ACV EVO S Grundfos Magna 1 C User manual

EVO S

Pump Kit

Grundfos Magna 1 Model C

When replacing any part on this

appliance, use only spare parts that you

can be assured conform to the safety

and performance specification that we

require. Do not use reconditioned or

copy parts that have not been clearly

authorised by ACV.

For the very latest copy of literature for

specification and maintenance practices

visit our website www/acv/com/gb

where you can download the relevant

information in PDF format.

Instructions

03/2023

UIN 236076 A01

ACV UK Ltd Evo S

1

236076 A01

CONTENTS

Section 1 - General...................................................................................2

1.1 Introduction.................................................................................2

1.2 Contents .....................................................................................2

Section 2 - Installation ..............................................................................3

2.1 Preparation .................................................................................3

2.2 Installation...................................................................................3

2.3 Pump Connections ....................................................................4

2.4 Operating Panel .........................................................................5

2.5 Setting The Control Function......................................................5

2.6 Control Functions........................................................................6

This kit includes the following items:

1.1 INTRODUCTION

1.2 CONTENTS

This kit is suitable for the Evo S 150.

This manual explains how to install the Pump Control

kit and determine the pump settings.

The Pump control kit converts the demand signal from

the boiler pump QX3 mains voltage output into a Volts

Free enable signal for the Grundfos Magna 1 Model C

SELV Start/Stop input signal.

Item Description

1. Relay Module Kit

2. Instructions

ACV UK Ltd Evo S

2

236076 A01

Section 1 - General

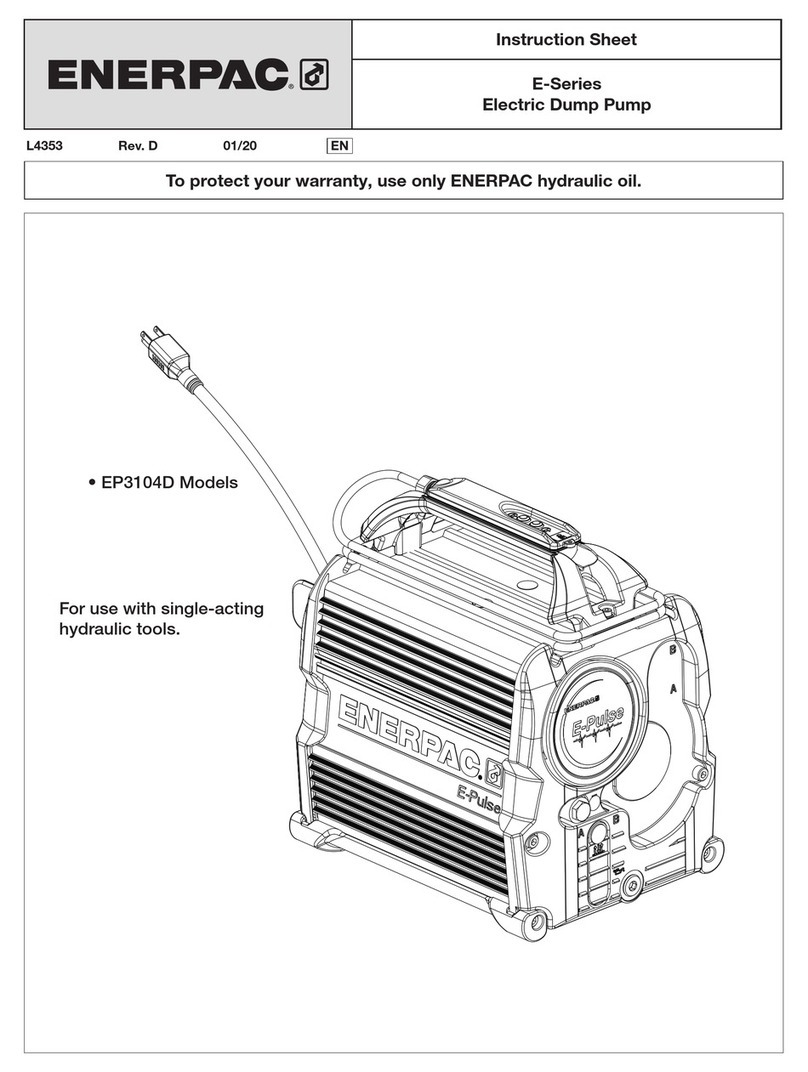

1. Connect the cables from the left-hand side of the relay

onto connection QX3, L3, connection 9-brown (live) and

connection 10-blue (neutral) on the boiler wiring strip.

2. Make sure that the right-hand side cable from the relay

goes through the provided cable clamp.

3. Insert the relay module into the space between the Mains

voltage and PELV installer connection terminals.

2.1 PREPARATION

2.2 INSTALLATION

Install the Pump Control kit as follows:

WARNING: Be careful when you install electrical

connections. Electric shock can cause serious injury or

death and can cause damage to equipment.

1. Make sure that the electrical power supply to the boiler is

set to OFF. For safe electrical isolation refer to Gas Safe

technical bulletin 118. All work must be carried out by a

competent person.

2. For access to the control box (refer to refer to manual

Evo S INSTALLATION, COMMISSIONING AND

SERVICING INSTRUCTIONS Frame 4.6.1).

2

ACV UK Ltd Evo S

3

236076 A01

Section 2 - Installation

1

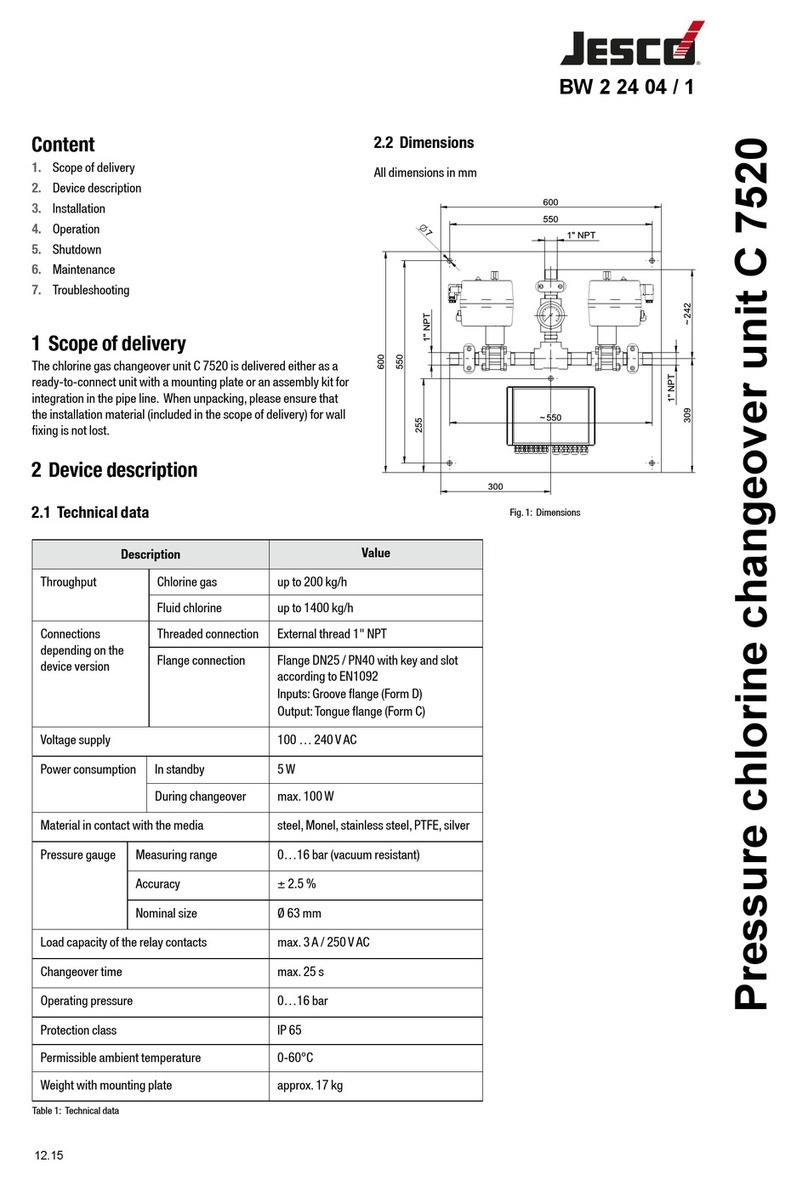

2.3 PUMP CONNECTIONS

Mains Voltage Connections 230 VAC

1. Connect a suitable 3 core cable between the Boiler and the Pump. 13-Green/Yellow (PE), 14-brown (live) and 15-blue

(neutral) on the boiler wiring strip, this provides the permanent supply to the pump.

2. Secure the Pump supply cable into the cable clamp at the boiler and the cable retention at the Pump.

In the supplied Grundfos Installation & Operating instructions refer to ‘Connection to the power supply, terminal-connected

Version’.

For the connection from the relay, refer to the supplied Grundfos installation and operating instructions ‘Digital input (Start/

Stop)’.

During the commissioning procedure, to achieve a temperature dierential

of 20°C at maximum rate, adjust the pump curve following the pump

manufacturer’s instructions.

S/S NC C

Evo S 150

Hydraulic

Conguration

Flow Rate

Q (m3/hr) ∆t 20°C Head (m) Pump Used

No separation 6.22 9.99 Magna 1 32 - 120F

LLH 6.22 10.19 Magna 1 32 - 120F

PHEX 6.28 11.52 Magna 1 40 - 150F

Section 2 - Installation

ACV UK Ltd Evo S

4

236076 A01

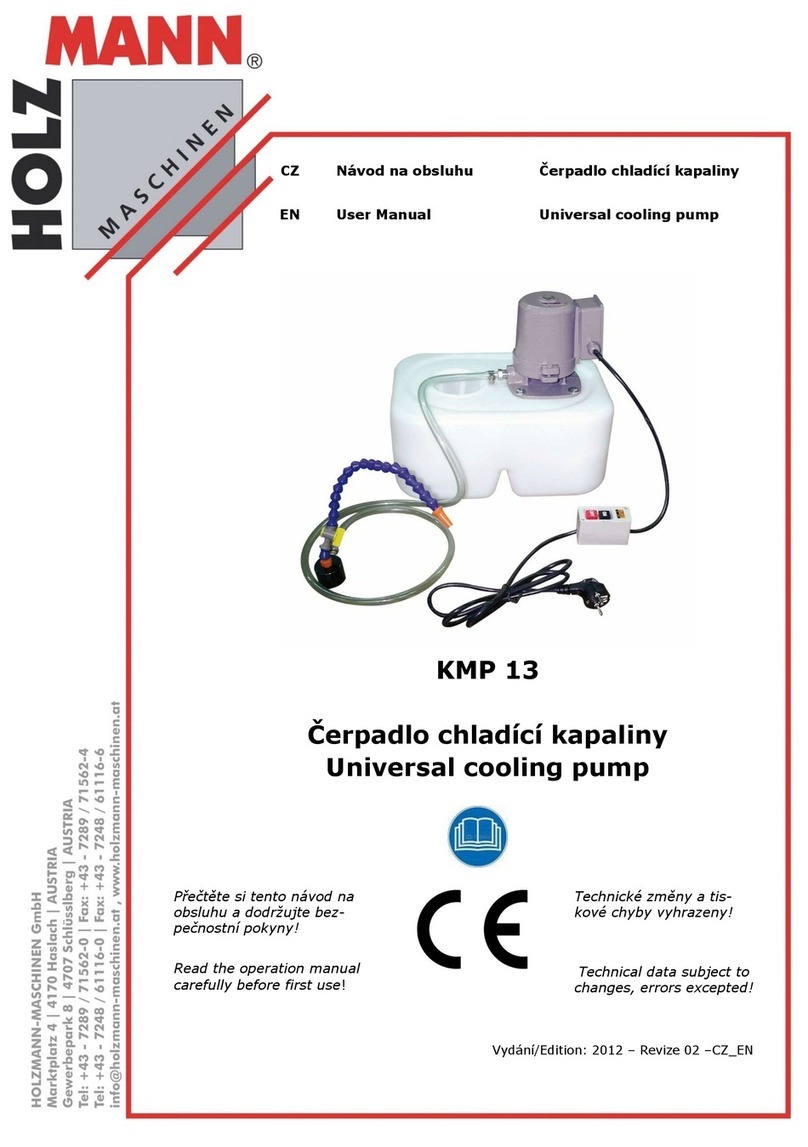

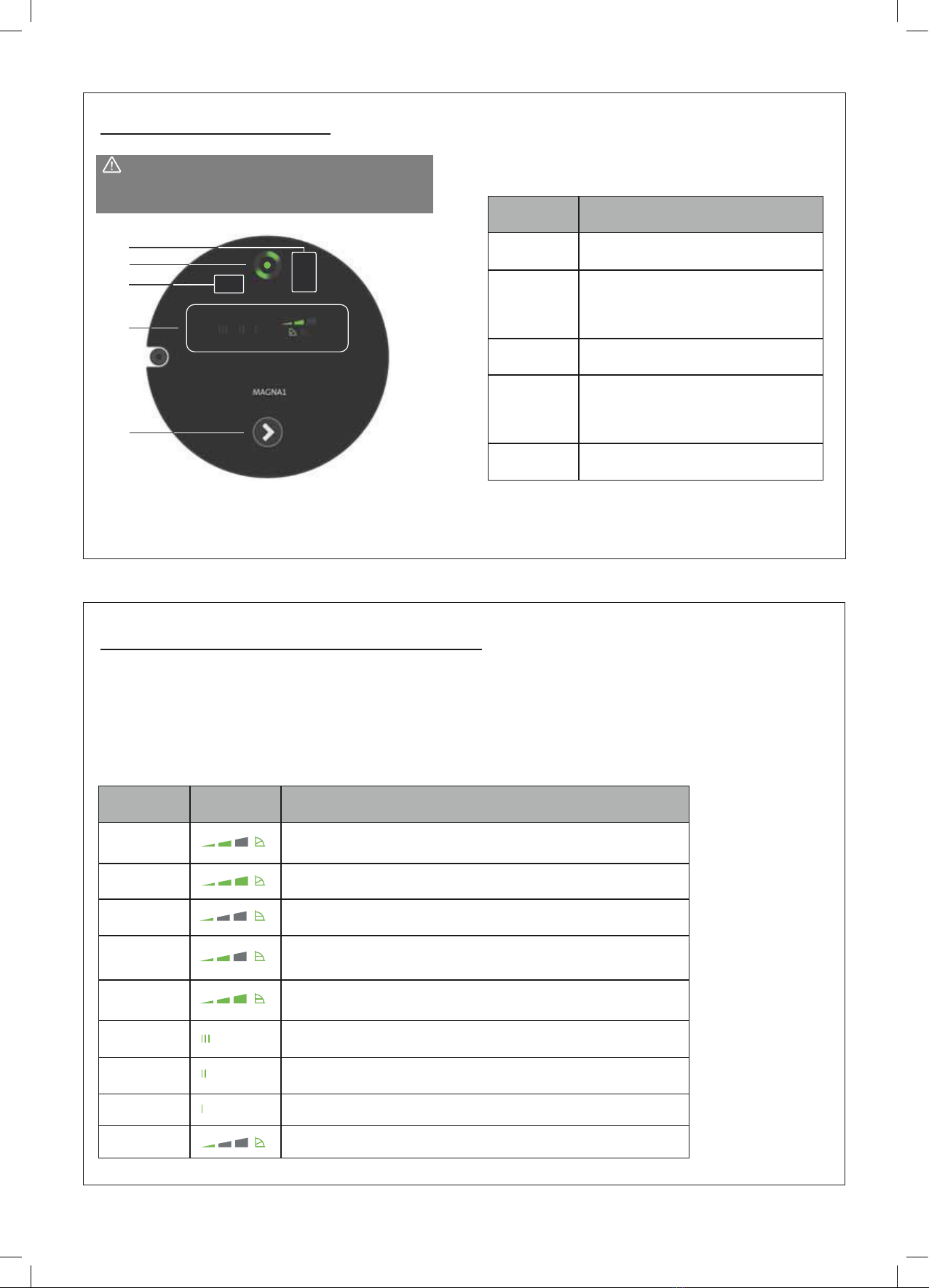

2.4 OPERATING PANEL

2.5 SETTING THE CONTROL FUNCTION

CAUTION: Hot surface - minor or moderate

personal injury. To avoid burns, only touch the

operating panel.

1

3

4

2

5

The operating panel on the pump comprises of the

following:

Position Description

1Infrared receiver for Grundfos GO.

Plug-connected versions.

2

Grundfos Eye.

Refer to Section 9.1 in the

Grundfos Magna1 Installation &

Operating instructions.

3Infrared receiver for Grundfos GO.

Terminal-connected versions.

4

LEDs indicate the control function.

Refer to Section 8.2 in the

Grundfos Magna1 Installation &

Operating instructions.

5Push-button for selection of a control

function

Position Description

0Intermediate proportional-pressure curve, referred to as PP2 factory

setting.

1Highest proportional-pressure curve, referred to as PP3.

2Lowest constant-pressure curve, referred to as CP1.

3Intermediate constant-pressure curve, referred to as CP2.

4Highest constant-pressure curve, referred to as CP3.

5Constant curve III.

6Constant curve II.

7Constant curve I.

8Lowest proportional-pressure curve, referred to as PP1.

The pump has nine control functions, refer to section 7 Control

Functions in the Grundfos Magna1 Installation & Operating

instructions. Select the control function by pressing the push-button

on the operating panel, see section 2.4 Operating Panel. The control

function is indicated by eight dierent light elds in the display.

Section 2 - Installation

ACV UK Ltd Evo S

5

236076 A01

2.6 CONTROL FUNCTIONS

Factory setting: Intermediate proportional-

pressure curve, referred to as PP2.

Proportional-pressure curve (PP1, PP2 or PP3)

Proportional-pressure control adjusts the pump

performance to the actual ow rate demand in the

system, but the pump performance follows the

selected performance curve, PP1, PP2 or PP3. See

below where PP2 has been selected.

PP3

PP2

PP1

Q

H

The selection of the right proportional-pressure setting

depends on the characteristics of the system in

question and the actual ow rate demand.

For further information, refer to section 7.4 Overview

of the control functions and 7.5 Selecting control

function in the Grundfos Magna1 Installation &

Operating instructions.

Constant-pressure curve (CP1, CP2 or CP3)

Constant-pressure control adjusts the pump

performance to the actual ow rate demand in the

system, but the pump performance follows the

selected performance curve, CP1, CP2 or CP3. See

below where CP1 has been selected.

Q

H

CP3

CP2

CP1

The selection of the right constant-pressure setting

depends on the characteristics of the system in

question and the actual ow rate demand.

For further information, refer to section 7.4 Overview

of the control functions and 7.5 Selecting control

function in the Grundfos Magna1 Installation &

Operating instructions.

Constant curve (I, II or III)

At constant-curve operation, the pump runs at a

constant speed, independently of the actual ow

rate demand in the system. The pump performance

follows the selected performance curve, I, II or III. See

below where II has been selected.

Q

H

The selection of the right constant-curve setting

depends on the characteristics of the system in

question.

For further information, refer to section 7.4 Overview

of the control functions and 7.5 Selecting control

function in the Grundfos Magna1 Installation &

Operating instructions.

Section 2 - Installation

ACV UK Ltd Evo S

6

236076 A01

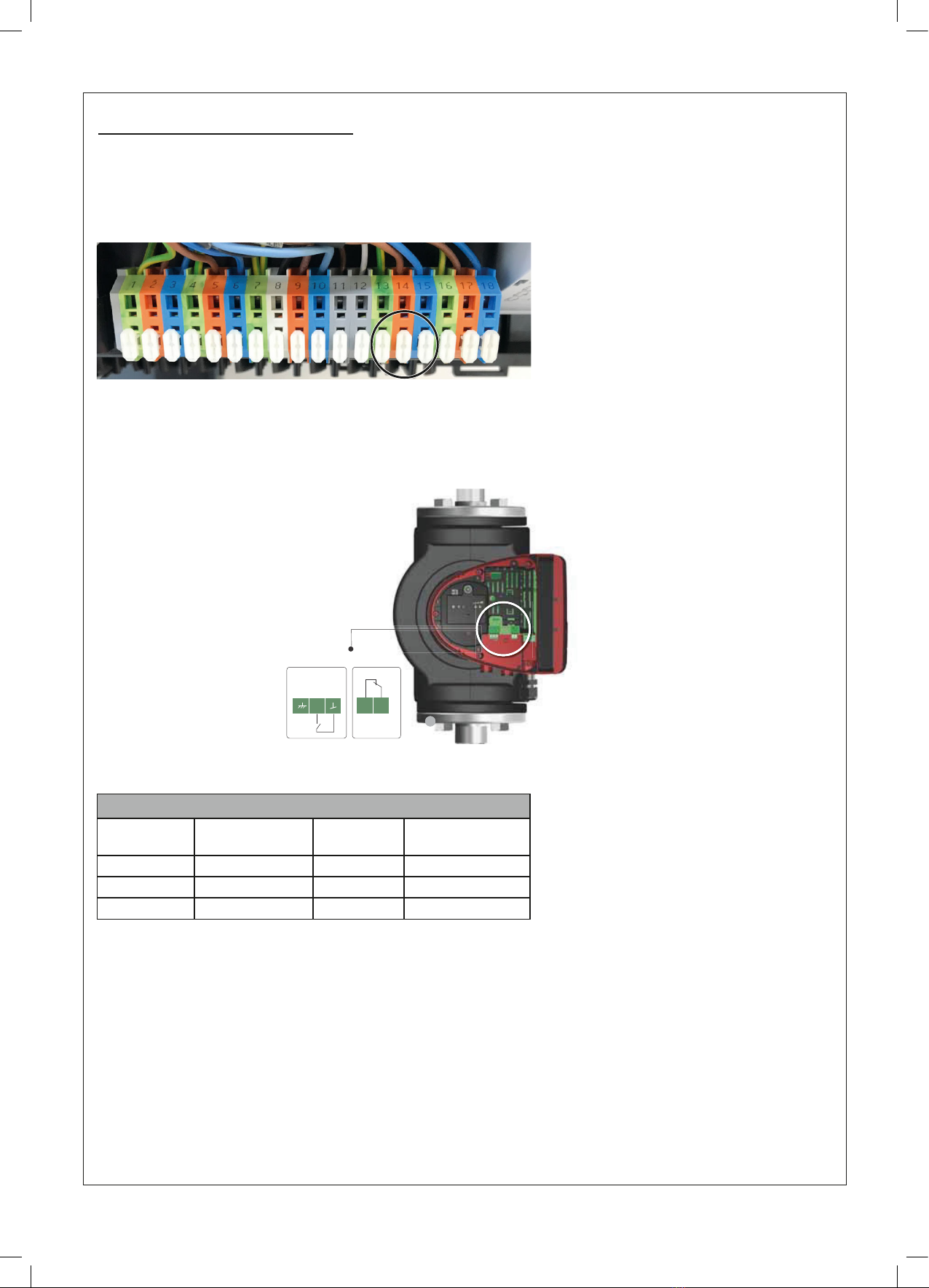

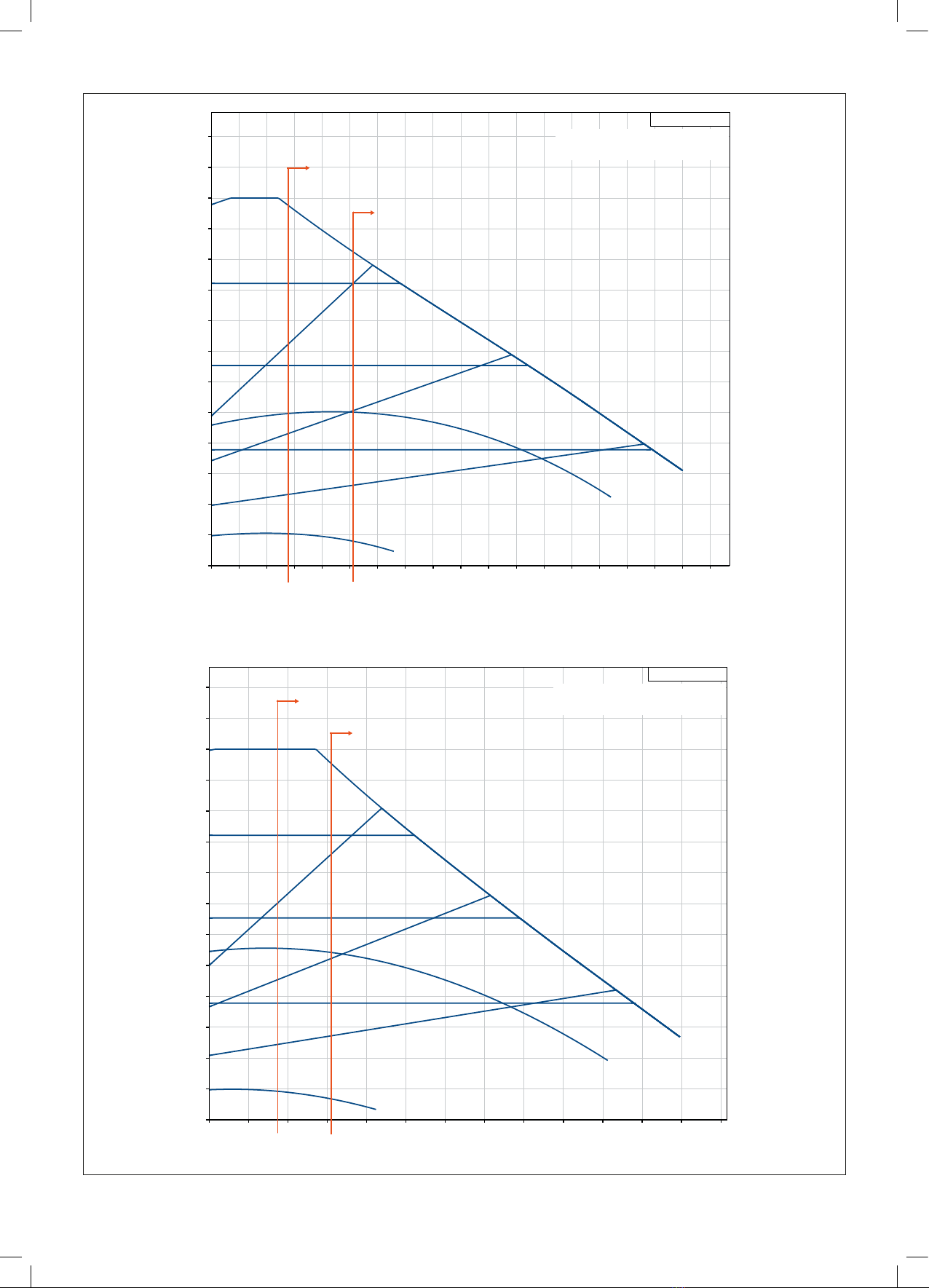

H

[m]

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

24 Q [m³/h]0 2 4 6 8 10 12 14 16 18 20 22

MAGNA1 40-150 F

Pumped liquid = Water

Liquid temperature during operation = 60 °C

Density = 983.2 kg/m³

3.44 6.23

Max Rate

Min Rate

H

[m]

0

1

2

3

4

5

6

7

8

9

10

11

12

13

17 Q [m³/h]0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

MAGNA1 32-120 F

Pumped liquid = Water

during operation = 60 °CLiquid temperature

Density = 983.2 kg/m³

2.75 5.16

Max Rate

Min Rate

Section 2 - Installation

ACV UK Ltd Evo S

7

236076 A01

Notes

ACV UK Ltd Evo S

8

236076 A01

Notes

ACV UK Ltd Evo S

9

236076 A01

ACV pursues a policy of continuing improvement in the design and performance

of its products. The right is therefore reserved to vary specication without notice.

ACV U.K. Limited

St. David’s Business Park,

Dalgety Bay

Fife, Scotland

KY11 9PF

Tel: 0044 (0)1383 820100

www.acv.com/gb

Table of contents

Popular Water Pump manuals by other brands

Lincoln

Lincoln SKF J Series installation instructions

dosatron

dosatron D 45 RE 3000 owner's manual

Rietschle

Rietschle VACFOX VC 150 operating instructions

Oase

Oase NEPTUN 600 operating instructions

Gardner Denver

Gardner Denver WELCH MPC 301 Zp Ex Operation manual

Drum

Drum SSC150 Service and repair manual

Husqvarna

Husqvarna PP 325 E Operator's manual

Utilitech

Utilitech 148012 manual

Becker

Becker O2-PACK U5.70 operating instructions

Krautzberger

Krautzberger MP-400 operating instructions

Oase

Oase BioSmart 5000 operating instructions

GORMAN-RUPP PUMPS

GORMAN-RUPP PUMPS 11 1/2A22-B Installation, operation, and maintenance manual with parts list