ACU-RITE

® 6

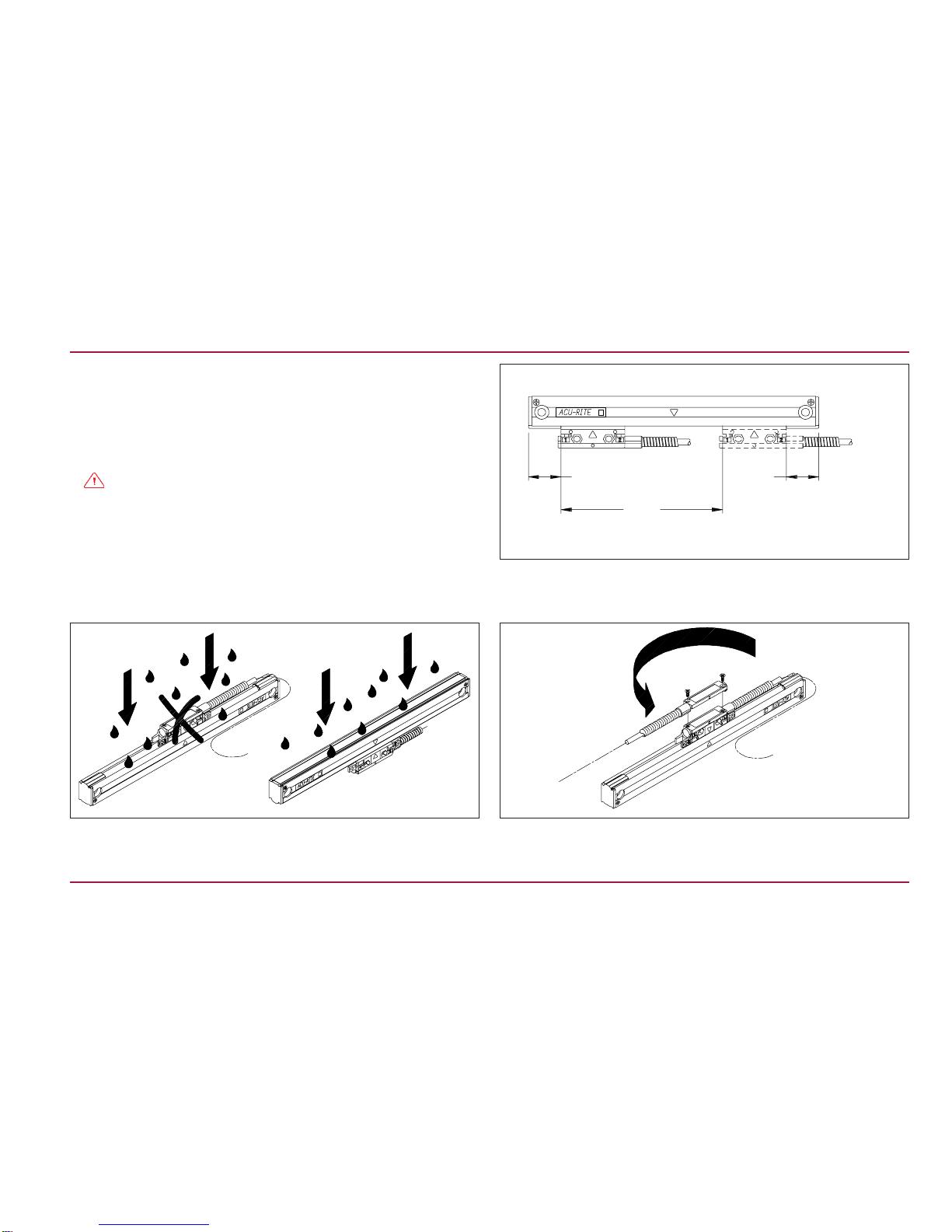

Backup Spar Dimensions ENC 150

“A” ± .015

“A” ± .005

“L” ± .015

5.000 typ. ± .015

Non

Accumulative

“B” typ. ± .015

Non Accumulative “A” Ref.

.750 ± .005

.110 ± .005

M4 Thru

∅.312 Thru

∅.500 C’Bore x .160 Dp.

“X” No. of holes

“E”

Backup spar

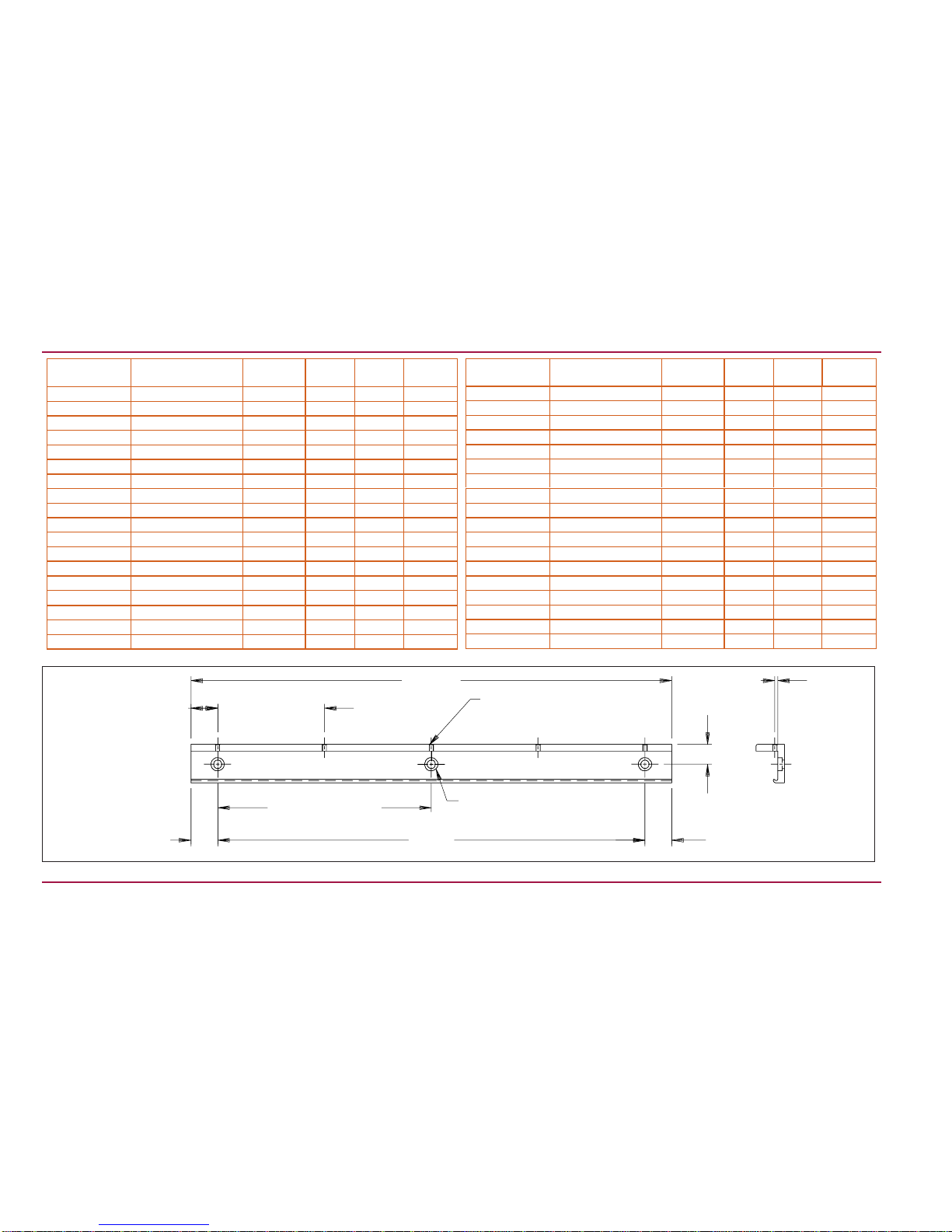

Part Number Linear Encoder

Measuring Length LA

X No.

Places B

385102-000 2 8.312 1.656 2 5.000

385104-000 4 10.312 2.656 2 5.000

385106-000 6 12.312 1.156 2 10.000

385108-000 8 14.312 2.156 2 10.000

385110-000 10 16.312 3.156 2 10.000

385112-000 12 18.312 4.156 2 10.000

385113-000 13 (Special) 19.312 1.44 2 16.43

385114-000 14 20.312 5.156 2 10.000

385116-000 16 22.312 1.156 3 10.000

385118-000 18 24.312 2.156 3 10.000

385120-000 20 26.312 3.156 3 10.000

385122-000 22 28.312 4.156 3 10.000

385124-000 24 30.312 5.156 3 10.000

385126-000 26 32.312 1.156 4 10.000

385128-000 28 34.312 2.156 4 10.000

385130-000 30 36.312 3.156 4 10.000

385131-000 31.5 38.030 4.015 4 10.000

385132-000 32 (“E” 34.812) 35.687 .437 4 11.604

Backup spar

Part Number Linear Encoder

Measuring Length LA

X No.

Places B

385135-000 35 (“E” 40.437) 41.312 .437 5 10.109

385136-000 36 42.312 1.156 5 10.000

385138-000 38 44.312 2.156 5 10.000

385140-000 40 46.312 3.156 5 10.000

385142-000 42 48.312 4.156 5 10.000

385148-000 48 54.312 2.156 6 10.000

385152-000 52 58.312 4.156 6 10.000

385154-000 54 60.312 5.156 6 10.000

385160-000 60 66.312 3.156 7 10.000

With Encoder 65 71.312 5.656 7 10.000

With Encoder 72 78.312 4.156 8 10.000

With Encoder 78 84.312 2.156 9 10.000

With Encoder 84 90.312 5.156 9 10.000

With Encoder 90 96.312 3.156 10 10.000

With Encoder 100 106.312 3.156 11 10.000

With Encoder 110 116.312 3.156 12 10.000

With Encoder 120 126.312 3.156 13 10.000