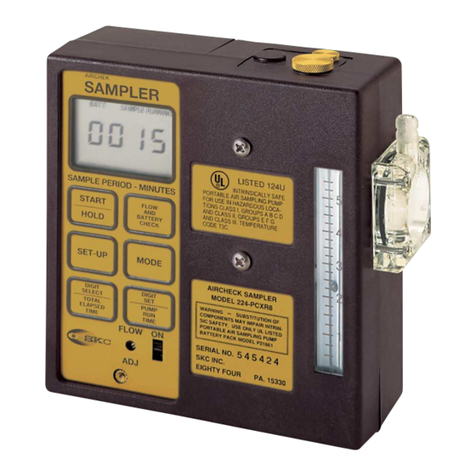

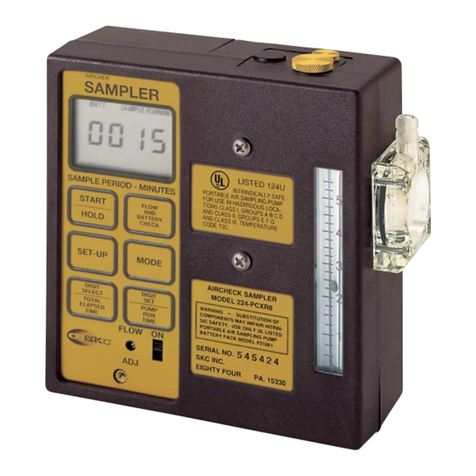

SKC AirChek XR5000 User manual

Other manuals for AirChek XR5000

2

Other SKC Water Pump manuals

SKC

SKC AirChek XR5000 User manual

SKC

SKC Leland Legacy User manual

SKC

SKC 220 Series User manual

SKC

SKC AirChek2000 User manual

SKC

SKC 224-44XR User manual

SKC

SKC AirChek Connect User manual

SKC

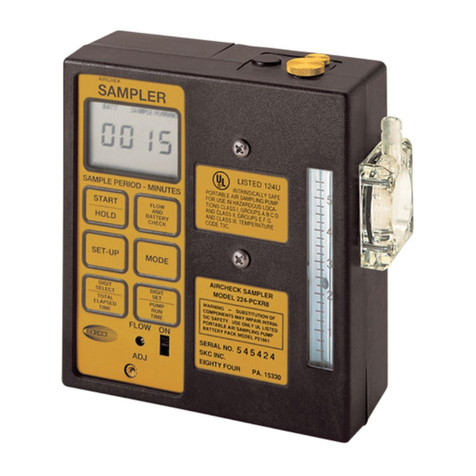

SKC 224-PCXR8 User manual

SKC

SKC 224-50MH User manual

SKC

SKC 210-1000 Series User manual

SKC

SKC Flite 3 User manual

SKC

SKC QuickTake 30 User manual

SKC

SKC AirChek 52 User manual

SKC

SKC Flite4 User manual

SKC

SKC 224-44XRM User manual

SKC

SKC AirChek TOUCH 220 Series User manual

SKC

SKC QuickTake 30 User manual

SKC

SKC Vac-U-Go 228-9605 User manual

SKC

SKC 224-44MTX User manual

SKC

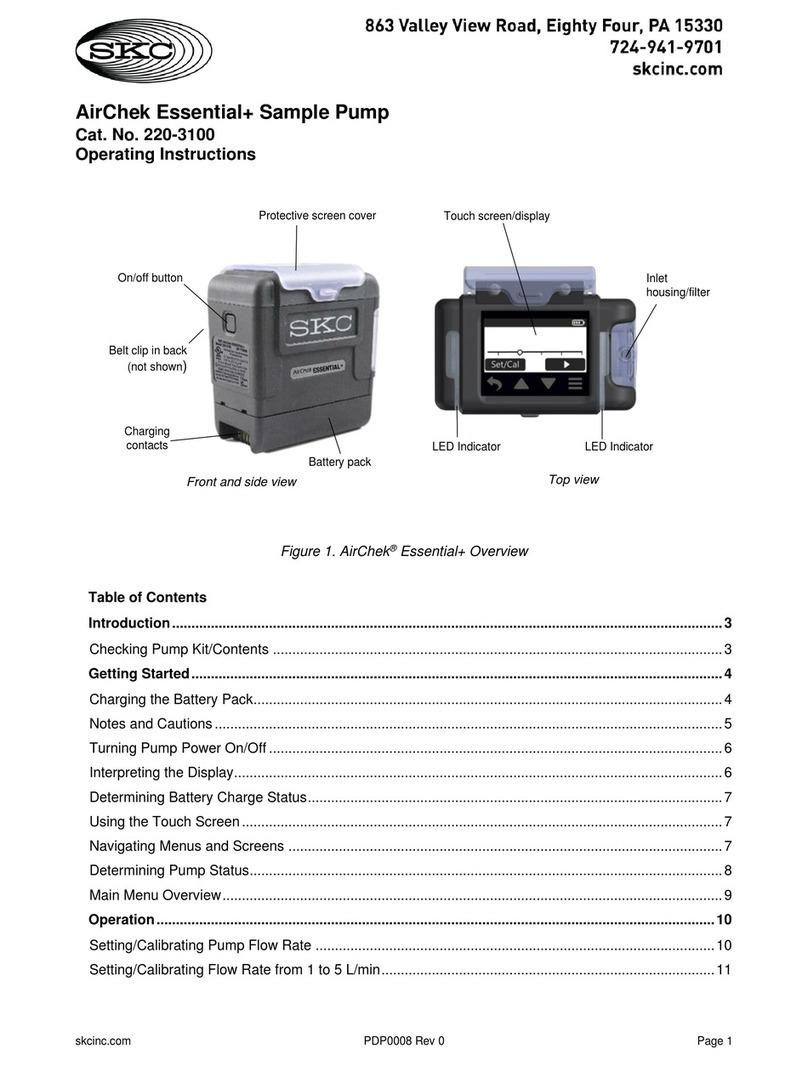

SKC AirChek 220-3100 User manual

SKC

SKC Flite 2 User manual

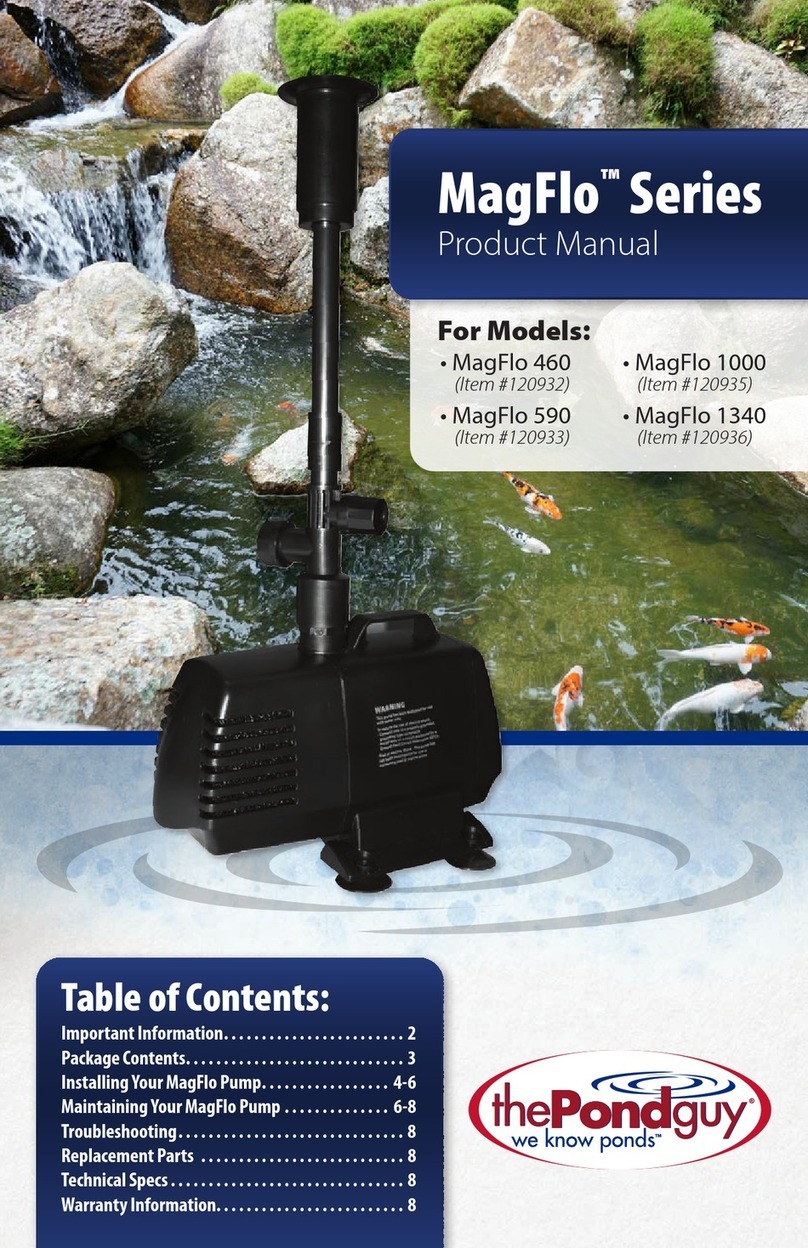

Popular Water Pump manuals by other brands

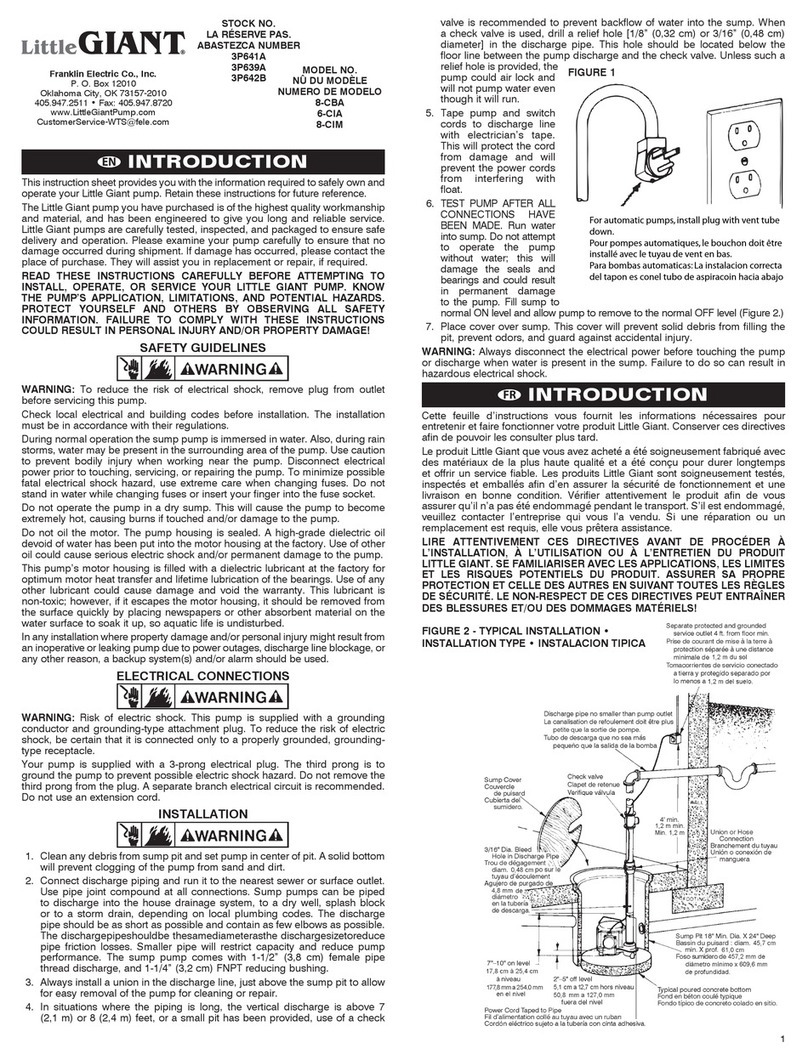

Little Giant

Little Giant 6EC-CIA-SFS installation guide

AL Tech

AL Tech RFR 400 operating instructions

Little Giant

Little Giant CS-SS installation instructions

Ecoplus

Ecoplus ECOair 1 instructions

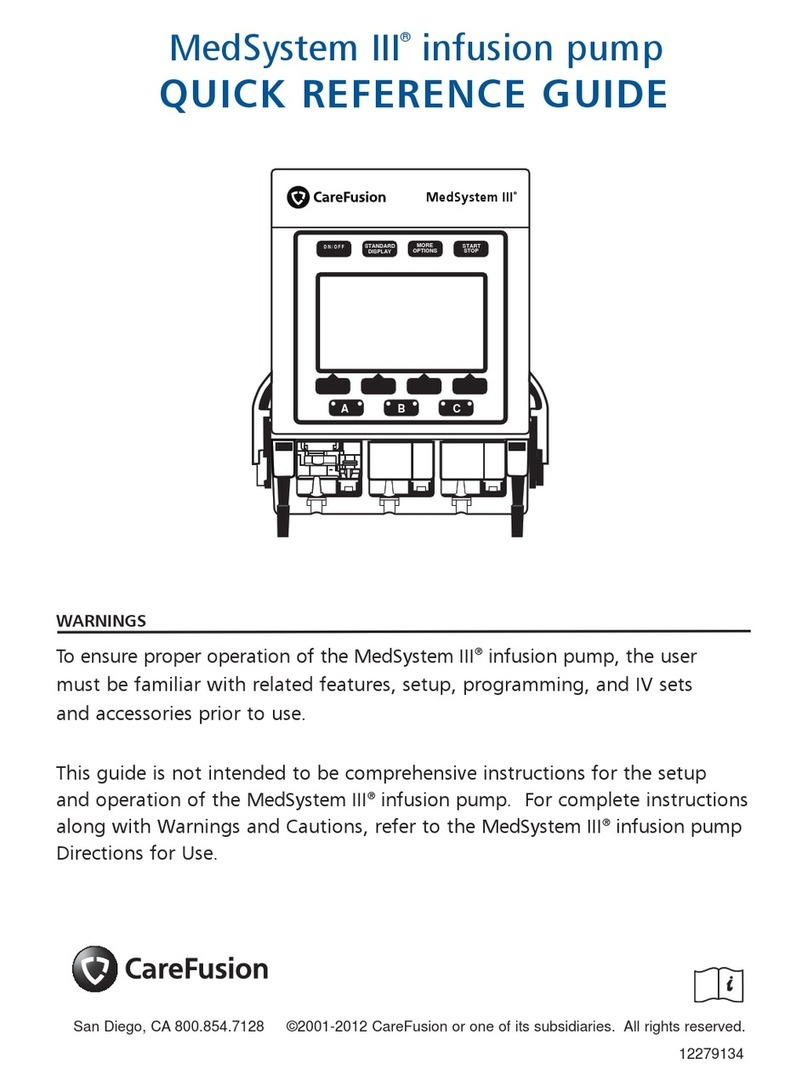

Care Fusion

Care Fusion MedSystem III Quick reference guide

FLORABEST

FLORABEST FGPS 1100 C3 Translation of the original instructions