Action 246-200D0 User manual

FUEL NOZZLE..................(4.50 90 DEGREE B) P/N V4.50 90DB

TYPE.........................................................PRESSURE ATOMIZING

FUEL TYPE......................................KEROSENE, #1 OR #2 DIESEL

FUEL CONSUMPTION...............................4.92 GPH / 18.6 LPHR

FUEL PRESSURE ..............................................120 PSI / 8 BAR

FUEL PUMP ..........................................(DANFOSS) V-100714-001

MOTOR - 1/4HP.....................................................P/N V00-20383

VOLTAGE..............................................................115V 1PH 60HZSPEED........................................................................3450 RPM

BURNER....................................................................V00-17345

VOLTAGE............................................... 115 VAC, 60 HZ, 1 PH

TEMPERATURE CONTROL - HIGH LIMIT.....P/N F04-00817-C1 CAM SWITCH...............................................................F04-00741A

CURRENT...........................................................................15 AMP

PULLEY.......................................(AK32 X 5/8) P/N R03-00132

PART NUMBER..............................................................F02-00042

SPEED.......................................................................1725 RPM

VOLTAGE ..............................................................115V 60HZ 1PH

HORSEPOWER............................................. 3/4 HP / 0.56 KW

PUMP ...................................................(TT941) P/N N07-00026

PULLEY................................................(AK69H) P/N R03-00669

COIL BACK PRESSURE REQUIRING DESCALING...................................................................50 PSI @ 2.0 GPM / 3.40 BAR @ 7.5 LPM

COIL SIZE................1/2"ID X 126' SCHEDULE 40 - P/N 53-200

COIL BACK PRESSURE (NEW)..................................................................................................5 PSI @ 2.0 GPM / 0.34 BAR @ 7.5 LPM

WEIGHT (DRY)....................................................650 LBS / 283 KG

MINIMUM WATER INLET PRESSURE..............40 PSI / 0.68 BAR

HOSE, HIGH PRESSURE.............3/8" X 16 1/2' P/N Y01-00016 FUEL TANK CAPACITY...............................................10 GAL / 38 L

BELT............................................(A30 SUPER II) P/N R02-00430-II

ALL DIMENSIONS ARE IN

IN INCHES UNLESS OTHERWISE

NOTED. 1 INCH = 25.4 MM

PUMP HEAD PRESSURE.....................................80 PSI / 6 BAR

TEMPERATURE LIMIT...............................UP TO 425 DEGREES

TEMPERATURE RISE...375°F @ 132 GPHR / 191°C @ 500 LPHR DRAFT/STACK INSTALLATION................0.2" - 0.04" WC READING

COMBUSTION SMOKE/BACHARACH SCALE......#1 OR #2 SMOKE

CARBON MONOXIDE ALLOWED...........................................0.01%

HEAT INPUT....................630,000 BTU/HR / 158,760 KCAL/HR

PULLEY BUSHING...............................(H X 24MM) P/N R04-00001

1

OPERATION TABLE OF CONTENTS

OIL FIRED ELECTRIC DRIVEN STEAM GENERATOR

08-21-08 Z08-11213TC

ECN-02981

SAFETY INSTRUCTIONS

Page Number

•Safety Symbols 3

•General 3

•Mechanical 3

•Electrical 4

•Fuel 4

INSTALLATION

•Location 5

•Electrical 5

•Extension Cord 5

•Venting 5

•Water Supply 5

•Barrier 6

•Water Conditions 6

•Freezing 6

•Cold weather 6

•Chemicals 6

VENTING

•Draft Diverters 6

•Venting Installation Information 7

OPERATION

• Pre Start-Up

7

• Start-Up 7

• Shut Down 8

MAINTENANCE

Machine

•Flushing 9

•Storage 9

•Belt Tension 9

•Coil Back Pressure 10

•Schedule 12

Burner

•Air Band Adjustment 13

•Fuel Pump Filter 13

•Transformer Check 13

•Buss Bar Alignment 14

•Burner Gun Remove/Replace 14

•Electrode Ass’y Adjustment 14

Fuel Filter See Parts List Section

TROUBLESHOOTING

Page Number

•Machine 15, 16

•Water Heater 21

•Oil Burner 19, 20

•Pump See Parts List Section

•Fuel Filter See Parts List Section

SERVICE

•Pump See Parts List Section

• Fuel Filter See Parts Lists Section

COMPONENT ADJUSTMENT

Burner

•Air Band Adjustment 13

•Buss Bar Alignment 14

•Electrode Ass’y Adjustment 14

OIL BURNER CONTROLS

•Normal Cycle 10

•Safety Timing 10

•High Limit and Thermostat Check 10

•Flame Detector Check 10

Hi-Limit Temperature Control

•Switch Action 11

•Non-Cycling Manual Reset 11

Steam Pressure Control

•Adjustments 11

PUMP OIL CHANGE

RECORD See Parts List Section

WARRANTY Inside Back Cover

2

OPERATION - TABLE OF CONTENTS

SAFETY, INSTALLATION, AND OPERATION

ELECTRIC DRIVEN OIL FIRED STEAM GENERATOR

08-08-03 Z08-11213

ECN-02981

MACHINE UNPACKING

ALL CLEANERS ARE CAREFULLY INSPECTED

AND CARTONED TO PROTECT AGAINST

SHIPPING DAMAGE. IF THERE IS DAMAGE OR

MISSING PARTS, THE TRANSPORTATION

COMPANY AGENT SHOULD MAKE A NOTATION

TO THAT EFFECT ON THE BILL. REFER TO THE

PARTS LIST IN THIS MANUAL AND ADVISE WHAT

PARTS ARE MISSING OR DAMAGED. IF

AVAILABLE, GIVE THE INVOICE NUMBER ON

ALL ORDER BILLS. THIS PROCEDURE WILL

ENABLE NEEDED PARTS TO BE SHIPPED

QUICKLY.

READ ALL Installation, Operation, and

Maintenance instructions before operating the

machine

NOTE: Refer to CLEANER MODEL for SERIAL

NUMBER location

NOTE: Dimensions are in inches unless otherwise

noted

IMPORTANT SAFETY

INSTRUCTIONS

The safety alert symbol.

This symbol is used to identify safety information

about hazards that can result in personal injury.

A signal word (DANGER, WARNING, or CAUTION)

is used with the alert symbol to indicate the

likelihood and the potential severity of injury. In

addition, a hazard symbol may be used to

represent the type of hazard

DANGER indicates a hazard which, if not

avoided, will result in death or serious injury.

WARNING indicates a hazard which, if not

avoided, could result in death or serious injury.

CAUTION indicates a hazard which, if not

avoided, might result in minor or moderate

injury.

CAUTION, when used without the alert

symbol, indicates a situation that could result

in damage to the equipment.

GENERAL SAFETY

1. Before operating this machine, read and observe

all safety, unpacking, and operating

instructions. Failure to comply with these

instructions could create a hazardous

situation.

2. The operator of this equipment should not

operate this equipment when fatigued or under

influence of alcohol or drugs.

3. The operator of this equipment should be

thoroughly familiar with its operation and

trained in the job to be accomplished.

4. The operator of this equipment should wear

protective face shields and other protective

clothing as required for safe operation.

5. Keep all protective covers and shields in place.

Operating this machine with moving parts

could allow operator or bystander serious

injury or even death.

6. Do not operate the machine if any mechanical

failure is noted or suspected.Keep all shields

in place.

7. Do not leave this machine unattended when it

is operating.

8. All installations must conform to all applicable

local codes. Contact your electrician, plumber,

utility company or seller for details.

9. If a water leak is found, DO NOT OPERATE THE

MACHINE. Shut off the motor and repair.

10. Follow instructions on how to stop the

machine and bleed pressures quickly. Be

thoroughly familiar with the controls.

11. When starting a job, survey the area for

possible hazards and correct before proceeding.

12. If chemicals are used in conjunction with this

equipment, read and follow the product label

directions.

13. During normal operation of this machine, hot

discharges and surfaces may be produced. DO

NOT use quick connectors on machines that

produce steam.

14. Do not start the burner unless a full flow of

water is coming from the steam trap. Air leaks

or insufficient water to the machine means less

than full flow of water through the coil. This

could cause hose failure and burns to the

operator.

3

08-08-03 Z08-11213A

ECN-02981

15. Always shut down machine before refueling.

16. Do not overfill the fuel tank. If any spillage

occurs, clean up immediately and/or neutralize

the spill before attempting to operate the

machine.

MECHANICAL SAFETY

1. All guards, shields, and covers must be replaced

after adjustments are made to prevent

accidental contact with hazardous parts.

2. Drive belts must be inspected and tightened

periodically to operate at optimum levels.

3. Inspect machine for damaged or worn

components and repair or replace to avoid

potential hazards. Do not operate the machine

if any mechanical failure is noted or suspected.

ELECTRICAL SAFETY

1. This machine must be electrically grounded.

Failure to have the machine grounded may

result in the operator being electrically shocked

and even death.

2. Do not plug–in or un–plug machine with wet

hands.

3. Keep power cords and connections (connectors)

out of water.

4. If an extension cord must be used to operate

this machine, it should be as short as possible.

The extension cord must be properly sized and

fitted with a grounding type plug and

receptacle.

5. All wiring and electrical connections should

comply with the National Electrical Code (NEC)

and with local codes and practices.

6. Fuses or circuit breakers should be compatible

with machine requirements. (See ELECTRICAL

section of MODEL SPECIFICATIONS for power

requirements.)

7. High voltage may be present within this

machine. Servicing should only be performed

by properly trained personnel.

FUEL SAFETY

1. Use only fuel #1 or #2 diesel. The use of incor-

rect fuel may result in fire or explosion and

severe injury to the operator.

2. Do not refuel machine while it is running or hot.

Allow it to cool sufficiently to prevent ignition

of any spilled fuel. Clean up any spilled fuel

before resuming operation.

3. Fuel burning equipment must have proper ven-

tilation for cooling, combustion air, and ex-

hausting of combustion products.

4. Stacking, where required, must be installed in

accordance with all local codes. A draft diverter

must be installed on a machine connected to

an exhaust stack to prevent improper opera-

tion.

5. Where stacking is not required, provide adequate

ventilations to prevent any possible accumu-

lation of hazardous fumes.

6. Personnel trained in and familiar with the type

of equipment being serviced should only per-

form adjustments to fuel burning equipment.

SAVE THESE SAFETY

INSTRUCTIONS

WARNING: DO NOT USE GASOLINE,

CRANKCASE DRAININGS, OR OIL

CONTAINING GASOLINE OR SOLVENTS.

AVERTISSEMENT: NE PAS UTILISER

D’ESSENCE DE PRODUITS DE VIDANGE

NI D’HUILE CONTENANT DE L’ESSENCE

OU DES SOLVANTS

WARNING: OPEN FLAME. Do not operate

this machine in an area with combustible

materials. A suitable fire extinguisher

should be available in operating area.

4

08-08-03 Z08-11213B

ECN-02981

INSTALLATION

1. LOCATION: This machine should be

installed by only qualified technicians. The

machine should be set upon a level surface

where it will not be affected by strong winds,

rain, snow, extreme heat, and freezing

temperatures. Install the machine

considering locations for chemical pick-up, fuel

connections, electrical connections, water

hook-up, venting, and maintenance.

All wiring and electrical connections should

comply with the National Electrical Code (NEC)

and with local codes and practices. Use the

chart on the next page for your cord selection

2. ELECTRICAL: Connect machine to an

electrically grounded circuit that is fused or

circuit breaker protected. The circuit must

match that specified in the ELECTRICAL

section under MODEL SPECIFICATION

3. EXTENSION CORD: The use of an extension

cord that has undersize wire compared to the

amp draw of your machine will adversely limit

the starting load carrying abilities of the motor

and machines performance. Use only 3-wire

extension cords that have 3-prong plugs and

3-pole cord connectors that accept the plug

from the product. Use only extension cords

that are intended for outdoor use. These

extension cords are identified by a marking

“Acceptable for use with outdoor appliances;

store indoors while not in use.” Use only

extension cords having an electrical rating not

less than the rating of the product. Do not

use damaged extension cords. Use an

extension cord in good repair free of frays or

cracks in the outer covering. Do not abuse

extension cord and do not yank on any cord to

disconnect. Keep cord away from heat and

sharp edges. Always disconnect the extension

cord from the receptacle before disconnecting

the product from the extension cord.

WARNING: To reduce the risk of

electrocution, keep all connections dry and off

the ground. Do not touch plug with wet hands.

CHART FIGURES ARE BASED ON NOT

MORE THAN 100 FOOT

(Based on Ambient Temperature of 86°F (30°C)).

*Use Amp Draw indicated the same or higher than

your machine output

EXAMPLE: Machine Amp Draw 51, use 55 (2

Conductor). The thermostat type of cord shall be

C, PD, E, EO, EN, S, SO, SRD, SJ, SJO, SV, SVO,

SP.

The thermoset plastic types shall be ET, ETT,

ETLB, ETP, ST, STO, SRDT, SJT, SJTO, SVT,

SVTO, and SPT.

WARNING: CARBON

MONOXIDE

HAZARD

4. VENTING: This machine emits carbon

monoxide, a deadly gas, and must be vented if

used in an enclosed area. Improper venting

can cause poor combustion, delayed ignition,

down drafts, and the possibility of freezing the

coil. Contact your distributor or local heating

and air conditioning dealer for proper

materials. Local codes must be observed.

5. WATER SUPPLY: This machine must have a

water supply meeting or exceeding the

maximum discharge volume specified in the

PERFORMANCE section, and a minimum

COPPER

WIRE SIZE

MINIMUM

AWG

MACHINE AMP

DRAW*

3 CONDUCTOR

WIRES

MACHINE AMP

DRAW*

2 CONDUCTOR

WIRES

16 10 13

15 -- --

14 15 18

12 20 25

10 25 30

835 40

645 55

460 70

280 95

WARNING: ELECTRICAL SHOCK

HAZARD

5

water inlet pressure specified in the GENERAL

section of the MODEL SPECIFICATIONS.

6. BARRIER: We recommend a barrier be installed

between the machine and wash area to prevent

moisture from coming in direct contact with

electrical controls, motors and transformers.

This will increase the machine’s life and lessen

electrical problems.

7. WATER CONDITIONS: Local water conditions

affect the coil adversely more than any other

element. In areas where troublesome

conditions may exist with like equipment (such

as water heaters), we recommend the use of a

water softener.

8. FREEZING: This machine must be protected

from freezing according to STORAGE section

of MACHINE MAINTENANCE.

9. COLD WEATHER: As the weather becomes

colder, fuel becomes thicker and may become

so viscous that the fuel will not flow properly.

As viscosity increases, the thicker oil can cause

delayed ignition, poor spray patterns, and

rumbling fires. As moisture will quickly

destroy fuel pumps, make certain that tank

openings are secure and moisture cannot

enter. In cold weather areas, frost build up

will occur in fuel tanks. As the weather warms

it turns to condensate, and the water will be

in the tank. Keep the tank clear of water, as

moisture reaching the fuel pump will cause

rust, and the pump will bind. A full fuel tank

will lessen condensation build up.

10. CHEMICALS: Mix chemicals per the chemical

manufacturers printed directions. Follow all

mixing, handling, application, and disposal

instructions. Wear gloves, boots, goggles, and

protective clothing appropriate for the chemical

being used

VENTING

WARNING: This machine emits carbon

monoxide, and deadly gas, and must be vented

if used in an enclosed area. Improper venting

can cause poor combustion, delayed ignition,

down drafts, and the possibility of freezing the

coil. Contact your distributor or

local heating and air conditioning

dealer for proper materials. Local

codes must be observed.

The information contained herein is offered for

reference only. You must comply with local

codes and investigate through your gas and

other utility companies when installing, as

there may be some special local requirements

you must comply with. Also see ANSI Z223.

1. DRAFT DIVERTERS: (STACKED CLEANERS)

Oil fired machines use a force air burner. The

oil burner can be influenced by “Natural Draft”

even though they have their own fan. A Bell

type draft diverter must be used here also.

THIS MACHINE IS NOT TO BE CONNECTED

TO A TYPE B GAS VENT.

NE PAS RACCORDER CET APPAREIL À UN

TUYAU D’ÉVACUATION DE GAZ DU TYPE B.

A. A draft diverter must be used on all

cleaners that are stacked. This includes

any chimney even if not expelled to the

outside.

B. Use a draft diverter of the inverted funnel

or bell type that meets all codes for

capacity and materials. Mount the draft

diverter directly to the stacking flange on

the machine

C. The draft diverter’s function is to insure

that the barometric pressures are as close

to the same as possible at the air inlet and

outlet to the coil and will not be changed

by either up drafts or down drafts.

D. Installation of a draft diverter WILL NOT

PREVENT THE COIL FROM FREEZING.

In areas where freezing temperatures are

common, some type of down draft

prevention must be used. Check local

08-08-03 Z08-11213CECN-02981 6

codes for acceptable methods for the

prevention of down drafts.

2. VENTING INSTALLATION INFORMATION:

A. Never Reduce the Stack size. The diverter

and stacking should be the same size as

the stack opening on the machine.B.

B. Straight Stacking through the roof

is preferred. Horizontal runs are not

desirable, but if necessary, be sure to pitch

the stack upward at a rate of two inches

per foot. When horizontal stacks are used,

vertical stacking must extend at least two

feet for every foot of horizontal stack.

C. Stack Extension above the roofline should

be sufficient to clear the peak of the roof.

(Refer to ANSI Z223.1 page 100 of

SPECIFICS)

D. A Rain Cap U.L. approved should be

installed on the stack

OPERATING

INSTRUCTIONS

PRE START-UP

1. The first time the machine is operated, after

repairs have been made, or if the machine has

set for a period of time (30 days or more) follow

the following procedures.

A. Check the tension of the belt (if so

equipped) per instructions in MACHINE

MAINTENANCE.

B. Flush the machine per instructions in

MACHINE MAINTENANCE.

C. Install float tank drain plug (if so equipped).

D. Open float tank ball valve (if so equipped).

2. CAUTION: Always use pipe or hose suitable

to carry live steam. The pipe or hose should be

large enough ID as not to restrict the flow.

3. CAUTION: If machine has been exposed

to sub-freezing temperatures, it must be

thoroughly warmed to above freezing before

operating. Failure to warm machine can cause

damage to the pump packings and other

components.

4. Read and observe all items in “CLEANER

INSTALLATION”.

START-UP

1. Refer to the MAINTENANCE SCHEDULE for

any maintenance to be performed before

operation

2. ELECTRICAL: Connect the machine to an

electrically grounded circuit that is fuse or

circuit breaker protected. Do not use any type

of adapter. If the correct type of receptacle is

not available, have one installed by a qualified

electrician.

3. OIL LEVEL: Check the oil level in the water

pump.

4. BELT: Make sure belt tension and condition

is as specified in MACHINE

MAINTENANCE.

5. STACK COVER: Remove the stack cover (if

so equipped).

6. FUEL FILTER: Inspect fuel filter for evidence

of water contaminants.

7. FUEL: Make sure the fuel lines are open

(CAUTION: Closed valves will DAMAGE the fuel

pump and void warranty). Use #1 or #2 diesel.

8. FUEL QUANTITY: Make sure the fuel supply

is sufficient to complete the job. See the

GENERAL section of MODEL

SPECIFICATIONS for the fuel tank capacity.

9. WATER SUPPLY: This machine must have a

water supply meeting or exceeding the

maximum discharge volume specified in the

PERFORMANCE section, and a minimum

water inlet pressure specified in the GENERAL

section of the MODEL SPECIFICATIONS.

10. LIME: Water containing large amounts of lime,

calcium or other similar materials can produce

a coating on the inside of the coil pipe.

11. FLOAT TANK: Check the float tank to assure

it is full and the float valve shuts off securely.

12.BLOWDOWN DISCHARGE VALVE: Check the

position of BLOWDOWN DISCHARGE VALVE

assuring it is in the CLOSED position as shown

above.

08-08-03 Z08-11213D

ECN-02981 7

WARNING: ELECTRIC SHOCK HAZARD

13. STEAM OUTLET VALVE: Check the position

of the STEAM OUTLET VALVE assuring it is

in the OPEN position.

CAUTION: A good flow of water must be present

at the outlet of the water trap before starting

the pump. Lack of water can cause coil

damage.

CAUTION: DO NOT RUN PUMP WITHOUT

WATER, AS THIS WILL CAUSE DAMAGE TO

THE PUMP AND VOID WARRANTY.

14. Turn the switch to the pump position.

15. Do not start the burner unless a full flow of

water is coming from the steam trap. Air leaks

or insufficient water to the machine means less

than full flow of water through the coil. This

could cause hose failure and burns to the

operator.

16. Turn the switch to the burner position.

CAUTION: Do not run the machine with the

burner switch in the on position when the fuel

tank is empty. This will cause damage to the

fuel pump and void warranty.

17. When starting to steam, slowly close the steam

outlet valve until the pressure gauge on the

coil outlet reaches 80 PSI. As it heats up the

steam discharge valve will have to be opened

gradually to maintain the 80 PSI reading until

the steam pressure remains at a constant

reading.

SHUT-DOWN

1. Slowly open the steam discharge valve.

2. Turn the switch from the burner position to

the pump position.

3. After cool, clear water is coming from the outlet

of the water trap, turn pump switch to the off

position.

4. Turn off the water supply.

5. Disconnect from electrical supply.

6. If freezing conditions may exist, refer to

STORAGE in MACHINE MAINTENANCE.

7. Replace stack cover (if so equipped).

08-08-03 Z08-11213EECN-02981 8

MACHINE

MAINTENANCE

FLUSHING

1. Connect machine to an electrically grounded

circuit that is fuse or circuit breaker

protected.

2. Connect machine to a pressurized water

supply meeting the requirements specified in

the GENERAL section of the MODEL

SPECIFICATIONS.

3. Turn on the water supply.

4. Check the float tank to assure it is full and

the float valve shuts off securely.

5. Check the position of the BLOW DOWN

DISCHARGE VALVE assuring it is in the

CLOSED position.

6. Check the position of the STEAM OUTLET

VALVE assuring it is in the OPEN position.

7. CAUTION: A good flow of water must be

present at the outlet of the water trap before

starting the pump. Lack of water can cause

coil damage.

8. CAUTION: DO NOT RUN PUMP WITHOUT

WATER, AS THIS WILL CAUSE DAMAGE TO

THE PUMP AND VOID WARRANTY.

9. Turn the switch to the PUMP position

10. When clean water flows from water trap, turn

switch to the OFF position..

11. If freezing conditions may exist, refer to

“STORAGE” section.

12. Dissconnect the electrical supply.

STORAGE

1. Disconnect the water supply.

2. Check the position of the BLOW DOWN

DISCHARGE VALVE assuring it is in the

CLOSED position.

3. Check the position of the STEAM OUTLET

VALVE assuring it is in the OPEN position.

4. Attach an air chuck to the air valve stem on

the pump assembly.

5. Apply air until a mixture of air and very little

water is coming from the water trap

6. Then turn switch to the burner position and

depress the vacuum switch. Run it for 45

seconds allowing any remaining water to turn

to steam. Allow air to blow for 60 seconds.

7. Remove the air chuck.

8. Fill a 1-gallon container with Ethylene Glycol

type antifreeze. Minimum should be a mixture

of ½ antifreeze and ½ water strength before

each use, as the antifreeze will dilute with each

use.

9. Pour the anti-freeze solution into the float

tank.

10. Turn on the switch to the PUMP position.

11. Turn off the switch just prior to running out

of antifreeze mixture.

12. Disconnect electrical supply.

13. Fill the fuel tank with kerosene or #1 or #2

diesel.

14. It is recommended to install a coil cover to keep

coil free of debris

15. Drain the float tank.

16. Place machine in a dry place protected from

weather conditions

BELT TENSION

1. Deflection for each inch of span between

pulley centers with a 6-pound force applied in

the middle of the span.

EXAMPLE: A 6-pound force applied at the

middle of an 8 inch span should produce a

deflection of 8/64 inch or 1/8 inch.

2. Belts can be tightened or loosened by

loosening the nuts holding the pump

assembly to the motor mount.

Then tighten or loosen the j-bolt on the motor

mount. Retighten the pump assembly after

the desired tension is reached.

SPAN

DEFLECTION

08-08-03 Z08-11213F

ECN-02981 9

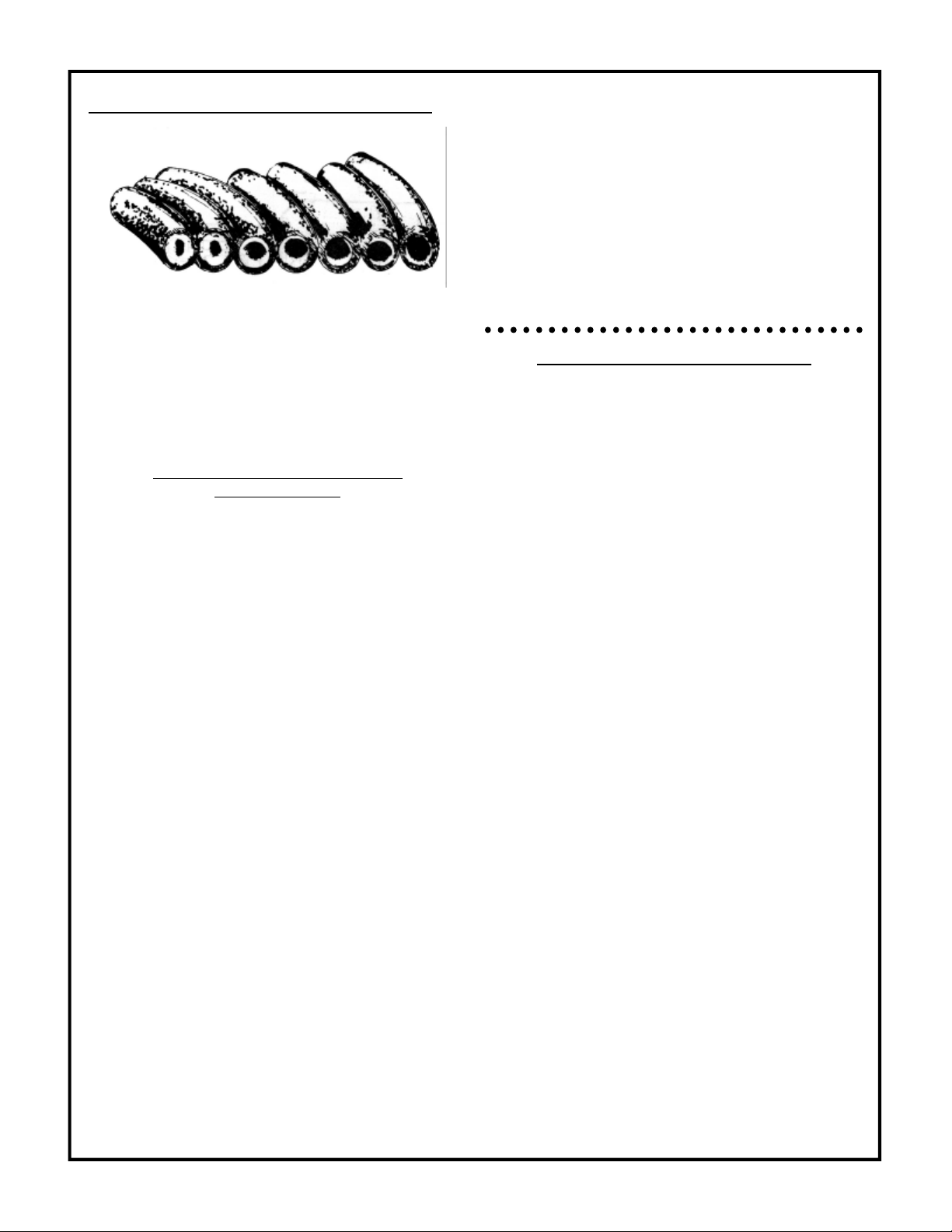

COIL BACK PRESSURE CHECK

Above is a cross section view showing the

progressive liming of coils.

A regular maintenance schedule for descaling your

heating coil is essential to insure its longevity.

The frequency of descaling depends upon the

amount of use and the condition of the water.

COIL BACK PRESSURE CHECK

INSTRUCTIONS

1. Check the condition of your water pump

unloader valve. Remove the hose and gun

assembly from the coil outlet.

2. Remove any flow restrictions, such as guns

and hoses, from the coil outlet.

3. Install a pressure gauge between the water

pump and coil inlet.

DISCHARGE VOLUME BACK PRESSURE

GPM REQUIRING

DESCALING

2-3 GPM 50 PSI

3-4 GPM 75 PSI

4-5 GPM 100 PSI

6 GPM 150 PSI

8-10 GPM 175 PSI

USE A 1000 PSI PRESSURE GAUGE

3. Turn on the water supply. Check the float

valve (if so equipped) to assure float tank is

full and the float valve shuts off securely.

4. Check the position of the ball valve (if so

equipped) on the outlet line of the float tank

assuring it is in the open position.

5. Turn on the pump switch. If the coil back

pressure reading is above that found in the

GENERAL section of the MODEL

SPECIFICATIONS then your machine needs

to be descaled.

A separate descaling pump is recommended so

scale and other chemicals will not come in contact

with your water pump and causes premature wear.

NOTE: Contact your local dealer for descaling of

your unit.

7. Disconnect the water supply.

8. Disconnect the electrical supply.

9. Reinstall the hose and gun assembly.

10. Remove the pressure gauge.

OIL BURNER CONTROLS

A. NORMAL CYCLE:

Turn cam to the burner position. The burner

should start and continue to run normally. (If

the burner starts, establishing flame, but then

locks out on safety, make "Flame Detector

Check" at this time.

B. SAFETY TIMING:

1. Let the burner run 5 minutes. Then remove one

of Flame Detector leads from "F" terminals.

After a time period corresponding to the safety,

stopping the burner.

2. Turn the cam switch to burner position.

3. Replace Flame Detector Lead removed step 1.

4. Wait 3 minutes. Then operate the manual reset

button on the front of control.

C. HIGH LIMIT AND THERMOSTAT CHECK:

1. Turn the cam switch to burner position.

2. Lower the setting of the high limit control to its

lowest setting. This setting should stop the

burner, unless the steam generator

temperature is below the minimum setting of

the high limit.

3. Return the high limit to it's proper setting.

Burner should restart.

4. With the burner running, turn thermostat to

it's lowest setting. This should stop the burner,

unless actual room temperature is below the

lowest setting of the thermostat. (Note: On

systems supplying domestic hot water, burner

will continue to run if low limit is not satisfied.)

5. Return thermostat to it's proper setting.

D. FLAME DETECTOR CHECK: (This test is not

required if control performs as described in

test A.)

08-08-03 Z08-11213G

ECN-02981 10

If the burner starts but the control locks out

(stopping the burner), check the flame detector

as follows:

1. Connect one end of the wire jumper to one of

the "F' terminals.

2. Turn the cam switch to burner position. As

soon as a flame has been established connect

other end of the wire jumper to the other "F"

terminal. WARNING: The control provides no

safety protection with the jumper installed. DO

NOT leave the burner in this condition except

for making this check. If the control still locks

out with the jumper installed, the control

should be replaced. If the control does not lock

out, however, check the operation of the flame

detector.

4. If safety lockout problem is of an intermittent

nature (only lockouts occasionally), the

following additional check may be made to

insure that the flame detector locations is not

a marginal one:

(a) Disconnect flame detector leads from "F"

terminals.

(B) Attach a jumper wire to one "F" terminal. Start

burner. Then immediately connect jumper wire

to the other "F" terminal. Burner should

continue to run.

(c) With burner running, attach flame detector

leads to an accurate ohmmeter. Reading of

ohm meter should also be acceptable,

Generally, though, the lower the reading, the

better the application, and less likely the

chance of a variation in the burner flame

causing a safety lock-out)

(d) If resistance of flame detector is over 1000

ohms, it may not be able to see the burner

flame properly . Check alignment of the flame

detectorthrough thehole inthe staticdisc. Clean

thishole if it is blocked by foreign matter. Check

for broken "F" wires.

(e) If flame detector alignment is a good but

resistance is still high, readjustment may be

necessary.

(f) WARNING: Be sure to remove wire jumper

after this flame detector check.

CHECKOUT PROCEDURE: Before leaving

installation, a complete operating cycle should

be observed to see that all components are

functioning properly. Limit switch function

should be tested to be sure the machine shuts

down when the limit contacts open.

HI LIMIT TEMPERATURE CONTROL

This control has been specifically designed to stop

heating equipment to prevent a dangerous

condition due to excessive temperatures.

A 240V neon pilot light (suitable for 120 to 240

VAC circuits) is included. It can be wired as

shown below to illuminate if the high limit trips

Switch Action:

It is the non-cycling manual reset

type of control which means

that if it's contacts open due

to the temperature exceeding

it's dial setting, the contacts

open, thereby stopping the heat

input to the machine.

MANUAL RESET BUTTON

Non-Cycling Manual Reset:

After this control has stopped the heat input to

the machine, it cannot be started unless some

authorized person pushes the reset button.

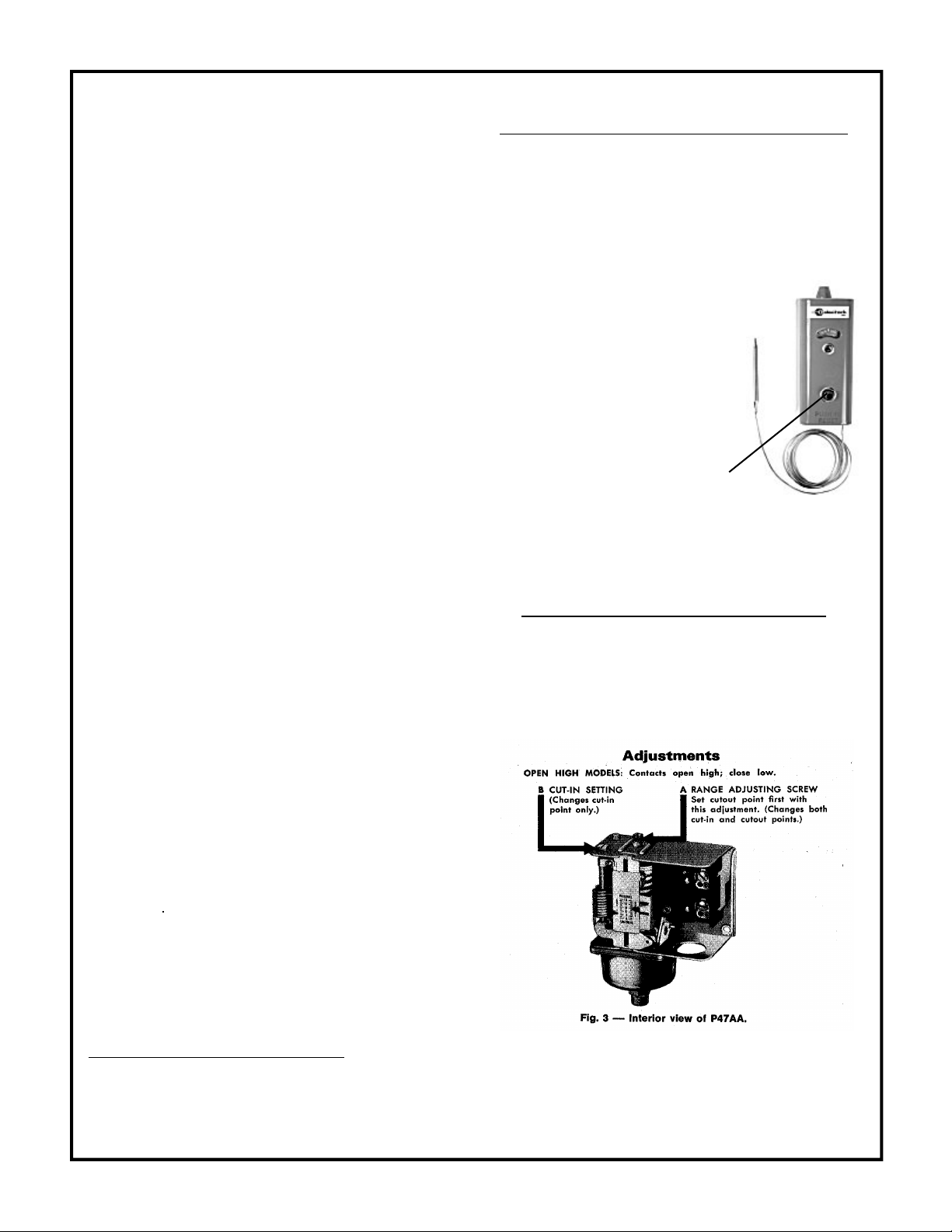

STEAM PRESSURE CONTROLS:

OPEN LOW MODELS: Contacts close high:

open low.

On open low models, range adjusting screw "A"

raises and lowers cut-in point (this also raises

or lowers cutout point by a like amount). Sat

cut-in point first with adjusting screw "B"

changes cutout point only. If control is

equipped with a lockout, contacts must be

reset by hand after opening.

08-08-03 Z08-11213H

ECN-02981 11

MOTOR DRIVEN STEAM

GENERATOR DAILY

EACH

HR

FIRST

8 HRS

AFTER

FIRST

50

HRS

EVERY

50

HRS

EVERY

100

HRS

EVERY

500

HRS

YEARLY

OIL BATH WATER PUMP:

Oil Level – check and add as needed per

PUMP SERVICE insert.

Oil Change – drain and refill per PUMP

SERVICE insert. CAUTION: Used oil must

be disposed into an environment safe

container and brought to an oil recycling

center.

Oil Contamination –Milky color indicates

water

HOSES:

Blistering, Loose Covering

Abrasion of cover exposing

reinforcement.

Cuts exposing reinforcement

BELTS:

Cracks or fraying

Belt Tension - For correct belt tension,

see MACHINE MAINTENANCE insert.

FILTER – WATER:

Check water inlet hose screen for debris

Check float tank screen for debris

LEAKS:

Check for water and build up of scale at

pipe connections.

FUEL:

Adequate fuel supply.

FILTER—FUEL:

If contaminants are present see FUEL

FILTER insert.

Remove and Replace fuel filter per FUEL

FILTER insert.

SCREEN—FUEL:

Check fuel pump screen for debris see OIL

BURNER MAINTENANCE insert.

BURNER NOZZLE:

Replace Nozzle as specified in BURNER

section of MODEL SPECIFICATIONS or

BURNER ASSEMBLY insert.

GUARDS AND SHIELDS:

Check that all guards and shields are in place

and secure.

MACHINE MAINTENANCE SCHEDULE

12 08-08-03 Z08-11213J

ECN-02981

OIL BURNER MAINTENANCE

OIL FIRED CLEANERS

08-05-03 Z08-00062

ECN-02981 Supersedes 06-05-01 Z08-00062

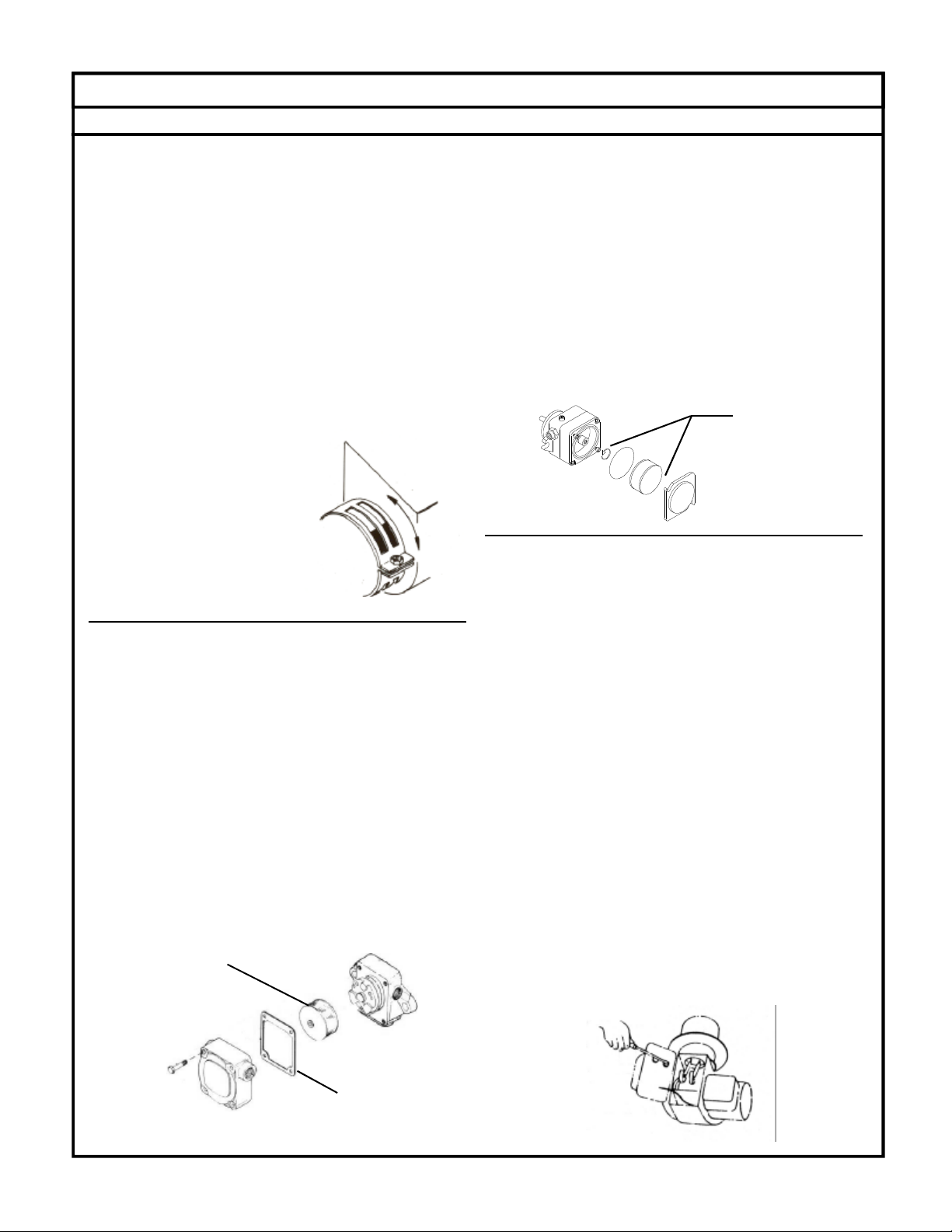

AIR BAND ADJUSTMENT

NOTE: The air band adjustment on this burner

has been preset at the factory (elevation

approximately 1400 feet). On equipment installed

where elevation is substantially different, the air

band(s) must be readjusted.

1. Loosen the cap screw retaining the air bands.

2. Move the air bands as indicated below with

the machine in operation.

NOTE: The air band should be set so the

exhaust gives the smoke spot specified in the

GENERAL section of the MACHINE

SPECIFICATIONS on a Shell-Bacharach scale.

If a smoke tester is not

available, a smoky

exhaust, oily odor, or

sweet smell indicates

insufficient air while eye-

burning fumes indicate

too much air.

3. Tighten the cap screw

retaining the air bands.

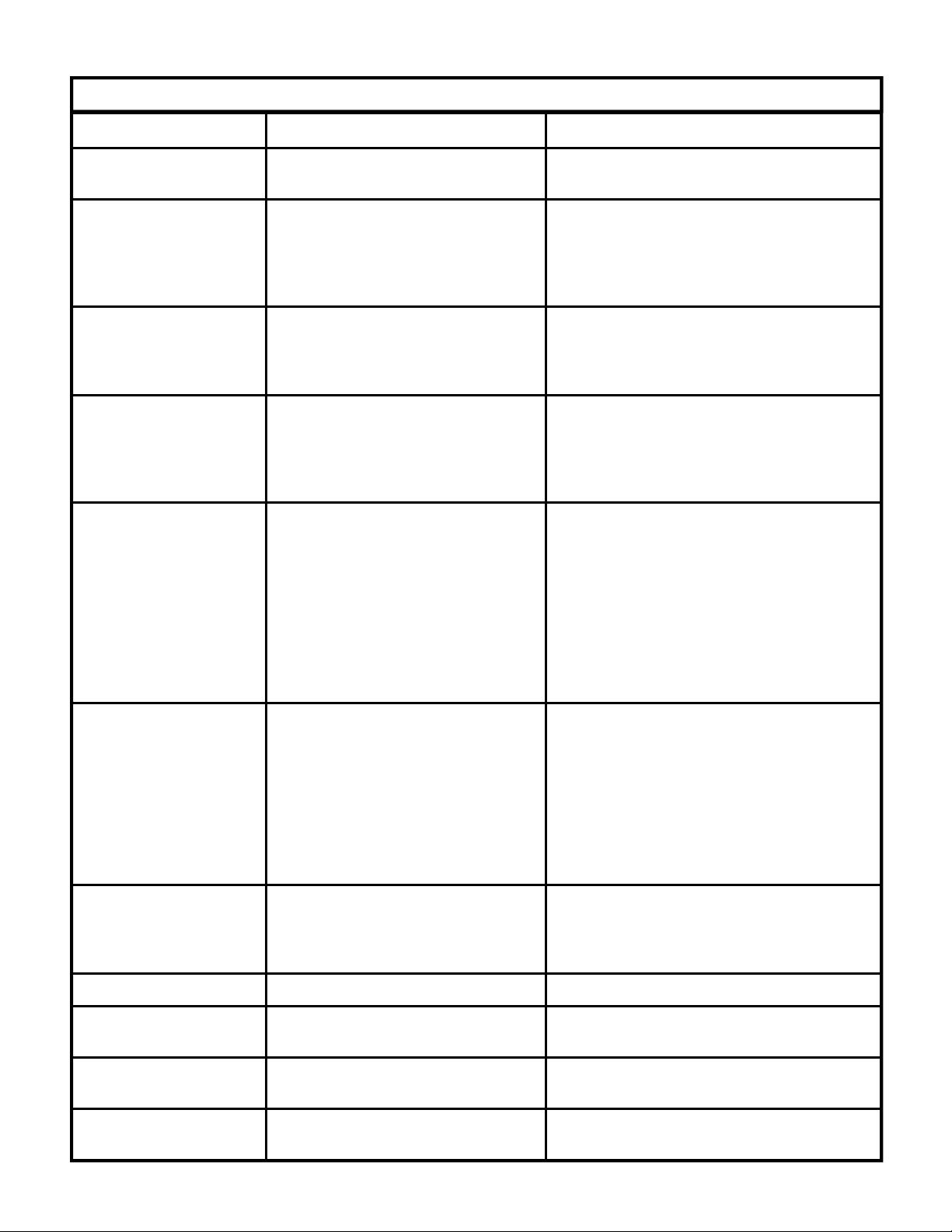

FUEL PUMP FILTER

SUNDSTRAND PUMP

1. Shut off fuel supply.

2. Loosen the 4 screws holding the cover to the

fuel pump housing.

3. Take cover and cover gasket off and pull

strainer off of pump housing.

4. Clean out any dirt remaining in the bottom of

strainer cover. If there is evidence of rust

inside of the unit, be sure to remove water in

supply tank and fuel filter.

5. Turn on fuel supply. Failure to do so will result

in fuel pump damage.

DANFOSS PUMP

1. Shut off fuel supply.

2. Loosen the 2 screws with 7/64 allen wrench

one turn.

3. Turn cover counter clockwise and pull strainer

and cover off of pump housing.

4. Clean out any dirt remaining in the bottom of

strainer cover. If there is evidence of rust

inside of the unit, be sure to remove water in

supply tank and fuel filter.

5. Reinstall reverse of removal.

6. Turn on fuel supply.

TRANSFORMER TEST

1. Remove burner junction box cover.

2. Turn on burner and make sure ignition

transformer is receiving rated voltage.

3. Turn off burner.

4. Loosen screw and swing transformer away from

burner gun assembly.

5. Turn on burner.

6. Short the high voltage terminals.

CAUTION: Use screwdriver with a well

insulated handle to avoid shock.

7. Open gap by drawing screwdriver away from

one electrode while touching the other.

8. The spark should jump between 5/8 inches

and 3/4 inches, if it doesn’t jump, replace

the transformer.

9. Turn burner off.

10.Partially close transformer. Check if buss bars

align and contact transformer electrodes. If

buss bars do not contact, see Buss Bar

Alignment.

11.Close transformer, reposition retainer clip and

tighten screw.

PART NUMBER

V00-99004

PART NUMBER

V00-14283-2

PART NUMBER

V00-14283-5

OIL BURNER MAINTENANCE

OIL FIRED CLEANERS

07-11-03 Z08-00062A

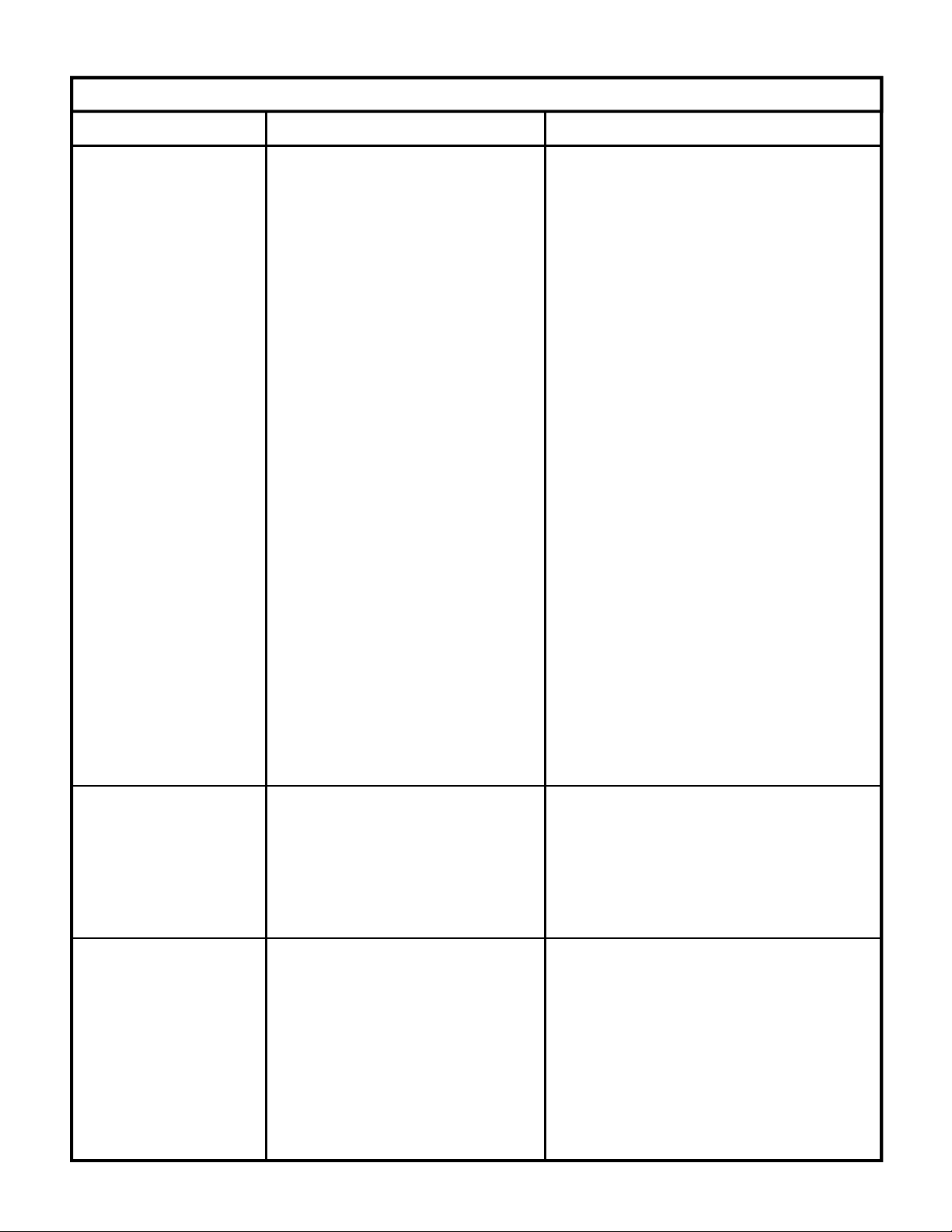

BUSS BAR ALIGNMENT

1.With burner off, loosen screw and swing the

transformer away from burner gun assembly.

2. Inspect the buss bars and transformer

electrodes for pitting or corrosion.

3. Partially close the transformer. Check if the

buss bars contact and are in alignment with

transformer electrodes.

4. Proper adjustment is obtained by gently

bending the buss bars until they spring

against, parallel, and are in full contact with

the transformer electrodes.

5. With buss bars aligned, carefully close and

fasten the transformer.

BURNER GUN REMOVAL

& INSTALLATION

1. Disconnect the fuel line from the burner gun

assembly oil line fitting. Loosen the other end

of the line and swing line out of the way.

2. Remove the retaining nut.

3. Loosen screw and swing transformer away from

burner gun assembly.

4. Carefully remove the burner gun assembly.

A. Check and replace electrode insulators if

cracked.

B. Clean burnt buss bars.

C. Clean carbon off electrodes.

D. Clean carbon off oil nozzle. (Use caution

not to scratch face of nozzle or orifice.)

E. Check for a loose oil nozzle. NOTE:

Check with dealer and/or replace nozzle

with proper nozzle.

5. Gently replace burner gun assembly in air

tube. CAUTION: Do not force. Forcing will

cause electrode misalignment

6. Reinstall the retaining nut.

Reinstall the oil line making sure both ends

are tight.

7. Partially close transformer. Check if buss bars

align and contact the transformer electrodes.

If buss bars do not contact, see Buss Bar

Alignment.

8. Close transformer, reposition retainer and

tighten screw.

ACCESSORIES

Z01-00095 – Fuel Nozzle Changing Wrench

Z01-00092 – Fuel Pump Wrench (Sundstrand)

Z01-00093 – Solenoid Wrench (ASCO)

ELECTRODE ASSEMBLY ADJUSTMENT

1.Loosen screws holding electrode assemblies.

2. Raise electrode tips 5/32 inches above

surface plane or end of oil nozzle.

3. Place each electrode tip 5/16 inches from

center of spray nozzle hole, maintaining

previous measurement.

4. Spread electrode tips to 1/8-inch gap

maintaining previous measurements.

5. When the proper measurements are obtained,

gently tighten screws that hold electrode

assembly in place. CAUTION: Do not over

tighten, as this will cause the electrode

insulator to fail.

ECN-02981 Supersedes 06-05-01 Z08-00062A 14

TROUBLE POSSIBLE CAUSE REMEDY

1. Machine will not

rise to operating

pressure.

A. Low fuel pressure.

B. Water in fuel piping.

C. Fuel filter clogged.

D. Poor combustion.

E. Improper fuel supply.

F. Temperature control

inoperative.

A. See BURNER on MODEL

SPECIFICATIONS for specified pressure.

B. Drain fuel tank and remove and replace

filter per FUEL FILTER INSERT.

C. Remove and replace fuel filter element per

FUEL FILTER INSERT.

D. See "Poor combustion".in OIL BURNER

TROUBLESHOOTING.

E. Use fuel specified in BURNER section of

the MODEL SPECIFICATIONS.

F. See HI-LIMIT TEMPERATURE CONTROL

in BURNER CONTROL SECTION.

2. Machine overheats. A. Insufficient water.

B. Temperature control

inoperative.

C. Improper fuel supply.

A. See Low Operating Pressure on MACHINE

TROUBLESHOOTING.

B. See HI-LIMIT TEMPERATURE CONTROL

in BURNER CONTROL SECTION.

C. Use fuel specified in BURNER section of

the MODEL SPECIFICATIONS.

3. Low operating

pressure.

A. Insufficient water supply.

B. Incoming water hose too

small.

C. Water supply hose too long.

D. Belt slippage.

E. Worn Belt.

F. Dirty or worn check valves in

water pump.

H. Water supply hose kinked.

I. Inlet filter screen clogged.

J. Motor runs slow.

K. Air leak in inlet plumbing.

L. Defective water pump.

M. Leaking discharge plumbing.

N. Restricted coil.

A. The water supply must meet or exceed the

maximum discharge volume specified in

the PERFORMANCE section, and

minimum water inlet pressure specified

in the GENERAL section of the MODEL

SPECIFCATIONS section.

B. Use larger water supply hose.

C. Use shorter water supply hose.

D. Tighten belt per instructions in

MACHINE MAINTENANCE insert.

E. Replace belt per CLEANER EXPLODED

VIEW.

F. See PUMP TROUBLESHOOTING.

H. Straighten hose.

I. Clean water filter screen or hose inlet

screen.

J. See "Pump motor starts slow or overheats

and stops" above.

K. Tighten all fittings.

L. See PUMP TROUBLESHOOTING.

M. If a water leak is found, DO NOT

OPERATE THE MACHINE. Disconnect

the power and repair plumbing.

N. See COIL BACK PRESSURE CHECK in

MACHINE MAINTENANCE.

4. Machine fumes

(exhaust burns eyes)

A. Too much combustion air.

B. Improper fuel pressure.

A. See BURNER TROUBLESHOOTING

INSERT.

B. See FUEL in MODEL SPECIFICATIONS

for specified pressure.

ELECTRIC MOTOR DRIVEN OIL FIRED CLEANERS

STEAM GENERATOR TROUBLESHOOTING

ECN -02981 08-21-03 Z08-11215

15

TROUBLE POSSIBLE CAUSE REMEDY

4. Excessive,

unusual noise.

A. Defective Pump.

B. Defective motor.

C. Pulleys rubbing.

D. Misalignment of pump & motor

A. See PUMP TROUBLESHOOTING.

B.Call service technician or take engine to

Repair/Warranty station.

C. Adjust shields or pulley(s).

D. Realign pump and engine.

5. Belts slipping. A. Belts too loose.

B. Excessive Back Pressure.

C. Defective Water Pump.

A. Tighten belt per instructions on

MACHINE MAINTENANCE.

B. See "Excessive Back Pressure" below.

C. See PUMP SERVICE.

6. Excessive Back

Pressure

A. Water pump turning too fast.

B. Coil built up with lime.

C. Relief valve defective.

A. See MODEL SPECIFICATIONS.

B. Delime coil.

C. Remove and replace.

7. Excessive

vibration.

A. Defective Belt.

B. Defective Pump.

C. Defective accumulator

A. Remove and replace using belt specified

in CLEANER EXPLODED VIEW or the

GENERAL section of MODEL

SPECIFICATIONS.

B. See PUMP TROUBLESHOOTING.

C. Recharge/Replace.

8. Pump motor

will not start

(motor does not

hum)

A. No Power.

B. Defective motor starter or

ON/OFF switch.

C. Defective motor.

A. Use a different outlet,check fuses in main

disconnect switch. Replace fuse if blown.

B. Call service technician.

C. Call service technician, or take motor to

Repair/Warranty station.

9. Pump motor

will not start

(motor hums)

A. Pump frozen.

B. Defective motor.

C. Defective water pump.

D. Excessive back pressure

A. Machine must be thoroughly warmed to

above freezing.

B. Call service technician or take motor to

Repair/Warranty station.

C. See PUMP SERVICE.

D. See "Excessive Back Pressure" above.

10. Pump motor

starts slow or

overheats and

stops.

A. Low voltage

B. Excessive back pressure

C. Defective motor

A. See "Low voltage".below.

B. See "Excessive Back Pressure".above.

C. Call service technician, or take motor to

Repair/Warranty station.

11. Pump motor

stops and will

not start.

A. Motor starter "kicked out" (if so

equipped) or thermal overload

tripped.

B. Excessive back pressure.

C. Defective motor.

A. Turn motor starter off to reset, then turn

on, or push thermal overload reset button

on motor.

B. See "Excessive Back Pressure". above

C. Call service technician, or take motor to

Repair/Warranty station.

12. Low voltage A. Incoming voltage incorrect.

B. Not large enough extension cord.

C. Too long extension cord

A. Have a qualified technician check the

motor terminal voltage. Correct voltage is

in MODEL SPECIFICATIONS.

B. Use an extension cord with amperes or

watts rating as high or higher than that of

the MODEL SPECIFICATIONS.

C. Shorten extension cord.

13. Machine

shocks

operator

A. Machine improperly grounded.

B. Outlet not grounded

A. STOP! Operating machine. Call service

technician.

B. Have properly wired outlet installed.

08-21-03 Z08-11215AECN -02981

ELECTRIC MOTOR DRIVEN OIL FIRED CLEANERS

STEAM GENERATOR TROUBLESHOOTING (CONT.)

16

PUMP TROUBLESHOOTING

08-27-03 Z08-00195

ECN-02981 Supersedes 06-00 Z08-00195

TROUBLE POSSIBLE CAUSE REMEDY

1. Oil leaking in the

area of water pump

crankshaft.

A. Worn crankshaft seal.

B. Bad bearing.

C. Grooved shaft.

D. Failure of retainer o-ring

A. Remove and replace.

B. Remove and replace.

C. Remove and replace.

D. Remove and replace.

2. Excessive play on

crankshaft.

A. Defective bearings.

B. Excess shims.

A. See "Worn bearing".

B. Set up crankshaft.

3. Loud knocking in

pump.

A. Loose conecting rod screws.

B. Worn connecting rod.

C. Worn bearings.

D. Loose plunger bushing screw.

A. Tighten connecting rod screws per

PUMP SPECIFICATIONS.

B. Replace connecting rod per PUMP

MAINTENANCE.

C. Replace bearings per PUMP

MAINTENANCE.

D. Tighten plunger screw per PUMP

SPECIFICATOINS.

4. Oil leaking at the

rear portion of the

pump.

A. Damaged or improperly

installed oil gauge window

gasket.

B. Damaged or improperly

installed rear cover.

C. Oil gauge loosed.

D. Rear cover screws loose.

E. Pump overfilled with oil,

displaced through crankcase

breather hole in oil

cap/dipstick.

A. Replace gasket or o-ring.

B. Replace gasket or o-ring.

C. Tighten oil gauge.

D. Tighten rear screws. to torque

values in PUMP SPECIFCATIONS. S

E. Drain oil: refill to recommended oil

level as stated in OIL LEVEL in PUMP

MAINTENANCE.

5. Water in crankcase A. May be caused by humid air

condensing into water inside

the crankcase.

B. Worn or damaged plunger

screw o-ring.

A. Maintain or step up lubrication

schedule.

B. Remove and replace. See PLUNGER

SERVICE in PUMP MAINTENANCE.

6. Worn bearing A. Excessive belt tension.

B. Oil contamination.

A. See BELT TENSION in MACHINE

MAINTENANCE.

B. Check oil type and change intervals

per PUMP SPECIFICATIONS.

7. Short bearing life A. Excessive belt tension.

B. Misalignment between pump

and motor.

C. Oil has not been changed on

regular basis.

A. See BELT TENSION in MACHINE

MAINTENANCE.

B. Re-align pump and motor.

C. Check oil type and change intervals

per PUMP SPECIFICATIONS.

8. Short seal life A. Damaged plunger bushing.

B. Worn connecting rod.

C. Excess pressure beyond the

pump's maximum rating.

D. High water temperature.

A. Replace punger bushing.

B. Peplace connecting rod.

C. Match pressure stated in PUMP

SPECIFICATIONS.

D. Lower water tempersture stated in

PUMP SPECIFCATIONS.

17

PUMP TROUBLESHOOTING

08-27-03 Z08-00195A

ECN-02981

TROUBLE POSSIBLE CAUSE REMEDY

9. Dirty or worn check

valves.

A. Normal wear.

B. Debris

A. Remove and replace.

B. Check for lack of water inlet screens.

10. Presence of metal

particles during oil

change.

A. Failure of internal component.

B. New pump.

A. Remove and disassemble to find

probable cause.

B. New pumps have machine fillings and

debris and should be drained and

refilled per PUMP SPECIFICATIONS.

11. Water leakage from

under head.

A. Worn packing.

B. Cracked/scored plunger.

C. Failure of plunger retainer

o-ring.

A. Install new packing.

B. Remove and replace plunger.

C. Remove and replace plunger retainer

o-ring.

12. Loud knocking

noise

in pump

A. Pulley loose on crankshaft.

B. Defective bearing.

C. Worn connecting rod.

D. Worn crankshaft.

E. Worn crosshead.

A. Check key and tighten set screw.

B. Remove and replace bearing.

C. Remove and replace connecting rod.

D. Remove and replace crankshaft.

E. Remove and replace crosshead.

13. Frequent or

premature failure of

the packing

A. Scored, damaged, or worn

plunger.

B. Overpressure to inlet manifold.

C. Abrasive material in the fluid

being pumped.

D. Excessive pressure and or

temperature of fluid being

pumped.

E. Over pressure of pumps.

F. Running pump dry.

A. Remove and replace plungers.

B. Reduce inlet pressure.

C. Install proper filtration on pump inlet

pumping.

D. Check pressures and fluid inlet

temperature; be sure they are within

specified range.

E. Reduce pressure.

F. Do not run pump without water.

14. Low Pressure A. Dirty or worn check valves.

B. Worn packing.

C. Belt slipping.

D. Improperly sized spray tip or

nozzle.

E. Inlet filter screen is clogged.

F. Pitted valves.

A. Clean/Replace check valves.

B. Remove and replace packing.

C. See BELT TENSION in MACHINE

MAINTENANCE.

D. See MACHINE SPECIFICATIONS for

specified spray tip or nozzle.

E. Clean inlet filter screen.

F. See VALVE SERVICE in PUMP

MAINTENANCE.

15. Erratic pressure:

pump runs rough

A. Dirty or worn check valves.

B. Foreign particles in valve

assemblies.

C. High inlet water temperature

A. Clean/Replace check valves.

A. Clean/Replace check valves.

C. See temperature in PUMP

SPECIFICATIONS.

16. Excessive vibration A. Dirty or worn check valves A. See "Dirty or worn check valves"

17. Scored plungers A. Abrasive material in fluid being

pumped.

A. Install proper filtration on pump inlet

plumbing

18. Pitted plungers A. Cavitation A. Decrease inlet water temperature

and/or increase inlet water pressure.

19. Cavitation A. High inlet fluid

temperatureLow inlet pressure.

A. Lower inlet fluid temperature.Raise

inlet fluid pressure.

18

OIL FIRED BURNER TROUBLESHOOTING

07-15-03 Z08-00191

ECN-02981 Supersedes 08-00 Z08-00191

TROUBLE POSSIBLE CAUSE REMEDY

1. Burner will not

ignite.

A. Electrodes out of alignment.

B. Electrode insulator failure.

C. Water flow switch not closing.

D. Vacuum switch not closing.

E. Temperature control switch not

closing.

F. Fuel solenoid valve not opening.

G. Weak transformer.

H. Faulty cad cell (if equipped).

I. Faulty primary control (if

equipped).

J. Burner motor thermal protector

locked out.

K. Wiring.

L. Burner switch.

M. Pump pressure.

N. Venting.

0. Sooting.

P. No fuel

A. See "ADJUSTING ELECTRODE

ASSEMBLY" in BURNER

MAINTENANCE SECTION.

B. Remove and replace if there are

breaks, cracks, or spark trails.

C. Adjust, repair, or replace switch.

D. Adjust, repair or replace switch.

E. Adjust or replace the TEMPERATURE

CONTROL.

F. Clean, repair, or replace solenoid.

G. Clean and check transformer

terminals. Check transformer for

spark per "TRANSFORMER TEST" in

BURNER MAINTENANCE SECTION.

H. Clean and test cad cell, replace if

required.

I. Replace primary control.

J. See "Burner motor thermal protector

locked out.

K. All wire contacts are to be clean and

tight. Wire should not be cracked or

frayed.

L. Test switch operation. Remove and

replace as necessary.

M. See "Low fuel pressure".

N. A downdraft will cause delayed

ignition. Soot deposits on the coil and

burner can interrupt air flow, and

cause shorting of the electrodes. Clean

as required.

O. Soot deposits on the coil and burner

can interrupt air flow, and cause

shorting of the electrodes. Clean as

required.

P. See "No fuel."

2. No fuel A.Clogged fuel filter.

B. Fuel leak.

C. Kinked or collapsed fuel line.

D. Low fuel pressure.

E. Faulty burner oil pump.

F. Air leak in intake lines.

G. Clogged burner nozzle

A. Remove and replace filter per FUEL

FILTER SECTION.

B. Repair as necessary.

C. Remove and replace fuel line.

D. See "Low fuel pressure".

E. Adjust pressure or replace.

F. Tighten all fittings.

G. Remove and replace (Do not clean).

3. Low fuel pressure A. Clogged fuel filter.

B. Clogged fuel pump filter

screen.

C. Fuel oil too viscous.

D. Air leaks in intake lines.

E. Kinked or collapsed fuel line.

F. Burner shaft coupling slipping.

G. Fuel Nozzle worn.

H. Faulty oil pump

A. Remove and replace filter per FUEL

FILTER page.

B. Remove pump cover and clean strainer

using a brush and clean fuel oil, diesel

oil or kerosene.

C. Operate a lighter oil or in warmer area.

D. Tighten all fittings.

E. Remove and replace.

F. Remove and replace.

G. Remove and replace with specified

nozzle on BURNER ASSEMBLY.

H. Remove and replace.

19

OIL BURNER TROUBLESHOOTING

07-15-03 Z08-00192

ECN-02981 Supersedes 09-00 Z08-00192

TROUBLE POSSIBLE CAUSE REMEDY

4. Pulsating pressure A. Partially clogged fuel pump

strainer or filter.

B. Air leaking around fuel pump

cover.

A. Remove and replace strainer per FUEL

PUMP FILTER in OIL BURNER

MAINTNANCE Section.

B. Check fuel pump cover screws for

tightness and damaged gasket.

5. Unit smokes A. Improper fuel.

B. Air to burner insufficient.

C. Fuel nozzle interior loose.

D. Water in fuel.

E. Gun out of alignment.

A. Refuel with FUEL specified on

MACHINE SPECIFICATIONS.

B. See AIR BAND ADJUSTMENT in OIL

BURNER MAINTENANCE section.

C. Replace nozzle.

D. Inspect fuel filter for water presence.

E. Bend oil pipe to center burner nozzle.

6. Burner motor

thermal protector

kicked out.

A. Low voltage.

B. Fuel too viscous.

C. Fuel pump defective.

D. Motor defective.

A. Voltage must match those specified in

the BURNER section of MACHINE

SPECIFICATIONS section.

B. Operate in warmer conditions or with

fuel adapted to cold weather

conditions.

C. Check that fuel pump turns freely.

D. Call service technician or take motor to

repair/warranty station.

7. Delayed ignition

(rumbling, noisy

starts)

A. Dirty or damaged electrodes.

B. Air adjustment open too far.

C. Poor fuel spray pattern.

D. Incorrect electrode setting.

E. Weak transformer

A. Clean or replace.

B. Readjust per AIR BAND ADJUSTMENT

in OIL BURNER MAINTENANCE

section.

C. Remove and replace with fuel nozzle

specified in BURNER ASSEMBLY.

D. Readjust per ADJUSTING

ELECTRODE ASSEMBLY in OIL

BURNER MAINTENANCE section.

E. See TRANSFORMER CHECK on OIL

BURNER MAINTENANCE section

8. Burner does not

electrically come on

A. Burner motor reset button

tripped.

B. High limit temp control reset

tripped if so equipped.

A. Reset if necessary.

CAUTION: Do not keep hitting the "reset

button" if you have oil pressure you

are just filling the burner combustion

chamber with oil and if ignited will

cause an explosion.

B. Reset if necessary.

20

Table of contents

Popular Portable Generator manuals by other brands

SIGLENT TECHNOLOGIES

SIGLENT TECHNOLOGIES UM0202X-E02D user manual

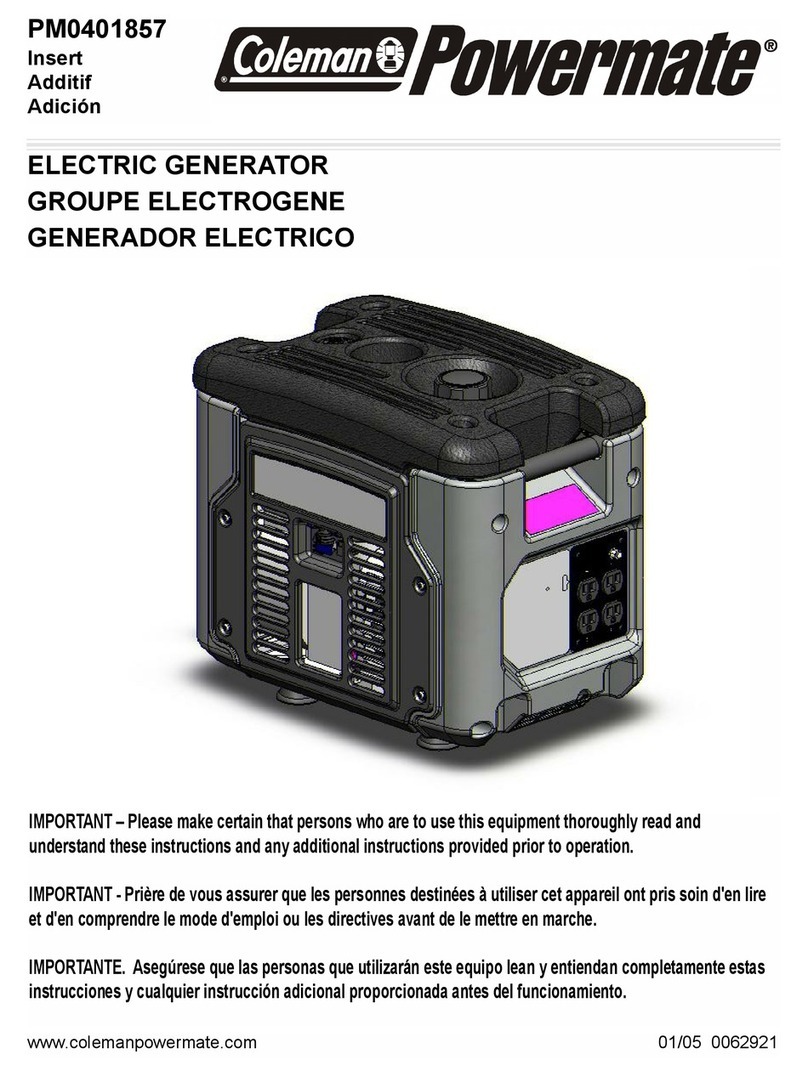

Powermate

Powermate PM0401857 user manual

BRICK

BRICK BGI3000S Original Notice

Mecafer

Mecafer MF4500E manual

Mitsubishi Heavy Industries

Mitsubishi Heavy Industries MGE1801 owner's manual

Clarke

Clarke IG2000D Operation & maintenance instructions

Stager

Stager YDE12000E user manual

Rohde & Schwarz

Rohde & Schwarz SMW-K141 user manual

PISCO

PISCO VNE04 user manual

HISPANUS

HISPANUS LIGEROS-3500 manual

Champion Global Power Equipment

Champion Global Power Equipment 500110-N Owner's manual & operating instructions

Tomahawk

Tomahawk TG2000i Operation manual