EN • 6

ENGLISHFRANCAISNEDERLANDSESpAñoLITALIANoDEuTSCH

662Y0500 • B

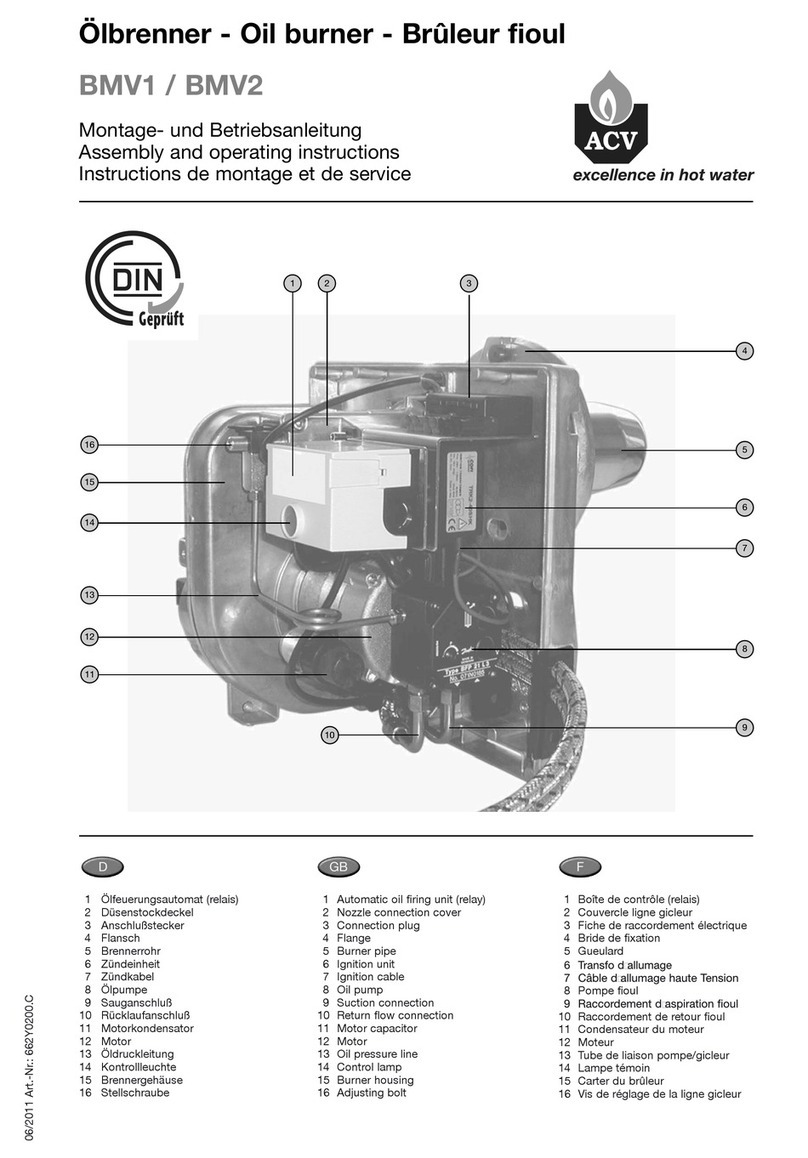

INSTALLATION

DIMENSIONS

When the burner is mounted to a boiler, the following dimensions

must be observed:

- Bolt circle: Ø 150 mm ± 1.5 mm

- Boiler door bore: min Ø 91 mm

INSTALLATION INSTRUCTIONS

When installing the oil hoses and connection wire, make sure that

the connection is strain-relieved and that the burner can be easily

placed in the service mounting bracket.

To commission the oil supply system, it must be vented via the

manometer connection of the oil pump.

Make sure that there are no leaks in the oil supply system!

Failure to do so can lead to combustion problems and dripping.

Replace the oil filter unit at the same time as replacing the burner!

Do not reverse phase and Mp!

Make sure that the protective earth conductor is properly

connected!

SYSTEM CHECK

Correct installation by a specialist company should include the

following:

1. Correct installation of oil lines and filter, leak testing and filling

with oil.

2. Compliance with relevant provisions of the Federal Water Act

(Wasserhaushaltsgesetz, WHG) relating to the laying of oil

lines and the anti-siphoning device.

3. Electrical connections must be installed in compliance with

local regulations. Use flexible cable for the burner connection.

4. The temperature of the oil in the storage tank and the oil lines

must be at least +5 degrees C.

5. Make sure that cold outside air cannot be drawn in.

BURNER ASSEMBLY

The BMR blue burner is particularly suitable for installing in

standard boilers (intermittent operation) for providing domestic

heating and hot water. Our design and development and test

conditions are precisely matched to these operating conditions.

SPECIAL APPLICATIONS

Special requirements and operating conditions must be observed

for the following fields of application:

• Dark radiators

• Ovens

• Drying chambers

• Annealing furnaces

• Industrial applications

Please seek our approval before using the burner in these applications!

It is advisable to consult ACV in the event of increased load in the

combustion chamber or increased thermal load.

Do not allow contaminated combustion air to enter the

burner!

This can be prevented by taking appropriate precautions,

particularly in areas contaminated with halohydrocarbons (printing

shops, hair salons, dry cleaners, laboratories).If in doubt, please

contact us.

Avoid excessive dust accumulation when the burner is

operating!

Avoid high air humidity and frost!

Good ventilation is essential!

We accept no liability for non-compliance with these

recommendations!

RECIRCULATION

The recirculation slots must on no account be covered by the door

cladding. Chamfer the door cladding as shown in the diagram if

necessary.

M 8

150

91

Flange adjustment

Chamfered door cladding

This recirculation opening must be kept clear

This mounting bracket must not be damaged