Actron Super AutoScanner CP9145 User manual

6XSHU

$XWR6FDQQHU

&3

&3

8VHU

’

V0DQXDO

Copyright Information

Copyright © 2004 Actron Manufacturing, Inc.

All rights reserved.

The information, specifications and illustrations in

this manual are based on the latest information

available at the time of printing. Actron

Manufacturing reserves the right to make

changes at any time without notice.

Tool Information

Complete the following list using the

function “Tool Information” on

page 2-5. Provide this information when

contacting customer support.

Serial No:

SW ID:

HW Ver:

Boot Ver:

Prod ID:

Board ID:

Burn Date:

Burn Loc:

• • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • Safety – i

!

6DIHW\3UHFDXWLRQV

For your safety, read this manual thoroughly before operating your Super

AutoScanner™. The safety messages presented below and throughout this

user’smanualarereminderstotheoperatortoexerciseextremecarewhenusing

this test instrument.

Before using the scan tool, always refer to and follow safety messages and

applicable test procedures provided by the manufacturer of the vehicle or

equipment being tested.

Use equipment only as described in this manual.

Read All Instructions

Read, understand and follow all safety messagesand instructions in this manual

andonthetestequipment.Safetymessagesinthissectionofthemanualcontain

a signal word with a three-part message and, in some instances, an icon. The

signal word indicates the level of the hazard in a situation.

Safety Messages

Safety messages are provided to help prevent personal injury and equipment

damage. All safety messages are introduced by a signal word indicating the

hazard level. The types of safety messages are:

Indicates an imminently hazardous situation which, if not

avoided, will result in death or serious injury to the operator

or to bystanders.

Indicates a potentially hazardous situation which, if not

avoided, could result in death or serious injury to the

operator or to bystanders.

Indicates a potentially hazardous situation which, if not

avoided, may result in moderate or minor injury to the

operator or to bystanders.

Indicates a situation which, if not avoided, may result in

damage to the test equipment or vehicle.

Safety messages contain three different type styles.

• Normal type states the hazard.

•Bold type states how to avoid the hazard.

•Italic type states the possible consequences of not avoiding the hazard.

Example:Engine systems can malfunction expelling fuel, oil vapors, hot

steam, hot toxic exhaust gases, acid, refrigerant and other debris.

Wear safety goggles and protective gloves, user and

bystander. Everyday eyeglasses only have impact resistant

lenses, they are NOT safety glasses.

Engine systems that malfunction can cause injury.

!

DANGER

!

WARNING

!

CAUTION

IMPORTANT

Safety Precautions • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • •

Safety – ii • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • •

!

Important Safety Instructions

Somevehiclesareequippedwithairbags.Youmustfollowvehicle

service manual’s warnings when working around the air bag

components or wiring. If the service manual’s instructionsare not

followed, the air bag may open up unexpectedly, resulting in

personal injury. Note that the air bag can still open up several

minutes after the ignition key is off (or even if the vehicle battery

is disconnected) because of a special energy reserve module.

Risk of electric shock.

• Do not exceed voltage limits betweeninputs as indicatedin

the “Specifications” on page 2-2.

• Use extreme caution when working with circuits that have

greater than 60 volts DC or 24 volts AC.

Electric shock can cause injury.

Risk of explosion.

• Wear safety goggles and protective clothing, user and

bystander.Everydayeyeglassesonlyhaveimpactresistant

lenses, they are NOT safety glasses.

• Do not use this system in environments where explosive

vapor may collect, such as in below-ground pits, confined

areas, or areas that are less than 18 inches above the floor.

• Use this equipment in locations with mechanical

ventilation providing at least four air changes per hour.

• Flammable fuel and vapors can ignite.

• Do not smoke, strike a match, or cause a spark in the

vicinity of the battery. Battery gases can ignite.

• Avoid making accidental connection between battery

terminals. Do not place uninsulated metal tools on the

battery.

• When removing battery cables, remove ground cable first.

• Avoid sparks when connecting or disconnecting power

leads to battery.

• Be sure ignition is OFF, headlights and other accessories

are OFF andvehicledoors areclosed before disconnecting

batterycables.Thisalsohelpspreventdamagetoon-board

computer systems.

• Always disconnect battery ground connections before

servicing electrical system components.

Explosion can cause injury.

Risk of poisoning.

• Use this equipment in locations with mechanical

ventilation providing at least four air changes per hour.

Engine exhaust contains odorless lethal gas.

• Route exhaust outside while testing with engine running.

Poisoning can result in death or serious injury.

!

DANGER

!

WARNING

• • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • Safety – iii

• • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • Safety Precautions

!

Battery acid is a highly corrosive sulfuric acid.

• Wear safety goggles and protective gloves, user and

bystander.Everydayeyeglassesonlyhaveimpactresistant

lenses, they are NOT safety glasses.

• Make sure someone can hear you or is close enough to

provide aid when working near a battery.

• Have plenty of fresh water and soap nearby. If battery acid

contacts skin, clothing, or eyes, flush exposed area with

soap and water for 10 minutes.

• Seek medical help.

• Do not touch eyes while working near battery.

Battery acid can burn eyes and skin.

Risk of fire.

• Wear safety goggles and protective clothing, user and

bystander.Everydayeyeglassesonlyhaveimpactresistant

lenses, they are NOT safety glasses.

• Do not position head directly over or in front of throttle

body. Do not pour gasoline down throttle body when

cranking or running engine, when working with fuel

delivery systems or any open fuel line.Engine backfirecan

occur when air cleaner is out of position.

• Do notuse fuel injector cleaningsolvents when performing

diagnostic testing.

• Keep cigarettes, sparks, open flame and other sources of

ignition away from vehicle.

• Keep a dry chemical (Class B) fire extinguisher rated for

gasoline, chemical and electrical fires in work area.

Fire can cause death or serious injury.

Risk of flying particles.

Wear safety goggles while using electrical equipment.

Electrical equipment or rotating engine parts can cause

flying particles.

Flying particles can cause eye injury.

Risk of burns.

Batteriescan produce ashort-circuit current high enoughto

weld jewelry to metal. Remove jewelry such as rings,

bracelets and watches before working near batteries.

Short circuits can cause injury.

Risk of burns.

• Do not remove radiator cap unless engine is cold.

Pressurized engine coolant may be hot.

• Do not touch hot exhaust systems, manifolds, engines,

radiators, sample probe, etc.

• Wear insulated gloves when handling hot engine

components.

• Testerleadscan becomehot afterextendedtestingin close

proximity to manifolds etc.

Hot components can cause injury.

!

WARNING

!

WARNING

Safety Precautions • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • •

Safety – iv • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • •

!

Risk of expelling fuel, oil vapors, hot steam, hot toxic exhaust

gases, acid, refrigerant and other debris.

• Wear safety goggles and protective clothing, user and

bystander.Everydayeyeglassesonlyhaveimpactresistant

lenses, they are NOT safety glasses.

• Engine systems can malfunction expelling fuel, oil vapors,

hot steam, hot toxic exhaust gases, acid, refrigerant and

other debris.

Fuel, oil vapors, hot steam, hot toxic exhaust gases, acid,

refrigerant and other debris can cause serious injury.

The engine compartment contains electrical connections and hot

or moving parts.

• Keep yourself, test leads, clothing and other objects clear

of electrical connections and hot or moving engine parts.

• Do not wear watches, rings, or loose fitting clothing when

working in an engine compartment.

• Do not place test equipment or tools on fenders or other

places in the engine compartment.

• Barriers are recommended tohelp identifydangerzones in

test area.

• Prevent personnel from walking through immediate test

area.

Contact with electrical connections and hot or moving parts can

cause injury.

Risk of injury.

• This equipment should be operated byqualified personnel

only.

• Use this equipment only as described in this manual. Use

only the manufacturer’s recommended attachments.

• Do not operate equipment with a damaged cord or if the

equipment hasbeen dropped or damaged, until it has been

examined by a qualified service representative.

Operation of this equipment by anyone other than qualified

personnel may result in injury.

Risk of unexpected vehicle movement.

• Block drive wheels before performing a test with engine

running.

• Unless instructed otherwise, set parking brake and put

gear selector in neutral for standard transmissions or park

for automatic transmissions.

• If vehicle has an automatic parking brake release,

disconnect release mechanism for testing and reconnect

when testing is completed.

• Do not leave a running engine unattended.

A moving vehicle can cause injury.

PRNDL2

!

WARNING

• • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • Safety – v

• • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • Safety Precautions

!

Risk of equipment or circuit damage.

• Unless specifically directed by the manufacturer, make

sure the ignition is OFF before connecting or

disconnecting connectors or any vehicle electrical

terminals.

• Do not create a short between battery terminals with a

jumper wire or tools.

Improper equipment use can cause equipment or circuit

damage.

Misdiagnosis may lead to incorrect or improper repair and/or

adjustment.

Do not rely on erratic, questionable, or obviously erroneous

test information or results. If test information or results are

erratic, questionable, or obviously erroneous, make sure

that all connections and data entry information are correct

and that the test procedure was performed correctly. If test

information or results are still suspicious, do not use them

for diagnosis.

Improper repair and/or adjustment may cause vehicle or

equipment damage or unsafe operation.

!

CAUTION

!

CAUTION

Safety Precautions • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • •

Safety – vi • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • •

!

ToC

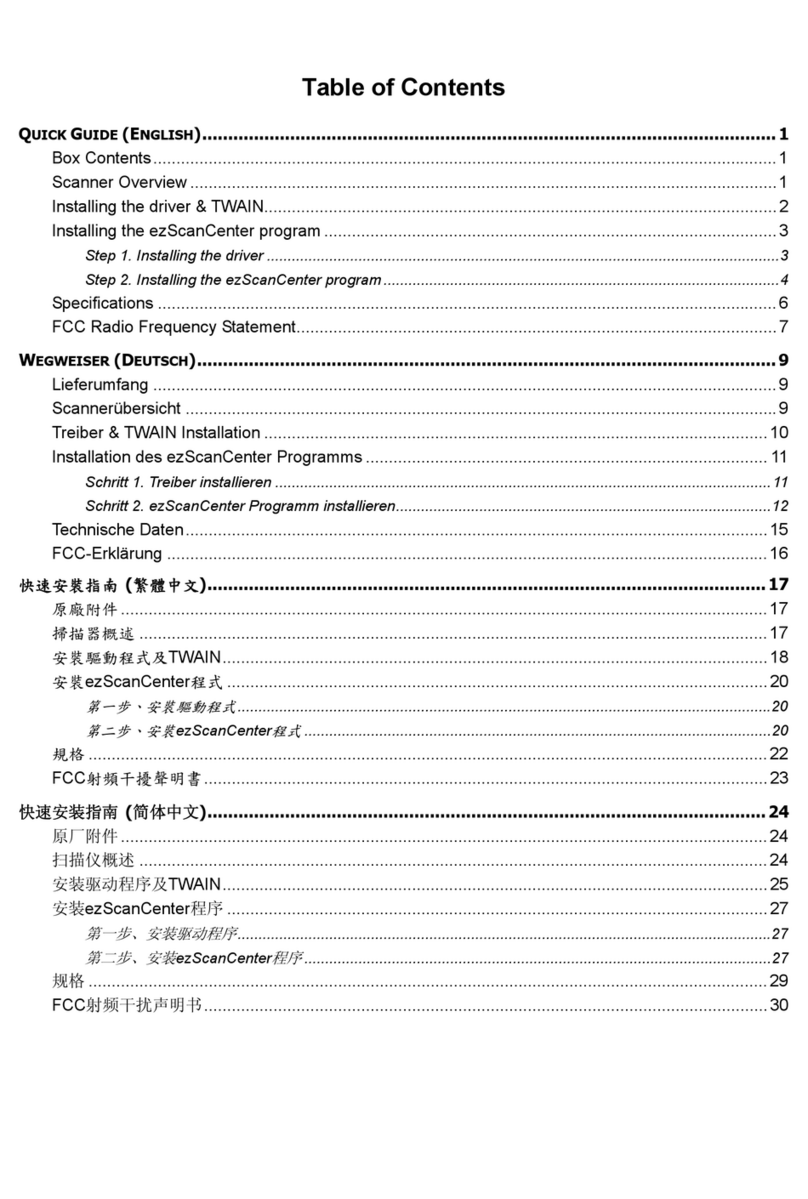

Table of Contents

Safety Precautions

Part 1 – Getting Started

Manual Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

On-Board Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Diagnostic Link Connectors (DLC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

OBD II (J1962) DLC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Ford Historic (OBD I) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

GM Historic (OBD I) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Chrysler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Diagnostic Trouble Codes (DTCs) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Vehicle Service Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

Part 2 – Using The Tool

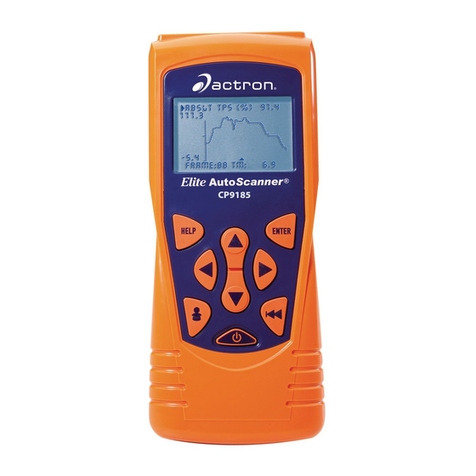

Tool Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Keyboard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Scan Tool Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Tool Power-Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Tool Navigation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Tool Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Vehicle Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Part 3 – Global OBD II Diagnostics

I/M Readiness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Read Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Erase Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

View Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

View Freeze Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Review Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Part 4 – GM Historic Diagnostics

Read Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Erase Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

View Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Review Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Field Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

ToC

Part 5 – Ford Historic Diagnostics

Read KOEO Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Read KOER Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Fast or Slow Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 5-4

Computed Timing Check (1984-1991 EEC-IV Vehicles) . . . . . . . . . . .. 5-5

Review Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Erase Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

EEC-IV Erase Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 5-7

MECS Erase Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 5-7

Wiggle Test (EEC-IV Vehicles) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

Output Switch Test (EEC-IV Vehicles) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

DCL Data Functions (EEC-IV Vehicles) . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

Cyl Balance Test (EEC-IV Vehicles) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

IVSC-Speed Ctrl (EEC-IV Vehicles) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-13

STAR Test Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-15

Part 6 – Chrysler Historic Diagnostics

Read Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Erase Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

View Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Switch Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

Actuator Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

Idle Speed Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

Sensor Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

Review Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

Part 7 – Help & Troubleshooting

How to Use On-Line Help . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Tool Does Not Power Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Using Non-OBD II Adapter Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 7-2

Using J1962 (OBD II) or Chrysler LH Adapter Cable . . . . . . . . . . . . . .. 7-2

Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

Vehicle Communication Fault . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 7-3

Operating Error or Erroneous Data . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 7-3

Battery Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

Tool Self-Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

Display Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 7-5

Keyboard Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 7-5

Memory Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 7-6

Program Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 7-6

Technical Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6

Appendix A – Data Link Connectors

Appendix B – Glossary

1

• • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • 1 – 1

3DUW *HWWLQJ6WDUWHG

The SUPER AutoScanner™ was developed by expertsin the automotive service

industry to help diagnose vehicles and assist in troubleshooting procedures. The

tool will monitor vehicle events and to read codes from the computer’s memory

to pinpoint problem areas.

Allinformation,illustrationsandspecificationscontainedinthismanualarebased

onthelatestinformationavailablefromindustrysourcesatthetimeofpublication.

No warranty (expressed or implied) can be made for its accuracy or

completeness, nor is any responsibility assumed by the manufacturer or anyone

connectedwithitforlossordamagessufferedthroughrelianceonanyinformation

contained in this manual or misuse of accompanying product. The manufacturer

reserves the right to make changes at any time to this manual or accompanying

product without obligation to notify any person or organization of such changes.

MANUAL CONVENTIONS

This manual provides instructions to setup and use your SUPER

AUTOSCANNER™. A glossary and application charts provide valuable

reference material. Some of the information shown in text or illustrations is

obtained using optional equipment. A Sales Representative can help determine

option availability. This section contains a list of conventions used.

Safety Messages

Refer to “Safety Precautions” at the beginning of this manual.

Check Note

A check note provides additional information about the subject in the preceding

paragraph.

Example:

✓Make sure the printer is turned on, on-line and connected.

Tips and Lists

Tips and lists provideinformation that applies to specific systems and processes.

Each tip is introduced by this icon ❒for easy identification.

Example:

❒Use the

83'2:1

arrow keys to move up/down through the display or

move the cursor ([) to a selectable item.

Equipment Damage

Situations arise during testing that could damage the vehicle or the test

equipment. The word IMPORTANT signals these situations.

Example:

Screens may differ slightly for vehicle make and year.

Functions and Selections

Diagnostic and tool functions performed by the tool are highlighted in bold.

Example:

Select Read Codes and press

(17(5

.

Getting Started • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • •

1 – 2• • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • •

1

Menus

The menus on the tool display are referenced in the procedures and are

highlighted in bold-italic text.

Example:

Press the

(17(5

key to return to theGM Function List.

Questions and Responses

Messages and user responses are CAPITALIZED.

Example:

Selecting NO displays a COMMAND CANCELLED message prompting you to

press

(17(5

to continue back to the OBDII Function List.

Manual References

Used to reference other sections of the manual. References include the “Title”

and page number (section-page).

Example:

Complete the following list using the function “Tool Information” on page 2-5.

Screens

The screens are presented as examples and may change as the software is

updated.

Example:

ON-BOARD DIAGNOSTICS

The original on-board diagnostics (OBD I) lacked consistency in communication

and interface while allowing different interpretations amongst vehicle

manufacturers. Ford used several types of engine control computers, Chrysler

used several types of data link connectors and GM varied the trouble codes and

communication protocols from year-to-year.

The following tables highlight changes for GM, Ford, and Chrysler. If this seems

confusing; don’t worry. Your tool makes it easy. Based on the VIN information

selected during Scan Tool setup, the processor is automatically recognized. All

you have to do is choose the correct adapter cable and jumper wires (if

necessary). Details on adapter cables and jumper wires may be found in

“Diagnostic Link Connectors (DLC)” on page 1-4.

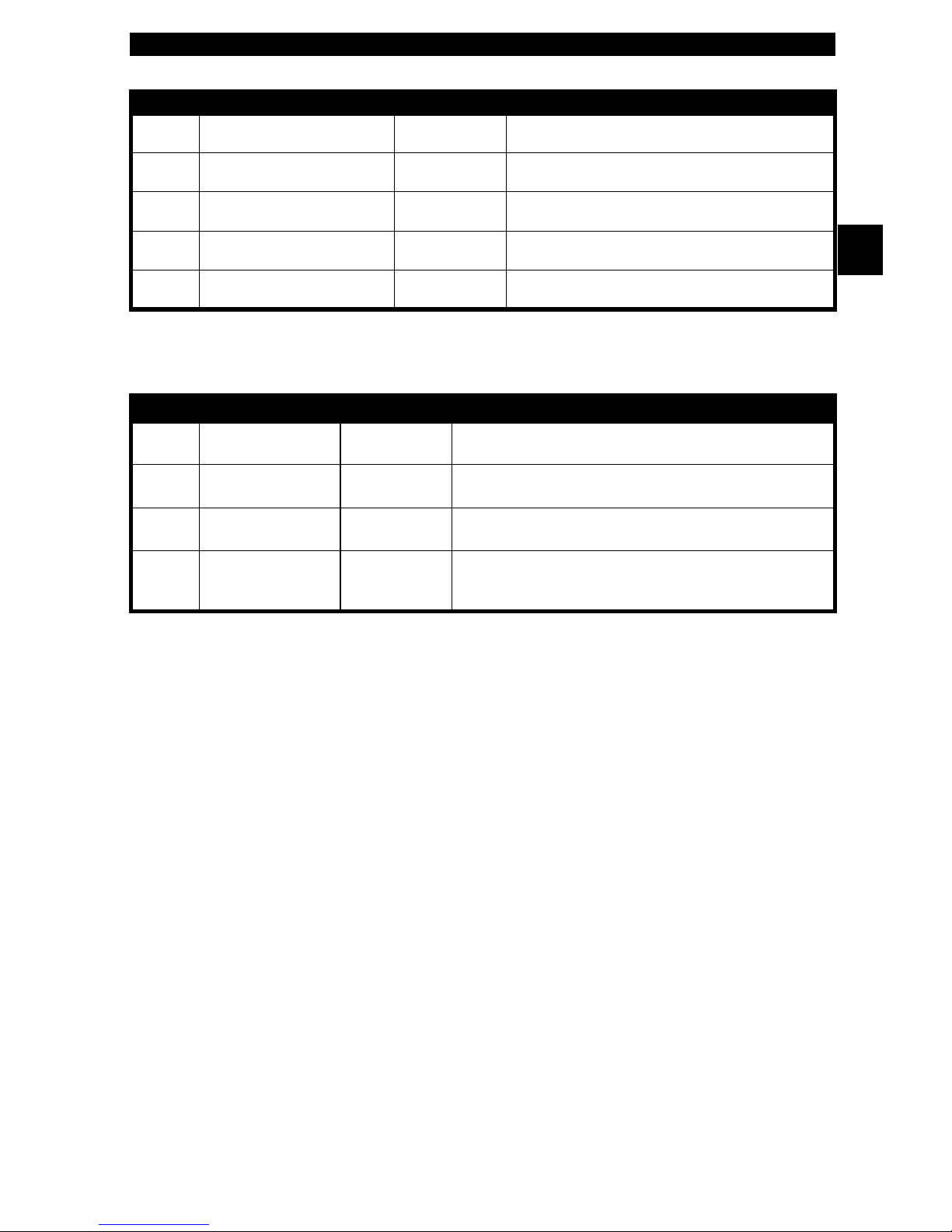

GM On-Board Diagnostics

System Years Description

OBD I Control Module

1981–1995

Most vehicles used the 12-pin ALDL (Assembly Line Data Link)

located under the dash on the driver side. Some 94-95 vehicles

used the 16-pin OBD II (J1962) data link connector (DLC), but

use the Historical application software. Refer to the vehicle’s

Vehicle Emission Control Information label.

OBD II Control Module

1994*-Present Complies with OBD II regulations and uses the J1962 DLC.

*

OBD II system used in certain 1994-1995 vehicles equipped with a 2.2L, 2.3L, 3.8L, 4.3L or 5.7L engines.

!3;@!7@G ^

[ *7:;5>7;39@AE;E

(AA>'7FGB ]

(AA>'7>8W(7EFE

• • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • 1 – 3

• • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • Getting Started

1

OBD II stands for On-Board Diagnostics version II. OBD II is a system that the

Society of Automotive Engineers (SAE) developed to standardize automotive

electronic diagnosis. Technicians now can use the same tool to test any OBD II

compliantvehicleswithoutspecialadapters.TheestablishedSAEguidelinesare:

• a universal diagnostic test connector, called the data link connector (DLC),

with dedicated pin assignments.

• a standardized location for the DLC, visible under the dash on the driver’s

side.

• a standardized list of diagnostic trouble codes (DTCs) used by all

manufacturers.

• a standardized list of parameter identification (PID) data used by all

manufacturers.

• the ability of the vehicle system to record a freeze frame of the operating

conditions when a fault occurs.

• expanded diagnostic capabilities that records a code whenever a condition

occurs that effects vehicle emissions.

• the ability to clear stored codes from vehicle memory with the scan tool.

In addition, SAE has published hundreds of pages of text defining a standard

communications protocol that establishes the hardware, software, and circuit

parameters of OBD II systems. Unfortunately, vehicle manufacturers have

different interpretations of this standard communications protocol. As a result, the

genericOBDIIcommunicationsschemeusedwillvary,dependingonthevehicle.

Ford On-Board Diagnostics

System Long Name Years Description

MCU

Microprocessor Control Unit 1980 –1991 Used in police vehicles, containing carbureted

engines. Uses the MCU DLC.

EEC-IV

Electronic Engine Control,

Fourth generation 1984 –1995 Most Ford vehicles equipped with North American

engines. Uses the EEC-IV DLC.

MECS

Mazda Electronic Control

System 1988 –1995 Vehicles equipped with Mazda-sourced engines.

Uses MECS 6-pin and 17-pin DLCs.

EEC-V

Electronic Engine Control,

Fifth generation 1994* – present Complies with OBD II regulations and uses the

OBD II J1962 DLC.

PTEC

Powertrain Electronic Con-

troller 2000 – present Complies with OBD II regulations and uses the

OBD II J1962 DLC.

* EEC-V OBD II system used in 1994-1995 vehicles equipped with a 3.8L or 4.6L engine.

Chrysler On-Board Diagnostics

System Long Name Years Description

SMEC

Single Module

Engine Controller 1989–1990 Used a 6-pin Serial Communication Interface (SCI) DLC

and has bidirectional capability.

SBEC

Single Board Engine

Controller 1989*–1995 Used two types of DLCs: a 6-pin SCI and a 6-pin LH series.

The first to allow a tool to reset the EMR light on trucks.

OBD II

PCM

OBD II Powertrain

Control Module 1995**– present Complies with OBD II regulations and uses the OBD II

J1962 DLC.

JTEC

Jeep/Truck Engine

Controller 1996– present Complies with OBD II regulations and uses the OBD II

J1962 DLC.

The JTEC system is used on light-duty trucks and Jeeps

* In 1989, the SBEC system was installed in selected vehicles with 3.0L V6 engines.

** Some vehicles in 1995 were equipped with the OBD II PCM.

Getting Started • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • •

1 – 4• • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • •

1

SAE publishes recommendations, not laws, but the Environmental Protection

Agency (EPA) and California Air Resources Board (CARB) made manyof SAE’s

recommendations legal requirements that vehicle manufacturers were required

to phase in over a three-year period. Beginning in 1994, vehicles with a new

engine management computer – about 10% of each manufacturers fleet – were

supposed to comply with OBD II standards. For 1995, OBD II systems were to

appearonabout40%ofthenewvehiclessoldintheUSA.Someofthe1994-1995

OBD II systems were not fully compliant, so the Government granted waivers to

givemanufacturerstimetofine-tunetheirsystems.Beginningin1996,mostofthe

new vehicles sold in the USA were fully OBD II compliant.

DIAGNOSTIC LINK CONNECTORS (DLC)

The Data Link Connector (DLC) allows the scan tool to communicate with the

vehicle’s computer(s). Before OBD II, manufacturers used different data link

connectorsto communicate withthe vehicle.The proper DLC adapter cable must

be used to connect the tool to the vehicle. Also, the vehicle’s DLC may be found

in several different places and have many different configurations. The following

describes the DLCs used by Ford, GM and Chrysler. The DLC location and types

for domestic vehicles can be looked up in the charts in “Appendix A – Data Link

Connectors” .

OBD II (J1962) DLC

Beginningin1996,vehiclessoldinthe

United States use the J1962 DLC, a

term taken from a physical and

electrical specification number

assigned by SAE (J1962). OBD II

defines the physical and electrical

specification for the DLC. The DLC

shouldbelocatedunderthedashboardonthedriversideofthevehicle.IftheDLC

is not located under the dashboard as stated, a decal describing its location

should be attached to the dashboard in the area the DLC should have been

located.

Because the OBD II J1962 connector has power and ground, you only need a

single cable connection to the tool for both power and tool communications.

AttachtheOBDIIadaptercabletotheextendercable,bothsuppliedwiththetool,

to connect the tool. Certain pins in the connector are reserved.

1 - Manufacturer Reserved

2 - J1850 Bus+

3 - Manufacturer Reserved

4 - Chassis Ground

5 - Signal Ground

6 - CAN High, J-2284

7 - K Line, ISO 9141-2 & ISO/DIS 14230-4

8 - Manufacturer Reserved

9 - Manufacturer Reserved

10 - J1850 Bus

11 - Manufacturer Reserved

12 - Manufacturer Reserved

13 - Manufacturer Reserved

14 - CAN Low, J-2284

15 - L Line, ISO 9141-2 & ISO/DIS 14230-4

16 - Battery Power

1

9

8

16

• • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • 1 – 5

• • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • Getting Started

1

Ford Historic (OBD I)

Since 1984, Ford used several different types of powertrain control modules

(PCM). Refer to “On-Board Diagnostics” on page 1-2. With the proper adapter

cables, your tool will be able to read these systems as well.

Use the Battery Power cable to provide 12V to the tool for all

systems.

EEC-IV System

The EEC-IV computer system

uses a large six-sided

connector and a pigtail

connector.

MCU System

The MCU computer system

uses the same six-sided

connector,but NOT thepigtail

connector. Leave the pigtail

unattached.

MECS (Mazda Electronic Control System)

MECS vehicles (1988 –1995) use either a 6-pin (with pigtail) or a 17-pin DLC. The

6-pin MECS adapter cable and jumper wires (P/N 9131) are used to connect the

tool to both DLCs. Both adapter cables are also available through your dealer.

6-Pin MECS.

IMPORTANT

Vehicle DLC

EEC-IV/MCU

Cable Adapter

EEC-IV/MCU

STI Pigtai

l

EEC-IV onl

y

To Scan

Tool

P/N CP9128

STI Pigtail

456

123

To Scan

Too l

6-Pin MECS

Clip to good

Vehicle ground

Cable Adapter

Vehicle DLC

6-Pin MECS

Pigtail

P/N CP9131

Getting Started • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • •

1 – 6• • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • •

1

17-Pin MECS

Use the 6-Pin

MECS and the

jumper wires.

MECS Ford Probe

Certain Probes have a WHITE TACH CONNECTOR located very

close to the 6-pin Self-Test connector and bundled in the same

wiring harness. This is NOT the STI (Self Test Input) Pigtail.

Connect the pigtail to

the BLACK STI

connector located

fartherbackonthewire

harness. If the tool is

connected to the

WHITE Tach

connector, serious

damage will result and

may void warranty.

Refer to the illustration.

GM Historic (OBD I)

Prior to1996, most GM vehicles used the standard 12-pin Assembly Line

DiagnosticLink(ALDL). Use theGM ALDL cable kit (p/nCP9127) which includes

the ALDL adapter and cigarette lighter power cable for these vehicles. In 1994 &

1995, certain GM vehicles used the J1962 DLC.

Use the Battery Power cable to provide 12V to the tool.

STI Pigtail

6-Pin MECS

STO

456

123

Clip to good

vehicle ground

Adapter Cable Vehicle DLC

17-Pin MECS

To

Scan Tool

P/N CP9128

IMPORTANT

STI

Pigtail

BLACK STI

Connector

WHITE

Tach

Connector

DO NOT USE!

6-Pin MECS

6-Pin MECS

456

123

To

Scan

Tool

Clip to good

vehicle ground

Cable Adapter

6-Pin MECS

Vehicle DLC

6-Pin MECS

Windshield

Wiper

Motor

P/N CP9128

IMPORTANT

• • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • 1 – 7

• • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • Getting Started

1

ALDL

The ALDL DLCs are usually located under

the dashboard on the driver’s side.

Corvettes & Fieros:

Sometimes, the DLC is located in the center console behind the ashtray. Refer to

vehicle service manual for exact location. It may be in full view, or it may be

recessed behind a panel. An opening in the panel should allow access to the

recessed connector.

Chrysler Use the Battery Power cable to provide 12V to the tool for both

systems.

SCI

The SCI (serial communicationsinterface)DLC is a 6-pin

connector located in the engine compartment. The

adaptercabletobeusedonthesevehiclesissuppliedwith

thetool.ThiscableislabeledCHRY onthe15pinDBstyle

connector and SCI on the vehicle end.

LH-series

The LH-series data link connector is used on LH platform

vehicles. The LH style DLC is a small, blue, rectangular

6-pin connector located in the passenger compartment

below the dashboard to the right of the steering column.

TheLHAdapterCable(P/N CP9130)is optionaland must

be purchased separately.

F

G

E

H

D

J

C

K

B

L

A

M

ALDL (P/N CP9127)

IMPORTANT

SCI (P/N CP9129)

LH (P/N CP9130)

Getting Started • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • •

1 – 8• • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • •

1

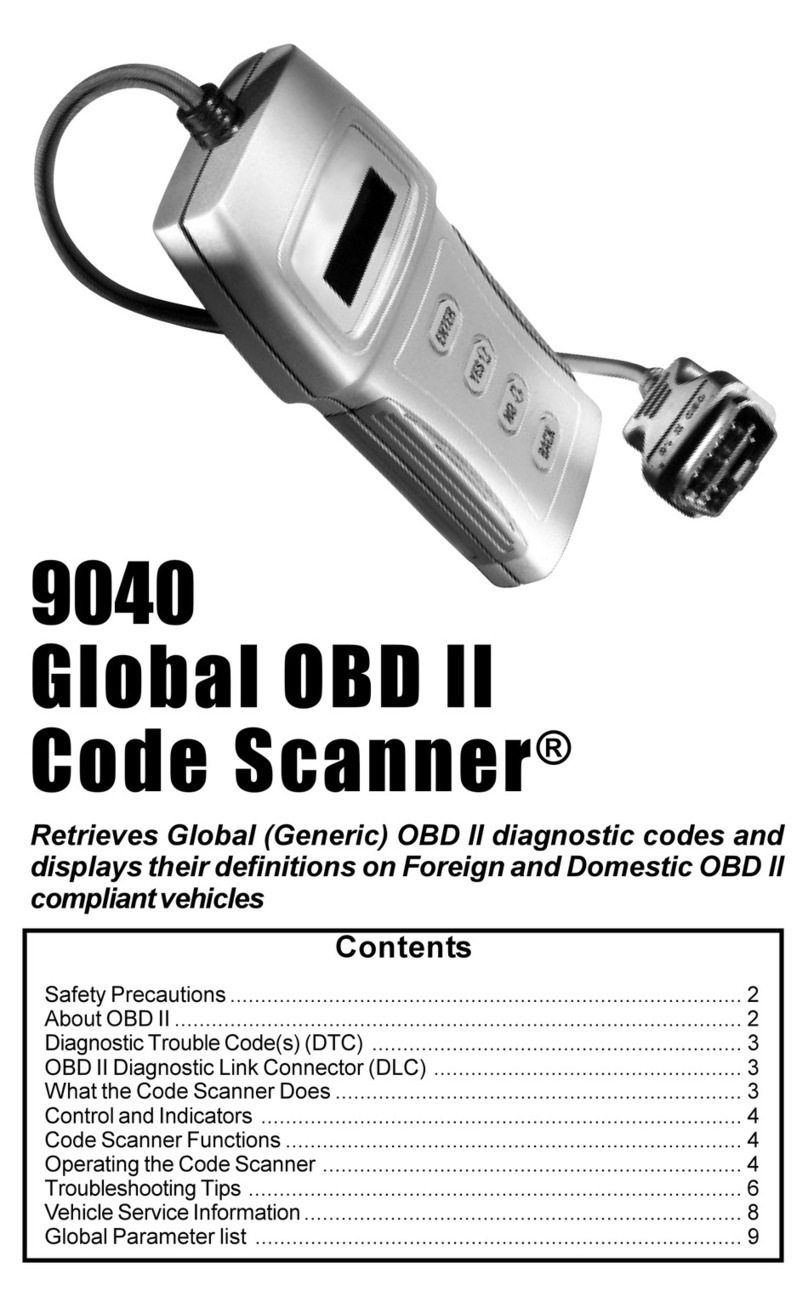

DIAGNOSTIC TROUBLE CODES (DTCS)

Diagnostic Trouble Codes (DTCs) consist of a five-digit alphanumeric code. The

DTC format and general code types are shown below. When the on-board

computer recognizes and identifies a problem, a DTC for that fault is stored in

memory. These codes are intended to help you determine the root cause of a

problem

.

J2012 and ISO 15031-6 are standards for all DTCs, established by the SAE,

International Organization for Standardization (ISO) and other governing bodies.

Codes and the definitions assigned by this specification are known as Generic

OBD II codes. OBD II requires compliance of this standard, and has made it a

standard for all cars, light trucks, APVs, MPVs, and SUVs sold in the U.S.Codes

not reserved by the SAE are reserved for the manufacturer and referred to as

Manufacturer Specific.

Example:

P0101 - Mass or Volume Air Flow Circuit Range/Performance Problem

P0 1 0 1

Vehicle Specific System

Powertrain Codes

P0xxx - Generic (SAE)

P1xxx - Manufacturer Specific

P2xxx - Generic (SAE)

P30xx-P33xx - Manufacturer Specific

P34xx-P39xx - Generic (SAE)

Chassis Codes

C0xxx - Generic (SAE)

C1xxx - Manufacturer Specific

C2xxx - Manufacturer Specific

C3xxx - Generic (SAE)

Body Codes

B0xxx - Generic (SAE)

B1xxx - Manufacturer Specific

B2xxx - Manufacturer Specific

B3xxx - Generic (SAE)

Network Communication Codes

U0xxx - Generic (SAE)

U1xxx - Manufacturer Specific

U2xxx - Manufacturer Specific

U3xxx - Generic (SAE)

Specific Fault Designation

Bx - Body

Cx - Chassis

Px - Powertrain

Ux - Network Comm.

x = 0, 1, 2 or 3

• • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • 1 – 9

• • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • Getting Started

1

VEHICLE SERVICE INFORMATION

The following is a list of publishers who have manuals containing electronic

engine control diagnostic information. Some manuals may be available at auto

partsstoresoryourlocalpubliclibrary.Forothers,youneedtowriteforavailability

and pricing, specifying the make, model and year of your vehicle.

Suitable manuals have titles such as:

• “Electronic Engine Controls”

• “Fuel Injection and Feedback Carburetors”

• “Fuel Injection and Electronic Engine Controls”

• “Emissions Control Manual”

... or similar titles

Chilt

on

B

oo

k

C

ompany

Chilton Way

Radnor, PA 19089

Haynes Publications

861 Lawrence Drive

Newbury Park, CA 91320

Cordura Publications

Mitchell Manuals, Inc.

Post Office Box 26260

San Diego, CA 92126

Motoríst Auto Repair Manual

Hearst Company

250 W. 55th Street

New York, NY 10019

General Motors Corporation:

Buick, Cadillac, Chevrolet, GEO, GMC,

Oldsmobile, & Pontiac

Helm Incorporated

Post Office Box 07130

Detroit, MI 48207

S

a

t

urn:

Adistra Corporation

c/o Saturn Publications

101 Union St.

Post Office Box 1000

Plymouth, MI 48170

Ford Motor Company:

Ford, Lincoln, & Mercury

Ford Publication Department

Helm Incorporated

Post Office Box 07150

Detroit, MI 48207

Chrysler Corporation:

Chrysler, Plymouth, & Dodge

Chrysler Motors Service Training

26001 Lawrence Avenue

Center Line, MI 48015

Getting Started • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • •

1 – 10 • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • •

1

Getting Started Notes

This manual suits for next models

1

Table of contents

Other Actron Scanner manuals

Actron

Actron 9040 User manual

Actron

Actron CP9690 Elite AutoScanner User manual

Actron

Actron CP9180 User manual

Actron

Actron CP9180 User manual

Actron

Actron Code Scanner CP9015 User manual

Actron

Actron CP9680 AutoScanner Plus Technical manual

Actron

Actron Code Scanner CP9015 User manual

Actron

Actron CP9190 User manual

Actron

Actron Professional Enhanced Scan Tool 9640A User manual

Actron

Actron 9640 User manual