Installation Manual 385072-41

P.N. 385072-214 Ed C 11/05 3Acu-Rite Companies Inc.

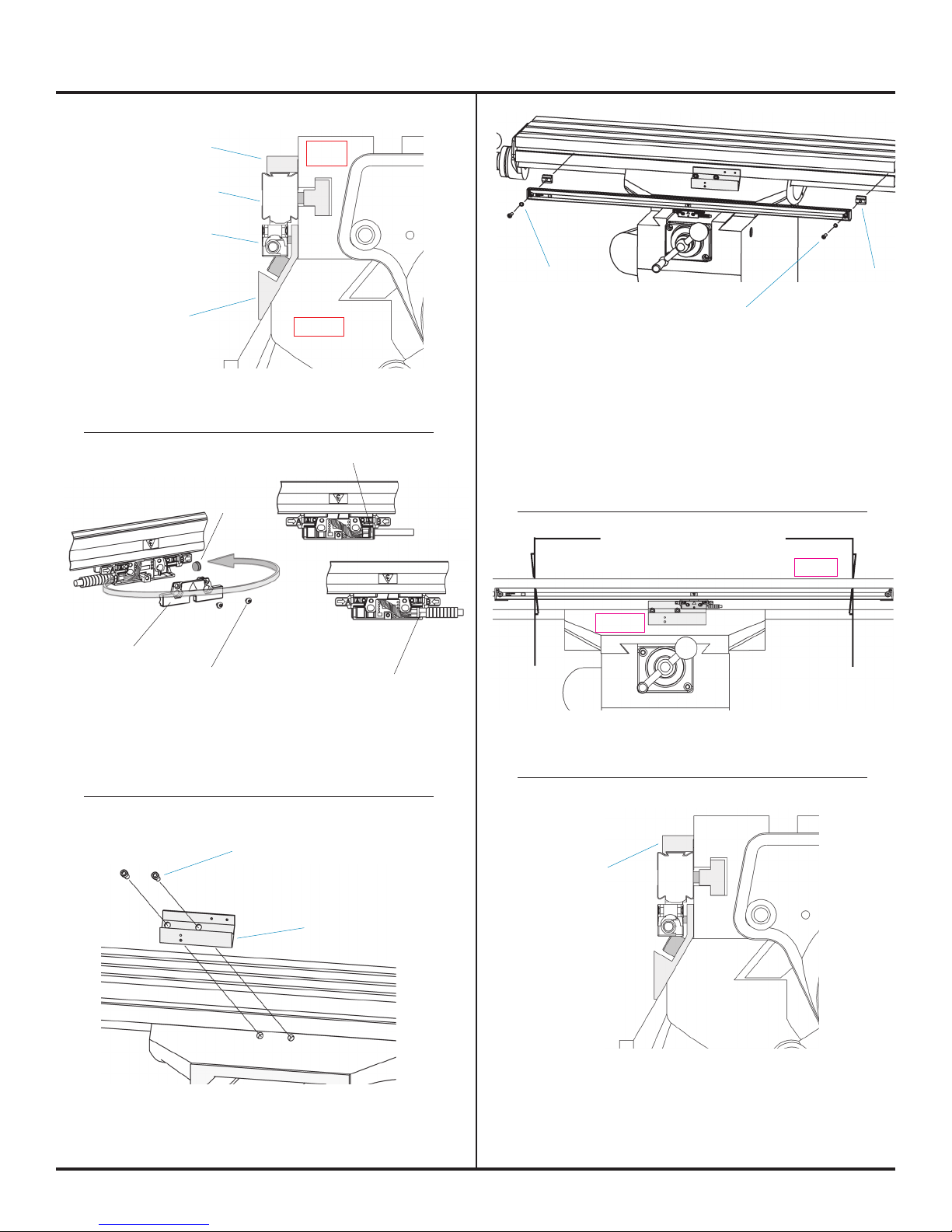

Alignment bracket removal ...

•Useallen wrench from set screw adjustment to slide

alignmentbracketsawayfromthereading head.

•Removealignmentbracketsandsaveforpossible

futureuse.

•Move the axis through its full travel. Confirm that

theassemblydoesnotinterferewiththemachine

movement.

Slide brackets back

away from the

reading head and

cable Twist brackets

45° to remove

Leveling set screws (3)

*8-32 x 3/4” SHCS (2)

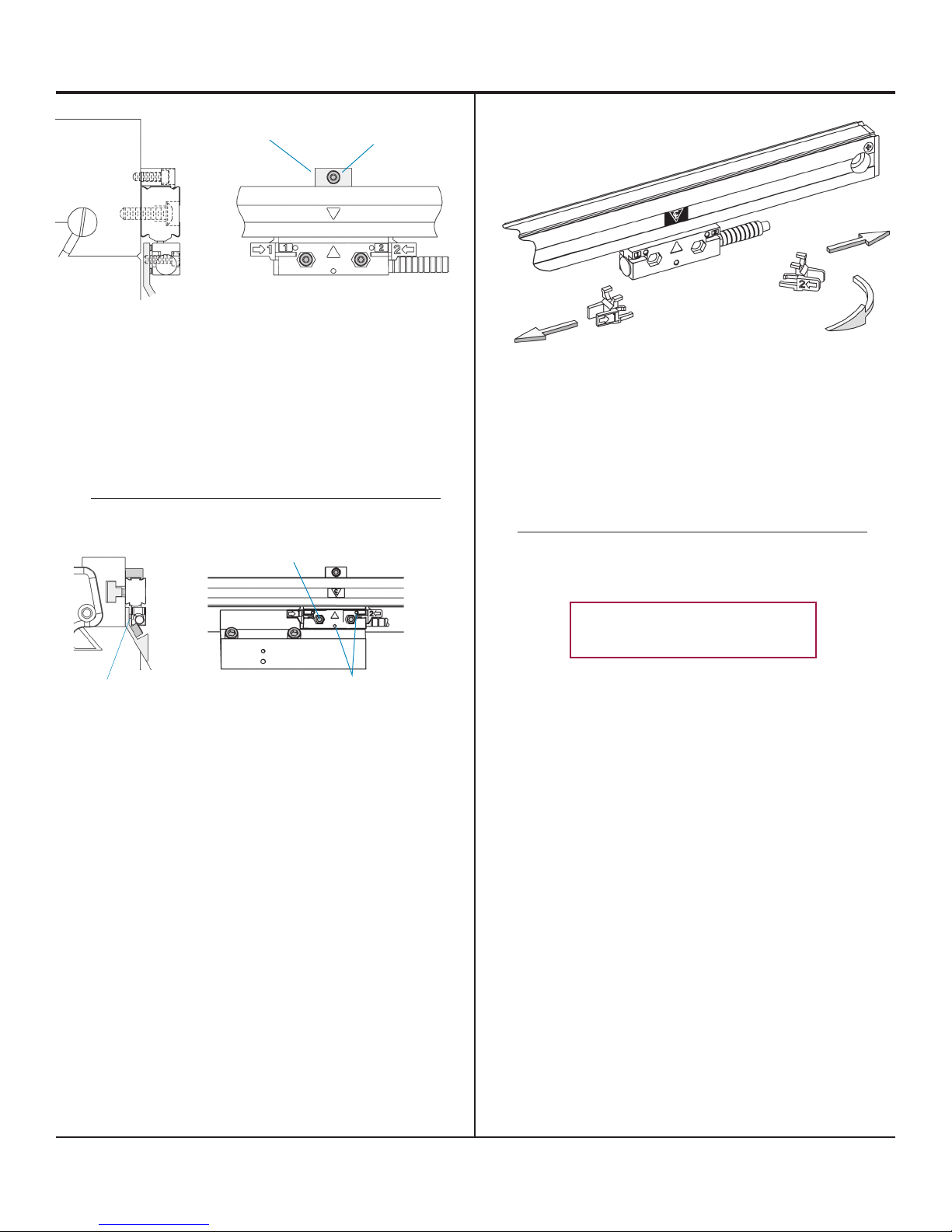

•Adjustthebracket so that the reading head

mountingholesalignwith the reading head casting.

Securethe bracket in place.

Reading head

mounting holes (2)

A gap will exist between

bracket and reading head.

•Insert the two *8-32 x 5/8” SHCS. Insure the bracket

isadjustedtoprovideproperscrewheadclearance.

Do Not Tighten Screws at this time.

•Set each leveling set screw by placing a .001” - .003”

feelergagebetweenthesetscrewandthebracket.

•Adjust each set screw until a slight drag is felt on the

feelergage.

• Evenly tighten the two 8-32 SHCS.

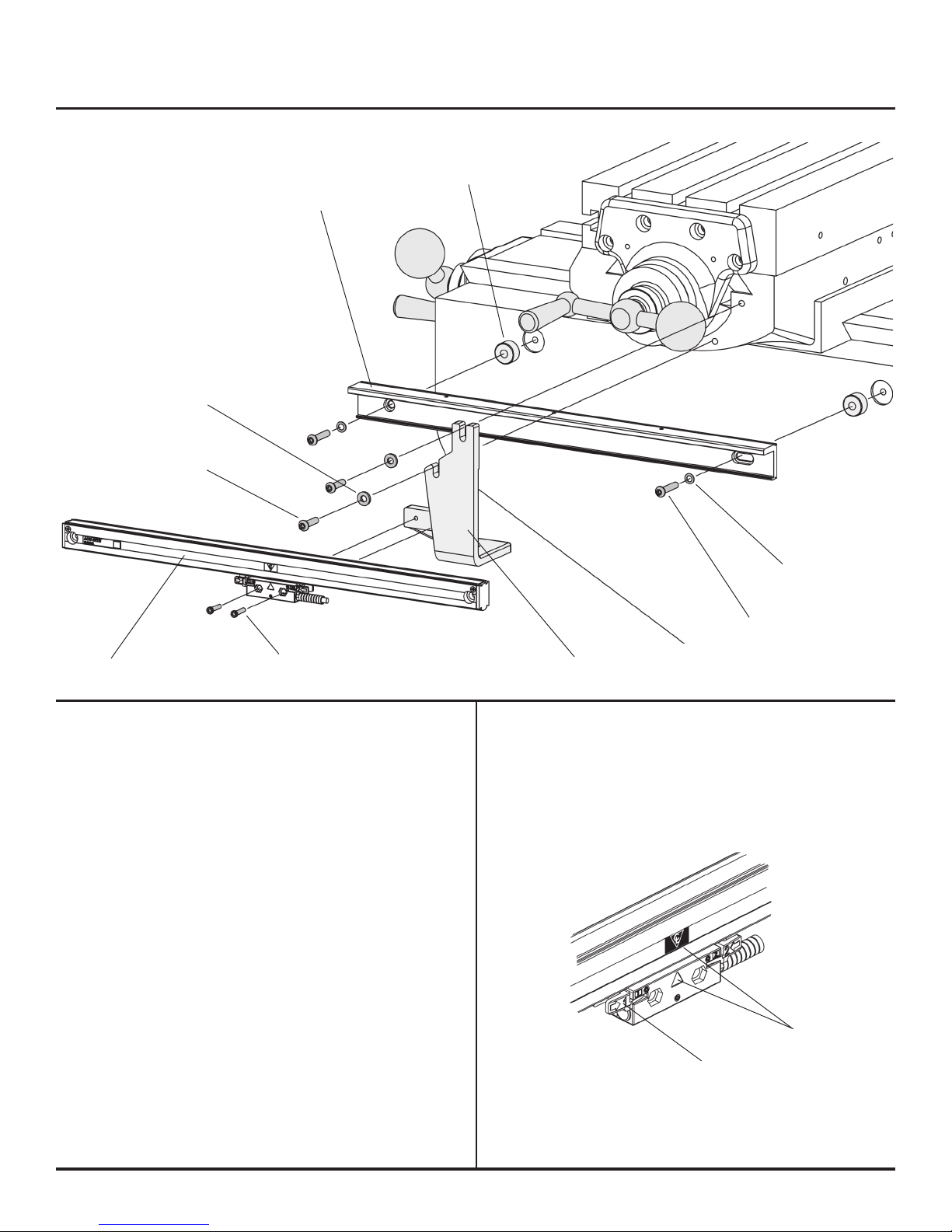

•Withthelongitudinalaxisinstallationcomplete,

routethecablesprovidingsufficientslackloopsfor

machinemovementtothereadout.

•Securecables by fastening with clips or ties.

•Attachthelinearencoderconnectorstothereadout.

•Completetheinstallationbyfollowingthestepsin

“CheckingYourInstallation”sectionintheencoder

“ReferenceManual”.

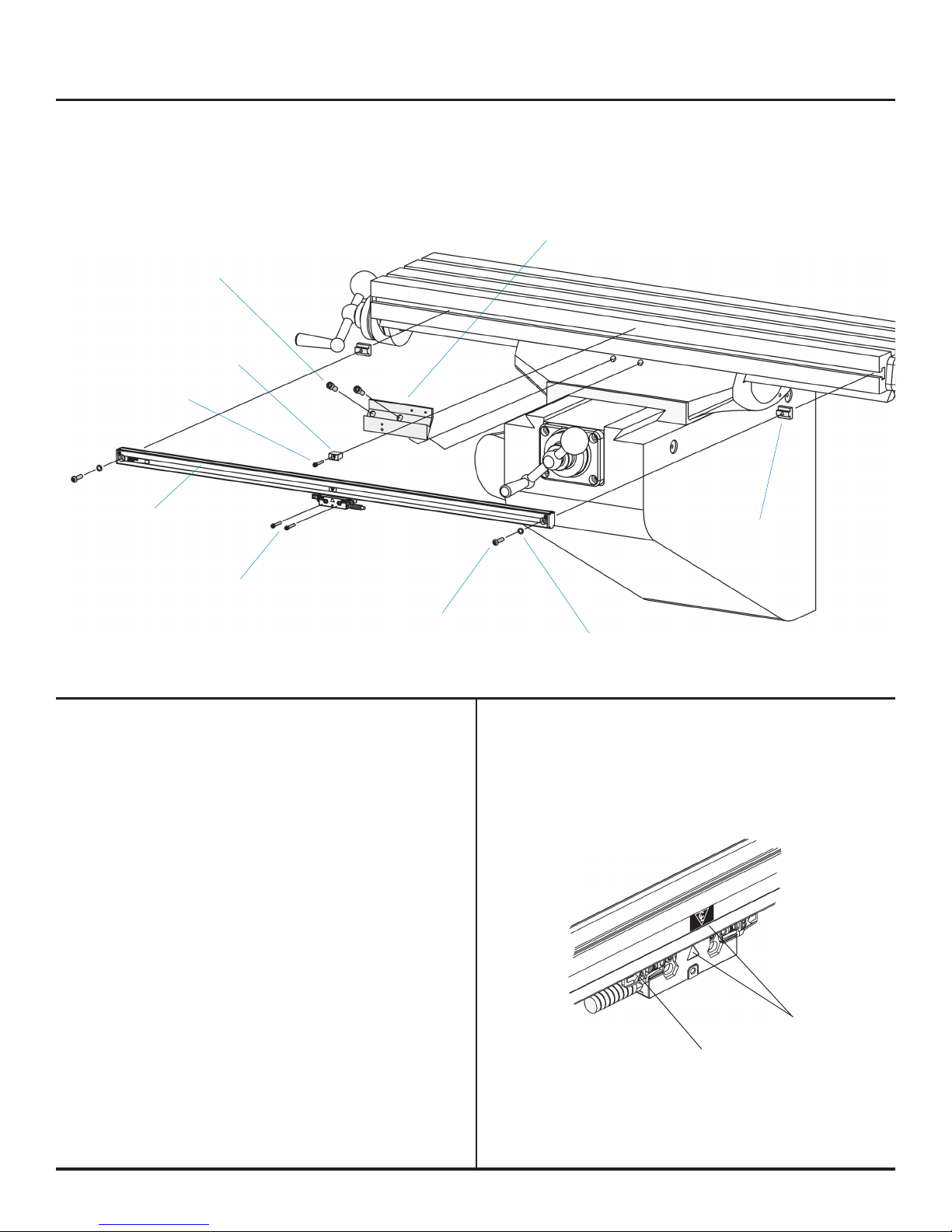

Encoder Installation Manual For: Bpt. Vert. Knee Milll

Cross Feed Y Axis - Right hand side

SENC 150

Reading head installation...