ACV EVO S Series User manual

EVO S

Grundfos UPMXXL 25-120

Pump Control

When replacing any part on this

appliance, use only spare parts that you

can be assured conform to the safety

and performance specification that we

require. Do not use reconditioned or

copy parts that have not been clearly

authorised by ACV.

For the very latest copy of literature for

specification and maintenance practices

visit our website www/acv/com/gb

where you can download the relevant

information in PDF format.

Instructions

03/2023

UIN 236075 A01

ACV UK Ltd Evo S

1

236075 A01

CONTENTS

Section 1 - General...................................................................................2

1.1 Introduction.................................................................................2

1.2 Contents .....................................................................................2

Section 2 - Installation ..............................................................................3

2.1 Preparation .................................................................................3

2.2 Installation...................................................................................3

2.3 Pumpconguration....................................................................4

2.4 Pump performance ....................................................................4

2.5 Pumpparametersettings...........................................................5

Table 1 - Evo S from ACV

Evo S Boiler Size

Evo S 40

Evo S 60

Evo S 70

Evo S 80

Evo S 100

Evo S 120

This kit includes the following items:

1.1 INTRODUCTION

1.2 CONTENTS

This kit is suitable for the following boilers:

Evo S range of boilers utilising the Grundfos UPMXXL

25-120 pump.

This manual explains how to wire the pump leads to the

installer wiring connections and determine the pump

settings within the boiler control.

The Pump is powered by a 230 V auxillary supply

within the boiler, and controlled by a PWM signal.

Item Description

1. Grundfos UPMXXL 25-120 pump

2. Fibre Washer Kit

3. Instructions

ACV UK Ltd Evo S

2

236075 A01

Section 1 - General

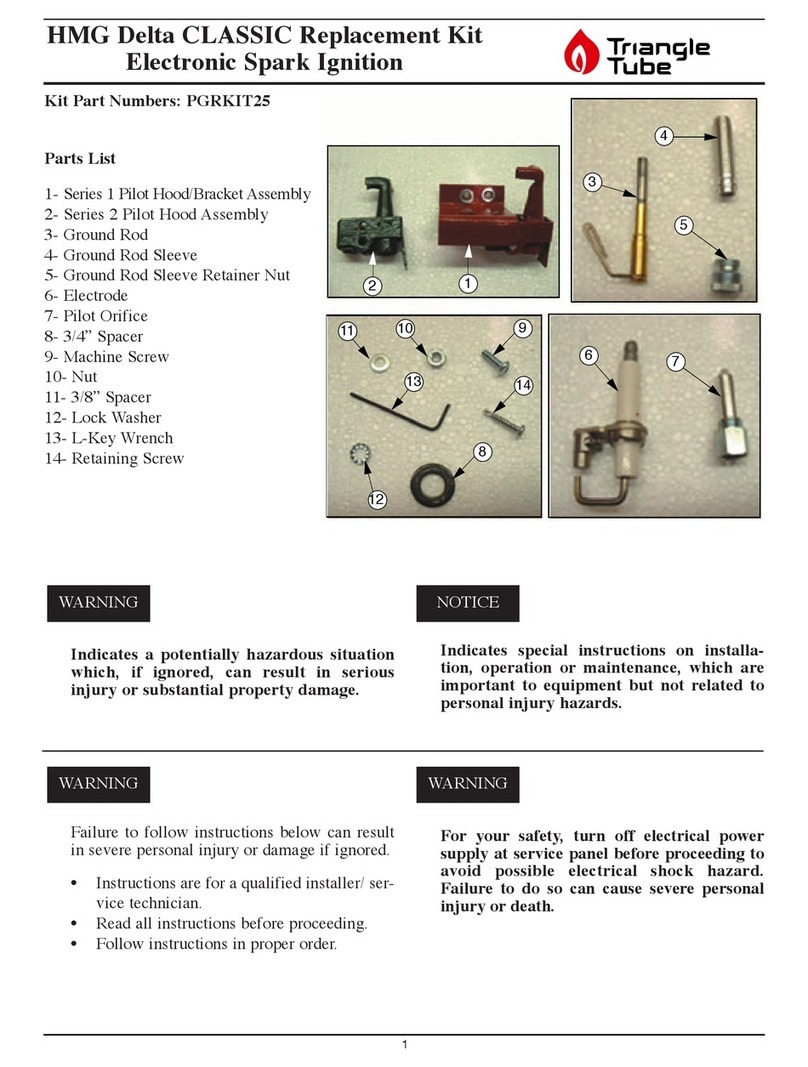

Install the pump electrical connections as follows (refer to Figure 1).

1. Mains power connections 13 earth, 14 live and 15 neutral.

2. PWM connections 37 ground (Blue) and 38 PWM (Brown) signal,

the remaining Black wire should be taped back or removed.

2.1 PREPARATION

2.2 INSTALLATION

Install the Pump Control kit as follows:

WARNING: Be careful when you install electrical connections.

Electric shock can cause serious injury or death and can cause damage

to equipment.

1. Make sure that the electrical power supply to the boiler is set to OFF. For

safe electrical isolation refer to Gas Safe technical bulletin 118. All work

must be carried out by a competent person.

2. For access to the control box (refer to manual ACV Evo S INSTALLATION,

COMMISSIONING AND SERVICING INSTRUCTIONS Frame 4.6.1).

Figure 1 - Pump electrical connections

Table 2 - Evo S no separation

Boiler model Flow rate Q (m³/hr) ∆t 20° C Head (m) Pump used

Evo S 40 1.72 4.58

Grundfos UPMXXL 25-120

Evo S 60 2.59 6.01

Evo S 70 3.02 5.81

Evo S 80 3.45 4.89

Evo S 100 4.28 7.29

Evo S 120 5.14 7.75

13 14 15 37 38

ACV UK Ltd Evo S

3

236075 A01

Section 2 - Installation

2.3 PUMP CONFIGURATION

2.4 PUMP PERFORMANCE

The following parameters congure the PWM output to

control a boiler pump.

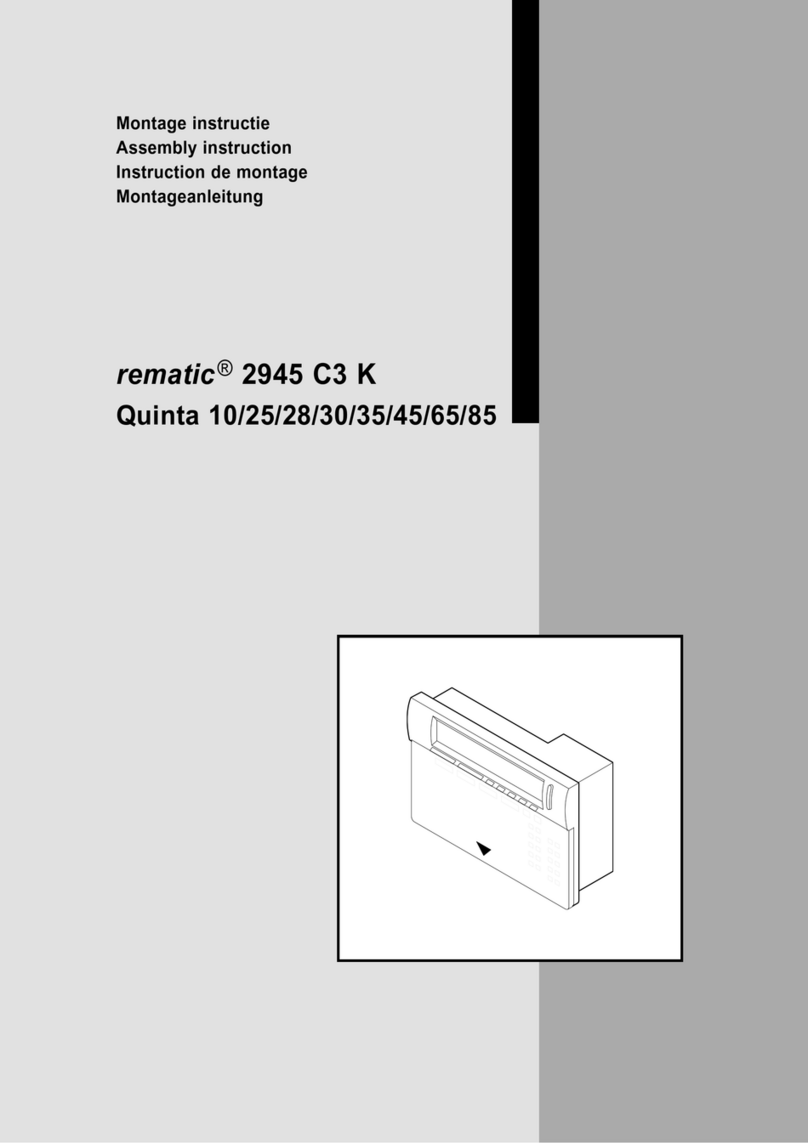

For pump performance refer to Figure 2 below.

Table 3 - Evo S PWM output

Line No. Parameter Settings

6085 Function output P1 Boiler pump Q1

6086 Signal logic output P1 Inverted

Figure 2 - UPMXXL pump performance curve (Blue line)

Section 2 - Installation

ACV UK Ltd Evo S

4

236075 A01

2.5 PUMP PARAMETER SETTINGS

The following parameters congure how the pump speed is to be

controlled.

Table 4 - Evo S pump speed control

Table 5 - Cascade Boiler with LLH

Line No. Parameter Settings

2320 Pump modulation Burner output

2321 Starting speed 100%

The following parameters determine the PWM values to achieve the ow rates for each boiler model.

Boiler Model Line No. Parameter Setting Flow Reading (8366)

l/m

40 2322 Pump speed min 69 9.5

2323 Pump speed max 95 28.7

2505 Threshold owDetect 8.3

60 2322 Pump speed min 69 19.2

2323 Pump speed max 95 39.3

2505 Threshold owDetect 16.7

70 2322 Pump speed min 69 19.2

2323 Pump speed max 95 50.0

2505 Threshold owDetect 16.7

80 2322 Pump speed min 59 38.3

2323 Pump speed max 95 69.3

2505 Threshold owDetect 35.0

100 2322 Pump speed min 69 38.3

2323 Pump speed max 95 71.7

2505 Threshold owDetect 35.0

120 2322 Pump speed min 80 50.0

2323 Pump speed max 95 86.0

2505 Threshold owDetect 45.8

Section 2 - Installation

ACV UK Ltd Evo S

5

236075 A01

Boiler Model Line No. Parameter Setting Flow Reading (8366) l/m

40 2322 Pump speed min 69 9.5

2323 Pump speed max 95 28.7

2505 Threshold owDetect 8.3

60 2322 Pump speed min 69 19.2

2323 Pump speed max 95 39.3

2505 Threshold owDetect 16.7

70 2322 Pump speed min 80 19.2

2323 Pump speed max 95 50.0

2505 Threshold owDetect 16.7

80 2322 Pump speed min 69 38.3

2323 Pump speed max 95 69.3

2505 Threshold owDetect 35.0

100 2322 Pump speed min 80 38.3

2323 Pump speed max 95 71.7

2505 Threshold owDetect 35.0

120 2322 Pump speed min 85 50.0

2323 Pump speed max 95 86.0

2505 Threshold owDetect 45.8

Table 6 - Cascade Boiler with PHEX

Notes

ACV UK Ltd Evo S

6

236075 A01

Boiler Model Line No. Parameter Setting Flow Reading (8366) l/m

40 2322 Pump speed min 9.5

2323 Pump speed max 28.7

2505 Threshold owDetect 8.3

60 2322 Pump speed min 19.2

2323 Pump speed max 39.3

2505 Threshold owDetect 16.7

70 2322 Pump speed min 19.2

2323 Pump speed max 50.0

2505 Threshold owDetect 16.7

80 2322 Pump speed min 38.3

2323 Pump speed max 69.3

2505 Threshold owDetect 35.0

100 2322 Pump speed min 38.3

2323 Pump speed max 71.7

2505 Threshold owDetect 35.0

120 2322 Pump speed min 50.0

2323 Pump speed max 86.0

2505 Threshold owDetect 45.8

Table 7 - Standalone Boiler

The process to determine the settings for a modulating boiler pump is dependent upon

the hydraulic properties of the installation. For setting of the minimum pump speed the

worst-case ow rate of the system should be set, this must be above the minimum ow

rate allowed by the boiler model. This will ensure that the minimum speed setting cannot

result in a ow rate lower than the minimum ow rate for the boiler model.

The table above shows the initial settings, these can then be adjusted to ensure that

the system ow meets the boiler model requirement. The actual value of the ow

through the boiler can be read from the boiler HMI under ‘Diagnostics heat generation’

8366, also by pressing the ‘I’ information button. The value is shown in l/m. So nal

adjustments can be made to ensure compliance.

Notes

ACV UK Ltd Evo S

7

236075 A01

Notes

ACV UK Ltd Evo S

8

236075 A01

Notes

ACV UK Ltd Evo S

9

236075 A01

ACV pursues a policy of continuing improvement in the design and performance

of its products. The right is therefore reserved to vary specication without notice.

ACV U.K. Limited

St. David’s Business Park,

Dalgety Bay

Fife, Scotland

KY11 9PF

Tel: 0044 (0)1383 820100

www.acv.com/gb

This manual suits for next models

6

Table of contents

Other ACV Boiler Supplies manuals