300S v

Introduction

Introduction

Software Version

The software version is shown on the initial power up screen.

300S

DRO axis availability.

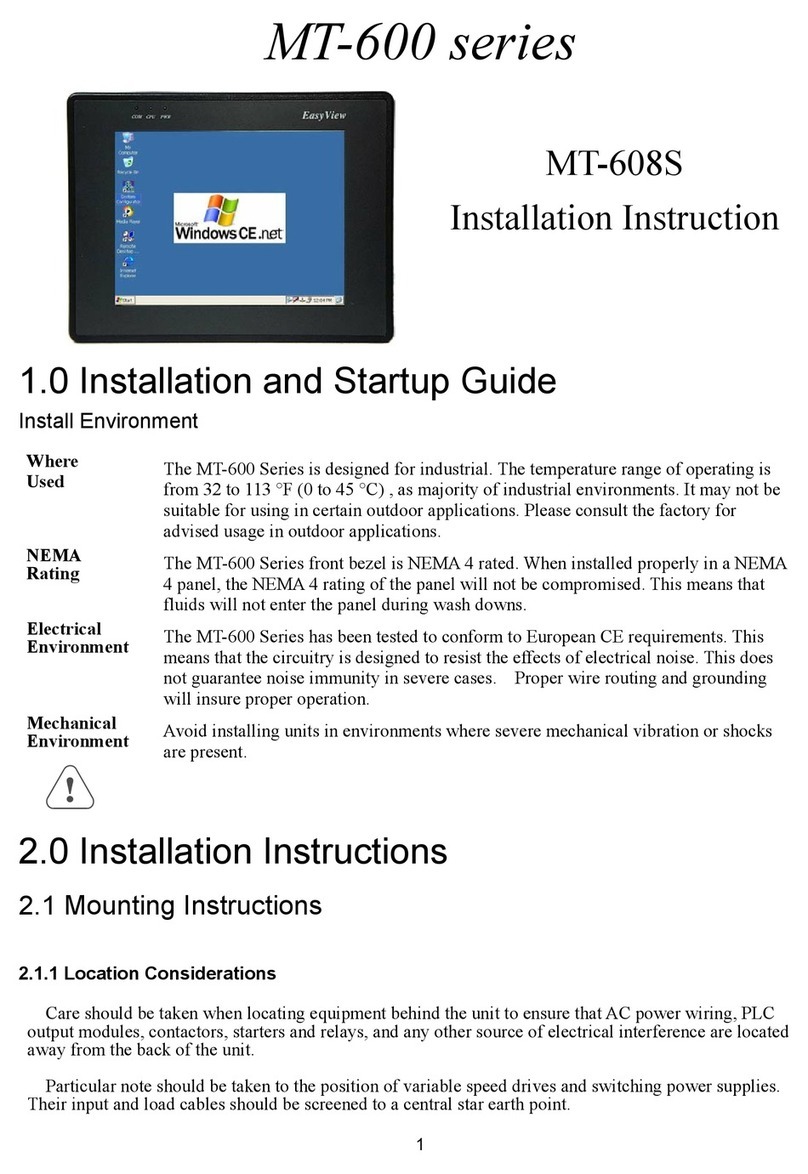

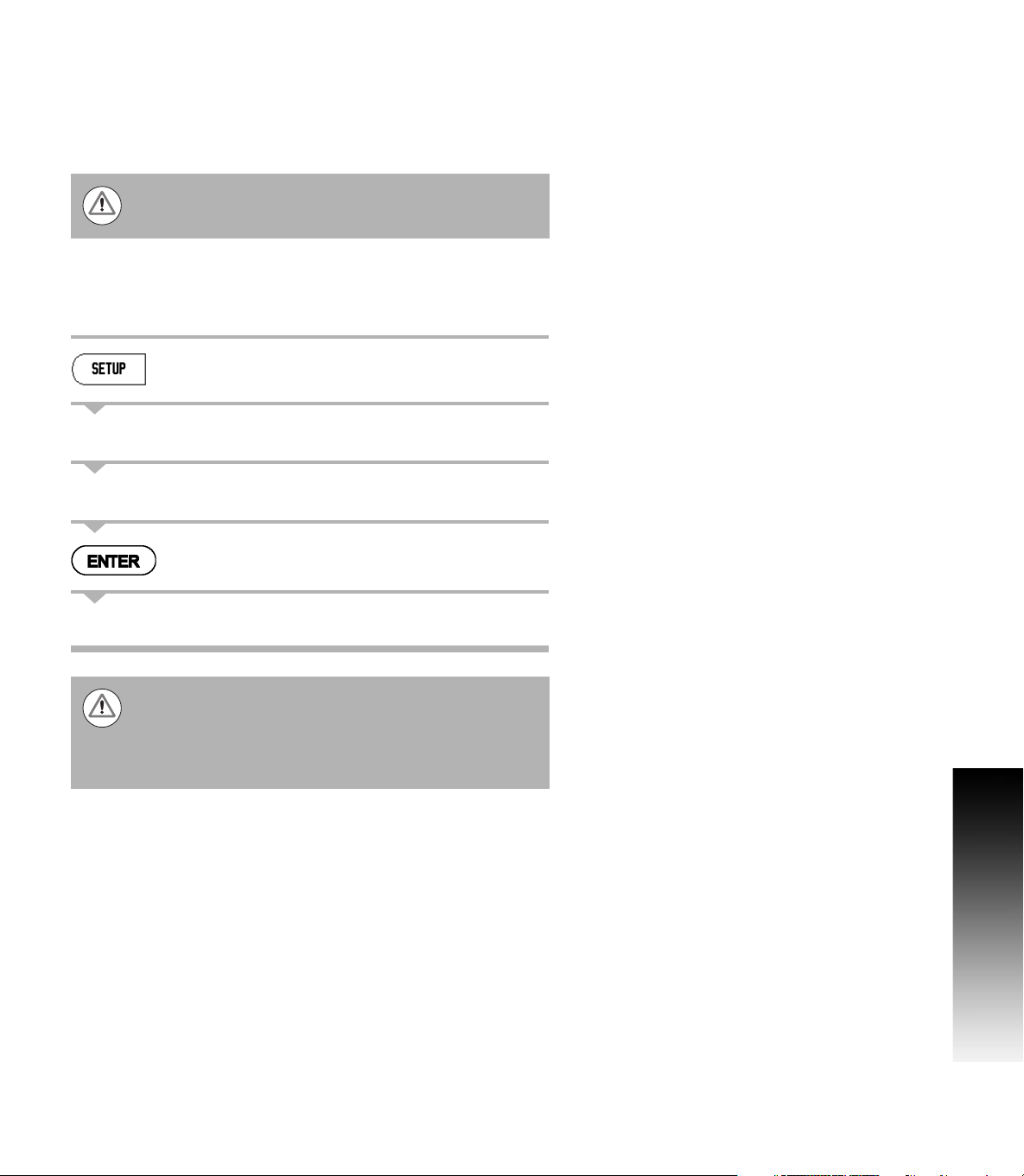

Symbols within Notes

Every note is marked with a symbol on the left indicating to the

operator the type, and/or potential severity of the note.

300S Fonts

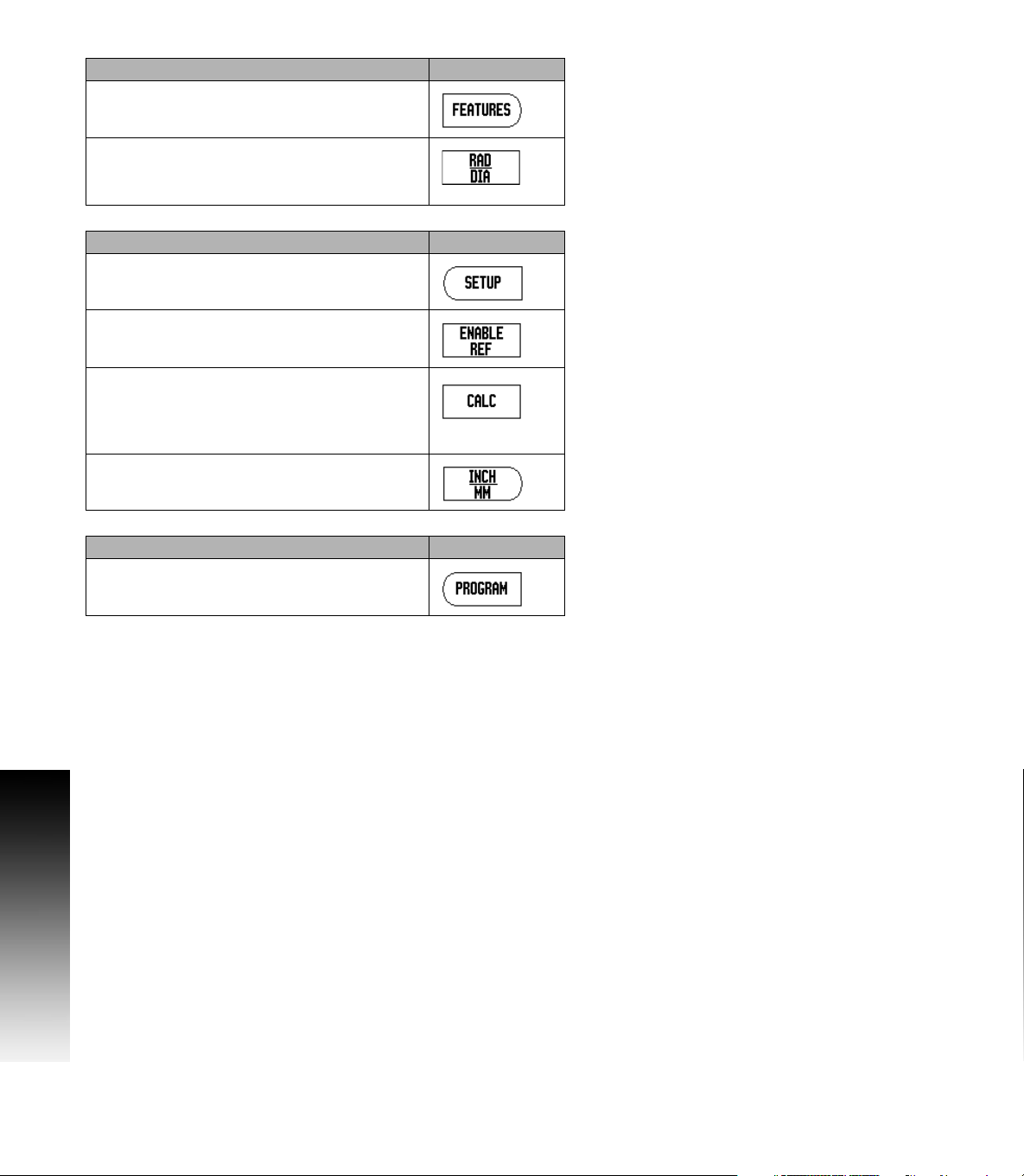

The following shows how soft keys, and hard keys are represented

within the text of this manual:

Soft keys - SETUP soft key

Hard keys - ENTER hard key

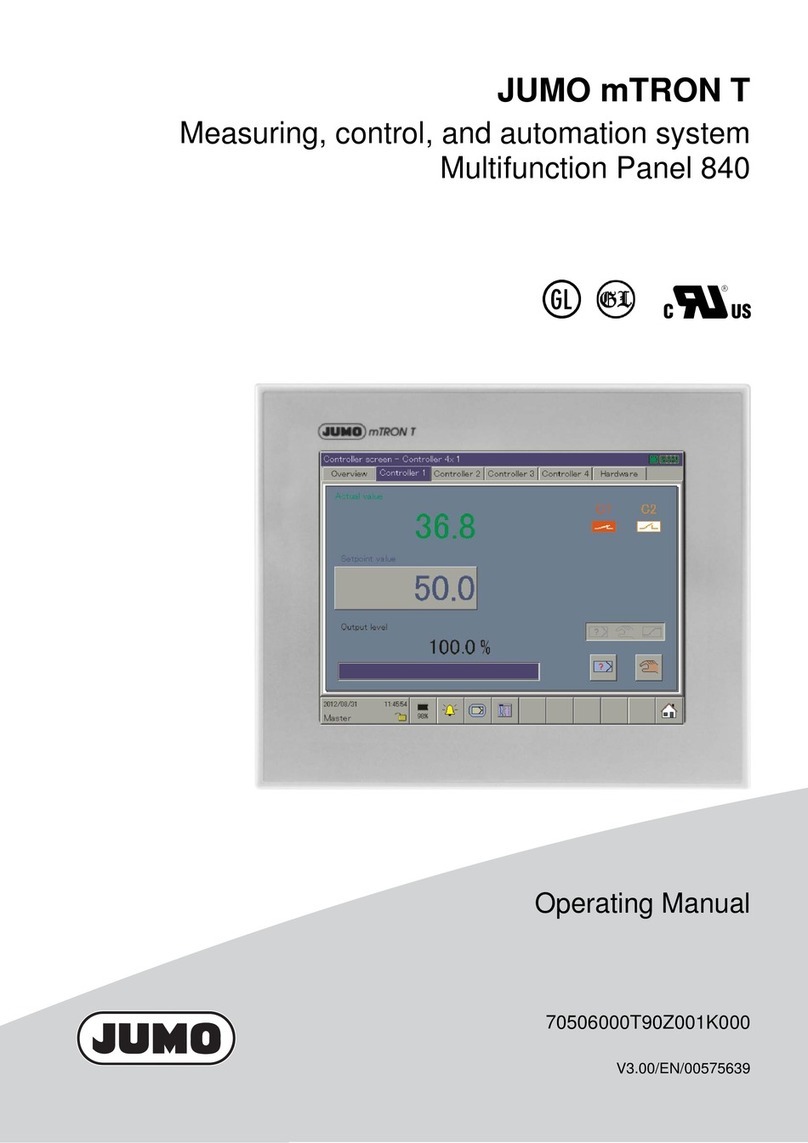

This User's Manual covers the functions of the 300S for

both milling, and turning applications. Operational

information is arranged in three sections: General

Operations, Mill Specific Operations, and Turn

Specific Operations.

The 300S Color DRO is available in two, three, and four

axis form. The 4 axis 300S DRO is used through out this

manual for illustration, and description of function keys.

General Information

e.g. on the behavior of the 300S.

Warning

e.g. when a special tool is required for a function.

Damage - Risk of electric shock

e.g. when opening a housing.