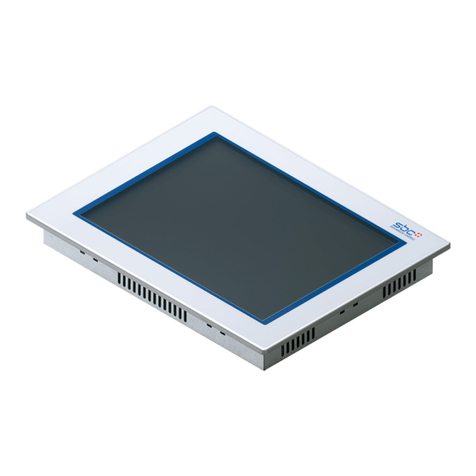

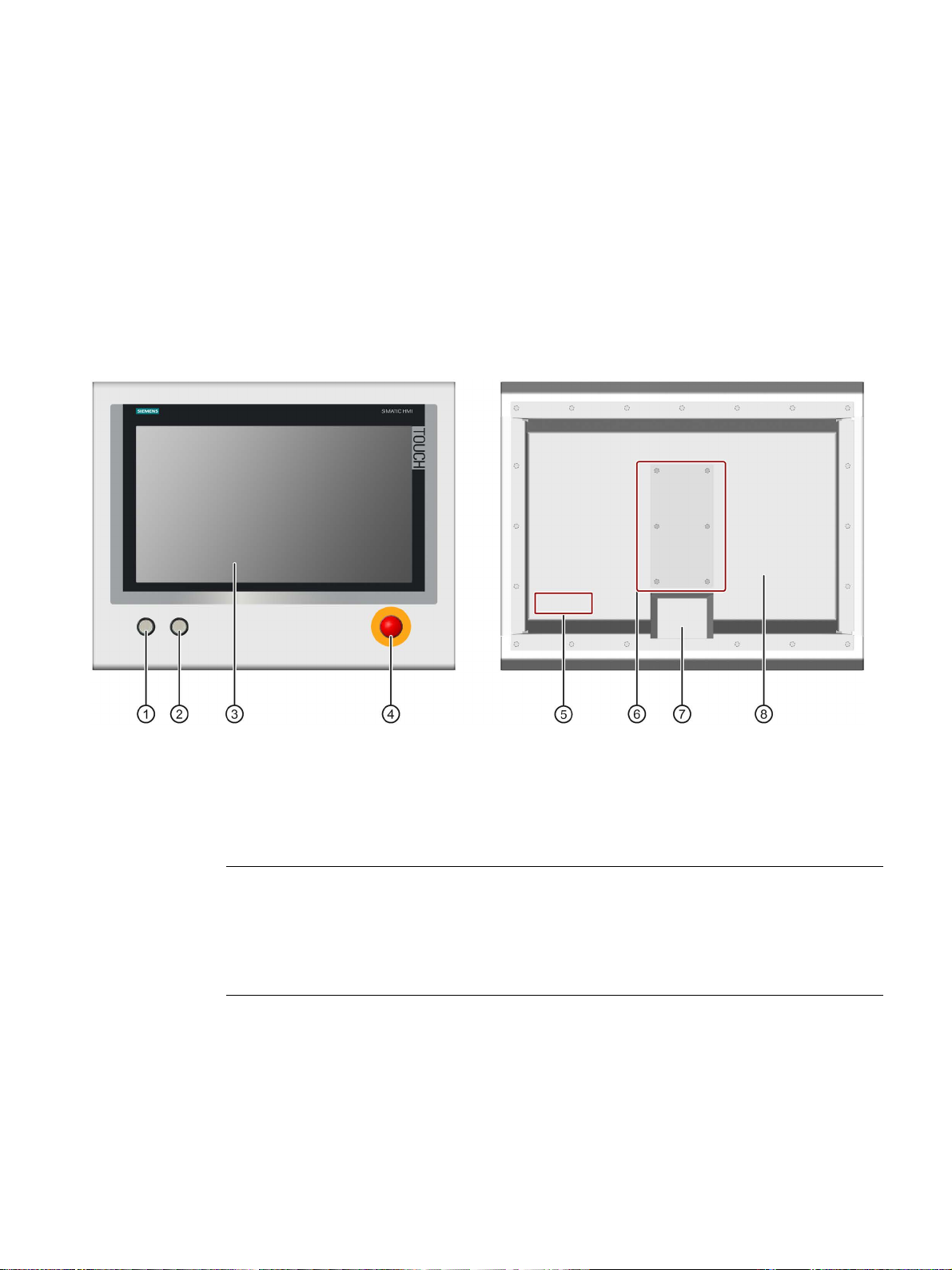

IFP1900 INOX PRO

4 Compact Operating Instructions, 07/2019, A5E35751632-AC

Preface........................................................................................................................................ 3

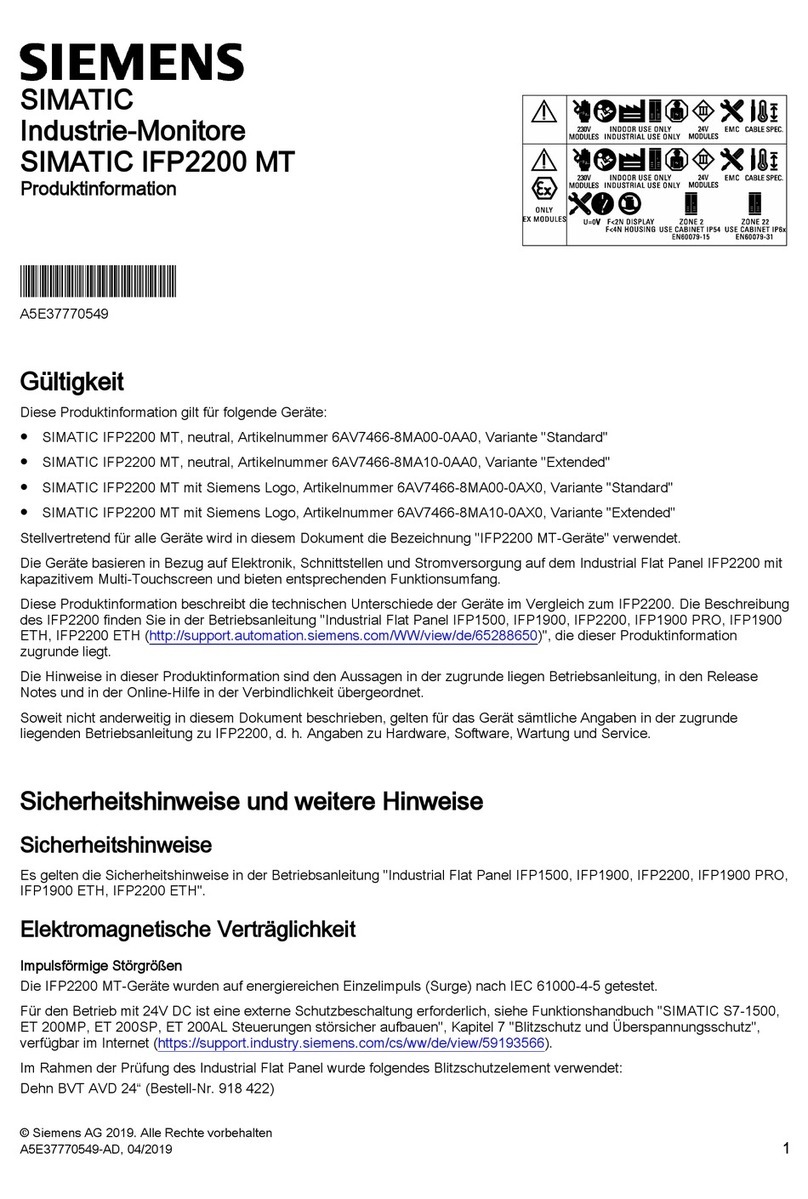

1 Product description ....................................................................................................................... 5

2 Safety instructions......................................................................................................................... 9

2.1 Intended use ....................................................................................................................... 9

2.2 General safety instructions .................................................................................................. 9

2.3 Notes about usage .............................................................................................................11

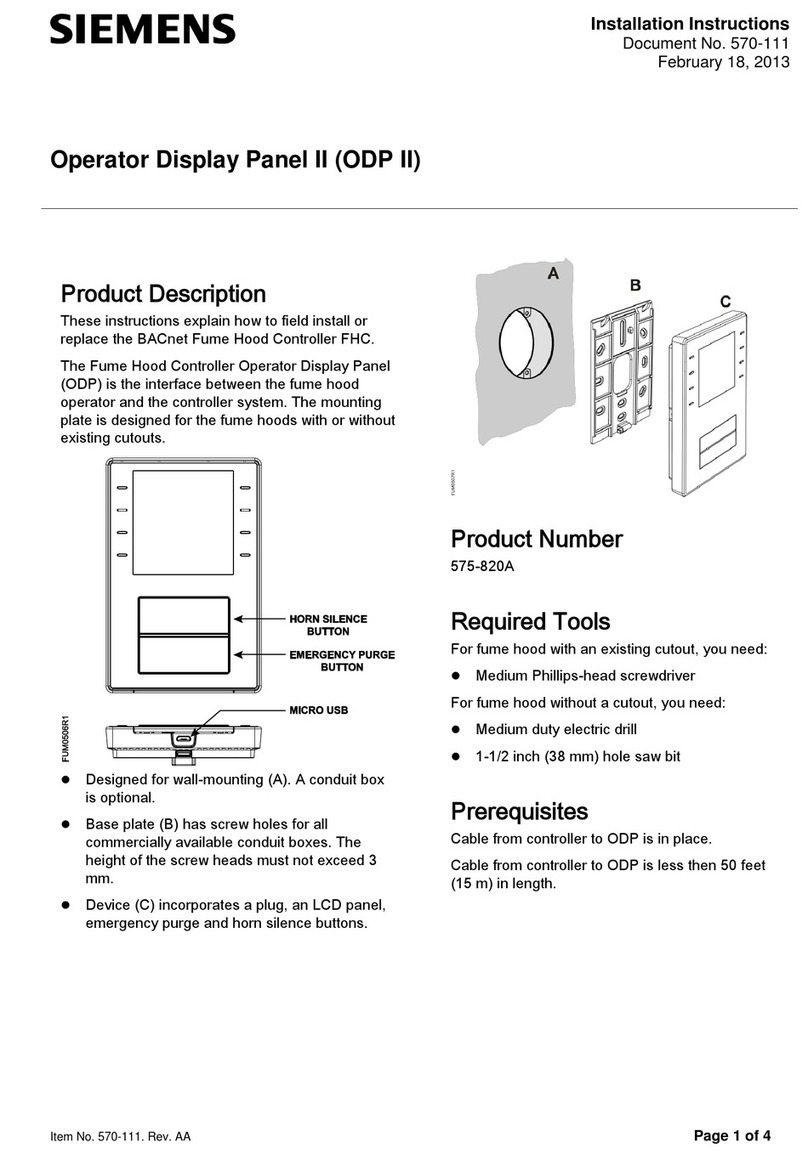

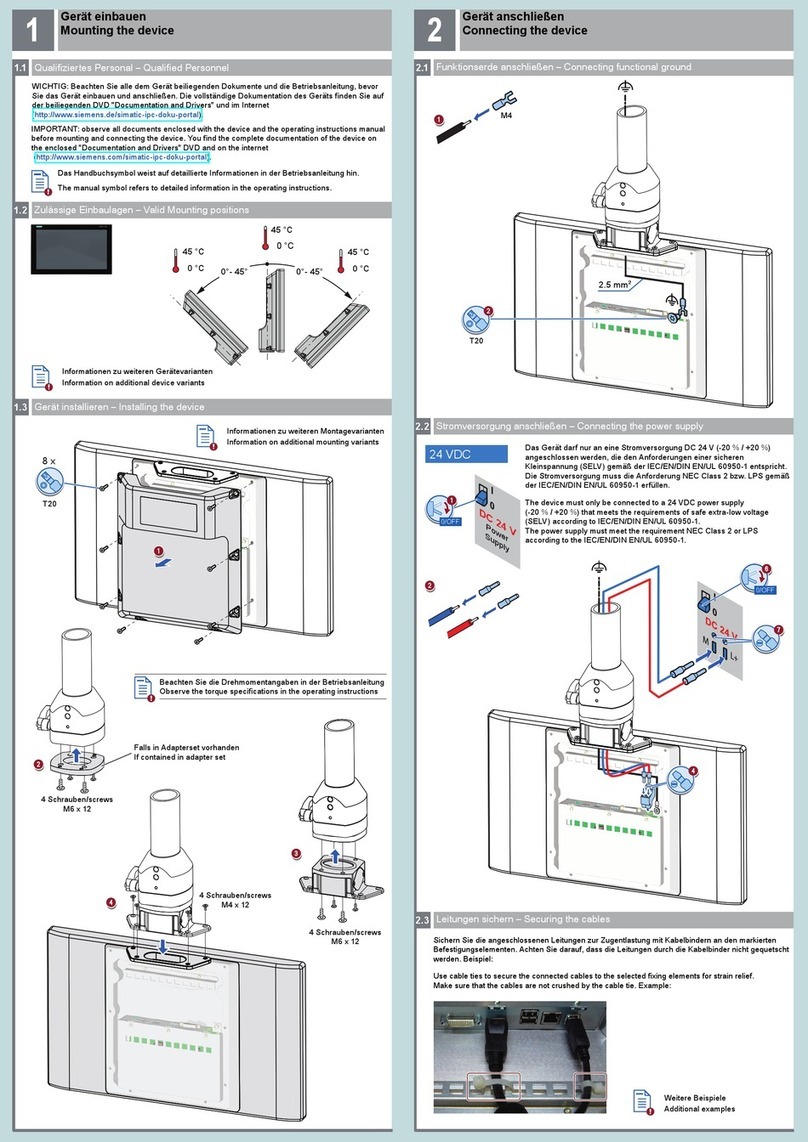

3 Installing the device..................................................................................................................... 12

3.1 Permitted mounting positions..............................................................................................12

3.2 Mounting and connecting the device...................................................................................12

3.3 Dismantling the device .......................................................................................................18

4 Commissioning the device ........................................................................................................... 19

5 Maintaining and repairing the device ............................................................................................. 20

5.1 General information on maintenance and servicing.............................................................20

5.2 Cleaning.............................................................................................................................20

5.2.1 Cleaning the device............................................................................................................20

5.2.2 Clean screen......................................................................................................................21

5.2.3 Chemical Resistance..........................................................................................................22

5.2.4 Working with stainless steel surfaces..................................................................................22

5.3 Resetting the device to factory settings...............................................................................24

5.4 Repair ................................................................................................................................24

6 Specifications ............................................................................................................................. 25

6.1 Certificates and approvals ..................................................................................................25

6.2 Guidelines and declarations ...............................................................................................26

6.3 Dimension drawings ...........................................................................................................27

6.3.1 IFP1900 INOX PRO ...........................................................................................................27

6.3.2 Mechanical interface of the device......................................................................................28

6.4 Technical specifications......................................................................................................28

6.4.1 General technical specifications .........................................................................................28

6.4.2 Environmental conditions....................................................................................................30

6.5 Description of the interfaces ...............................................................................................31

6.5.1 Pin assignment of the internal terminal strip........................................................................31

A Technical support........................................................................................................................ 32

A.1 Service and support ...........................................................................................................32