The ENC 150 precision glass scale linear encoder provides the

accuracy and reliability of an ACU-RITE measuring system with

digital output (analog output available). Features and options

include:

Digital resolutions of 1, 2, 5, or 10 µm.

Accuracy grades of ±3, and ± 5 µm / 1000mm.

Home reference signal (Ref. Mark) coded or 200mm interval.

Vinyl or Armor cables of 5, 10, and 15 ft. length.

Mounting fasteners, center supports, and backup spars.

Installation brackets and accessories.

Contact your Authorized ACU-RITE Distributor for assistance with

selection of product options and accessories.

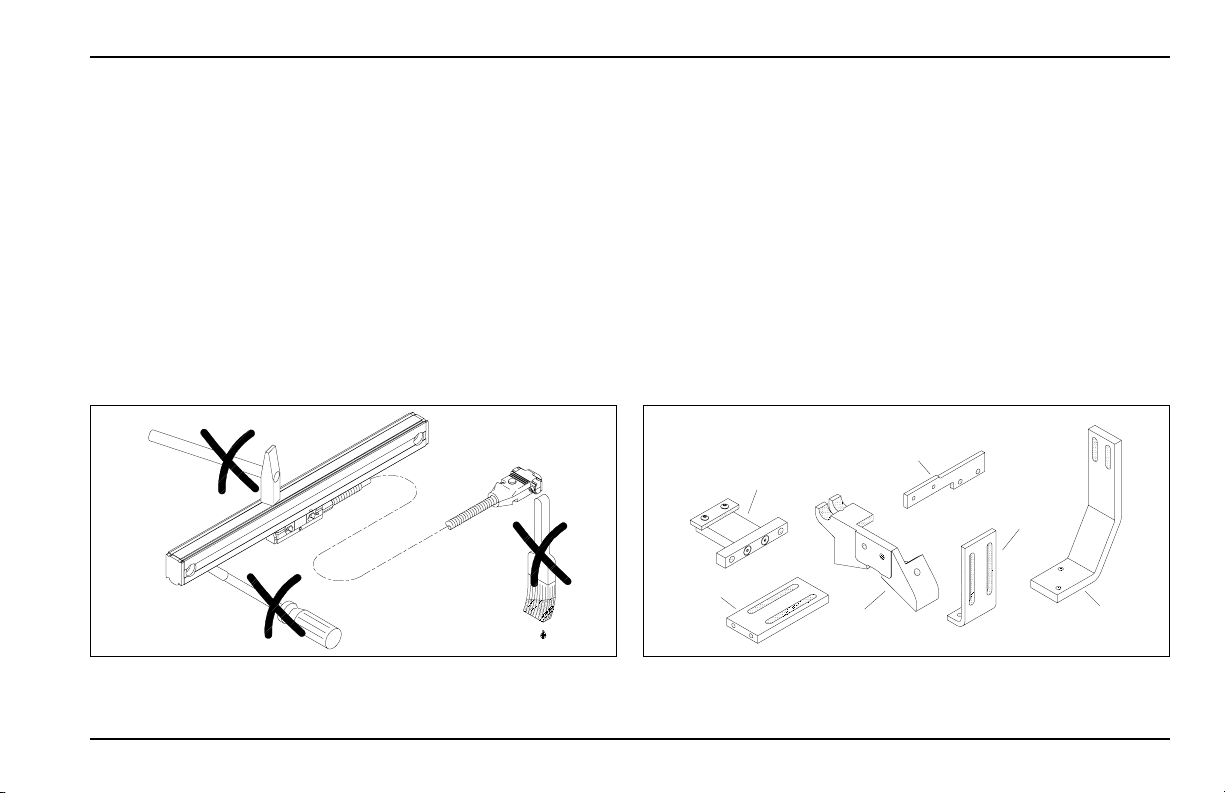

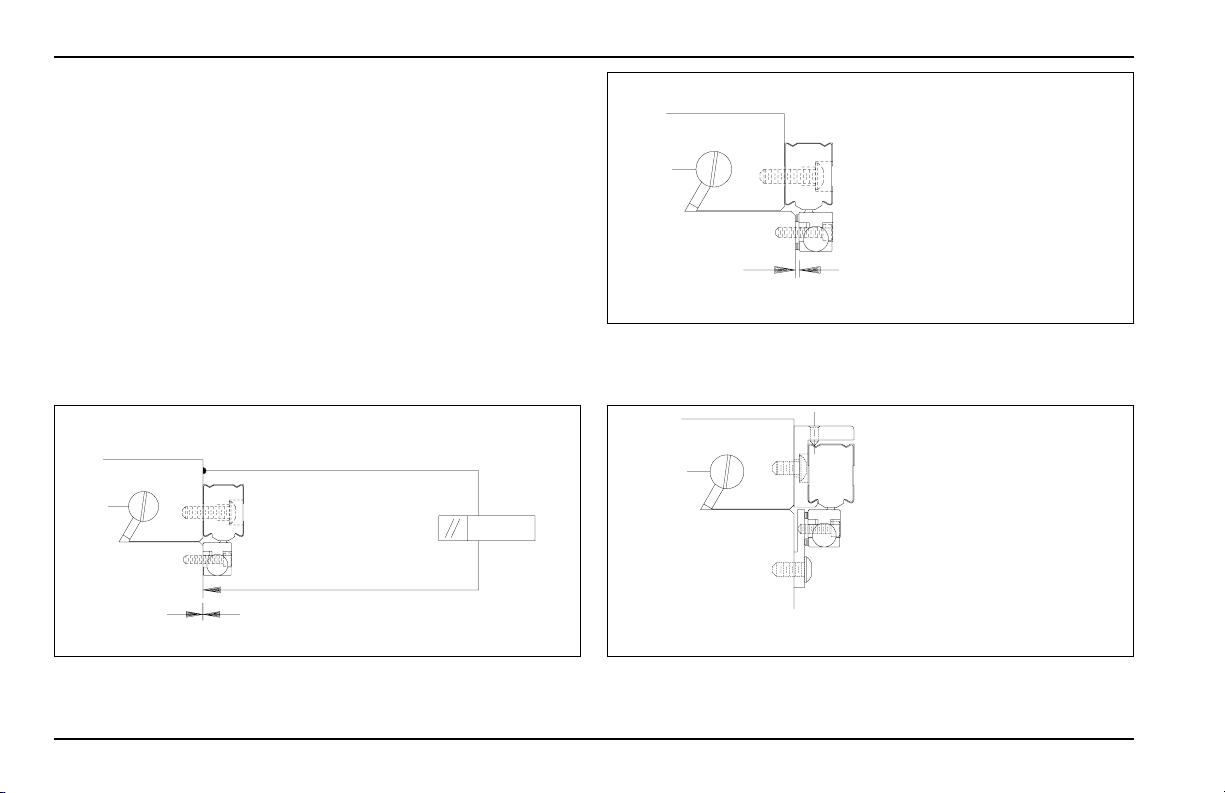

A) ENC 150 Linear Encoder

B) Backup Spar

C) Linear Encoder Reference Manual

D) Cable Mounting Hardware

E) Linear Encoder Mounting Hardware

F) Backup Spar Mounting Hardware

ACU-RITE ® 2

Introduction ENC 150

C

A

Shipping carton

contents

D

E

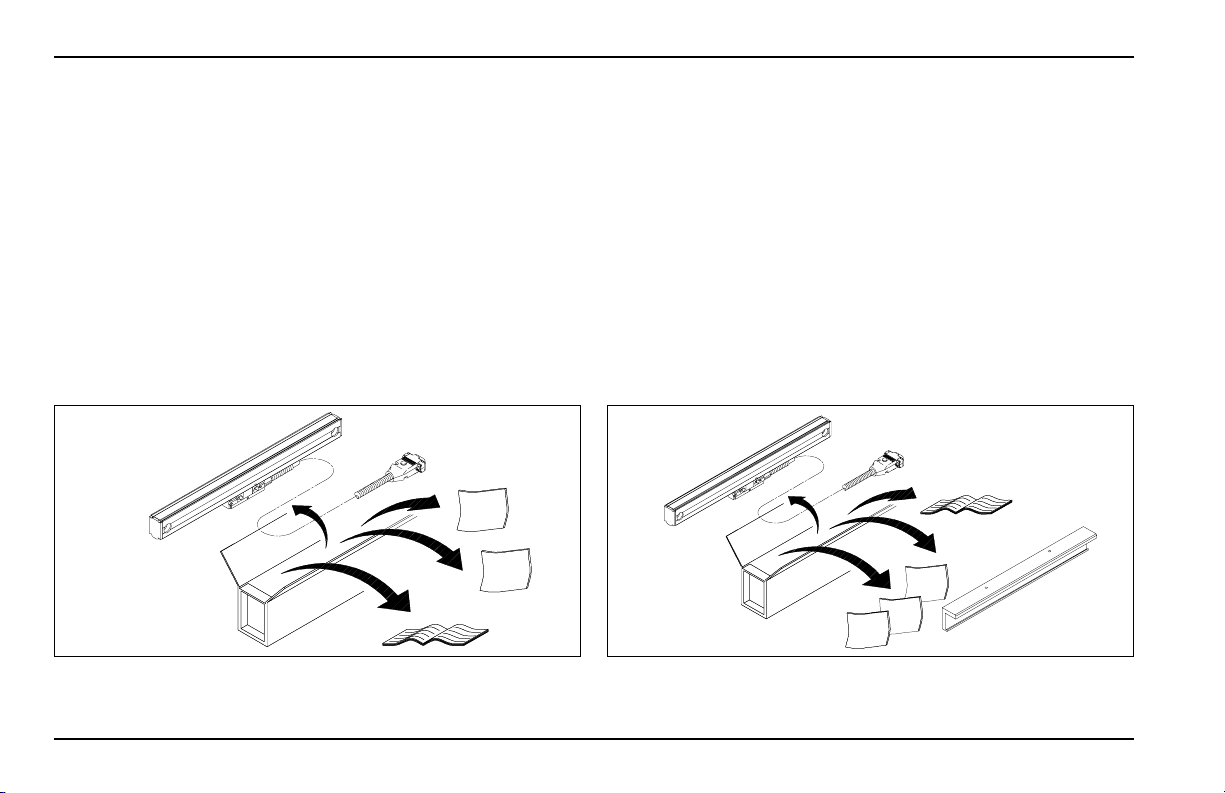

ENC 150

2 thru 60

B

C

A

E

D

F

Shipping carton

contents

ENC 150

65 and over

For future ordering information or warranty service, record the linear

encoder catalog number located on the scale assembly tag, and

the serial number from the reading head tag.

Catalog No. Serial No.

Axis # 1: _______________ __________________

Axis # 2: _______________ __________________

Axis # 3: _______________ __________________

Axis # 4: _______________ __________________

Date of purchase: _______________ __________________

Distributor: _______________ __________________

Address: _______________ __________________

Telephone: _______________