PLEASE READ - Safety Information

WARNING

Improper installation and use of the Acumen screen can result in serious injury or death. Primarily, injuries can occur if the unit falls due to imprecise

installation, mishandling of the unit during installation, or installation on an insufficient wall or ceiling structure. Please use extreme care.

1.

Please read the following installation guidelines thoroughly and follow them

carefully. Failure to do so may cause product to fall or otherwise fail, and could

result in serious injury.

2.

Installation and calibration of the unit should only be performed by an

authorized, qualified, and experienced professional. In particular, electrical

work and wiring [indicated in diagram by dashed lines] must be completed only

by a qualified professional electrician who has read this manual completely

and is familiar with the construction and operation of this equipment and the

hazards involved.

3.

Do not affix the unit to walls or ceilings that have inadequate strength

to permanently hold the unit during use. It is the owner’s and installer’s

responsibility to confirm the wall or ceiling to which the unit attaches is

sufficient to permanently hold the weight and stress loads of the unit at all

times. Draper, Inc., is not responsible for improper installation, application,

testing, or workmanship related to the product at place of installation.

4.

It is the installer’s responsibility to make sure appropriate fasteners are used

for mounting.

5.

All hardware must be installed level. Unit must be level and square.

6.

Never leave the area while operating the unit during installation, maintenance,

or normal operation, unless it is secure and safe.

7.

Before testing or operation, carefully inspect the entire area and path

(especially

underneath)

of unit to be sure no persons or objects are in the area.

8.

Turn off power and any nearby equipment or cables carrying electricity before

connecting switches, wires, controls, or electrical components.

9.

Do not wire motors in parallel without written permission from Draper, Inc.

10.

During testing or operation, carefully watch the surrounding area for any

potential safety concerns including nearby persons or objects.

11.

After installation, the entire system, including all sensors, should be carefully

tested to ensure safe and normal operation. Extreme care should be taken

during testing to remain clear of moving parts to avoid possible injury.

12.

Operation of unit should be performed only by authorized and qualified

personnel, who have been trained in its safe and effective operation and

understand its safety features.

13.

The safety features of the unit should never be disabled, bypassed, or

overridden. The system should not be operated until all safety features are

properly and completely installed, calibrated, and tested.

14.

Unit may need to comply with local, state, or district rules and regulations, in

particular when installed in schools. All applicable rules and regulations should

be reviewed before installation and use.

15.

Failure to precisely follow installation guidelines invalidates all

warranties.

16.

Custom products/installations may not be reflected in this manual. Call Draper,

Inc., if you have questions about the installation of custom products or any

questions about your installation.

Before Beginning Installation

1.

Look for any job site conditions that could interfere with installation or

operation of the system.

2.

Read carefully and be sure to understand all installation instructions and

all related operations manuals. These instructions are intended to serve

as a guide for the installer and owner. They should be followed closely and

combined with the expertise of experienced qualified installers. Draper, Inc., is

not responsible for improper installation, application, testing, or workmanship

related to the product at place of installation. Please retain all instructions for

future use.

3.

Open cartons lengthwise.

4.

Locate and lay out all pieces.

5.

Inspect all boxes to make sure you have received the proper unit and parts.

Controls may be shipped separately, or in same carton as unit.

6.

If you have any difficulties with installing, servicing, or operating your unit, call

your dealer or Draper, Inc., 765-987-7999.

Important Safety Information Important Safety Information

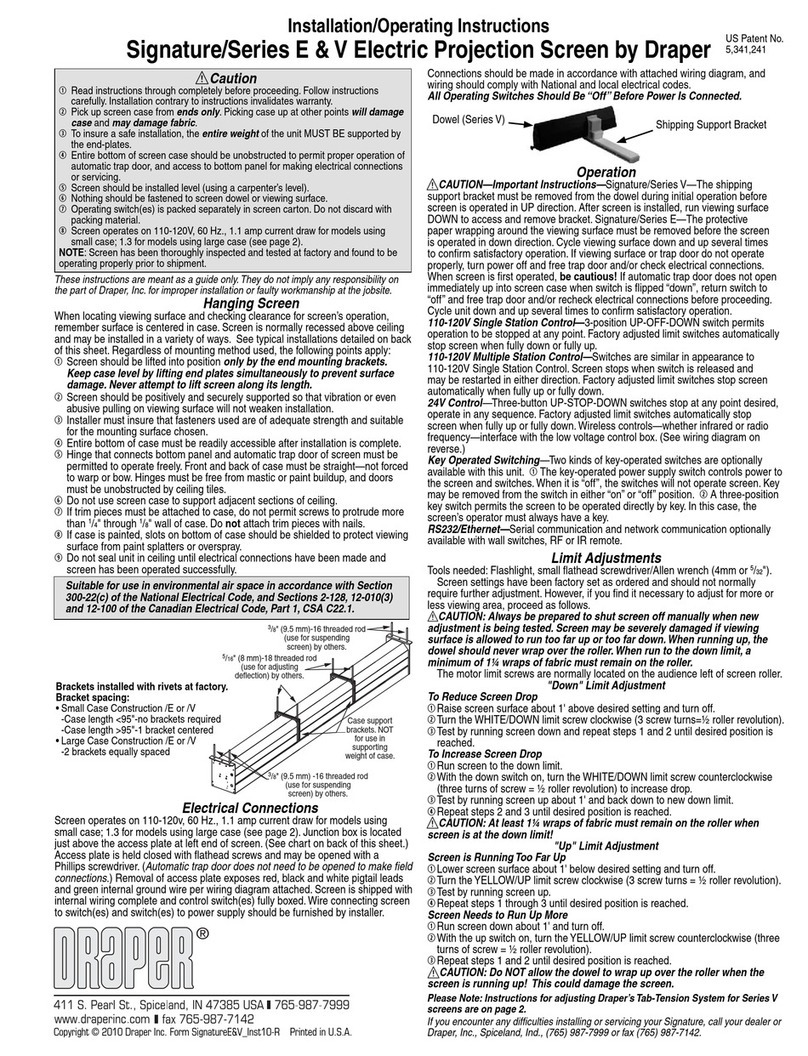

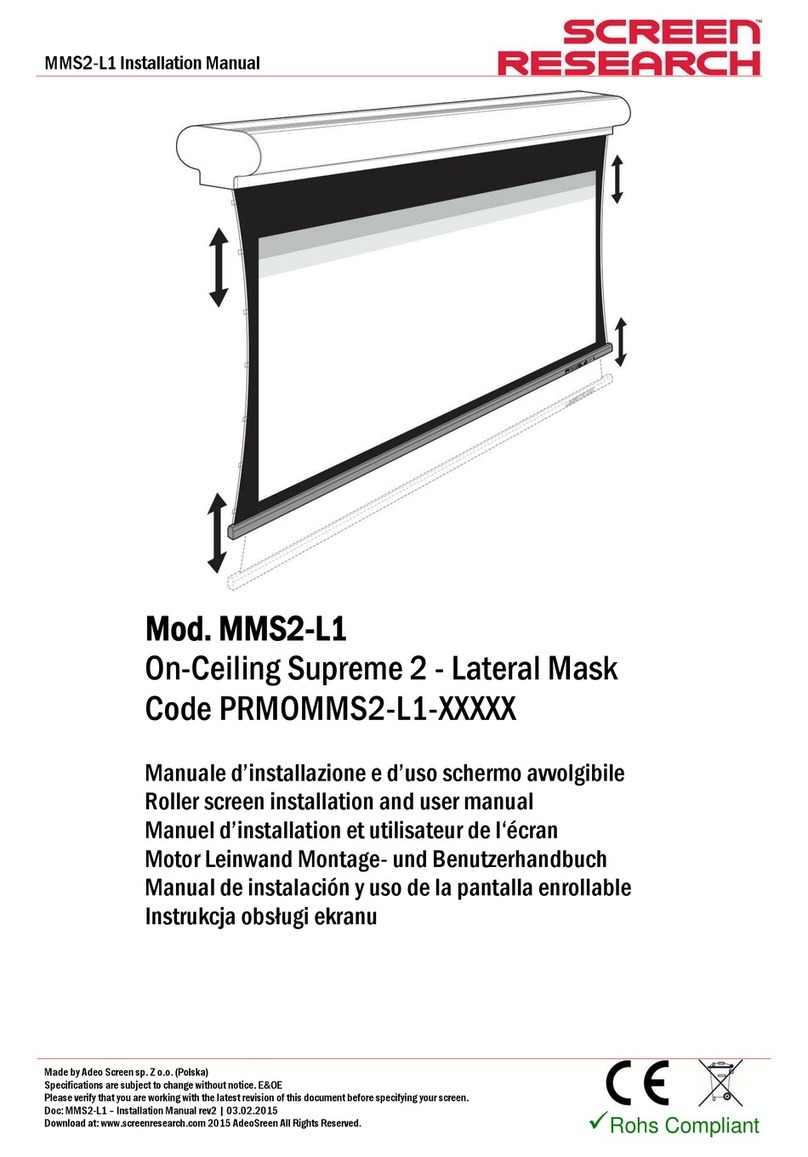

Section 1 - Electrical Connections

Screen operates on 215-240V, 50 Hz. current. Screen ships with internal wiring complete and control switch

(es)

fully boxed.

Electrical wire for connecting screen to switch

(es)

and switch

(es)

to power supply should be furnished by installer

Please Note: Screen must be installed in accordance with requirements of Local Building Codes, Canadian Electrical Code

(CEC)

, CAN/CSA C22.1 and National

Electric Code

(NEC)

, NFPA 70. An appropriate disconnect device shall be provided as part of building installation.

CAUTION: All operating switches should be "off" before power is connected.

page 2 of 12

Acumen™ E & V - 220V