* Please make inquiry about other details to the following.

OVERSEAS MARKETING TEAM

3884-1

MINAMIMINOWA,

KAMIINA,

NAGANO-PREF

,

399-4588,

JAPAN

TEL:

+81-(0)265-76-7751

F

AX:

+81-(0)265-76-3305

E-mail:

[email protected]Safety Instructions

Nozzle

Lock pin

Fixing screw

Vacuum release solenoid valve

Vacuum port block with sensor unit

Diffuser

O-ring

Circuit diagram

Limit circuit

-0V

(Black)

+24V

(Red)

ANALOG OUT

(Black)

+10.8~30VDC

(Brown)

-0V (Blue)

Main

circuit

How to fit and release Tubing

How to fix Vacuum Generator VN

6.4

12

How to adjust vacuum release flow

Vacuum release air flow adjusting needle

The vacuum release air flow rate can be

increased by turning the needle left.

The vacuum release air flow rate can be

decreased by turning the needle to the right.

The vacuum release air flow rate can be

increased by turning the needle left.

The vacuum release air flow rate can be

decreased by turning the needle to the right.

How to replace the filter elementHow to replace the silencer element

How to install, remove and clean the nozzle and diffuser

How to replace silencer elements for manifold type

Specifications

Ejector characteristics

Solenoid valve specifications

Vacuum release function

Vacuum switch specifications

Voltage

Electric

current

about 20msec

Electric current and voltage waveform at valve excitation

At start-up

(power consumption: 2.2W)

At start-up

(power consumption: 2.2W)

At retention

(power consumption: 0.6W)

Vacuum flow

20

8+10.3×n

(n=No. of manifold)

10

How to replace cartridge fitting

Thank you for purchasing PISCO

product. Please be sure to read this

User's Manual before using this item in

order to make sure the safety. Please

keep this manual handy with care, so that

you can refer to it whenever necessary.

PISCO products catalogues include

Common Safety Instructions for PISCO

products and Vacuum equipment. Please

confirm the Safety Instructions as well

before using this item.

Vacuum GeneratorVN

Vacuum pump system-compatible unitVNP

User's Manual

HIR0070-00

●Warning

[Products Handling]

1. Do not step onto or place objects on the devices. These may cause falling accident, fall of devices, injuries from falling and

malfunctions from device breakage.

2. Do not wash or paint the devices with solvent or water. Solvent use may cause breakage of resin parts and malfunction by

port clogs.

3. Mishandling of compressed air is dangerous. Conduct assembly and maintenance of devices with pneumatic equipment

by persons with enough knowledge and experience.

4. Since this item is not of explosion-proof structure, do not use it with or in surroundings containing flammable or explosive

gases or fluids. Avoid use it where there are constant pressures of 0.1MPa (14.5psi) or above in the vacuum circuit.

[Products maintenance]

1. Carry out maintenance and checks of equipment only after turning power off, shutting air off and making certain that the

residual pressure in the piping has dropped to zero.

2. When installing wiring and piping, be sure to switch off the power and make sure there is no miswiring and mispiping before

applying power and air.

3. In tightening the screw, use the recommended tightening torque. The recommended tightening torque for xing device is

specied on "How to x Vacuum Generator VN". The recommended tightening torque for solenoid valve is 0.15 ~ 0.2N·m.

Improper tightening may cause air leakage, dropout or breakage of the products.

[Products application]

1. For the operation of the valve, make certain that the leakage

current is less than 1mA. Leakage current larger than that may

cause malfunction.

2. Avoid applying excessive vibration or shocks to the devises. It

may damage devises and lead to malfunction of solenoid valve.

3. Long continuous power supply to the valve may raise the

temperature of the coil. Heat may cause burns or affect the

surrounding equipment adversely. Consult PISCO about such

applications.

4. Current limit circuit is adopted for the solenoid valve. It features

the current drop when the coil is energized and retains current.

Therefore, the use in the location having vibration or shock

greater than the specication below must be avoided. It may

cause valve malfunction.

●Caution

[Products Handling]

1. Do not pull or bend lead wires of solenoid valve or vacuum switch excessively. Doing so may result in disconnection of lead

wires or connector components broken.

2. Compressed air contains plenty of drain (Water, oxidized oil, tar and foreign particles etc.). Since drain may cause

performance drop, conduct air dehumidication by the after-cooler and drier, then improve air quality.

3. Never supply rubricated air.

4. Rust and inow of foreign particles in piping cause malfunction and performance drop. Therefore, install a lter (ltration

capacity: max. 5μm) just before the air supply port. On top of it, Prior-to-use and periodic ushing is recommended.

5. Do not use the devises in the atmosphere of corrosive and ammable gas. In addition, do not use the gas as uid admitted.

Since this product is not explosion-proof type, it may cause re and explosion.

6. Do not use the devices in locations where they can be exposed to water drops, oil drops, dust, etc. Since this product is not

drip or dust proof type, they may cause breakage or performance drop.

7. The lead wire of solenoid valve is polarized. Therefore, the solenoid valve is not activated by wrong polarity.

8. If continuous current is supplied to the solenoid for 15 minutes or more, please limit number of such energization to 10 times

per day maximum.

[Products maintenance]

1. When replacing cartridge ttings for air supply (PS, PV) or vacuum (V) port, be sure to remove extraneous matter from the

seal and x the fastening pin rmly in place.

2. The performance of silencer tted ejector unit and lter tted vacuum pump compatible unit may deteriorate due to dust

trapped in the elements. Therefore, we recommend cleaning well or replacing the elements at just the right time.

[Products application]

1. In selecting the piping to the vacuum (V) port, save piping bore and length for enough effective sectional area. Insufcient

effective sectional area may cause performance drop in characteristics such as suction ow and vacuum release airow.

2. In selecting the piping to the supply (PS,PV) port, save piping bore and length for enough effective sectional area.

Insufcient effective sectional area may cause performance drop due to short supply of compressed air and vacuum ow.

3. This product is not equipped with a vacuum lter. Therefore, use PISCO vacuum lter at the same time. If the lter is not

used, dust or other particles are accumulated inside the product and cause vacuum performance drop (ejector unit) and

solenoid valve malfunction such as air leakage. (ejector unit and vacuum pump compatible unit) (Recommended lter: VFU

series and VFJ series)

4. As the series number of manifolds increases, there is limitation on the simultaneous activation-allowable series depending

on the condition of the air supply (supply port size, piping length, regulator processing flow rate and etc.) and/or air

consumption (vacuum characteristics) of ejector and other such problems may possibly be encountered. Consult PISCO

sales ofce on this matter.

5. Although vacuum Generator VN series manifold type is the open to air exhaust by individual unit, the exhaust air from a

vacuum-generating unit may be exhausted to the vacuum port of other non-activating units. If this is a matter, please consult

PISCO sales ofce.

■Common to all VN series

Unit Ejector unit Vacuum pump compatible unit

Fluid admitted Air

Service pressure range 0 ~ 0.55MPa

Service temperature range 5 ~ 50°C (Non condensing)

Service humidity range 35 ~ 85%RH (Non condensing)

Protective structure IEC standard IP40 equiv.

Vibration and shock resistance 50m/s2max. /150m/s2max.

Working vacuum – 0 ~ -100kPa

■Ejector unit

Model Nozzle dia.

(mm)

Pressure supply

(MPa)

Final vacuum

(-kPa)

Suction ow

(l/min[ANR])

Air consumption

(l/min[ANR])

VNE04 0.4 0.35

90.4

2 6

VNH05 0.5 0.5 7 11.5

VNE05 0.35 3 8

VNH06 0.6 0.5 9.5 16

VNE06 0.35 5 12

■Common to all VN series

Unit Ejector unit Vacuum pump compatible unit

Item

Vacuum making solenoid valve Vacuum release solenoid valve

Vacuum supply solenoid

valve

Vacuum release solenoid valve

Operating system Direct operation

Valve construction Elastic seal, poppet valve

Voltage rating DC24V

Allowable voltage range ±10%

Surge limiting circuit Equipped with surge noise filter

Power consumption On start-up: 2.2W, On retention: 0.6W (Equipped with power saving circuit)

Operation indicator Green LED

Service pressure range 0 ~ 0.55MPa 0 ~ 0.55MPa -100 ~ 0kPa 0 ~ 0.55MPa

Valve type Normally closed

Response time (※)Max. 5msec. at vacuum generation (OFF→ON) and vacuum stop (ON→OFF).

Wiring method Connector type (Cable length: 500mm)

Red color lead wire: +24VDC, Black color lead wire: -0V

(※) The response time is the time elapsed, at supply of a supply pressure and the rated supply voltage, before a change in pressure is detected at

the vacuum port. The time required to reach vacuum and the time required to release the vacuum, both measured at the end of the piping (at

the work piece), depend on factors such as the volume (piping length) and vacuum release airow., etc.

■Common to all VN series

Vacuum release air ow 0 ~ 20l/min[ANR] (Air supply pressure is 0.5MPa)

* Variable by vacuum release flow adjusting needle.

■Vacuum pump compatible unit

Vacuum ow 8l/min[ANR] (Air supply pressure is -80kPa)

■Common to all VN series

Item Negative pressure type (-V1) Compound pressure type (-R1)

Wire connection method Connector type Grommet type

Supply voltage DC10.8 ~ 30V (ripples included)

Current consumption 20mA max. (DC24V at no-load)

Pressure detection Proliferated semiconductor pressure sensor, gauge pressure

Service pressure range -100 ~ 0kPa -100 ~ 300kPa

Proof pressure 1,000kPa 600kPa

Storage temperature range -20 ~ 70°C (Atomospheric pressure, hummidity less than 65%RH)

Operating temperature range -10 ~ 60°C (Non condensing)

Operating humidity range 35 ~ 85%RH (Non condensing)

Protective structure IEC standard IP40 equiv.

Analog output

Output voltage 1 ~ 5V

Zero-point voltage

1±0.04V (= at atmospheric) 1±0.1V (= at -100kPa)

Max. rated pressure voltage

4.6±0.04V (= at -90kPa) 5±0.1V (= at 300kPa)

Linearity ±0.5%F.S. max. (at Ta=25°C)

Temperature characteristics

±2%F.S. max. (0 ~ 50°C、Ta=25°C)

Output current

0.495mA max. (Load resistance: 10kΩmax.)

1mA max. (Load resistance: 5kΩmax.)

■Solenoid valve ■Pressure sensor

(1). Tube insertion

Simply insert a tubing into the tube

end of tting of Vacuum Generator

VN(ejector equipped with tube

fitting) and Vacuum unit VNP

(vacuum pump compatible unit

equipped with tube fitting). The

lock-claws automatically fix the

tubing, and elastic sleeve seals the tube surrounding. Please

refer to ''2. Cautions on the tting of tube'' in Common Safety

Instructions for Quick-Fitting Joint of general catalogue.

(2). Tube Release

In case of releasing the tube, push

the release ring. The lock-claws

open and the tube can be released.

Before releasing the tube, make

certain to turn off the air supply.

Use M3 screws to x the unit with the two mounting holes by the recommended tightening torque of 0.3-0.5N.m. Use of a

torque other than the recommended level may cause dropout or breakage of the products. (Please refer to the following

drawing for the dimension of hole pitch).

Turning the airflow adjustment needle clockwise decreases the flow rate of vacuum release air, while turning the needle

counterclockwise increases the ow.

● Warning

1. When removing tubing from the unit, be sure to turn offthe air supply and discharge residual air pressure completely.

2. Install the piping by checking the location of air supply port, vacuum port and exhaust port in the catalogue.

● Caution

1. Do not apply excessive vibration or shock to the unit. Using it in such condition can lead to malfunctions and/or errors.

● Caution

1. Make sure to use an appropriate at-blade screwdriver for adjusting vacuum release airow.

2. This product incorporates an internal spring as the needle rotation lock. Therefore, a locknut is not equipped on the

needle. Do not use a wrench on the hexagonal part. It may cause breakage.

● Caution

1. Do not pull or bend lead wire, connector cable, and sensor cable excessively or avoid excessive repeated motion. Such

use may cause the disconnection of wire/cable or breakage of the product.

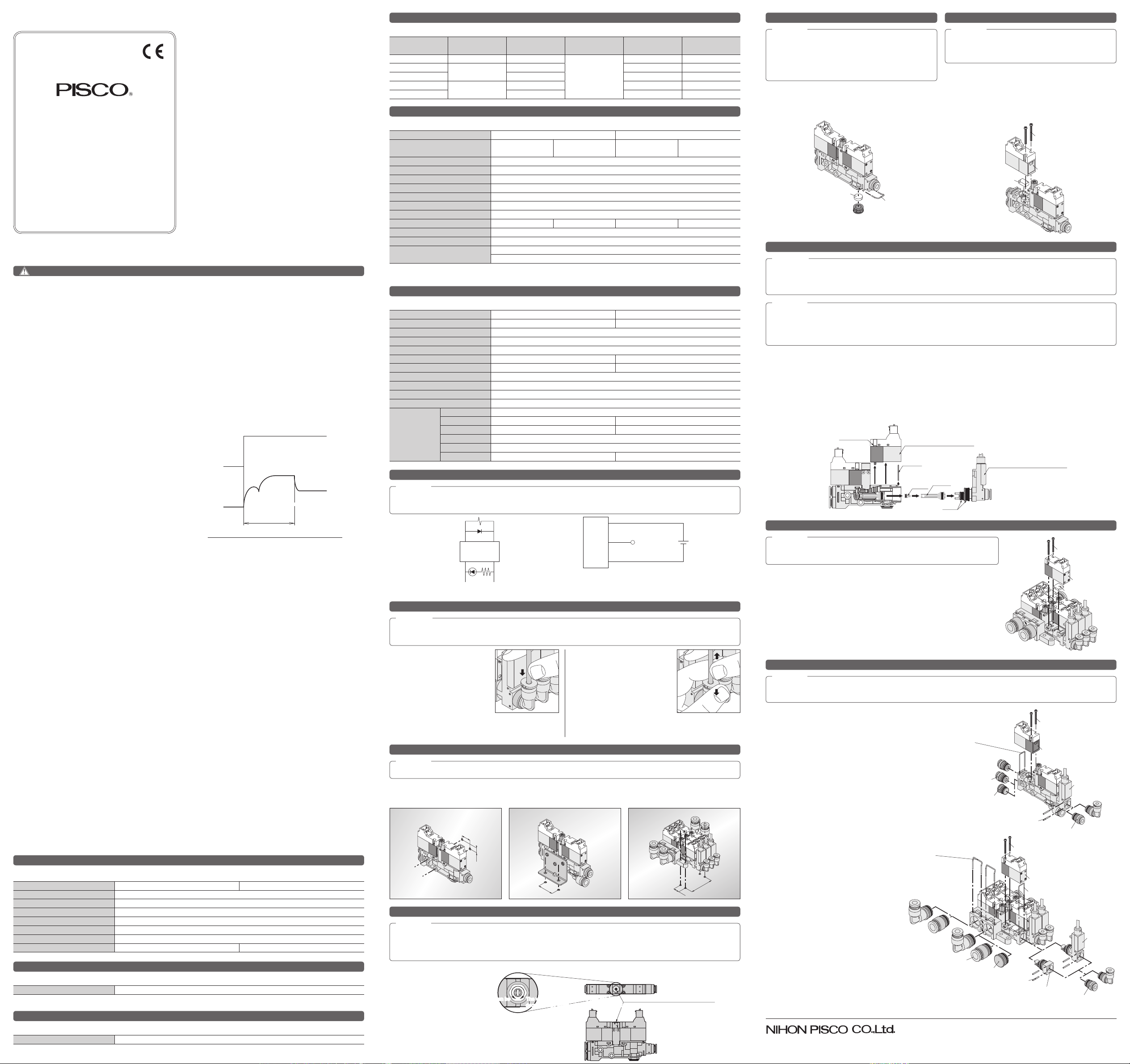

Manifold typeFixing stand alone type using bracketDirect xing of stand alone type

To remove the diffuser, rst remove the vacuum release solenoid valve, locking pin for vacuum port block with or without sensor

unit. Then, pull out the diffuser using needle-nose pliers etc. To prevent the nozzle from jumping out, cover the main body with

a cushioning material (sponge etc.), and supply vacuum making air (*1) and energize vacuum making solenoid valve. After the

nozzle has been blasted out by air, remove the cushioning material and take out the nozzle.

Remove any foreign matter attached to the nozzle, diffuser interior and seal using air blow, through wiping (*2) etc.

Install the nozzle on the diffuser, and insert to the main body, taking care that the nozzle is not detached from the diffuser. Push

in the diffuser by taking care not to damage the tip and install the vacuum port block with or without sensor unit. After inserting

the locking pin to x the vacuum port, tighten the vacuum release solenoid valve by the xing screws with a tightening torque

of 0.15-0.2N.m. For installation of the silencer element, refer to "How to replace the silencer elements".

Replacement of filter elements (Model : VN012B32) of

vacuum pump compatible unit, stand-alone type is conducted

by removing the xing screws of vacuum supply valve by an

appropriate Philips screwdriver. After new lter element has

been put in place, conrm that lter packing for the vacuum

supply solenoid valve is placed in right position, and x the

screws rmly at a tightening torque of 0.15-0.2N.m.

As for the replacement of silencer element (Model

:VN012B33) of ejector system-compatible unit stand-alone

type, pull the locking pin by a flat-blade screwdriver. After

replacing the element, make sure the locking pin is firmly

inserted.

Replacement of silencer elements (Model : VN013B19) of manifold type ejector

unit is conducted by removing the vacuum release valve by an appropriate Philips

screwdriver. After new silencer element has been put in place, confirm that the

rubber gasket for vacuum supply solenoid valve is placed in right position, and x

the screws rmly at a tightening torque of 0.15-0.2N.m.

● Caution

1. After replacing the filter element, be sure to fix the

valve by fixing screws firmly with a tightening torque of

0.15 ~ 0.2N·m.

● Caution

1. After replacing the silencer element, be sure to insert

the lock pin firmly.

2. Be careful of the direction of locking pin. If the locking

pin is inserted in reverse, the pin may drop off due to

vibration.

● Warning

1. When supplying air to the unit, do not direct the nozzle outlet at human body. The nozzle may jump out, causing injury.

2.

By supplying air without having installed the vacuum release valve, the air blows out from the square hole of main unit. In

cases like this, close vacuum release air adjusting needle completely before supplying air.

● Caution

1. After replacing the silencer element, be sure to fix the valve by fixing screws

firmly with a tightening torque of 0.15 ~ 0.2N·m.

● Caution

1. When installing the vacuum port block to the main body, be sure to conrm that no dust, uff, etc. are sticking to the

O-ring.

2. Do not damage the nozzle, diffuser interior, sealing surface, seal parts (O-ring) and interior part of main body. Otherwise,

the unit performance may deteriorate.

Lock pin

Silencer element

Fixing screw

Vacuum supply solenoid valve

Filter element

Fixing screw

Vacuum release

solenoid valve

Silencer element

● Caution

1. When installing cartridge tting, be sure to conrm that no dust, uff, etc. are sticking to the O-ring. Do not damage the

interior part of main body. The damage causes performance drop due to air leakage in vacuum circuit.

<Stand-alone type>

■Vacuum port

Pull out the spring pins (2 pieces) inserted from the side of

vacuum port block with or without sensor unit by the jig like

ø1mm pin and replace the cartridge tting.

■Supply port

Using a suitable Philips screwdriver, remove the vacuum

making solenoid valve or vacuum supply solenoid valve.

Pull out the locking pin of ports (air supply port, air supply

port for vacuum generation and air supply port for vacuum

release) using a flat-blade screwdriver and replace the

cartridge ttings. After checking the rubber gasket for the

solenoid valve is not missing, securely tighten the two xing

screws at a torque of 0.15-0.2N.m.

<Manifold type>

■Vacuum port

Using a suitable Philips screwdriver, remove

the vacuum release solenoid valve. Pull out

the locking pin using a flat-blade screwdriver

and remove the vacuum port block with or

without sensor unit. Pull out the spring pins (2

pieces) inserted from the side of the vacuum

port block by the jig like ø1mm pin and replace

the cartridge ttings. After checking the rubber

gasket for the solenoid valve is not missing,

securely tighten the two fixing screws at a

torque of 0.15-0.2N.m.

■Supply port

Pull out the locking pin of ports using a flat-

blade screwdriver and replace the cartridge

ttings.

* Be careful of the direction of locking pin. If the

locking pin is inserted in reverse, the pin may

drop off due to vibration.

Fixing screw

Vacuum release solenoid valve

Lock pin for vacuum port

Vacuum port

block with

Sensor unit

Vacuum port block

Spring pin

Cartridge

Lock pin for vacuum

making air supply port &

air supply port

Plug

Cartridge

Fixing screw

Vacuum making solenoid valve or

Vacuum supply solenoid valve

Lock pin for vacuum

making air supply port &

air supply port

Cartridge

Spring pin

Plug

Cartridge

Vacuum port block

with or without

sensor unit