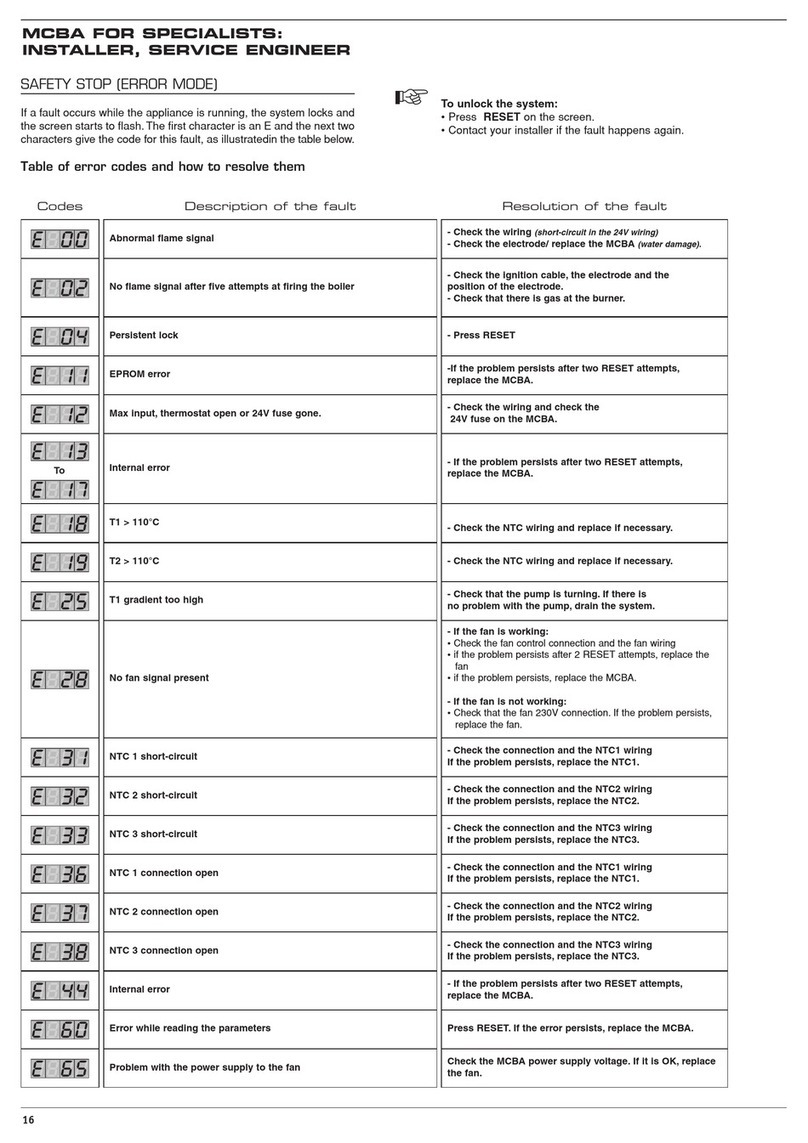

664Y4300.E

EnglishFRAnÇAisnEDERlAnDsEspAñoliTAliAnoDEuTschpolsKi

WORKING PRINCIPLE

The boiler is a high performance hot water producer using indirect

heat transfer due to its Tank-in-Tank technology.

At the centre of the there is a stainless steel cylinder through

which the flue tubes pass. It is surrounded by a mild steel shell containing the

primary water (neutral fluid). The outer shell extends down to the combustion

chamber and also surrounds the flue gas tubes. The heat exchange surface is

therefore larger than that of traditional direct fired hot water boilers.

The gas or oil burner heats the primary fluid which indirectly heats the stainless

steel cylinder containing the hot water. As with all Tank-in-Tank systems, the

cylinder is corrugated over its full height and suspended in the boiler by its hot

and cold water connections.

The fact that the cylinder expands and contracts as it is used and that cold

water is not in contact with the intense heat of the burner flame prevents scale

formation. This resistance to scale, along with the anti-corrosion properties of

the stainless steel mean that sacrificial anodes are not needed.

The has a major advantage over other hot water boilers: it heats hot

water with a primary circuit, which allows the primary fluid to also be used

for heating.

STANDARD EQUIPMENT

- on/off switch

- summer/winter selector

- thermostat adjustable from 60°C to 90°C

- temperature-pressure gauge

- limit thermostat (auto-reset) 95°C

- manual reset safety thermostat 103°C

- primary safety valve 3Bar

- hot water safety valve 7Bar

- drain down valve

- body fully insulated with rigid polyurethane foam

- on/off switch

- summer/winter selector

- thermostat adjustable from 60 °C to 90 °C

- temperature-pressure gauge

- limit thermostat (auto-reset) 95 °C

- manual reset safety thermostat 103 °C

- primary safety valve 3 Bar

- hot water safety valve 7 Bar

- manual four-way valve (servomotor available as an option)

- circulator with automatic air eliminator

- primary expansion tank 10 litre

- hot water expansion tank 2 litre

- drain down valve

- body fully isolated with rigid polyurethane foam

OPTIONAL EQUIPMENT

- Balanced flue kit (except for Delta Pro 55)

- Control Unit kit (Delta Pro Pack only)

- Servomotor (Delta Pro Pack only)

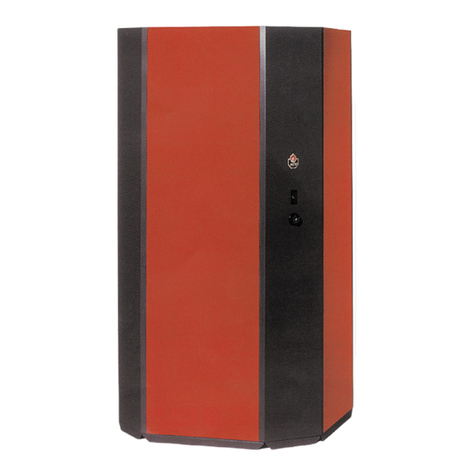

CONSTRUCTION FEATURES

The boiler is covered by a steel casing which has been scoured and phosphated

before being stove enamelled at 220°C.

The boiler body containing the primary fluid is constructed with STW 22 steel.

This is tested at a pressure of 4.5bar (maximumservice pressure = 3 bar).

The internal ring-shaped inner tank is constructed from Chrome/Nickel 18/8

stainless steel and has a large heat exchange surface area to quickly heat the

water. It is corrugated over its height by an exclusive manufacturing process

and is entirely argon arc welded using the TIG (Tungsten Inert Gas) method.

This includes:

The different models include, depending on their power, 4 or 8

steel flue tubes with an internal diameter of 64mm. Each tube is equipped

with a stainless steel turbulator designed to improve thermal exchange and

reduce flue gas temperature.

The combustion chamber of all the models is entirely water

cooled.

The boiler body is fully insulated by rigid polyurethane foam with a high

coefficient thermal insulation, sprayed-on without the use of CFCs.

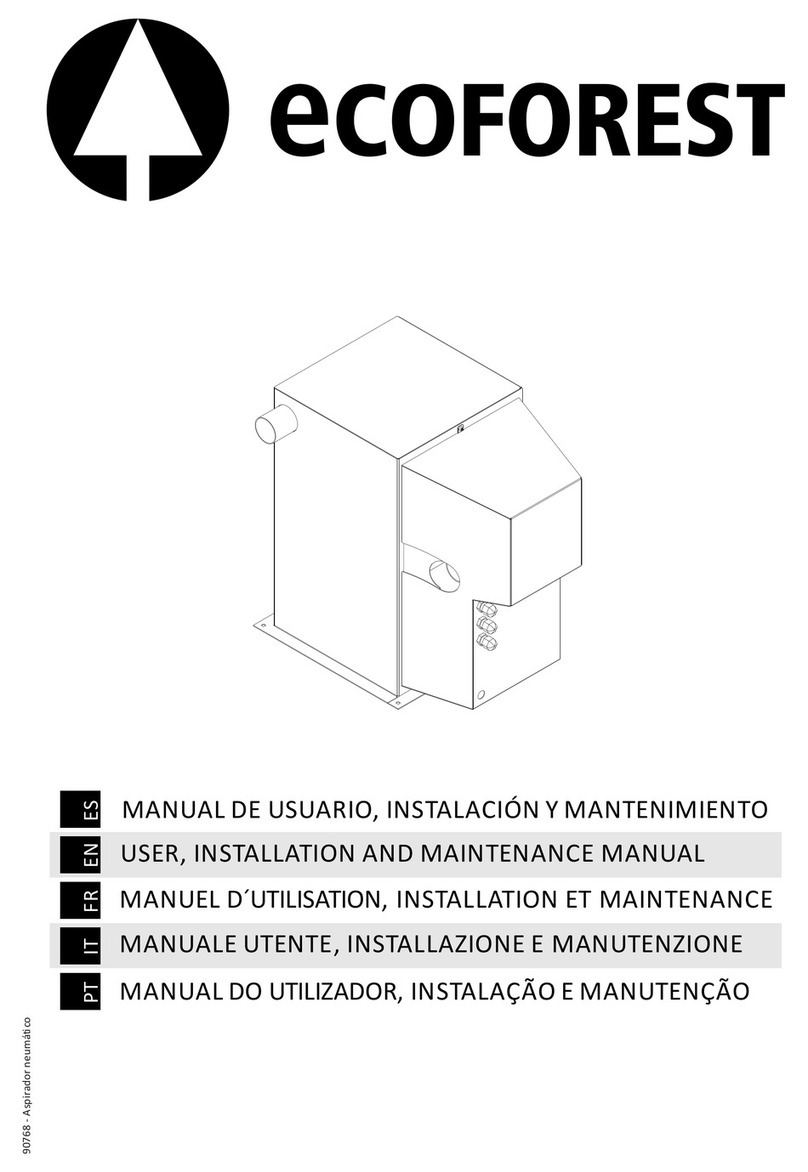

DESCRIPTION OF THE BOILER

1. Flue reduction collar with easy access for servicing

2. Rigid polyurethane foam insulation

3. PVCC dip tube with cold water diffuser

4. Control thermostat and thermometer bulb

5. Burner chamber plate with refractory ceramic fibre

insulation

6. 95 °C cut-off thermostat and manual reset safety thermostat

bulb

7. Flue tubes

8. Turbulators

9. Stainless steel "Tank-in-Tank" hot water cylinder

10. Primary circuit (heating)

11. Combustion chamber

12. Boiler base

13. Heating flow

14. Heating return

15. Domestic hot water outlet

16. Domestic cold water supply

17. Primary hot water safety valve [7 bar]

18. Primary heating safety valve [3 bar]

19. Flue connection Ø 100mm

20. Drain down valve

21. Hot water expansion tank [2 litres]

22. Heating circulator with built-in automatic air eliminator

23. Four-way mixer valve (optional motor)

24. Heating expansion tank [10 litres]

DEsCrIptIoN