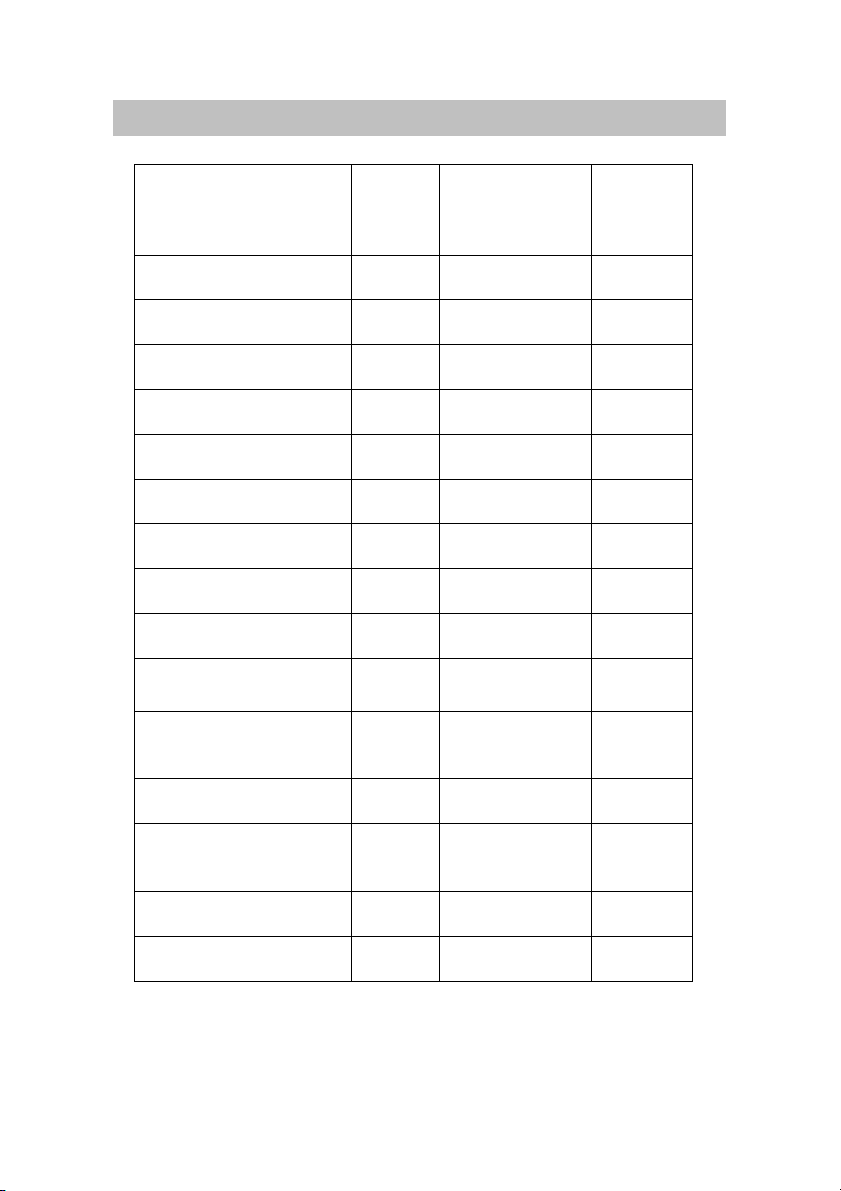

TABLE OF CONTENTS

1. Application ........................................................................................2

2. Specification .....................................................................................3

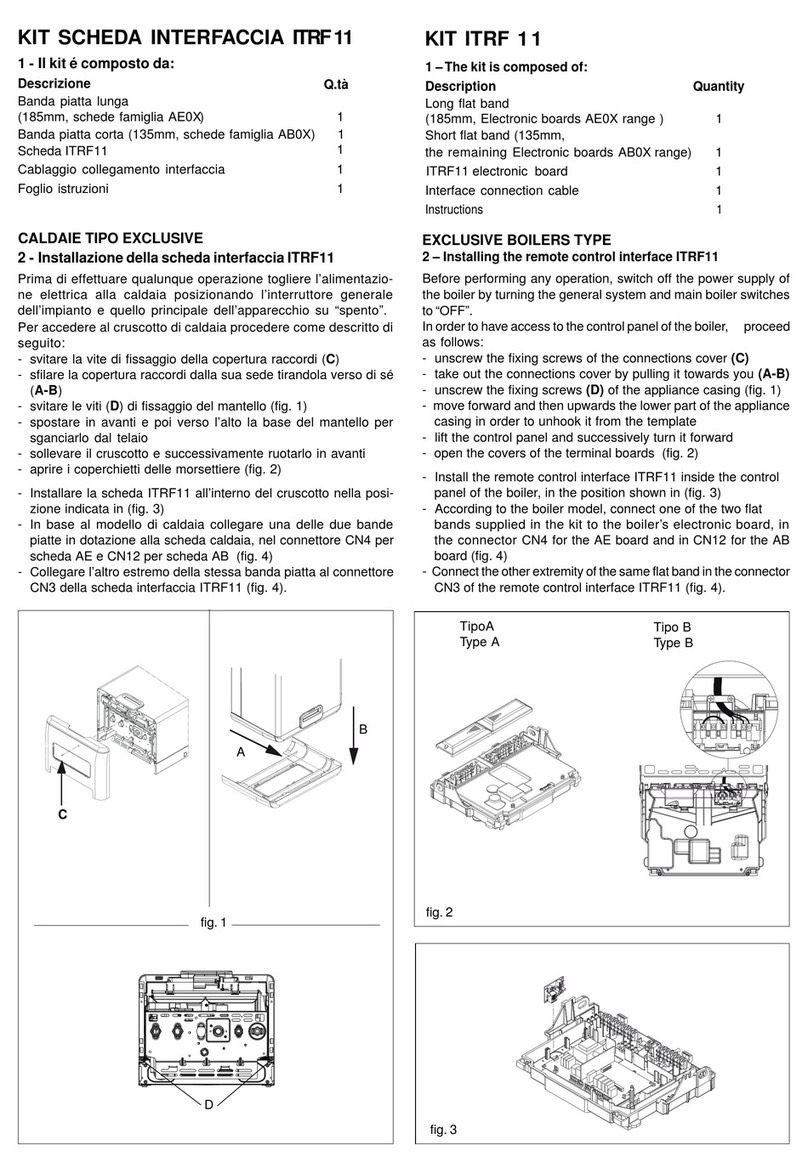

3. Connecting external device (feeder, fan, pump ) .............................4

3.1 Connecting remote control panel ................................................5

3.2 Remote panel upply ..................................................................6

3.3 Panel-central unit communication ...............................................7

4. Configuration parameter ..................................................................8

5. Service parameter ............................................................................9

6. Front panel button .............................................................................10

6.1 Diode indicating the operation of external device .....................12

7. Driver handling..................................................................................13

7.1 Fir t run .......................................................................................13

7.2 Changing function parameter in the driver menu........................13

7.3. Burning up to the boiler...............................................................14

8. Operating mode (standby, off, setting fire, regulation, running)...16

9. Alarm depending on temperature .....................................................17

9.1 Water temperature higher than 90 ˚C............................................17

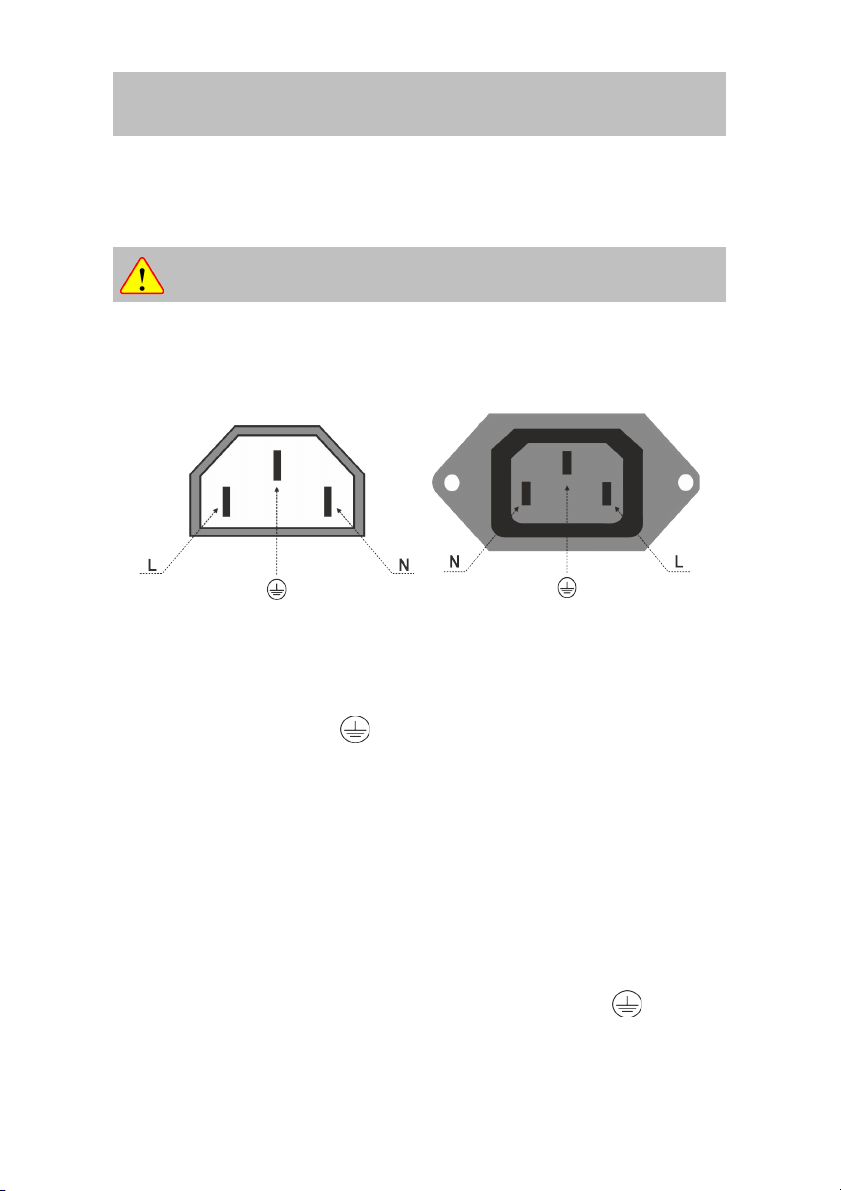

9.2 Water temperature in the range of 80-90 ˚C..................................18

9.3 Screw/feeder' pipe overheating alarm..........................................18

9.4 Temperature drop alarm ...............................................................19

9.5 “Anti-fro t”alarm .........................................................................19

9.6 Thermal alarm (hardware protection)...........................................19

10. Temperature en or failure alarm ......................................................20

(C/H sensor failure, breakdown of: Tfeed, Tflo, Th/w, Tcir)

11. Mode (D/N, ECO, ROOM, NORM, CAL).......................................24

12. Circulation pump handling................................................................24

12.1 Central heating pump..................................................................25

12.2 Hot water pump..........................................................................25

12.3 Hot water container priority................................................26

12.4 Underfloor heating pump............................................................27

12.5 Circulation pump........................................................................28

13. Time and date etting ........................................................................29

14. Time zone upport (calendar and day/night mode)............................30

14.1 Day/night mode..........................................................................30

14.2 Calendar.....................................................................................31

15. Temperature en or ...........................................................................32

16. Explanation of configuration parameter ............................................34

17. U e of the room thermo tat.................................................................38

18. Safe u e of the driver..........................................................................40

1