Aczet MB 54 User manual

Moisture Analyzer

Operating Instructions

Aczet Moisture Analyzer

Electronic Moisture Analyzer

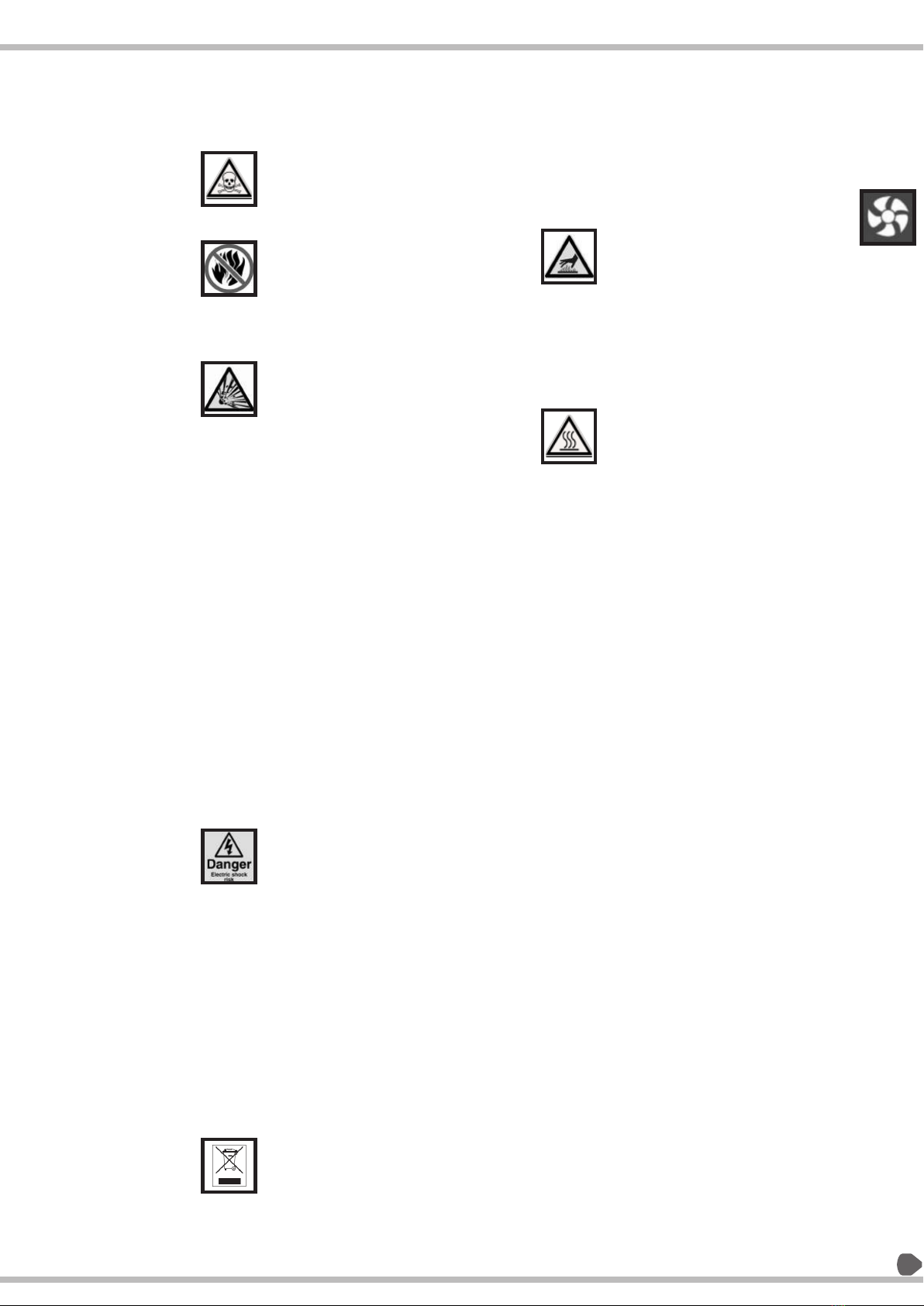

qDo not use a sample that could make

a dangerous chemical reaction and

cause an explosion or poisonous gas,

when the sample is heated.

qKeep flammables away from the

analyzer.

qDo not use the analyzer in ambient

ignitable gas. It may cause explosion

and fire.

qUse a power source (voltage,

frequency, outlet type) adapted to

the specification of the analyzer. If

excessive voltage is used, the

analyzer may overheat and be

damage or cause a fire.

qTurn off the power switch and remove

the power cord from the socket,

when replacing the halogen lamp.

Touching the halogen lamp connector

carelessly may cause an electric

shock.

qDo not disassemble the analyzer. It

may cause an error, damage,

receiving an electric shock or fire. If

the analyzer needs service or repair,

contact the local aczet service

center.

qAvoid getting the analyzer wet. It is

not a water-resistant analyzer. If

there is leakage of liquid into the

analyzer, it may cause damage to the

analyzer or receiving electric shock.

qDo not look at the active halogen

lamp to protect your eyes from

damage.

qDo not drop, hit or crack the

glassware including the halogen

lamp, to avoid any injury.

qWhen the halogen lamp is used

beyond 3000 hours, we recommend

replacing the lamp with a new one to

avoid trouble.

qWhen discarding a halogen lamp, do

not break it to avoid scattering glass

and injury.

CAUTION

qDo not touch the heater cover, the

halogen lamp, glass-housing, pan

handle, sample pan and sample

without adequate protection, it

could cause a burn or scar.

qParts of the analyzer are very hot

when a measurement finishes. For

operation, use the specified grips of

the heater cover and pan handle. Use

the standard accessory tools.

qWhen the analyzer is used in a room

where hot air does not diffuse, it

may unexpectedly overheat. In this

case, adjust the drying temperature

or move the analyzer to a place with

adequate ventilation.

qAvoid leaving the analyzer in direct

sunlight, as that could cause

discoloration of the case or a

malfunction.

qUse only aczet accessories as they

are optimally designed for use with

your moisture analyzer

Safety And Warning :

5

Introduction :

6

Moisture analyzer is used as a quick and reliable means of

determining the moisture content in solid, pasty and liquids

by the thermo-gravimetric principle. Moisture analyzer

saves work and speedup your routine measurement.

To ensure proper utilization of the moisture analyzer, go

through the operating instructions very carefully.

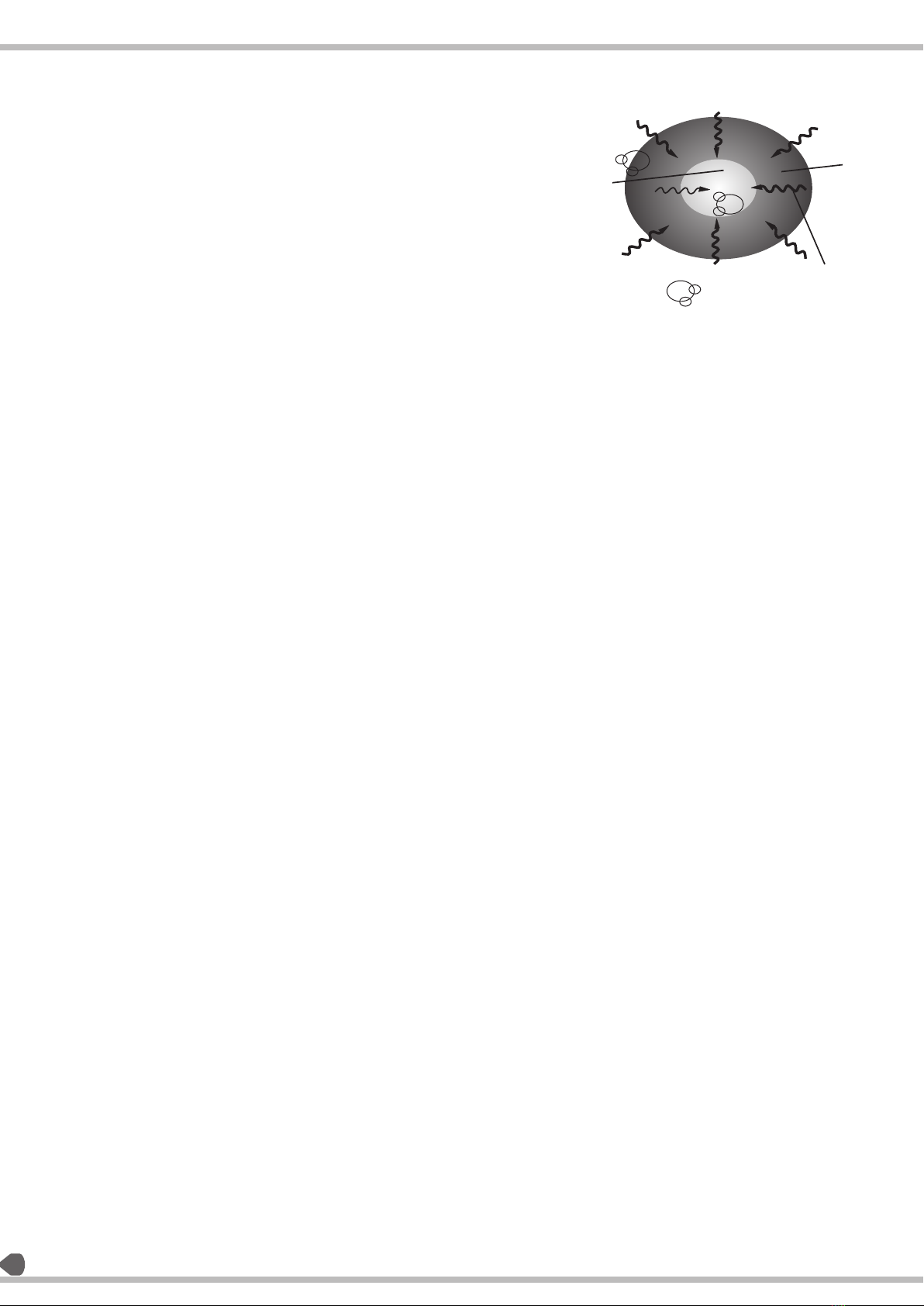

PRINCIPLE OF MOISTURE ANALYZER:

qWhat is moisture?

The moisture of a material is often mistakenly equated

with its water content. In fact, the moisture of a material

includes of all the volatile components which are given off

when the sample is heated, resulting in a decrease in sample

weight. Among such volatile substances are:

qWater

qOrganic solvents

qOils

qAlcohol

qFats

qFlavorings

qProducts of decomposition (When a sample is to

overtheated) etc.

There are many methods to determine the moisture content

of a substance.

Basically, these methods can be divide into two categories:

When absolute methods are used, the moisture content is

directly determined (for example, as a weight loss

registered during the drying routine). These methods include

oven drying, infrared drying, and microwave drying. All

three of these methods are thermo gravimetric.

When deductive methods are used, the moisture content is

indirectly determined.

A physical property, which is related to the moisture in the

substance, is measured (e.g., absorption of electromagnetic

rays). These methods include Karl-Fischer titration, infrared

spectroscopy, microwave spectroscopy, etc.

Thermo gravimetric is the process of determining the loss of

mass that occurs when a substance is heated. In this process,

the sample is weighed before and after being heated, and

the difference between the two weights is calculated.

In a conventional drying oven, circulating hot air warms the

sample from the outside to the inside. Efficiency is lost

during drying because as the moisture evaporates, it cools

the sample surface.

By contrast, infrared rays (IR rays) penetrate a sample

without being impeded. Having reached the interior of a

sample, they are converted into heat energy, which

stimulates evaporation, thus drying the sample. A small part

of the IR rays is reflected from the surface of the substance.

qHow does a moisture analyzer work?

The moisture analyzer consists of two essential components;

a weight analyzer and a heater. The sample is placed in the

moisture analyzer and the analyzer captures the initial

weight. An infrared energy heater is used to heat the sample.

During the test the analyzer records the weight. When the

sample no longer looses weight the analyzer shuts off the

heat and uses the final weight to calculate moisture

contents.

Infrared rays

Volatile Contents

Heated

Area

Samples

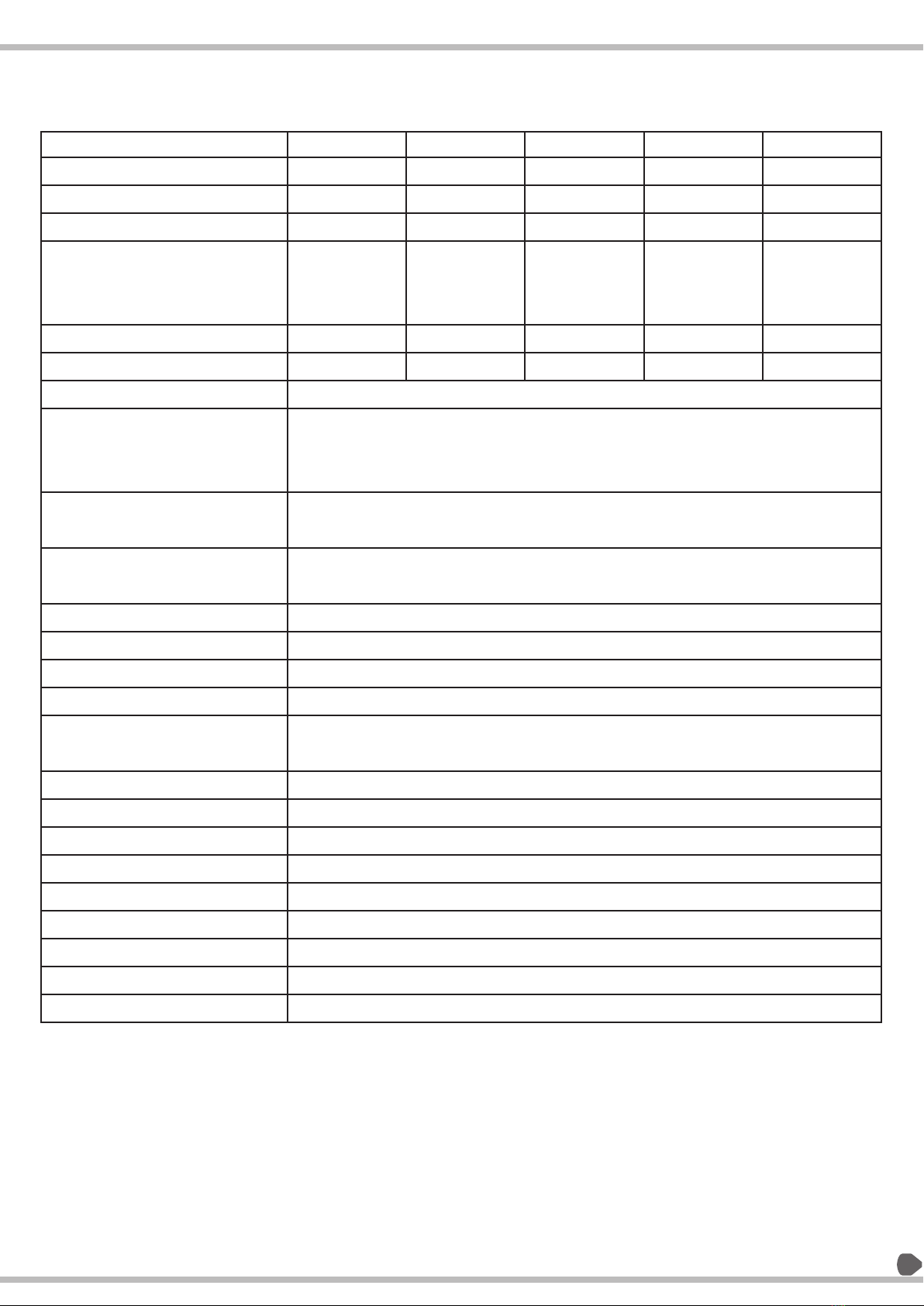

Type / Model

Max Weighing Capacity

Readability

Readability moisture %

Repeatability (Std Dev), %M

for initial Sample weight = 2g

for sample weight = 10g

Tare Range

Min Mass of sample

Drying temperature range

Switch off criteria

Heating Profile

Unit of Measurement

Heating Unit

Program Memory

Compile

Data storage Memory

Statistics

Stand by temperature

Data Interface Port

Print Out

Display

Power Supply

Power Consumption (Watt)

Housing Dimension mm

Weight Approx

Packing Dimension mm

0 0

30 C to 175 C

Auto, Manual, User Def

Weight / Time, User Def

% unit / time, Intelligent

Standard, Gentle, Rapid,

Steps, High Temperature

% M, %D, %R (ratio), Gm/Lt,

%M Atro, %D Atro

Infra Red Halogen

40 Method

Yes

Last 1000 results storage

Method or Batchwise last more than

9,99,999 data statistics are stored

0 0

30 C to 100 C

RS232C Bidirectional, USB, Ethernet, PS2

GLP Compliant, User Configurable

Graphical LCD display with LED backlit

230 v/50Hz or 115v/60Hz

Max 415

211 (w) x 342 (d) x 187 (h)

5kg

325 (w) x 390 (d) x 285 (h)

MB 200

200 g

0.001g

0.001%

0.1%

0.03%

200 g

200 mg

MB 40

40 g

0.001g

0.001%

0.1%

0.03%

40 g

200 mg

MB 50

50 g

0.001g

0.001%

0.1%

0.03%

50 g

200 mg

MB 54

50 g

0.1 mg

0.0001%

0.05%

0.02%

50 g

200 mg

MB 120

120 g

0.001g

0.001%

0.1%

0.03%

120 g

200 mg

Technical Parameters :

7

Getting Started :

8

Transportation and storage:

Transportand Shipping

qMoisture analyzer is a precision analyzer. Handle it with

care.

qAvoid shaking it or subjecting it to any heavy jolts or

vibrations during transport.

qAvoid severe temperature fluctuations and getting the

analyzer damp (condensation) during transportation.

qAvoid direct exposure to sunlight.

qNOTE:

The moisture analyzer should ideally be shipped and

transported in its original packaging to avoid damage

in transit.

Storage

If you do not intend to use the analyzer for a long time,

unplug it from the electrical supply, clean it

thoroughly and store it in a place that meets the

following conditions:

qNo shaking or vibrations.

qNo fluctuations in temperature.

qNo direct exposure to sunlight.

qNo moisture.

Unpacking :

Moisture analyzer comes in environment-friendly

packaging specifically developed for this precision

analyzer, which provides optimum protection to the

analyzer during transportation.

Follow instructions carefully when you unpack the

Moisture analyzer in order to avoid damaging it:

qThis is a precision analyzer, Unpack the analyzer

carefully and gently.

qWhen temperature outside is very low, the analyzer

should first be stored for a few hours in the unopened

transport package in a dry room at normal room

temperature, so that no condensation settles on the

analyzer when it is unpacked.

qCheck the moisture analyzer for any external

noticeable signs of damage immediately after you

unpack it. If you find that it has been damaged in

transit, inform your Aczet Service Center

immediately.

qIf the is not being put into operation immediately after

purchase, store it in a dry place with minimal

fluctuations in temperature.

Dimension :

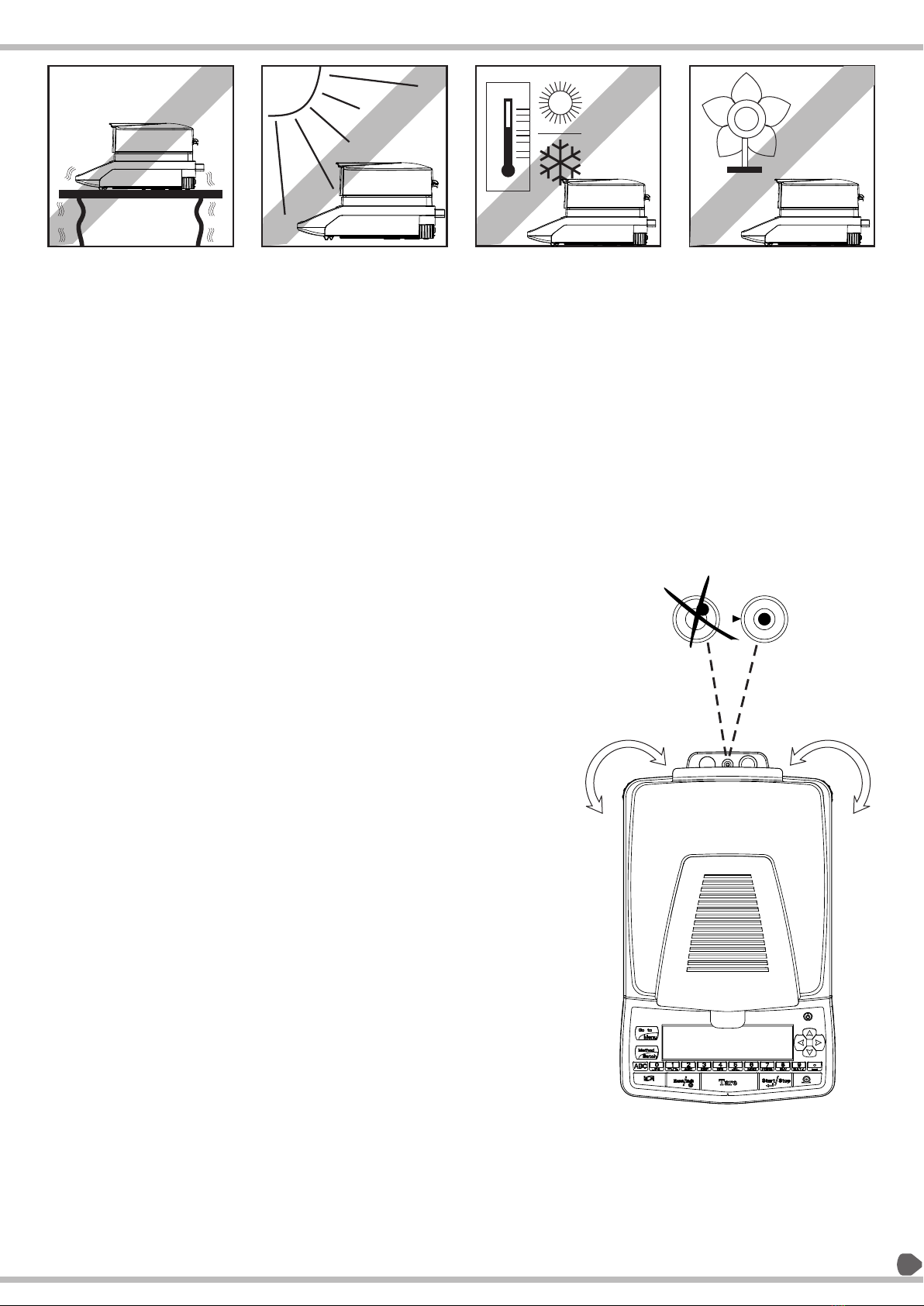

Selecting The Location :

The moisture analyzer is designed to provide reliable

results under normal ambient conditions in the laboratory

and in industry. When choosing a location to set up your

moisture analyzer, observe the following so that you will

be able to work with added speed and accuracy

qTolerable ambient temperatures

qTemperature: 15°C - 30°C

qRelative humidity: 25% - 85%, non-condensing

qPut the analyzer on a rigid, firm flat base,

preferably exposed to no vibrations.

qMake sure that the analyzer cannot be shaken or

knocked over

qDo not expose it to direct sunlight

qAvoid drafts and excessive temperature fluctuations

qLeave enough clear space around the analyzer to

prevent a buildup of heat.

qDo not expose the analyzer to high levels of

moisture for long periods of time. Avoid letting

condensation form on the analyzer. If analyzer is

cold, let them warm up to room temperature

(approx. 20°C) before connecting them to the

mains.

qCondensation is practically impossible on analyzer

which is connected to the mains.

INSPECTION AND ASSEMBLY

The moisture analyzer does not come fully assembled.

Once you have unpacked all the parts, check that the

delivery is complete and assemble the individual

components in the order indicated below.

Accessories delivered:

q25 aluminum pans

q1 sample holder

q1 pan insert

q1 power cable

q1 CD for Operating Manual

q1 Pan cover

q1 Pack of fuse

Levelling your Balance :

Purpose:

qTo compensate for irregularity at the place of

installation

qThis is particularly important for testing liquid

samples, which must be at a uniform level in the

sample pan

qAlways level the moisture analyzer again every time it

has been moved to a different location.

qRotate the leveling feet as needed to adjust the

moisture analyzer

qIn order to function properly, the moisture analyzer

must be precisely horizontal.

qThe analyzer is fitted with a "leveling bubble" and two

rotatable feet for level-control, with the aid of which

it is possible to compensate for small height

differences and/or unevenness in the surface on

which the analyzer is kept.

qThe screw feet must be adjusted so that the air bubble

is precisely in the center of the sight glass of the

leveling bubble.

qPlease refer for leveling of the Analyzer.

9

10

Follow safety instructions when connecting the analyzer to

the mains:

NOTE:

qThe analyzer may only be operated using the original

mains cord supplied.

qIf the mains cord supplied is not long enough, only use

an extension cord fitted with a protective earth

conductor.

qPlug the mains cord into a socket which has been

installed in accordance with regulations and is fitted

with a PE terminal.

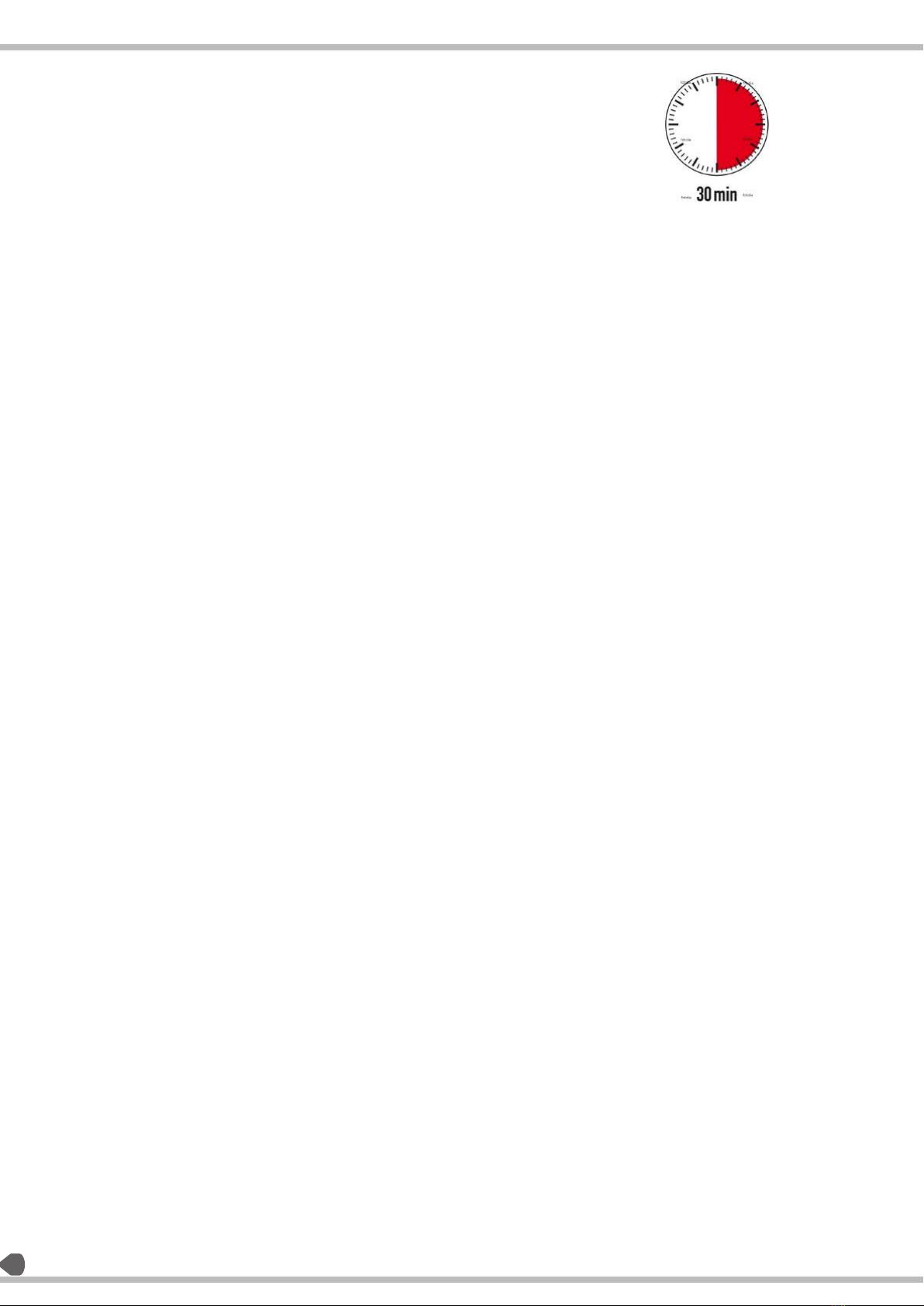

For technical reasons, the heating unit is designed in the

factory to accommodate a voltage of 230 V or 115 V and in

accordance with your order. Check that the settings match

the local settings

Warm up time:

To obtain the precise results, the moisture analyzer must

warm up for at least 30 minutes

after initial connection to AC power or after a relatively long

power outage. Only after

this time will the moisture analyzer give the desired

performances of the moisture

determination.

Note: The analyzer must be carefully relevelled each time it

is moved in order to obtain accurate measurement

11

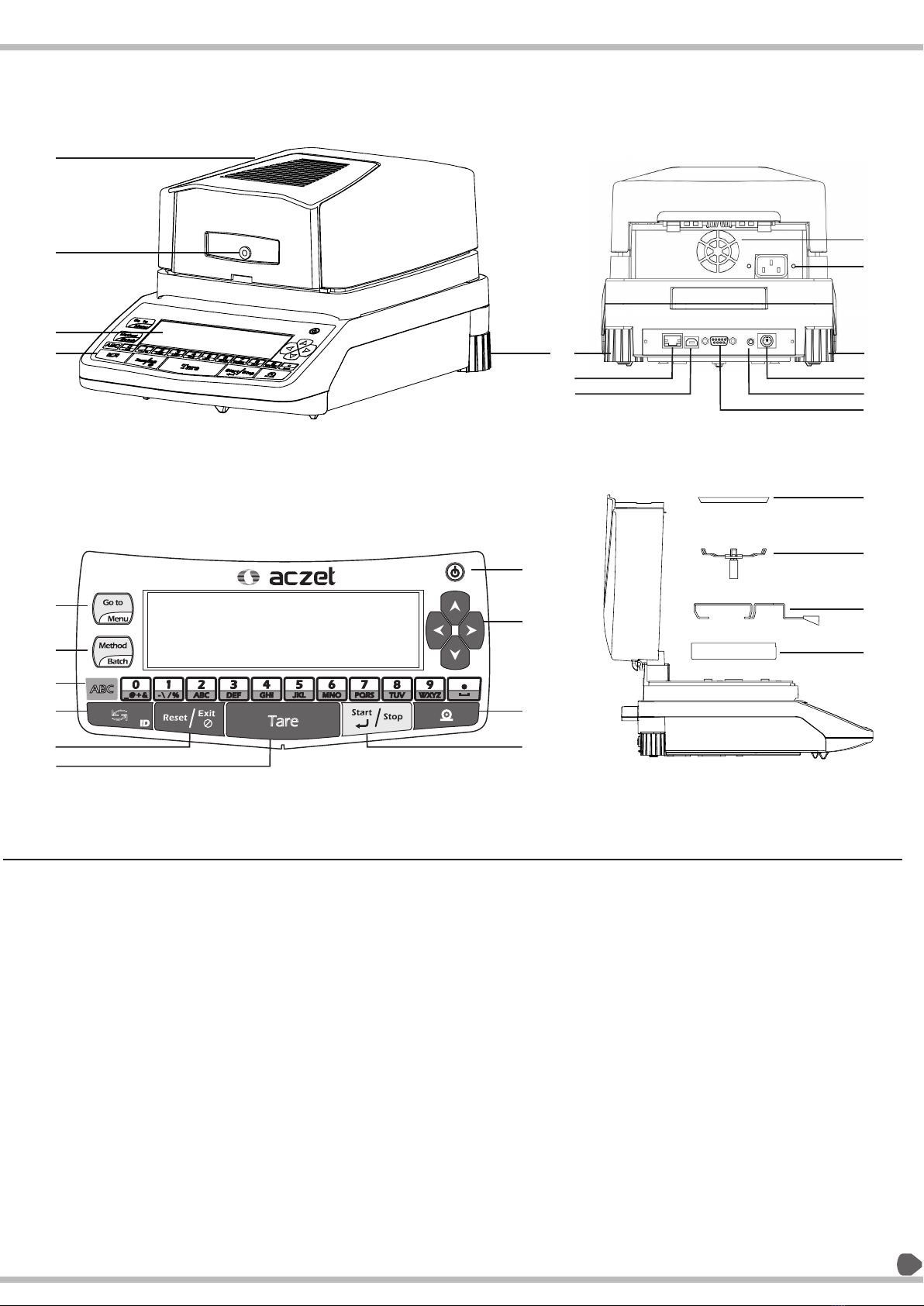

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

25

26

22

23

24

19

20

21

No. Designation

1 Top Chamber

2 RTD Insert

3 Display

4 Keypad

5 Goto/Menu key

6 Method/Batch Key

7 Alpha / Numeric On / Off key

8 Toggle Key

9 Reset/Exit Key

10 Tare Key

11 Start / Stop Key

12 Print Key

13 Up/Down/Right/Left Arrow Key

No. Designation

14 Power ON / OFF Key

15 Pan Cover

16 Pan Holder

17 Pan Stand

18 Pan

19 Legs

20 Ethernet Port

21 USB Port

22 Rs232 Port

23 Foot Key

24 Ps2 Connector

25 AC Plug

26 Cooling Fan

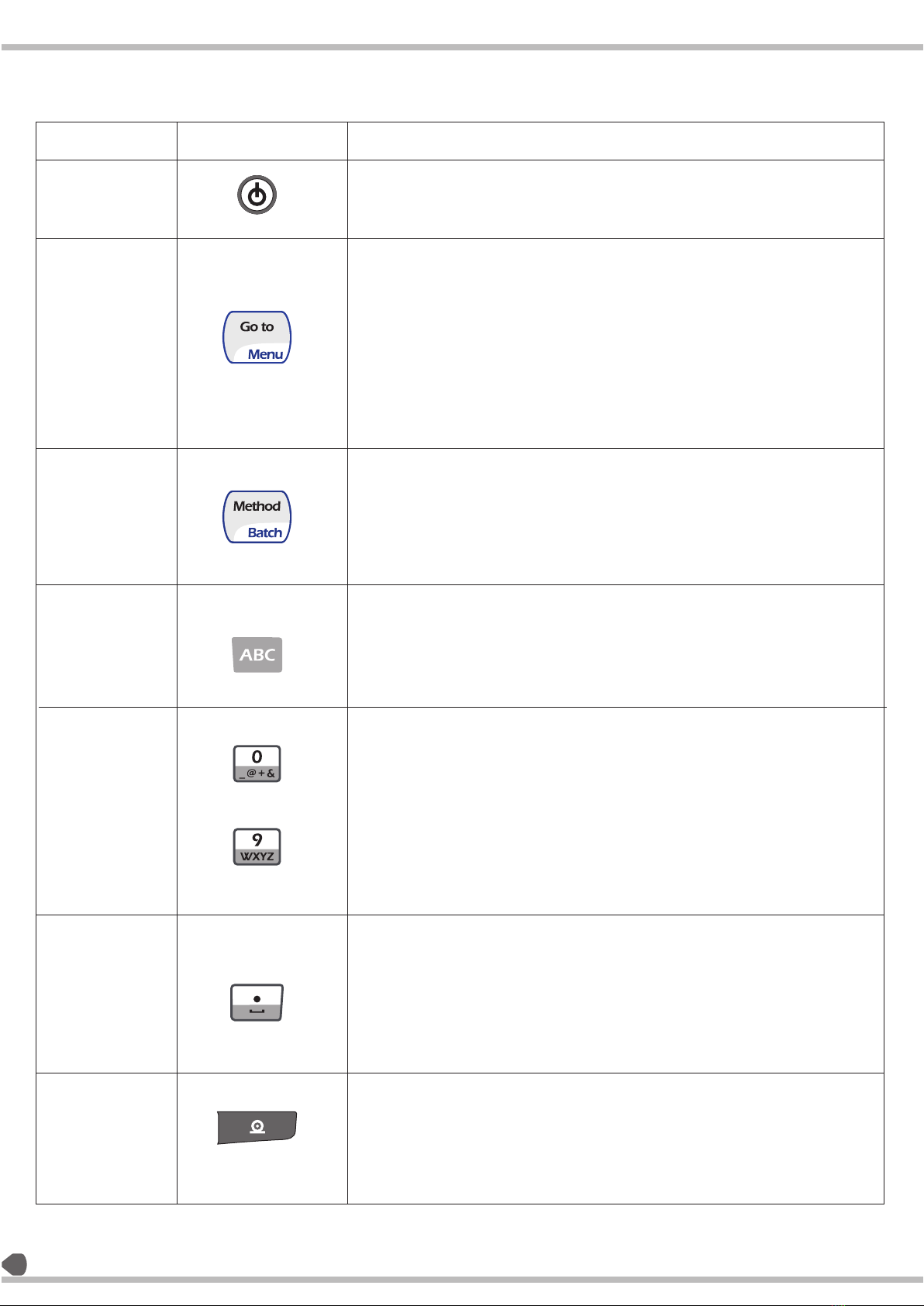

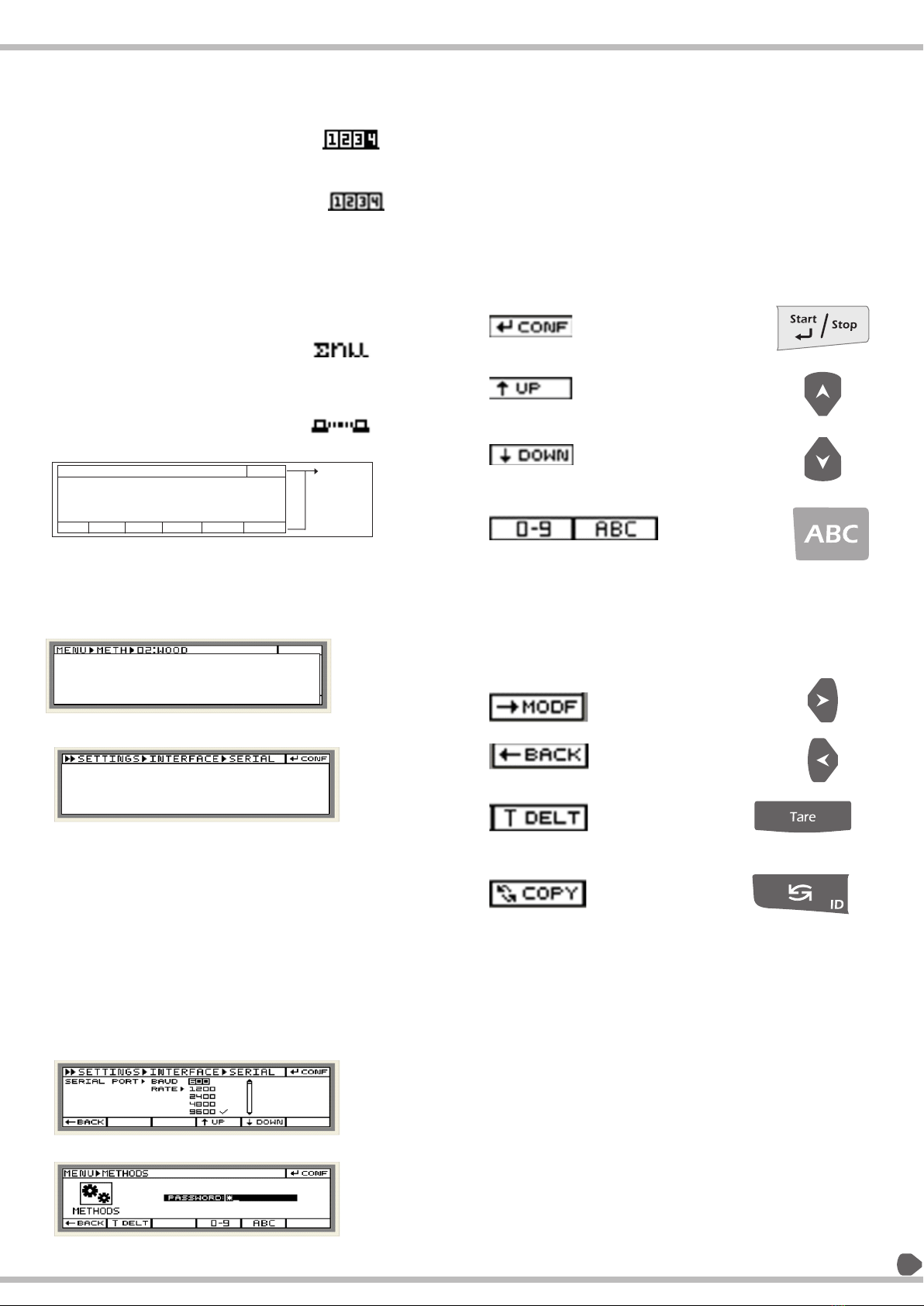

Symbol Description

qThis key is used to put the analyzer in Stand-by mode and to wake up

from the stand-by mode.

qThis key is active in all the menus, sub-menus and moisture

qPressing this key once makes the use of 'GO TO' function

and pressing it for two seconds makes the use of 'MENU'

functionality.

qThe 'GO TO' functionality is a short-cut key that can be

configured in settings=> soft key.

qBy default, the short-cut assigned to 'GO TO'/ MENU key is ‘

MAIN MENU'.

qThe 'MENU' function displays the very first menu of the MB.

qThis key can be used to come back to simple weighing from

anywhere in the menu.

qThis key will not be active during the drying process.

qPressing the key once makes the use of METHOD function

and pressing it for 2 second makes the use of BATCH

function.

qIn METHOD function, the user will go directly to the Method

List,

qIn BATCH function, the user will go directly to the Batch List,

if it is activated by the user.

qThis key is used to activate the alphabet and symbol keys on

the number keys wherever it is required.

qPressing this key once activates the number keys in to

alphabet keys and pressing it again get the number keys

back into the alphabet state.

qDuring the drying process, this key will be deactivated.

qThese keys are multiplexed with special symbols and

alphabets.

qDuring the drying process, these keys will be deactivated.

qIf alphabets are active, pressing the key again within 1

second will print the second value in the given set.

qIf no other key is pressed, then after 1 sec, the cursor will

shift to the next position.

qIf any other key is pressed within this 1 sec, the last pressed

character will be taken at the corresponding place and the

current key pressed will be taken on the next character and

the timer for 1 sec will start again.

qSingle press of this key gives a decimal point, pressing it

second time will give 'blank space' if alphabet key is not

previously pressed. For other options the alphabet key must be pressed.

qPressing this key for the first, second, third and fourth time will give '

blank space', ':', '*' and decimal point respectively, with alphabet key

previously pressed.

q

Display during drying if Intelligent switch-off is selected.

qPress Manually for Printing

Used as Cancel Function key for the Paste option in Method List & Info

Name

On / Off Key

Menu & Go-to key

Method &

Batch key

Alpha bet key

Number Keys

Decimal Point &

space key

Print Key

12

3.7 Keypad Description :

13

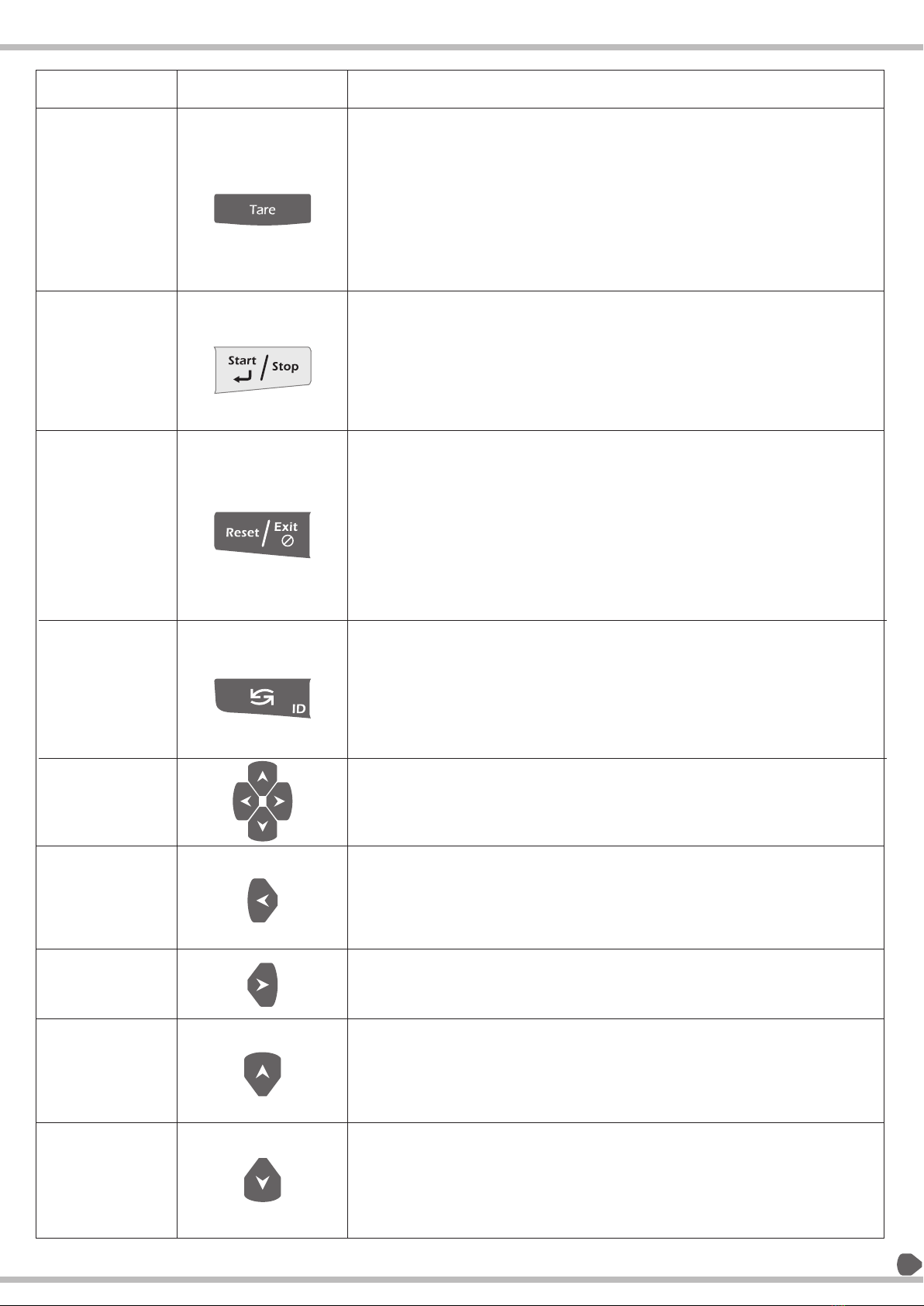

q

done by single press any time during the weighing.

qIt can be used as 'Delete' key in method list.

qThis key can be used as 'Backspace' whenever there is alpha-numeric

value to be entered and as 'Delete' in User ID, password and ID.

qThis key will be deactivated during the drying process except in the

Steps heating profile.

qIf Steps heating profile is selected and drying is going on, this key can be

used for 'Info Display'.

qAlso used to remove parameters from selected list in print format.

qThe 'Start/ Stop' function is to Start or Stop the drying process.

qThe process of heating can be started if stopped by single press of the

key any vice-versa by single press.

qThe 'Enter' function is used to confirm certain value that can be numeric

as well as alpha numeric.

qAfter 'Enter' is pressed, the value is stored.

qThe 'EXIT' function is used to exit back to the pre analysis mode from

anywhere in the menu.

qThe 'RESET' function is used to reset the process after getting the result

and starting the process again. Pressing it after getting the final result

brings the system back to simple weighing.

qThe Exit is active in menu and sub-menu and Reset is active after the

completion of process.

qThe 'Cancel Function' won't be active in processes like drying, printing,

data transfer, calibration, hardware test etc.

qIt is also used to exit from previous result menu to current result display.

qThis key provides two functions: Toggle and ID.

qThe Toggle function is used to change the drying units.

qThe ID function is used to change the available IDs and store them.

qThe ID function is active only in pre analysis mode.

qThe Toggle function is active only in drying mode.

qWhen step and intelligent are used together this key is used to display

internal result.

qThese keys are used to navigate through the menus and sub-menus.

qDuring the drying process, these keys are inactive.

qAfter the process, the keys are used to view past result and their

statistics.

qThe Left Arrow key is used to exit a sub-menu in the menu list and to

take one step back.

qAfter the completion of process, this key is used to scroll through the past

results.

qPressing left will show the chronologically descending results.

qThe Right Arrow key is used to enter a sub-menu in the menu list.

qAfter the completion of process, this key is used to scroll through the past

results once the Left Arrow key is pressed.

qThe Up Arrow key is used to navigate in upward direction in the menu list.

qAfter the completion of the process, this key is used to enter the statistics

of the result obtained.

qIf this key is used to after using the left or right arrow, the statistics of

previous results are shown.

qThe Down Arrow key is used to navigate in downward direction in the

menu list.

qAfter the completion of the process, this key is used to exit the previously

entered statistics (by left and up arrow key) of the result obtained.

qPressing this key without the Up Arrow key previously pressed will have

no effect.

In pre analysis mode, this key is used to Tare the weight, which can be

Symbol

Name

Tare Key

Start / Stop &

Enter Key

Exit / Reset

Cancel Function

Key

Toggle key

Navigation key

The left arrow key

The Right arrow

key

The Up arrow key

The Down arrow

key

Description

q

q

q

q

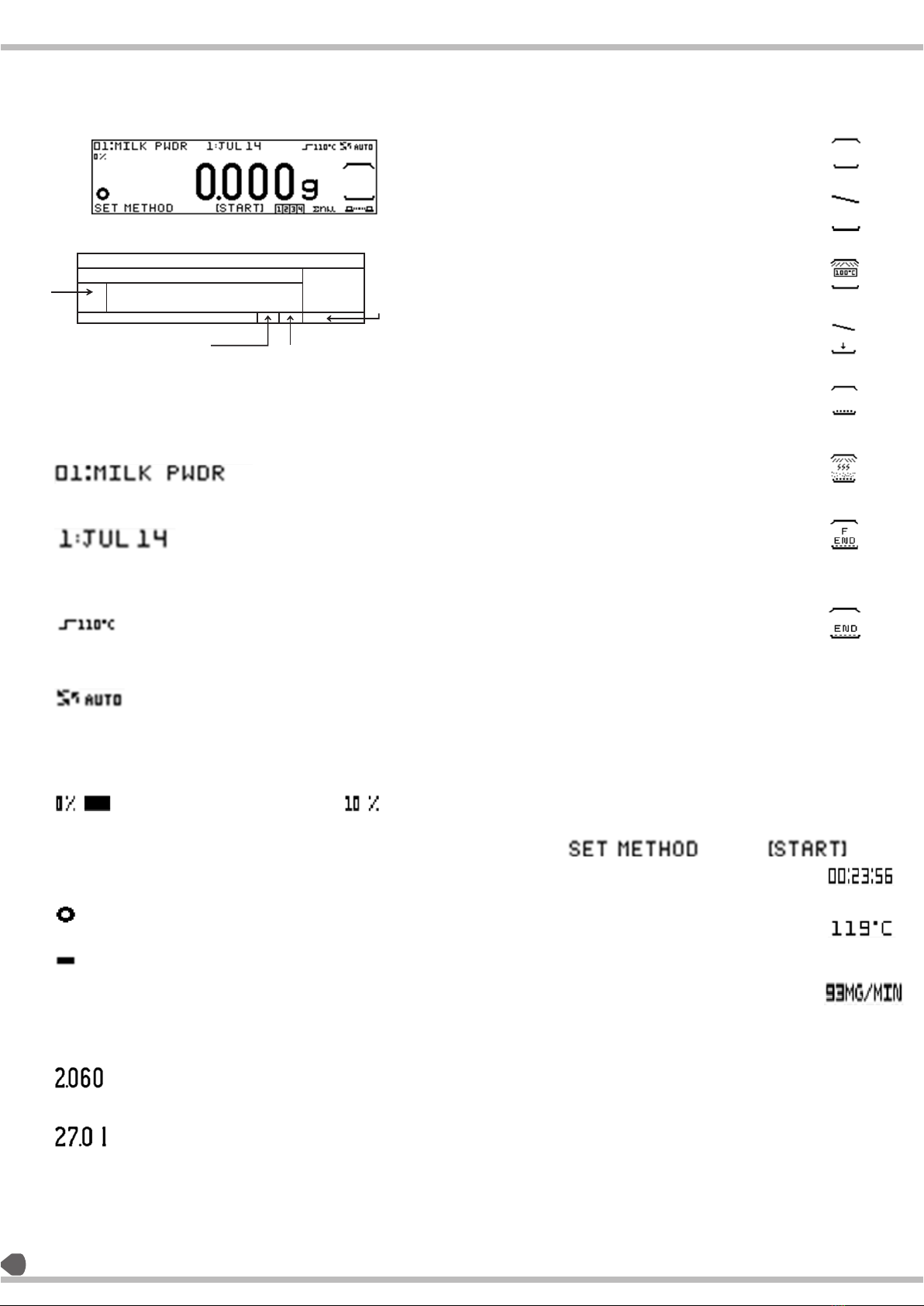

Method / batch information row

This Row contains the following information:

Method number and name 10 characters max

Batch number and name 10 characters max

Heating profile symbol and set temperature

standard 110°C (Default)

Switch off criterion symbol

Automatic (Default)

Capacity Bar :

The capacity bar indicates the amount of

weight kept on the pan in terms of percentage

the bar is displayed as follows :

Stability and + / - sign indicator :

This section displays the following:

Stability symbol is displayed as

Minus symbol is displayed as

Measurement and weighing values

This section displays the following:

The weighing result value as

The moisture result value as

14

Knowing Your Moisture Analyzer : q

q

Heating chamber status

The chamber status can be displayed as follows:

The chamber close displays as

The chamber open status is displays as

The stand by temp status is displays as

While Preparing sample status is display as

The prepared sample status is displays as

While heating the sample status is displayed as

If the determination is ended forcefully

status is displayed as

If the determination ends with switch off

Criterion satisfied status is displayed as

Next step / analysis info row :

The Next step / analysis info row will have

text which will guide you to perform a

successful sample preparation before

moisture analysis starts.

Example :

The Next step / analysis info row will display

analysis information at the time of moisture

determination or drying process.

The following things will be displayed:

The current analysis time status is displayed as

The current chamber temperature status

is displayed as

The last minute moisture loss in terms of

weight status is displayed as

Stability / + -- sign

indicator

Method / batch information Row

Capacity bar Heating

Chamber

Status

Next step / analysis info row

Configured ID's indicator

Communication

Symbol

Measurement / weighing

Values

Statistics Symbol

15

q

q

q

Configurable ID's indicator:

The configured IDs of the loaded method will

be displayed as inverted font:

th

Example 1: if only 4 ID is configured as yes in

current load then status is displayed as

Example 1: if all 4 ID's is configured as no in

current load method then status is displayed as

Note : all the ID's are configurable.

The statics symbol indicates that the scale

is incorporated with statistical functionality is

displayed as

The communication symbol is displayed as

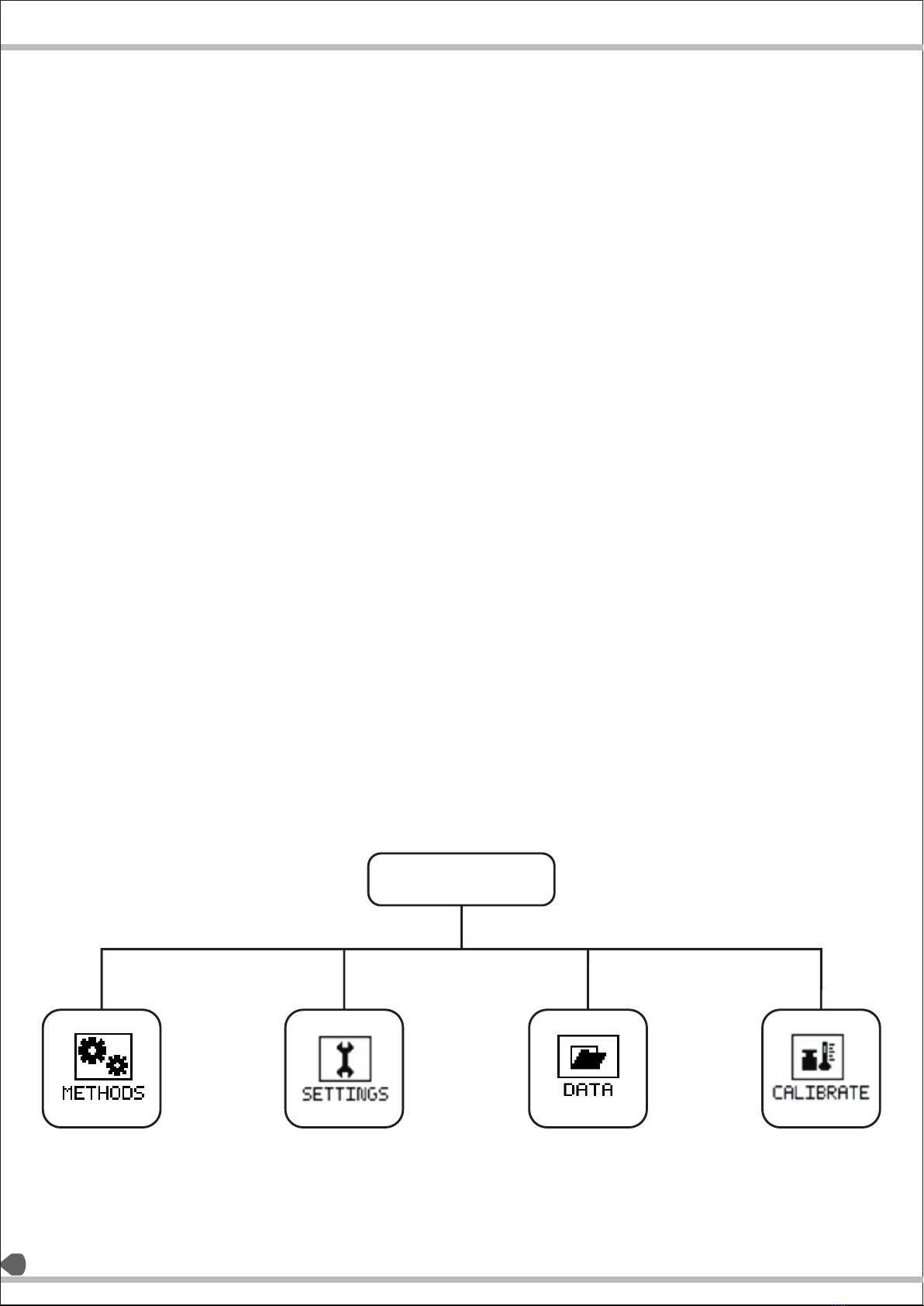

Menu and it structure:

The menu and its structure can be divided as:

Current sub menu structure guide:

The current menu structure guide indicates

in which sub menu we are currently in:

Example 1 :

Example 2:

Function

indicating box

Current sub menu structure guide

Menu and its sub menu fields

Menu and its sub menu fields

The Menu and its sub menu fields will

display menu structure and its fields

In this section you can edit, set, modify

and confirm a particular parameter:

Function indicating box :

There are total seven boxes which indicates a particular

function to be performed when the desired key is

pressed on pressing the key respective box is inverted

indicating the key is pressed the following are the

function that can be represented by this boxes and

their equivalent keys :

Function displayed as Keys

[Note: ABC key is used to switch from alphabetic to

number mode and vice versa in single press

The inverted box will be indicated as active function]

Data Input / Output

You can choose between:

interface port for:

Aczet printer

(such as the CPR-02)

computer (PC) Via serial port.

computer (PC) Via USB port.

computer (PC) Via ethernet port.

USB application *

PS2 keyboard

q

q

q

q

q

q

16

At the Time of Initialization :

qPower on the AC mains. The number of sequence of operation will

occur. The aczet logo will be displayed for approximately 10 seconds

during first step of boot up sequence.

qThe capacity bar is filled during the step.

qThe version number is displayed in the third step.

qThe system enters into the standby mode in the fourth step of boot

up sequence.

qOn coming out from standby mode, the system will enter the pre

analysis mode and will show the default or the last active method and

settings.

qIt will show 0.000 g on display as per the initial zero setting mechanism

and a stability symbol.

qThe top row of the screen will show method name to the left, which is

00:DEFAULT

qIf the data storage mode in the settings is batch wise, then the current

active batch name will be displayed in the center of the top row.

qHowever, nothing will be shown if the selected data storage mode is

method wise which is also the default condition and shown above.

qWhichever Method will be selected by the user, it will be retained even

after going into standby or on power off and will be shown when the

analyzer is powered on again or waking up from the stand-by mode.

qCurrent weight on the pan can be printed using print key in pre analysis

mode.

qThe cover condition, open or close, will be shown by its symbol to the

right side. Here, the symbol shows that the cover is closed.

qAlso shown on the screen are the current active heating profile and

switch-off criterion. Here the default condition for heating profile is

standard heating with temperature 110°c and switch off criteria as

AUTO.

qThe symbols related to ID and statistics are also shown in the bottom

row. There are four IDs, ID 1, 2, 3, 4; by default, no ID is selected.

17

START/STOP KEY:

qThe user needs to press the start/stop key to start the moisture

determination process and to force end the moisture determination

process unless manual switch off criteria is activated.

GOTO/ MENU KEY:

qOn pressing the menu key the user can enter into the GOTO menu,

with the currently active menu in the soft key in the settings.

qBy long pressing the menu key (i.e. for 2 seconds), the user can enter

in the main menu, with four sub menu – method, settings, data,

calibrate, std wt cal. whichever is selected in the soft key submenu

under settings

METHOD/BATCH LOAD KEY:

qBy pressing the METHOD/ BATCH key, the user can load the required

method.

qBy long pressing the METHOD/BATCH key for 2 seconds, the user can

load the batch for a particular method if

the data storage mode is batch wise. If not, then long pressing this

key will let the user enter in the METHOD

LOAD menu.

TARE KEY:

qOn the main screen, tare key is used to tare (i.e. bring the weight on

the pan to zero) and display 0.000g on

the screen.

TOGGLE KEY:

qThis key is used to toggle between the IDs and modify them.

PRINT KEY:

qThe print key is used to print the weight on the pan.

ON/OFF:

The system goes to standby from any menu

User Menu :

KEYS ACTIVE:

qGOTO / MENU KEY:

When the user presses this key gently, it enters the menu which is

selected in the settings. => Soft key

When the user presses the MENU / GOTO key for 2 sec, then the

system displays four sub menus:

qMethod

qSettings

qData

qCalibrate

qStd wt cal

qLEFT KEY:

It moves the cursor towards left in a cyclic

mann er. E.g.: method s=> calibrate=>

data=>settings

qRIGHT KEY:

It moves the cursor towards the right in the

cyclic manner. e.g.: method=> settings=>data=>

calibrate.

qENTER KEY:

On pressing this key, the user can enter the

selected sub menu.

qMENU KEY AND EXIT KEY:

On pressing this key, the user can exits into pre

analysis mode.

qON OFF KEY :

On pressing the on off key, the user can enter in

standby mode.

qMETHODS

A method is basically a collection of parameters

which suits a particular sample.

For the purpose of moisture determination, the

system provides forty methods with one default

method. The user can set the parameters of any

particular method such that it best suits the

sample for the drying process.

qSETTINGS:

This section includes all the settings related to

moisture analyzer. This is the 1st sub menu which

the user should refer to after powering the

analyzer for the first time. The settings like date,

time, language, contrast etc can be set in this

sub menu.

qDATA:

This sub menu saves the results of the samples

method wise or batch wise depending upon the

data storage mode in the settings menu. By

default, the data in the data menu is stored

method wise.

The user can view the results, its statistics, print

the results and also send the data to pc.

qCALIBRATE:

It can be defined as the act of checking or

adjusting (by comparison with a standard) the

accuracy of a measurement;

The user can perform weight as well as

temperature calibration.

In case of moisture analyzer, temperature

calibration can be described as adjusting the

observed temperature of the sample with the

actual temperature.

User Menu

18

SETTINGS:

STEP 1 (Entering the setting sub menu):

q

When the settings is shown inverted, pressing the enter key will display the settings sub-menu.

qIf setting feature is selected in the soft key, the user can press the MENU once and the settings sub-menu will be displayed.

STEP 2(password protection):

qRefer to Page 45 Step 2

STEP3 :( exiting the settings menu)

qExit/reset key: exits to the PRE ANALYSIS SCREEN.

qLeft arrow key: exits from sub menus in steps.

qMenu key: to exit directly to PRE ANALYSIS SCREEN.

Keys active:

qUp / down arrow: to go through the list of options in settings.

qLeft key: back function: to go back to the previous page.

qRight key: modify: to modify the highlighted parameter.

qMenu key: to exit directly to Pre analysis screen.

LANGUAGE: when pressed enter key, the user is provided with 6 language options.

– English (u.k.)

– English (u.s.a)

By pressing the menu key for 2 sec when in PRE ANALYSIS SCREEN, the user can enter into the main menu.

21

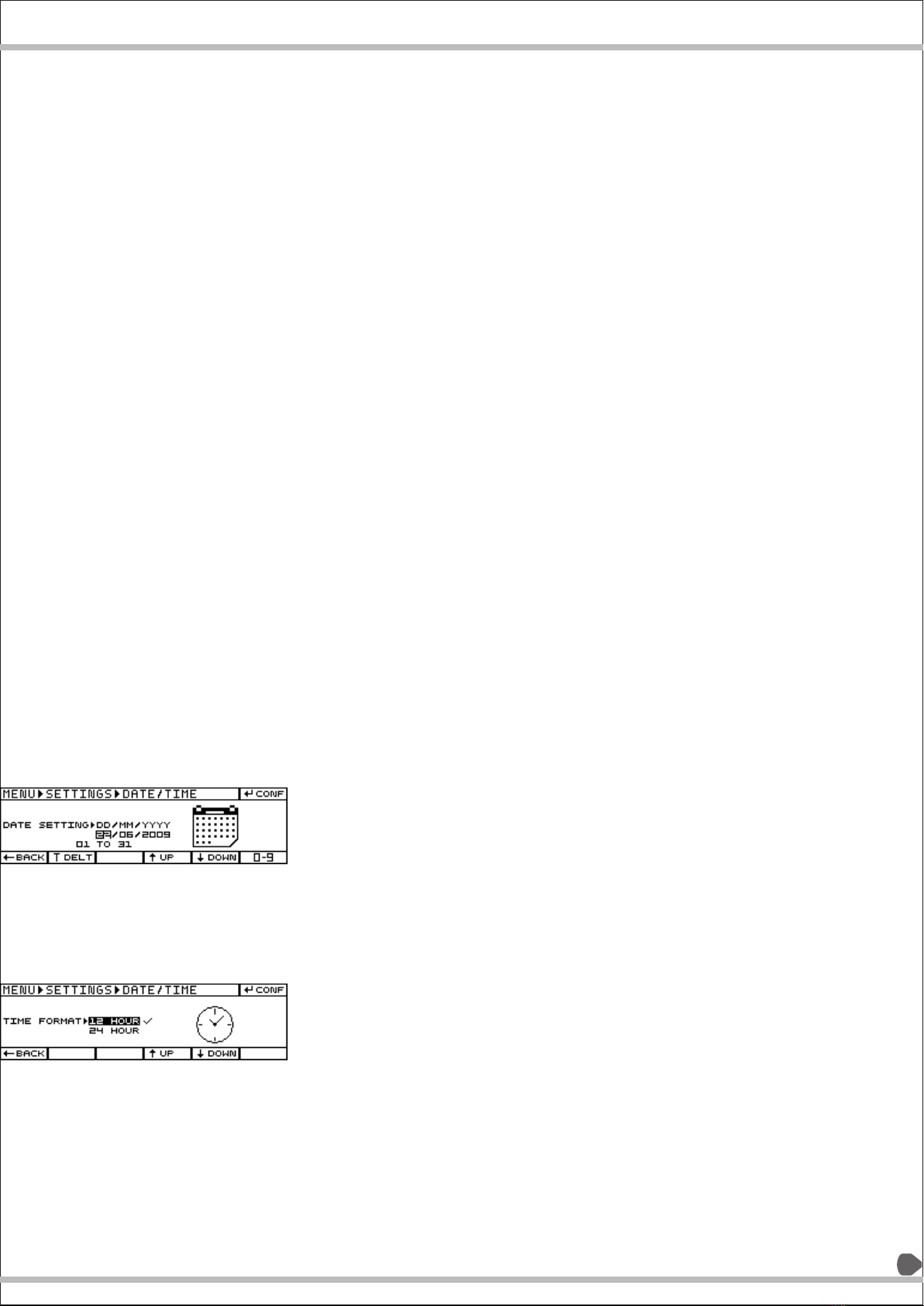

DATE AND TIME:

The user can set the date and time by pressing the enter key (i.e. modify

function). Using the up and down key, the user can select either date or

time and then press enter key to modify date or time.

Date: pressing enter when date is selected, displays the below screen:

Using up/ down keys the user can move the cursor from date to month

and year. Using the tare key, the users has to 1st delete the default value

and then add the date, month and year respectively. Pressing enter will

confirm the date.

NOTE: If the user tries to enter the value for date, month or year

which is out of the range suggested by the system, then the system

displays “ERROR!!! INVALID DATE”

Time: it is further subdivided into

Time format:

q12hour

q24 hour

Time setting:

it is same as that of date setting. User can change the time format as

well as time by modifying both the parameters i.e. by right arrow key.

NOTE: If the user tries to enter the value for hours or minutes which

is out of the range suggested by the system, then the system displays

'ERROR!!! INVALID TIME’

22

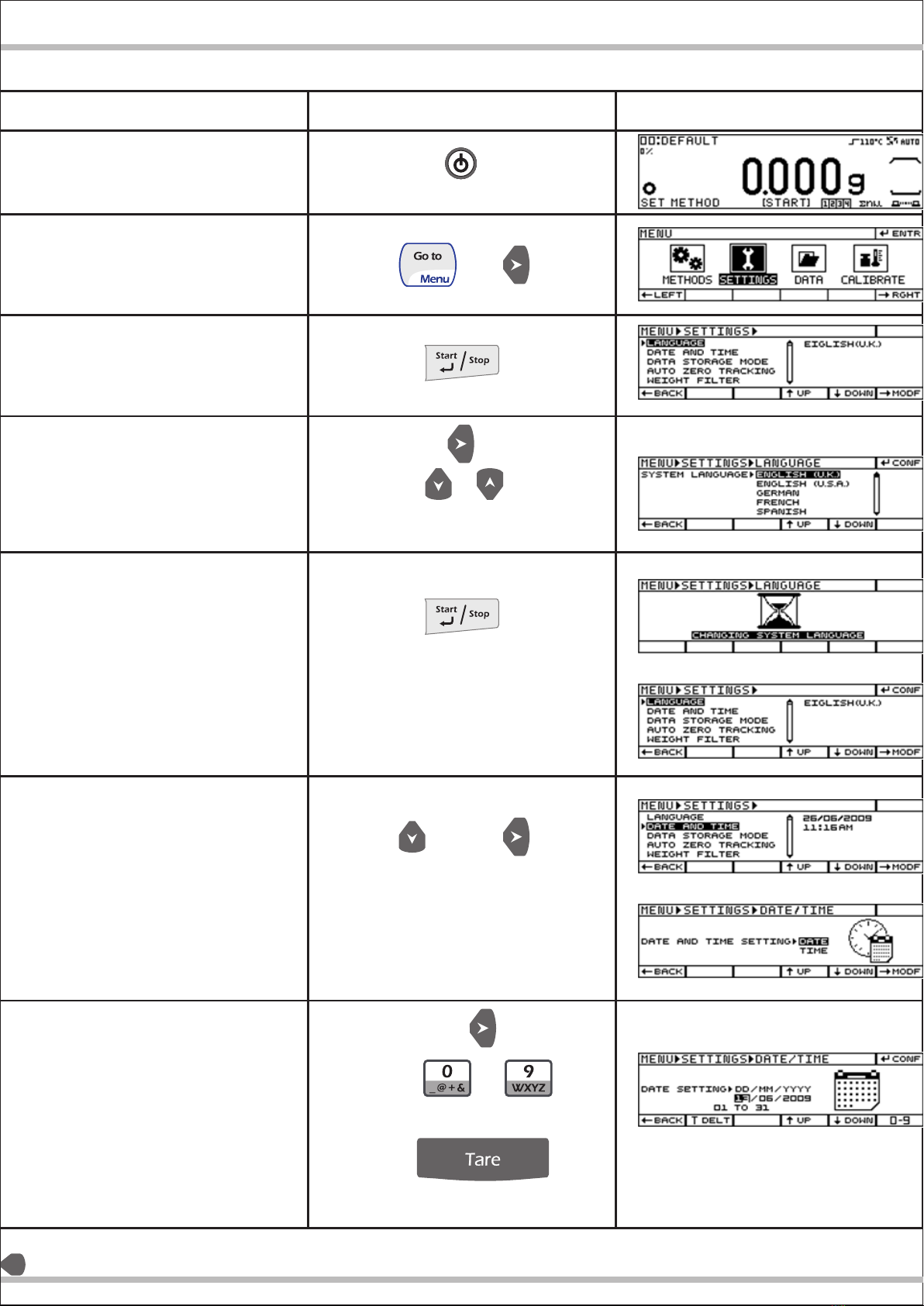

Example for Entering Date & Time

Steps followed

Key pressed (Instruction) Display screen

Power on the Moisture analyzer

Press the Menu key to Enter Main

Menu

Enter in settings menu

Selecting language

Confirming language

Navigation to date and time

and modifying

Entering Date

(For scrolling the selection)

To

For deleting or backspace

Example for Entering Date & Time

Steps followed

Key pressed (Instruction) Display screen

To

To

(For deleting or backspace)

(For deleting or backspace)

23

Toggle to month

Toggle to Year

Confirming Date

Navigation to time and modifying

Modifying time format

Confirming time format

Navigation to time setting and

modify

Toggling of selection and entering

Toggling of selection for AM / PM Mode

Confirming date

Exiting to Pre analysis screen

(For scrolling the selection)

Data Storage Mode :

DATA STORAGE MODE:

CONCEPT:

This is one of the most important features of our moisture analyzer.

Understanding the importance of data memory, we design it

highly dynamic gives great flexibility to user to use almost all

available 1000 memory for moisture determination results.

The user can view and print this last 1000 Data stored any time.

Also user can view and print statistics of this data stored.

For giving user great flexibility for using complete memory storage

it is designed with two options

qMethod wise

qBatch wise

NOTE: Whenever user changes the data storage mode, then all

the previous data will be lost.

METHODWISE:

qThe data will be stored Method wise if the selection is made as

Method wise in Menu=>Settings=>Data Storage.

qMoisture analyzer has the provision of 41 methods, 40

retainable methods and 1 default method.

qThe parameters of the method to be loaded can be selected

from the method option in the menu, depending upon the

type of sample to be taken for moisture determination.

qBalance will store the details of last 25 samples of moisture

determination for that particular method.

qApart from maintaining the details like date, time, weight and

the result, the balance also calculate and store statistics for

that particular method with every additional moisture

determination.

qIf the data to be stored goes beyond 25, the first data

available in the particular Method will be deleted and the

latest data will be stored at position 25.Although the first data is

deleted but it will still be used to calculate updated statistics.

qA batch is a part of method. The data will be stored batch wise if the selection is made as batch wise in

Menu=>Settings=>Data Storage. Batch wise is generally selected when the user needs flexibility in the data

storage capacity. Unlike method wise, there is no such restriction of storing only 25 data. The user can store

even 1000 data in a batch.

qThere is no preset or configurable numbers of data can be store per batch. It will keep on storing data till

1000 data memory randomly.

qMaximum number of batches that can be formed is 100.

qWhen user save 1001th data than it will delete first data of that particular batch where this data is been

stored, Keeping Statistics updated with even deleted data.

qIf any parameter of the method is changed then the batch gets locked. The user cannot add any data to

that batch but the batch can still be viewed.

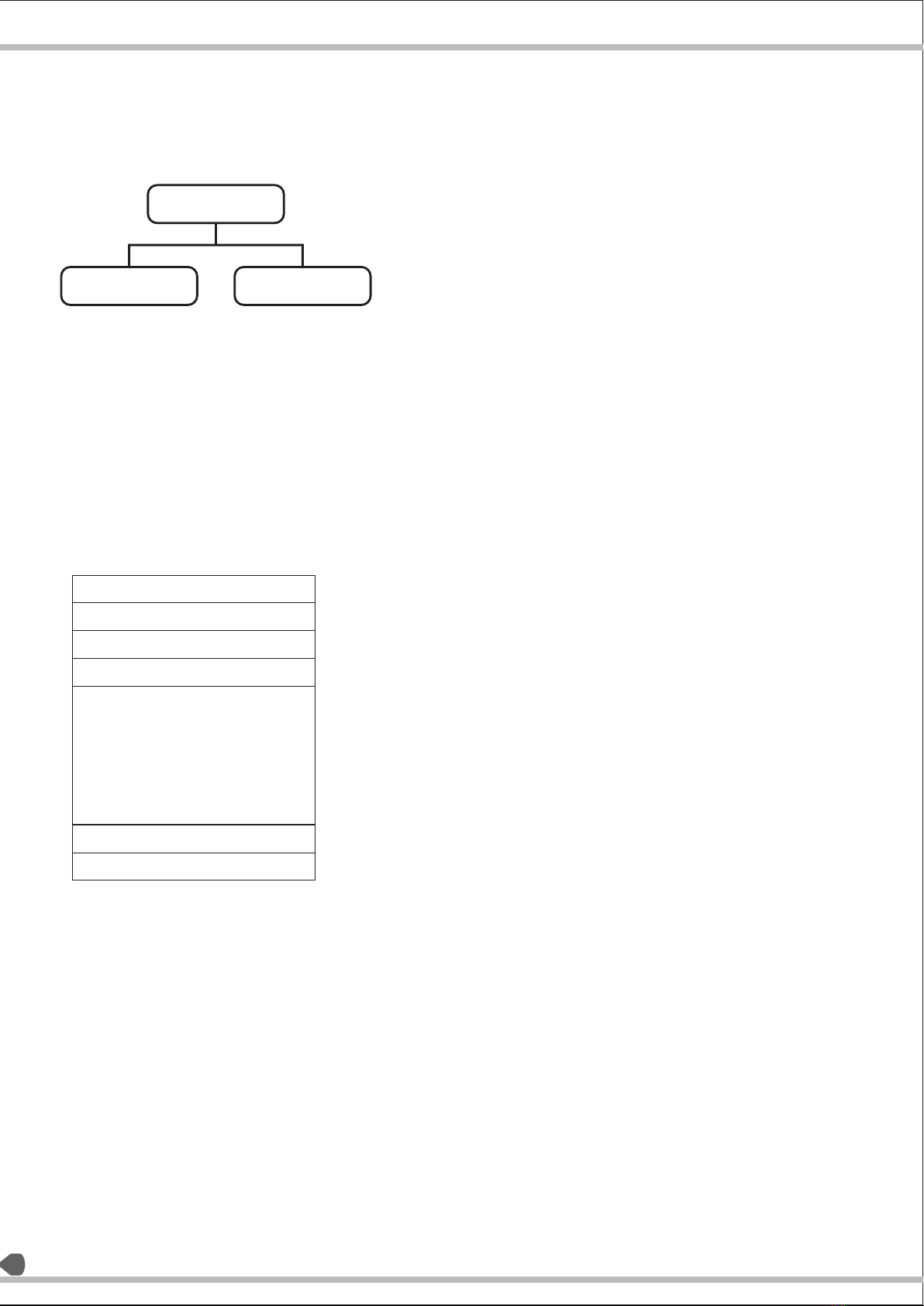

Method Wise Batch Wise

Data Storage

Method 1: 25 data

Method 2: 25 data

Method 3: 25 data

Method 4: 25 data

-

-

-

-

-

Method 40: 25 data

40 METHODS=1000 DATA

24

BATCH WISE:

CONDITION 1:

CONDITION 1:

In this example,

q236 data are stored in batch 1 of method 1 (M1).

q253 data are stored in B2 of M1.

q14 data are stored in B3 of M1.

q97 data are stored in B4 of M15.

q350 data are stored in B5 of M23.

q50 data are stored in B6 of M50.

qThus, the total of 1000 data is stored. Since only 6 batches are

formed, the user can form 94 more batches but in order to save

data in those 94 batches, the user will have to delete some data

from the previous batches.

CONDITION 2:

CONDITION 2:

qThe user, here, has saved all the 1000 data in one batch itself.

Hence no data can be saved in other batches.

qB1 has 1000 data, the user can make 99 batches but cannot save

data in it unless and until some of the data is deleted.

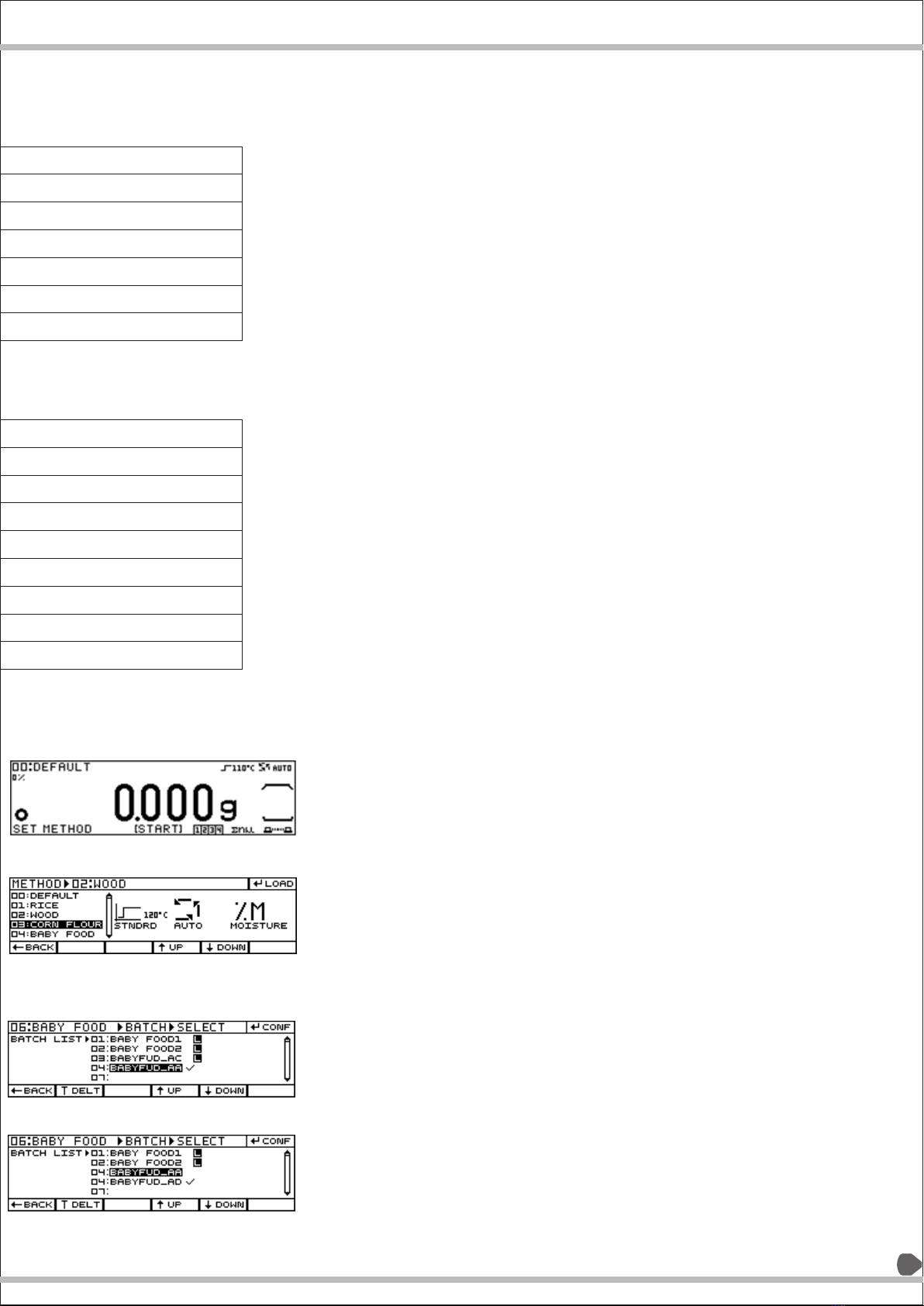

METHOD / BATCH LOAD:

METHOD SELECTION: METHOD SELECTION:

qOn entering the Method Selection sub-menu by pressing the

METHOD key in pre analysis mode, the list of all 40 methods will

be shown with selection on the top of the list.

qOn pressing the ENTER key to load the method, the system will

Pre-Analysis Mode activate it and exit to the pre analysis mode.

qThe selected method's preview will be shown as displayed

besides and the current active method's name will be displayed on

the top of the display.

qFor the moisture determination processes further, this method

will be active.

qTo change the active method, the user has to follow the same

procedure again.

BATCH SELECTION:

BATCH SELECTION (If Data storage mode is Batchwise):

qIn this mode of data storage, the data will be sorted and stored

according to the batches, as per the assignment by the user.

qWhen the batch wise is selected, on pressing the batch key for 2

sec, the user can form or select the batch to store the result of

the upcoming process, the display will show the list of all the

batches related to current active method.

qInitially, when the batch wise data storage mode is selected,

there will be no batches formed in any of the methods.

qSo you will have to create it.

Method 01: B1: 236 Data

Method 01: B2: 253 Data

Method 01: B3 :14 Data

Method 15: B4: 97 Data

Method 23: B5: 350 Data

Method 24:B6: 50 Data

=6 Batches: 1000 Data

Method 1: B1: 1000 Data

M1: B2: 0 Data

M1: B3: 0 Data

M2: B5: 0 Data

-

-

-

-

M2: B100: 0 Data

25

This manual suits for next models

4

Table of contents

Other Aczet Measuring Instrument manuals