ACS contsys MIR-491 User manual

MIR-491

MIR-49

1

Industrial and process controller MIR-491

Operating manual

English

BAL-491-65511

Valid from: 07/2002

ACS-Control System GmbH

© ACS-Control System GmbH •Printed in Germany (0207)

All rights reserved. No part of this document may be reproduced or published in any form or by any means

without prior written permission from the copyright owner.

A publication of ACS-Control System GmbH

Lauterbachstraße 57 1/2

D-84307 Eggenfelden

Germany

BlueControl

More efficiency in engineering,

more overview in operating:

The projecting environment for the controller MIR-491

ATTENTION!

Mini Version and Updates on

www.acs-controlsystem.d

e

Description of symbols:

gGeneral information

aGeneral warning

lAttention: ESD sensitive devices

Contents

1Mounting ..............................5

2Electrical connections .......................6

2.1 Connecting diagram .........................6

2.2 Terminal connection.........................7

3Operation .............................10

3.1 Front view .............................10

3.2 Behaviour after power-on .....................11

3.3 Operating level ...........................11

3.4 Mainenance manager / Error list ..................12

3.5 Self-tuning .............................14

3.5.1 Selecting the method ( ConF/Cntr/tunE).............15

3.5.2 Self-tuning start .............................15

3.5.3 Optimization at the set-point ......................16

3.5.4 Self-tuning cancellation .........................17

3.5.5 Acknowledgement procedures in case of unsuccessful self-tuning. . . 17

3.5.6 Examples for self-tuning attempts ...................17

3.6 Manual self-tuning .........................19

3.7 Alarm handling...........................20

3.8 Operating structure.........................21

4Configuration level ........................22

4.1 Configuration survey........................22

4.2 Configuration parameters .....................23

4.3 Set-point processing ........................39

4.4 MIR-491 cooling functions ....................40

4.4.1 Standard ( CyCl=0) .........................40

4.4.2 Water cooling linear ( CyCl=1)...................40

4.4.3 Water cooling non-linear ( CyCl=2).................41

4.4.4 Heating and cooling with constant period ( CyCl=3)........42

4.5 Configuration examples ......................43

4.5.1 Signaller (inverse) ............................43

4.5.2 2-point controller (inverse) .......................44

4.5.3 3-point controller (relay & relay) ....................45

4.5.4 3-point stepping controller (relay & relay) ...............46

4.5.5 Continuous controller (inverse) .....................47

4.5.6 ∆-Y - Off controller ..........................48

4.5.7 MIR-491 with measured value output..................49

5Parameter setting level ......................50

5.1 Parameter survey ..........................50

5.2 Parameters .............................51

5.3 Input scaling ............................53

5.3.1 Input Inp.1 and InP.3 ........................54

5.3.2 Input InP.2...............................54

5.4 Second set of parameters......................54

6Calibration level .........................55

7Special functions .........................58

7.1 DAC®– motor actuator monitoring ...............58

7.2 MIR-491 as Modbus master ....................60

8BlueControl ............................61

9Versions ..............................62

10 Technical data...........................63

11 Safety hints ............................68

11.1 Resetting to factory setting.....................69

12 Notes ................................70

13 Index ................................74

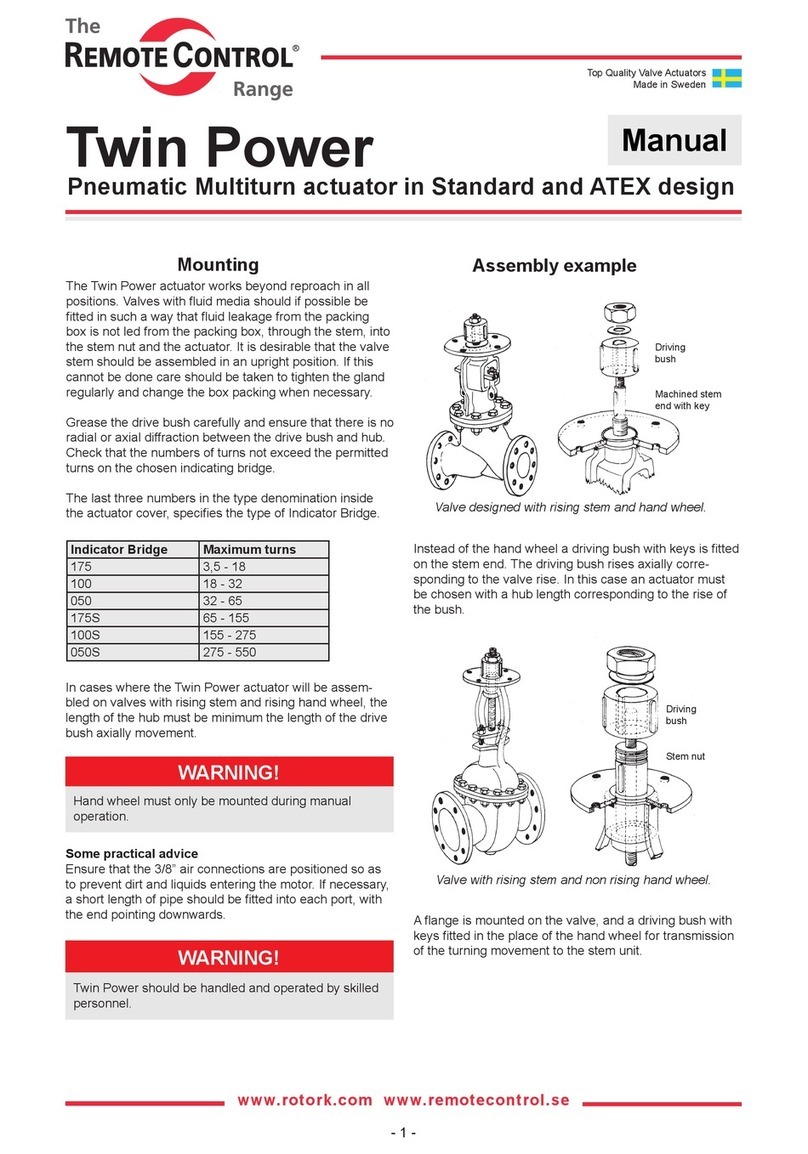

1Mounting

Safety switch:

For access to the safety switch, the controller must be withdrawn from the

housing. Squeeze the top and bottom of the front bezel between thumb and

forefinger and pull the controller firmly from the housing.

1Factory setting 2Default setting: display of all levels

suppressed, password PASS =OFF

lCaution! The unit contains ESD-sensitive components.

Mounting

Operating manual MIR-491 5

or:

%

max.

95% rel.

max. 60°C

0°Cmin.

96 (3.78")

48 (1.89")

Loc

min.48 (1.89")

10 (0.4")

1..10

(0.04..0.4")

118 (4.65")

45

+0,6

(1.77" )

+0.02

92

+0, 8

(3.62" )

+0. 03

*

Ü

*

Ü

Safety switch

MIR-491

123

è

1200

1199

°C

°F

SP.2

SP.E

para

func

Ada

Err

4

Loc open Access to the levels is as adjusted by means of

BlueControl (engineering tool) 2

closed 1all levels accessible wihout restriction

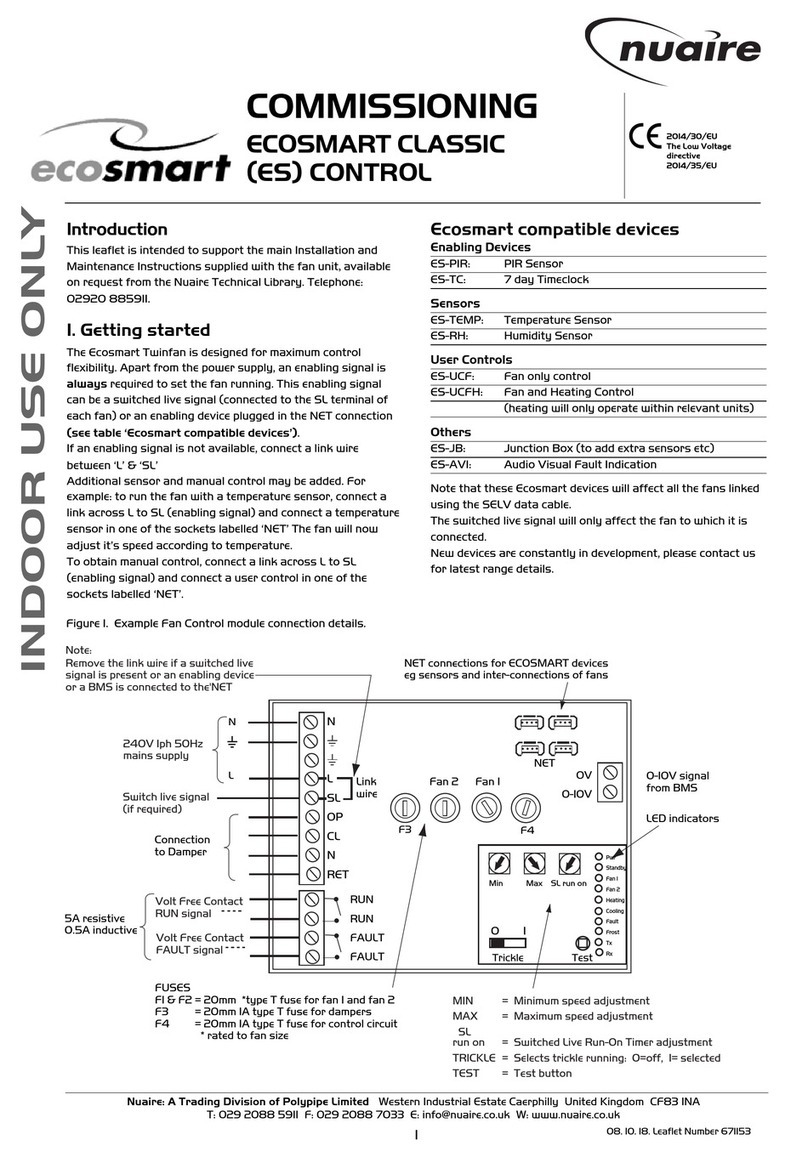

2Electrical connections

2.1 Connecting diagram

gThe controller is fitted with flat-pin terminals 1 x 6,3mm or 2 x 2,8mm

to DIN 46 244

Electrical connections

Connecting diagram 6 Operating manual MIR-491

1

3

4

5

6

7

8

9

10

11

12

13

14

15

17

(2)

(16)

mA

(mV)

(mV)

Volt

mA

INP2

INP3

INP1

di2

di1

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

Option

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

17

(16)

OUT1

OUT2

OUT3

OUT4

90...250V

24VUC

0%

100%

V

V

mA

HC

KS90-1. -2

5

...

KS90-1. -4...

KS90-1. -5...

KS90-1..-.1...

di2

di3

UT

RXD-B

GND

RXD-A

TXD-B

TXD-A

RS485 RS422

Modbus RTU

RGND

DATA B

DATA A

9

0

8

3

2

17

6

5

4

abcd

e

a

b

a

bc

d

e

+24V DC

24V GND

OUT5

OUT6

!

2.2 Terminal connection

Power supply connection 1

See chapter 10 "Technical data"

Connection of outputs OUT1/2 2

Relay outputs (250V/2A), potential-free

changeover contact

Connection of outputs OUT3/4 3

arelay (250V/2A), potential-free

changeover contact

universal output

bcurrent (0/4...20mA)

cvoltage (0/2...10V)

dtransmitter supply

elogic (0..20mA / 0..12V)

Connection of input INP1 4

Input for variable x1 (process value)

athermocouple

bresistance thermometer (Pt100/ Pt1000/ KTY/ ...)

ccurrent (0/4...20mA)

dvoltage (0/2...10V)

Connection of input INP2 5

aHeating current input (0...50mA AC)

or input for ext. set-point

(0/4...20mA)

bPotentiometer input for position

feedback

Connection of input INP3 6

As input INP1, but without voltage

Connection of inputs di1, di2 7

Digital input, configurable as switch or

push-button

Connection of inputs di2/3 8(option)

Digital inputs (24VDC external),

galvanically isolated, configurable as switch or push-button

Electrical connections

Operating manual MIR-491 7 Terminal connection

L

N

+

_

SSR

3

4

5

6

9

10

11

12

13

14

15

1

2

3

4

5

8

9

10

11

12

13

14

15

17

(16)

2

1

8

7

6

7

Logik

5INP2 current tansformer

6

9

10

11

12

13

14

15

1

2

3

4

5

6

7

8

9

10

11

12

13

14

17

(16)

L

N

+

5

43

2

1

8

7

15

2OUT1/2 heating/cooling

Connection of output UT9(option)

Supply voltage connection for external energization

Connection of outputs OUT5/6 0(option)

Digital outputs (opto-coupler), galvanic isolated, common positive control

voltage, output rating: 18...32VDC

Connection of bus interface !(option)

RS422/485 interface with Modbus RTU protocol

aIf the universal output OUT3 or

OUT4 is used there may be no

external galvanic connection

between measuring and output

circuits!

* Interface description Modbus RTU in speperate manual: see page 62.

Electrical connections

Terminal connection 8 Operating manual MIR-491

1

2

3

K

+

-

+

-

13V

22mA

13

14

15

11

12 13

17

(16)

14

15

12

11

10

3OUT3 transmitter supply

13

14

15

Option

17

(16)

1

3

4

5

6

7

8

9

10

11

12

13

14

15

17

(2)

(16)

+24VDC

5mA

5mA

0V

1

2

3

K

+

-

+

-

17,5V

22mA

14

13

+

-

15

OUT3

10

11

12

x

J

J

89 di2/3, 2-wire transmitter supply

1

3

4

5

6

7

8

9

10

11

12

13

14

15

17

(2)

(16)

option

1

3

4

5

6

7

8

9

10

11

12

13

14

15

17

(2)

(16)

option

1

3

4

5

6

7

8

9

10

11

12

13

14

15

17

(2)

(16)

option

11

12

13

14

15

10

11

12

13

14

15

10

11

12

13

14

15

RGND RGND RGND

RT

RS485-RS232

converter

PC

DATA A

DATA B

DATA A

DATA B

DATA A

DATA B

J

max. 1000m

"Twisted Pair” cable

10

RT

R=100 Ohm

RGND connection optional

R = 120...200 OhmT

R = 120...200 OhmT

9RS485 interface (with RS232-RS485 interface converter) *

MIR-491 connecting example:

aCAUTION: Using a temperature limiter is recommendable in

systems where overtemperature implies a fire hazard or

other risks.

Electrical connections

Operating manual MIR-491 9 Terminal connection

12

+

_

SSR

+

_

SSR

+

_

SSR

Series connection

Parallel connection

+

_

SSR

+

_

SSR

4V

4V

4V 12V

I =22mA

max

I =22mA

max

12V 11

10

10

11

12

Logic

3OUT3 as logic output with solid-state relay (series and parallel connection)

+

_

L

1

L2

N1

N2

Fuse

1

2

3

4

7

5

8

6

9

10

11

12

13

14

15

Fuse

TB 40-1

Temperature limiter

1

Fuse

SSR

Reset

key

Contactor

Heating

1TB 40-1 Temperature limiter

Standard version (3 relays):

TB40-100-0000D-000

Product of the PMA Prozeß- und

Maschinen-Automation GmbH

r

++

3

4

5

6

7

8

9

11

13

14

15

1

2

3

4

5

6

7

8

9

10

11

12

13

14

17

(16)

15

2

1

12

10

Logik

MIR-491

3Operation

3.1 Front view

LED colours:

LED 1, 2, 3, 4: yellow

Bargraph: red

other LEDs: red

gIn the upper display line, the process value is always displayed. At parameter,

configuration, calibration as well as extended operating level, the bottom display

line changes cyclically between parameter name and parameter value.

Operation

Front view 10 Operating manual MIR-491

MIR-491

123

(

1

2

3

4

5

6

$

7

8

%

&

(

è

è

è

/

1200

1199

°C

°F

SP.2

SP.E

para

func

Ada

Err

4

6

7

7

8

3

4

5

9

0

SP.2

E

§" !

rr

§"

"

1Status of switching outputs

OuT.1... 6

2Process value display

3Set-point, controller output

4Signals display on °C or °F

5Signals ConF and PArA level

6Signals aktive function key

7Self-tuning active

8Entry in error list

9Bargraph or clear text display

0SP.2 is effective

!SP.E is effective

"Set-point gradient effective

§Manual/automatic switch-over:

Off: Automatic

On: Manual

(changing possible)

Blinks: Manual

(changing not possible

(rConF/Cntr/MAn)

$Enter key:

calls up extended operating

level / error list

%Up/down keys:

changing the set-point or the

controller output value

&Manual mode /spec. function

(→ConF /LOGI )

/Freely programmable function

key

(PC connection for

BlueControl (engineering

tool)

3.2 Behaviour after power-on

After supply voltage switch-on, the unit starts with the operating level.

The unit is in the condition which was active before power-off.

If MIR-491 was in manual mode before power-off, the controller starts with

correcting value Y2 after switching on again.

3.3 Operating level

The content of the extended operating level is determined by means of

BlueControl (engineering tool). Parameters which are used frequently or the

display of which is important can be copied to the extended operating level.

Operation

Operating manual MIR-491 11 Behaviour after power-on

Ò

Ò

Ù

Ù

Ù

Ù

A

utomat

i

c

Extended operating level

M

anua

l

i

i

only

display

switching

Display

Error list (if error exists)

Y21

1199

1200

1199

È

Ì

È

Ì

Y21

1199

1200

1199

È

Ì

FbF.1

126

Err

2

126

Err

time

out

time

out

time

out

3.4 Mainenance manager / Error list

With one or several errors, the extended operating level

always starts with the error list. Signalling an actual entry

in the error list (alarm, error) is done by the Err LED in

the display. To reach the error list press Ùtwice.

Error list:

Operation

Mainenance manager / Error list 12 Operating manual MIR-491

1200

1199

°C

°F

SP.2

SP.E

para

func

Ada

Err

Err LED status Signification Proceed as follows

blinks Alarm due to existing error -Determine the error type in the error list

via the error number

-Remove the error

lit Error removed,

Alarm not acknowledged -Acknowledge the alarm in the error list

pressing key Èor Ì

-The alarm entry was deleted.

off No error,

all alarm entries deleted

Name Description Cause Possible remedial action

E.1 Internal error,

cannot be removed - E.g. defective EEPROM - Contact ACS service

- Return unit to our factory

E.2 Internal error, can be reset - e.g. EMC trouble - Keep measurement and power

supply cables in separate runs

- Ensure that interference

suppression of contactors is

provided

E.3 Configuration error,

can be reset -wrong configuration

-missing configuration

-Check interaction of

configuration / parameters

FbF.1 Sensor break INP1 -Sensor defective

-Faulty cabling

-Replace INP1 sensor

-Check INP1 connection

Sht.1 Short circuit INP1 -Sensor defective

-Faulty cabling

-Replace INP1 sensor

-Check INP1 connection

POL.1 INP1polarity error -Faulty cabling -Reverse INP1 polarity

FbF.2 Sensor break INP2 -Sensor defective

-Faulty cabling

-Replace INP2 sensor

-Check INP2 connection

Sht.2 Short circuit INP2 -Sensor defective

-Faulty cabling

-Replace sensor INP2

-Check INP2 connection

POL.2 INP2 polarity -Faulty cabling -Reverse INP2 polarity

FbF.3 Sensor break INP3 -Sensor defective

-Faulty cabling

-Replace INP3 sensor

-Check INP3 connection

Sht.3 Short circuit INP3 -Sensor defective

-Faulty cabling

-Replace sensor INP3

-Check INP3 connection

POL.3 INP3 polarity -Faulty cabling -Reverse INP3 polarity

gSaved alarms (Err-LED is lit) can be acknowledged and deleted with the digital

input di1/2/3, the è-key or the Ò-key.

Configuration, see page 30: ConF /LOGI /Err.r

gIf an alarm is still valid that means the cause of the alarm is not removed so far

(Err-LED blinks), then other saved alarms can not be acknowledged and deleted.

Error status:

Operation

Operating manual MIR-491 13 Mainenance manager / Error list

Name Description Cause Possible remedial action

HCA Heating current alarm (HCA) -Heating current circuit

interrupted, I< HC.A or I>

HC.A (dependent of

configuration)

-Heater band defective

-Check heating current circuit

-If necessary, replace heater

band

SSr Heating current short circuit

(SSR) -Current flow in heating circuit

with controller off

-SSR defective

-Check heating current circuit

-If necessary, replace

solid-state relay

LooP Control loop alarm (LOOP) -Input signal defective or not

connected correctly

-Output not connected correctly

-Check heating or cooling

circuit

-Check sensor and replace it, if

necessary

-Check controller and

switching device

AdA.H Self-tuning heating alarm

(ADAH) -See Self-tuning heating error

status

-see Self-tuning heating error

status

AdA.C Self-tuning heating alarm

cooling (ADAC) - See Self-tuning cooling error

status

- see Self-tuning cooling error

status

LiM.1 stored limit alarm 1 - adjusted limit value 1 exceeded - check process

Lim.2 stored limit alarm 2 - adjusted limit value 2 exceeded - check process

Lim.3 stored limit alarm 3 - adjusted limit value 3 exceeded - check process

Inf.1 time limit value message - adjusted number of operating

hours reached

- application-specific

Inf.2 duty cycle message

(digital ouputs) - adjusted number of duty cycles

reached

- application-specific

Error status Signification

2Existing error Change to error status 1 after error removal

1Stored error Change to error status 0 after acknowledgement in error list

0No error/message not visible, except with acknowledgement

Self-tuning heating ( ADA.H) and cooling ( ADA.C) error status:

DAC function ( DAC) error status:

3.5 Self-tuning

After starting by the operator, the controller makes a self-tuning attempt. The

controller uses the process characteristics for quick line-out to the set-point

without overshoot.

gSelf-tuning start can be locked via BlueControl (engineering tool) ( P.Loc).

gti and td are taken into account only, if they were ≠OFF previously.

Operation

Self-tuning 14 Operating manual MIR-491

Error status Description Behaviour

0No error

3Faulty control action Re-configure controller (inverse idirect)

4No response of process

variable The control loop is perhaps not closed: check sensor,

connections and process

5Low reversal point Increase ( ADA.H) max. output limiting Y.Hi or

decrease ( ADA.C) min. output limiting Y.Lo

6Danger of exceeded set-point

(parameter determined) If necessary, increase (inverse) or reduce (direct) set-point

7Output step change too small

(dy > 5%) Increase ( ADA.H) max. output limiting Y.Hi or reduce

(ADA.C) min. output limiting Y.Lo

8Set-point reserve too small Increase set-point (invers), reduce set-point (direct)

or increase set-point range

(rPArA /SEtp /SP.LO and SP.Hi )

9Impulse tuning failed The control loop is perhaps not closed: check sensor,

connections and process

Error status Description Behaviour

0No error

3Output is blocked Check the drive for blockage

4Wrong method of operation Wrong phasing, defect motor capacitor

5Fail at Yp measurement Check the connection to the Yp input

6Calibration error Manual calibration necessary

3.5.1 Selecting the method ( ConF/Cntr/tunE)

tunE =0Step attempt during start-up (if X SP - 60 K):

The controller outputs 0% or Y.Lo and waits, until the process

is at rest. This is followed by:

2-point controller: step attempt for heating loop. Then,

the determined parameters are used for

line-out to the set-point.

3-point controller:as2-point controller. Now, the heating

output is frozen and a cooling pulse

(100%) for the cooling loop is output.

After determination of cooling parameters,

control is continued using the heating

and cooling parameters.

tunE =1Pulse attempt during start-up (if X SP - 60 K):

Controller outputs 0% or Y.Lo and waits, until the process is

at rest. This is followed by:

2-point controller: pulse attempt (100%) for heating loop.

followed by line-out to the set-point using

the determined parameters.

3-point controller:as2-point controller. The heating output

is frozen and a cooling pulse (100%) for

the cooling loop is output.

After determination of cooling parameters,

control is continued using the heating

and cooling parameters.

tunE =2Always step attempt during start-up: see TunE =0

gWith 3-point stepping controller configured, only the step attempt after start-up

is available for self-tuning ( tunE =0).

3.5.2 Self-tuning start

Strt =0Only manual start by pressing keys Ùand È

simultaneously or via interface is possible.

Strt =1Manual start by press keys Ùand Èsimultaneously

via interface and automatic start after power-on and detection

of process oscillations.

gIf the process value is higher than the set-point minus 60 K (X ≥SP-60K)and

self-tuning is started manually, the control to the set-point is using the old

parameters followed by an optimization at the set-point.

Operation

Operating manual MIR-491 15 Self-tuning

gIf the process value is smaller than the set-point minus 60 K (X ≤SP-60K),

self-tuning after start-up is done automatically by the controller ( tunE =0/1).

gIf the controller detects process oscillations of more than ±2,5K with

Strt =1configured, the control parameters are preset for calming the process

followed by optimization at the set-point.

3.5.3 Optimization at the set-point

With the difference between process value and set-point smaller than 60 K and

self-tuning started manually, optimization at the set-point is used.

For this, control to the set-point is using the control parameters.

When the process value has reached the set-point, a pulse attempt with reduced

correcting variable (for process protection, max. 20%) is made with the active

loop (Y>0 heating pulse, Y<0 cooling pulse). I.e. by optimization at the

set-point, the optimum control parameters either for the heating or the cooling

loop are determined.

The correcting variable pulse can be output by the controller in positive or

negative direction. If possible, the controller outputs a pulse in negative direction

(process protection against temperature increase).

+In which case does the controller use the optimization at the set-point?

wProcess ≥set-point - 60K with manual self-tuning start

wafter step attempt failure after start-up or power-on

wwith active gradient ( PArA/SETP/r.SP≠OFF) and manual self-tuning

start or self-tuning start after power on

wwith active start-up circuit ( ConF /Cntr /SP.Fn =10) and manual

self-tuning start or self-tuning start after power-on

Operation

Self-tuning 16 Operating manual MIR-491

Ada LED status Signification

blinks Waiting, until process

calms down

lit Self-tuning is running

off Self-tuning not activ

or ended

1200

1199

°C

°F

SP.2

SP.E

para

func

Ada

Err

3.5.4 Self-tuning cancellation

By the operator:

Self-tuning can always be cancelled by the operator. For this, press Ùand È

key simultaneously. With manual-automatic switch-over configured via Òkey,

self-tuning can also be canceled by actuating Òkey. The controller continues

operating with the old parameters in automatic mode in the first case and in

manual mode in the second case.

By the controller:

If the Err LED starts blinking whilst self-tuning is running, successful self-tuning

is prevented due to the control conditions. In this case, self-tuning was cancelled

by the controller. The controller continues operating with the old parameters in

automatic mode. In manual mode it continues with the old controller output

value.

3.5.5 Acknowledgement procedures in case of unsuccessful self-tuning

1. Press keys Ùand Èsimultaneously:

The controller continues controlling using the old parameters in automatic

mode. The Err LED continues blinking, until the self-tuning error was

acknowledged in the error list.

2. Press key Ò(if configured):

The controller goes to manual mode. The Err LED continues blinking,

until the self-tuning error was acknowleged in the error list.

3. Press key Ù:

Display of error list at extended operating level. After acknowledgement

of the error message, the controller continues control in automatic mode using

the old parameters.

Cancellation causes:

rpage 14: "Error status self-tuning heating ( ADA.H) and cooling ( ADA.C)"

3.5.6 Examples for self-tuning attempts

(controller inverse, heating or heating/cooling)

Start: heating power switched on

Heating power Y is switched off (1).

When the change of process value X

was constant during one minute (2),

the power is switched on (3).

At the reversal point, the self-tuning

attempt is finished and the new

parameter are used for controlling to

set-point W.

Operation

Operating manual MIR-491 17 Self-tuning

t

2

100%

Y

0%

X

W

Start r13treversal point

blinks

Start: heating power switched off

The controller waits 1,5 minutes (1).

Heating power Y is switched on (2).

At the reversal point, the self-tuning

attempt is finished and control to the

set-point is using the new parameters.

Self-tuning at the set-point a

The process is controlled to the

set-point. With the control deviation

constant during a defined time (1),

i.e. with the process value equal to the

set-point, the controller outputs a

reduced correcting variable pulse

(max. 20%) (2). After determination

of the control parameters using the

process characteristic (3), control is

started using the new parameters

(4).

Three-point controller a

The parameter for heating and cooling

are determined in two attempts. The

heating power is switched on (1).

Heating parameters Pb1,ti1,

td1 and t1 are determined at the

reversal point. The process is

controlled to the set-point (2). With

constant control deviation, the

controller provides a cooling

correcting variable pulse (3). After

determining its cooling parameters Pb2,ti2,td2 and t2 (4) from the

process characteristics , control operation is started using the new parameters

(5).

aDuring phase 3, heating and cooling are done simultaneously!

Operation

Self-tuning 18 Operating manual MIR-491

t

100%

Y

0%

X

W

start r12treversal point

blinks

t

2

100%

Y

0%

X

W

13

blinks

4

rt

Start r

t

+100%

Y0%

-100%

X

W

treversal

point

Start r12

3

45

rt

3.6 Manual self-tuning

The optimization aid should be used with units on which the control parameters

shall be set without self-tuning.

For this, the response of process variable x after a step change of correcting

variable y can be used. Frequently, plotting the complete response curve (0 to

100%) is not possible, because the process must be kept within defined limits.

Values Tgand xmax (step change from 0 to 100 %) or ∆t and ∆x (partial step

response) can be used to determine the maximum rate of increase vmax.

The control parameters can be determined from the values calculated for delay

time Tu, maximum rate of increase vmax, control range Xhand characteristic K

according to the formulas given below. Increase Xp, if line-out to the set-point

oscillates.

Operation

Operating manual MIR-491 19 Manual self-tuning

Formulas

K = Vmax * Tu controller behavior Pb1 [phy. units] td1 [s] ti1 [s]

With 2-point and

3-point controllers,

the cycle time must be

adjusted to

t1 /t2 ≤0,25 * Tu

PID 1,7*K 2*Tu 2*Tu

PD 0,5 * K Tu OFF

PI 2,6 * K OFF 6*Tu

PKOFF OFF

3-point-stepping 1,7 * K Tu 2 * Tu

Parameter adjustment effects

Parameter Control Line-out of disturbances Start-up behaviour

Pb1 higher increased damping slower line-out slower reduction of duty cycle

lower reduced damping faster line-out faster reduction of duty cycle

td1 higher reduced damping faster response to disturbances faster reduction of duty cycle

lower increased damping slower response to disturbances slower reduction of duty cycle

ti1 higher increased damping slower line-out slower reduction of duty cycle

lower reduced damping faster line-out faster reduction of duty cycle

Tu

Tg

t

x

y

100%

0%

t

Yh

Xmax

{X

{t

y = correcting variable

Yh= control range

Tu = delay time (s)

Tg = recovery time (s)

Xmax = maximum process value

Vmax =Xmax

Tg ={

{

x

t=max. rate of

increase of process value

3.7 Alarm handling

Max. three alarms can be configured and assigned to the individual outputs.

Generally, outputs OuT.1... OuT.6 can be used each for alarm signalling. If

more than one signal is linked to one output the signals are OR linked. Each of

the 3 limit values Lim.1 …Lim.3 has 2 trigger points H.x (Max) and L.x (Min),

which can be switched off individually (parameter = “OFF”). Switching

difference HYS.xof each limit value is adjustable.

1: normally closed ( ConF/Out.x/O.Act=1)

2: normally open ( ConF/Out.x/O.Act=0)

Operation

Alarm handling 20 Operating manual MIR-491

L.1

LED LED

HYS.1 HYS.1

H.1

InL.1 InH.1

SP

22

1

H.1

LED

HYS.1

InL.1 InH.1

2

1

ÜOperaing principle Src.x=0,6,7

L.1 =OFF

LED

HYS.1

H.1

InL.1 InH.1

SP

2

1

*Operating principle Src.x=1,2

L.1 =OFF

L.1

LED

HYS.1

InL.1 InH.1

21

H.1 =OFF

L.1

LED

HYS.1

InL.1 InH.1

SP

21

H.1 =OFF

L.1

LED LED

HYS.1 HYS.1

H.1

InL.1 InH.1

2

21

Other manuals for MIR-491

1

Table of contents

Other ACS contsys Controllers manuals