit

(SSR)

- Current flow in heating

circuit with controller off

- SSR defective

- Check heating current circuit

- If necessary, replace solid-state relay

LooP Control loop

alarm (LOOP) - Input signal defective or not

connected correctly

- Output not connected

correctly

- Check heating or cooling circuit

- Check sensor and replace it, if

necessary

- Check controller and switching

device

AdA.H Self-tuning

heating alarm

(ADAH)

- See Self-tuning heating

error status

- see Self-tuning heating error status

AdA.C Self-tuning

heating alarm

cooling (ADAC)

- See Self-tuning cooling

error status

- see Self-tuning cooling error status

dAC DAC-Alarm Actor error see errorstatus DAC-function

LiM.1/

2/3stored limit

alarm 1/2/3 - adjusted limit value 1/2/3

exceeded

- check process

Inf.1 time limit value

message - adjusted number of

operating hours reached

- application-specific

Inf.2 duty cycle

message

(digital ouputs)

- adjusted number of duty

cycles reached

- application-specific

E.5 Internal error in

DP module self-test errorinternal

communication interrupted Switch on the instrument

againContact PMA service

dp.1 No access by bus

master bus errorconnector

problemno bus connection Check cableCheck connectorCheck

connections

dp.2 Faulty

configuration Faulty DP configuration

telegram Check DP configuration telegram in

master

dp.3 Inadmissible

parameter

setting telegram

sent

Faulty DP parameter

setting telegram Check DP parameter setting

telegram in master

dp.4 No data

communication Bus errorAddress

errorMaster stopped Check cable connectionCheck

addressCheck master setting

- Service kontaktieren

ACS-CONTROL-SYSTEM GmbH l Lauterbachstr. 57 l D-84307 Eggenfelden l www.acs-controlsystem.de l [email protected] 15

Self-tuning heating ( ADA.H) and cooling ( ADA.C) error status:

DAC function ( DAC) error status:

Operation

KS 90-1 / KS 92-1 15 Error list / Maintenance manager

Error status Description Behaviour

0No error

3Output is blocked Check the drive for blockage

4Wrong method of operation Wrong phasing, defect motor capacitor

5Fail at Yp measurement Check the connection to the Yp input

6Calibration error Manual calibration necessary

Error

status Description Behaviour

0No error

3Faulty control

action Re-configure controller (inverse idirect)

4No response of

process variable The control loop is perhaps not closed: check sensor,

connections and process

5Low reversal point Increase ( ADA.H) max. output limiting Y.Hi or decrease (

ADA.C) min. output limiting Y.Lo

6Danger of exceeded

set-point (parameter

determined)

If necessary, increase (inverse) or reduce (direct) set-point

7Output step change

too small (dy > 5%) Increase ( ADA.H) max. output limiting Y.Hi or reduce (

ADA.C) min. output limiting Y.Lo

8Set-point reserve too

small Acknowledgment of this error message leads to switch-over to

automatic mode.If self-tuning shall be continued,

increase set-point (invers), reduce set-point (direct)

or decrease set-point range

(rPArA /SEtp /SP.LO and SP.Hi )

ACS-CONTROL-SYSTEM GmbH l Lauterbachstr. 57 l D-84307 Eggenfelden l www.acs-controlsystem.de l [email protected]

16

3.5 Self-tuning

For determination of optimum process parameters, self-tuning is possible.

After starting by the operator, the controller makes an adaptation attempt, where-

by the process characteristics are used to calculate the parameters for fast line-out

to the set-point without overshoot.

The following parameters are optimized when self-tuning:

Parameter set 1:

Pb1 - Proportional band 1 (heating) in engineering units [e.g. °C]

ti1 - Integral time 1 (heating) in [s]ronly, unless set to OFF

td1 - Derivative time 1 (heating) in [s]ronly, unless set to OFF

t1 - Minimum cycle time 1 (heating) in [s]ronly, unless Adt0 was

set to “no self-tuning” during configuration by means of

BlueControl®.

Pb2 - Proportional band 2 (cooling) in engineering units [e.g. °C]

ti2 - Integral time 2 (cooling) in [s]ronly, unless set to OFF

td2 - Derivative time 2 (cooling) in [s]ronly, unless set to OFF

t2 - Minimum cycle time 2 (cooling) in [s] ronly, unless Adt0

was set to “no self-tuning” during configuration by means of

BlueControl®.

Parameter set 2: analogous to parameter set 1 (see page 25)

3.5.1 Preparation for self-tuning

wAdjust the controller measuring range as control range limits. Set values

rnG.L and rnG.H to the limits of subsequent control.

(ConfigurationrControllerrlower and upper control range limits)

ConFrCntrrrnG.L and rnG.H

wDetermine which parameter set shall be optimized.

-The instantaneously effective parameter set is optimized.

rActivate the relevant parameter set (1 or 2).

wDetermine which parameter set shall be optimized (see tables above).

wSelect the self-tuning method

see chapter 3.5.3

-Step attempt after start-up

-Pulse attempt after start-up

-Optimization at the set-point

Operation

Self-tuning 16 KS 90-1 / KS 92-1

ACS-CONTROL-SYSTEM GmbH l Lauterbachstr. 57 l D-84307 Eggenfelden l www.acs-controlsystem.de l [email protected] 17

3.5.2 Optimization after start-up or at the set-point

The two methods are optimization after start-up and at the set-point.

As control parameters are always optimal only for a limited process range, vari-

ous methods can be selected dependent of requirements. If the process behaviour

is very different after start-up and directly at the set-point, parameter sets 1 and 2

can be optimized using different methods. Switch-over between parameter sets

dependent of process status is possible (see page ).

Optimization after start-up: (see page 4)

Optimization after start-up requires a certain separation between process value

and set-point. This separation enables the controller to determine the control pa-

rameters by evaluation of the process when lining out to the set-point.

This method optimizes the control loop from the start conditions to the set-point,

whereby a wide control range is covered.

We recommend selecting optimization method “Step attempt after start-up”

with tunE = 0 first. Unless this attempt is completed successfully, we recom-

mend a “Pulse attempt after start-up”.

Optimization at the set-point: (see page 18)

For optimizing at the set-point, the controller outputs a disturbance variable to the

process. This is done by changing the output variable shortly. The process value

changed by this pulse is evaluated. The detected process parameters are conver-

ted into control parameters and saved in the controller.

This procedure optimizes the control loop directly at the set-point. The advantage

is in the small control deviation during optimization.

3.5.3 Selecting the method ( ConF/Cntr/tunE)

Selection criteria for the optimization method:

Step attempt after start-up Pulse attempt after

start-up Optimization at the

set-point

tunE = 0 sufficient set-point reserve

is provided sufficient set-point reserve is

not provided

tunE = 1 sufficient set-point

reserve is provided sufficient set-point reserve is

not provided

tunE = 2 always step attempt after

start-up

Sufficient set-point reserve:

inverse controller:(with process value < set-point- (10% of rnGH -rnGL)

direct controller: (with process value > set-point + (10% of rnGH -rnGL)

Operation

KS 90-1 / KS 92-1 17 Self-tuning

ACS-CONTROL-SYSTEM GmbH l Lauterbachstr. 57 l D-84307 Eggenfelden l www.acs-controlsystem.de l [email protected]

18

3.5.4 Step attempt after start-up

Condition: - tunE = 0 and sufficient set-point reserve provided

or - tunE = 2

The controller outputs 0% correcting variable or Y.Lo and waits, until the process

is at rest (see start-conditions on page 8).

Subsequently, a correcting variable step change to 100% is output.

The controller attempts to calculate the optimum control parameters from the pro-

cess response. If this is done successfully, the optimized parameters are taken

over and used for line-out to the set-point.

With a 3-point controller, this is followed by “cooling”.

After completing the 1st step as described, a correcting variable of -100% (100%

cooling energy) is output from the set-point. After successfull determination of

the “cooling parameters”, line-out to the set-point is using the optimized parame-

ters.

3.5.5 Pulse attempt after start-up

Condition: - tunE = 1 and sufficient set-point reserve provided.

The controller outputs 0% correcting variable or Y.Lo and waits, until the process

is at rest (see start conditions page 8)

Subsequently, a short pulse of 100% is output (Y=100%) and reset.

The controller attempts to determine the optimum control parameters from the

process response. If this is completed successfully, these optimized parameters

are taken over and used for line-out to the set-point.

With a 3-point controller, this is followed by “cooling”.

After completing the 1st step as described and line-out to the set-point, correcting

variable "heating" remains unchanged and a cooling pulse (100% cooling energy)

is output additionally. After successful determination of the “cooling parame-

ters”, the optimized parameters are used for line-out to the set-point.

3.5.6 Optimization at the set-point

Conditions:

wA sufficient set-point reserve is not provided at self-tuning start (see page 17).

wtunE is 0 or 1

wWith Strt =1configured and detection of a process value oscillation by

more than 0,5% of (rnG.H -rnG.L) by the controller, the control

parameters are preset for process stabilization and the controller realizes an

optimization at the set-point (see figure “Optimization at the set-point”).

wwhen the step attempt after power-on has failed

wwith active gradient function ( PArA/SETP/r.SPOFF), the set-point

gradient is started from the process value and there isn't a sufficient set-point

reserve.

Operation

Self-tuning 18 KS 90-1 / KS 92-1

ACS-CONTROL-SYSTEM GmbH l Lauterbachstr. 57 l D-84307 Eggenfelden l www.acs-controlsystem.de l [email protected] 19

Optimization-at-the-set-point procedure:

The controller uses its instantaneous parameters for control to the set-point. In li-

ned out condition, the controller makes a pulse attempt. This pulse reduces the

correcting variable by max. 20% 1, to generate a slight process value unders-

hoot. The changing process is analyzed and the parameters thus calculated are re-

corded in the controller. The optimized parameters are used for line-out to

theset-point.

With a 3-point controller, optimization for the “heating“ or “cooling” parameters

occurs dependent of the instantaneous condition.

These two optimizations must be started separately.

1If the correcting variable is too low for reduction in lined out condition it is

increased by max. 20%.

Operation

KS 90-1 / KS 92-1 19 Self-tuning

set-point

process value

correcting

variable

Optimization at the set-point

ACS-CONTROL-SYSTEM GmbH l Lauterbachstr. 57 l D-84307 Eggenfelden l www.acs-controlsystem.de l [email protected]

20

3.5.7 Optimization at the set-point for 3-point stepping controller

With 3-point stepping controllers, the pulse attempt can be made with or without

position feedback. Unless feedback is provided, the controller calculates the mo-

tor actuator position internally by varying an integrator with the adjusted actuator

travel time. For this reason, precise entry of the actuator travel time (tt), as time

between stops is highly important. Due to position simulation, the controller

knows whether an increased or reduced pulse must be output. After supply volta-

ge switch-on, position simulation is at 50%. When the motor actuator was varied

by the adjusted travel time in one go, internal calculation occurs, i.e. the position

corresponds to the simulation:

Simulation actual position

Internal calculation

tt

Internal calculation always occurs, when the actuator was varied by travel time

tt in one go , independent of manual or automatic mode. When interrupting the

variation, internal calculation is cancelled. Unless internal calculation occurred

already after self-tuning start, it will occur automatically by closing the actuator

once.

Unless the positioning limits were reached within 10 hours, a significant deviati-

on between simulation and actual position may have occurred. In this case, the

controller would realize minor internal calculation, i.e. the actuator would be clo-

sed by 20 %, and re-opened by 20 % subsequently. As a result, the controller

knows that there is a 20% reserve for the attempt.

Operation

Self-tuning 20 KS 90-1 / KS 92-1

Other manuals for MIR-491

1

This manual suits for next models

1

Table of contents

Other ACS contsys Controllers manuals

Popular Controllers manuals by other brands

COLORKINETICS

COLORKINETICS ColorDial Pro installation instructions

Atronix

Atronix X45/10 Installation and operating instructions

Timeguard

Timeguard TS900B operating instructions

Show Tec

Show Tec PLE-30-040 user manual

SMART-AVI

SMART-AVI EZ-WALL 2X2L user manual

Contro l4

Contro l4 C4-EA5 installation guide