Adaptive P1507 User manual

28x96 Front Access Full Matrix LED Sign

Maintenance Manual

1.07-inch, 1.35-inch, and 1.75-inch Pitch Signs with 2 Controllers

P1507/P1514

Manual part number: 1507610501 rev. A

Revision date: December 10, 2007

© Copyright 2007 Adaptive Micro Systems LLC. All rights reserved.

Adaptive Micro Systems

7840 North 86th Street

Milwaukee, WI 53224 USA

414-357-2020

414-357-2029 (fax)

http://www.adaptivedisplays.com

Adaptive is a regisered trademark of Adaptive Micro Systems. All other brand and product names are

trademarks or registered trademarks of their respective companies.

March 2, 2006 Front Access Full Matrix LED Sign Maintenance Manual (pn 1507610501 rev. A)

Front Access Full Matrix LED Sign Maintenance Manual (pn 1507610501 rev. A) 3

Contents

Introduction............................................................................ 7

Purpose ..................................................................................................................................................... 7

Revision history......................................................................................................................................... 7

Related documentation.............................................................................................................................. 7

Safety information ..................................................................................................................................... 7

Battery backup........................................................................................................................................... 8

System overview ..................................................................... 9

Introduction............................................................................................................................................... 9

VMS control system .................................................................................................................................. 9

LED brightness control system................................................................................................................ 10

Environmental control system — sign housing....................................................................................... 10

Electrical system...................................................................................................................................... 10

Equipment description..............................................................13

General description.................................................................................................................................. 13

Outside views — 1.07-inch pitch sign..................................................................................................... 14

Outside views — 1.35-inch pitch sign..................................................................................................... 15

Outside views — 1.75-inch pitch sign..................................................................................................... 16

Inside view — 1.07-inch pitch sign ......................................................................................................... 17

Inside view — 1.35-inch pitch sign ......................................................................................................... 18

Inside view — 1.75-inch pitch sign ......................................................................................................... 19

Controller plate ....................................................................................................................................... 20

Sign controllers #1 and #2....................................................................................................................... 21

Sign power panels ................................................................................................................................... 23

LED driver board...................................................................................................................................... 24

Maintenance .........................................................................25

Physical Inspection.................................................................................................................................. 25

Front lens cleaning................................................................................................................................... 25

Air filter cleaning...................................................................................................................................... 26

AlphaXpress DMS Sign (Texas DOT) Maintenance Manual (pn 1509620301) March 2, 2006

4Front Access Full Matrix LED Sign Maintenance Manual (pn 1507610501 rev. A)

Part replacement ....................................................................27

List of field-replaceable parts................................................................................................................... 27

Controlling electrostatic discharge (ESD) ................................................................................................ 27

Opening a sign......................................................................................................................................... 28

Sign controller board replacement........................................................................................................... 32

Power supply replacement....................................................................................................................... 35

Diode module replacement ...................................................................................................................... 37

Relay replacement ................................................................................................................................... 39

LED driver board replacement ................................................................................................................. 41

Fan replacement ...................................................................................................................................... 42

Heater replacement.................................................................................................................................. 43

Front Access Full Matrix LED Sign Maintenance Manual (pn 1507610501 rev. A) 5

List of figures

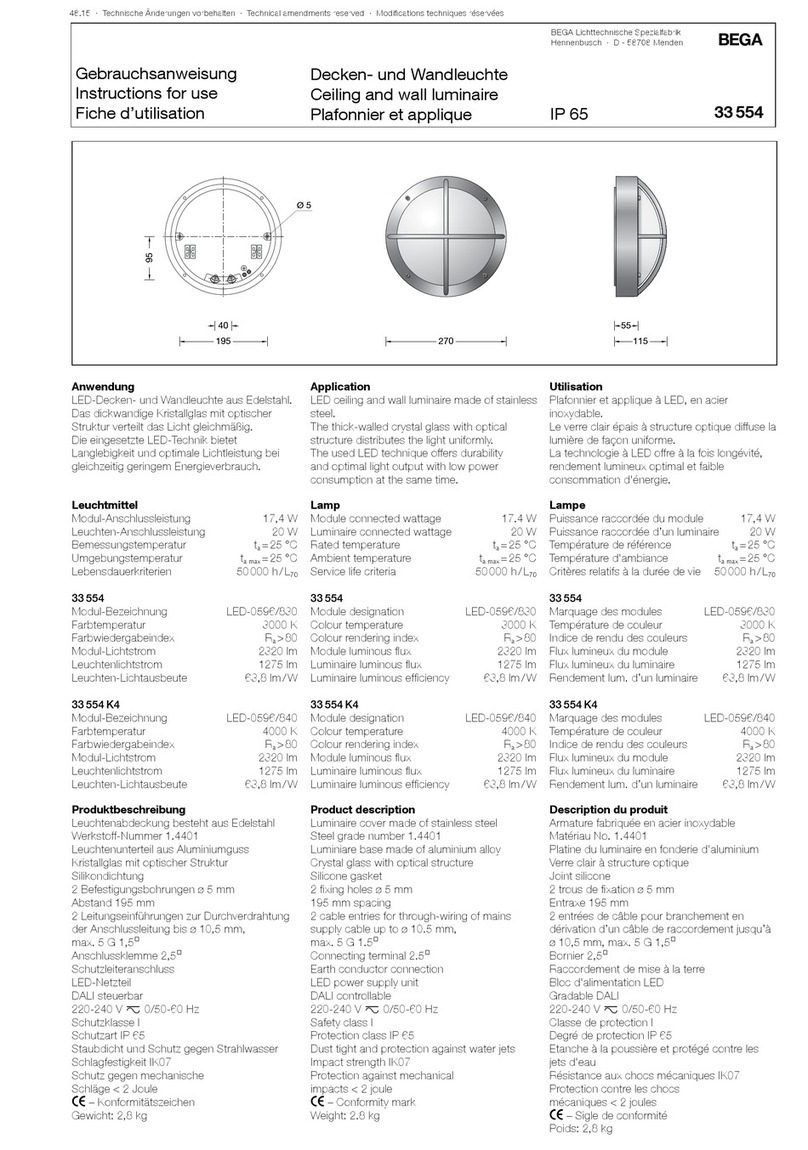

Figure 1: Location of the 3V lithium battery on the sign’s controller, page 8

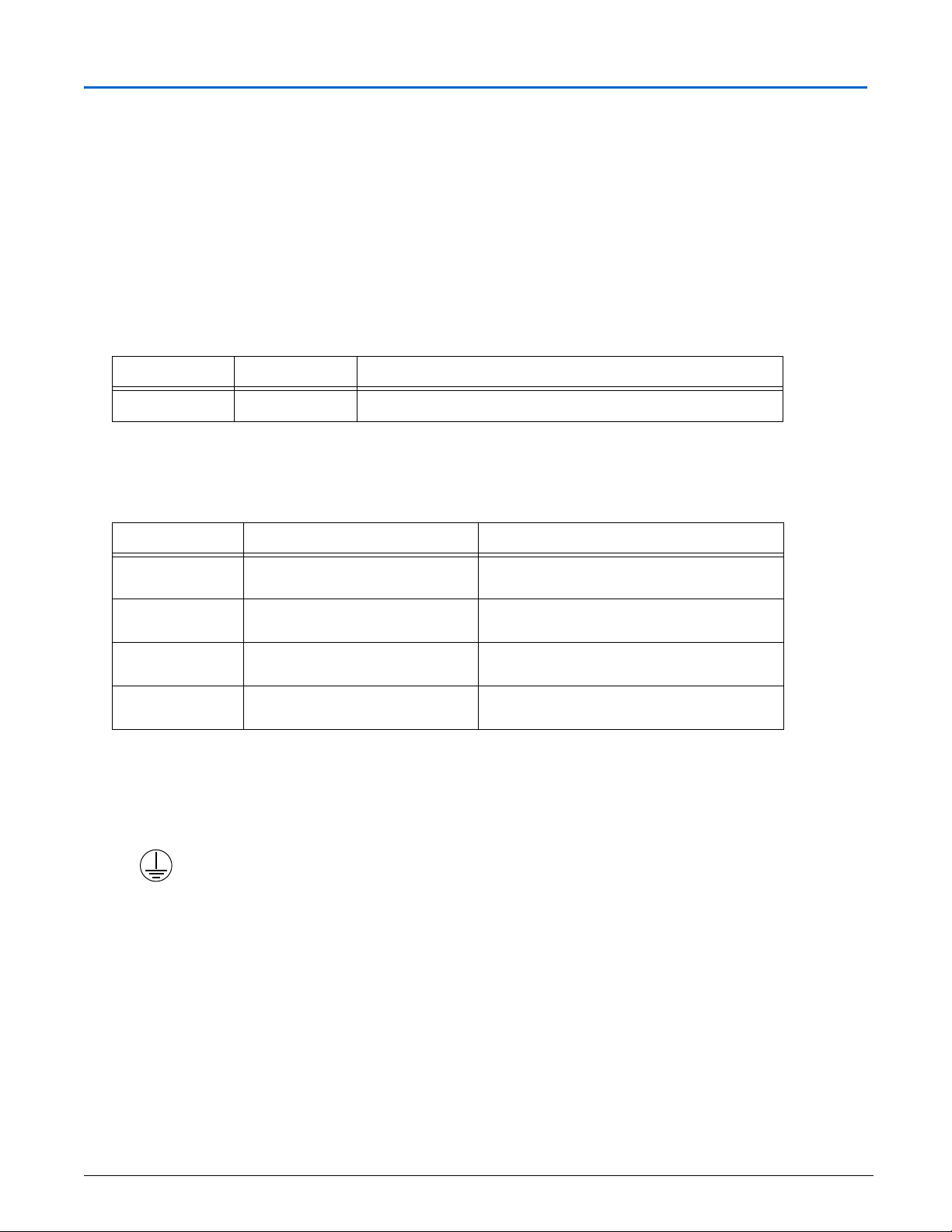

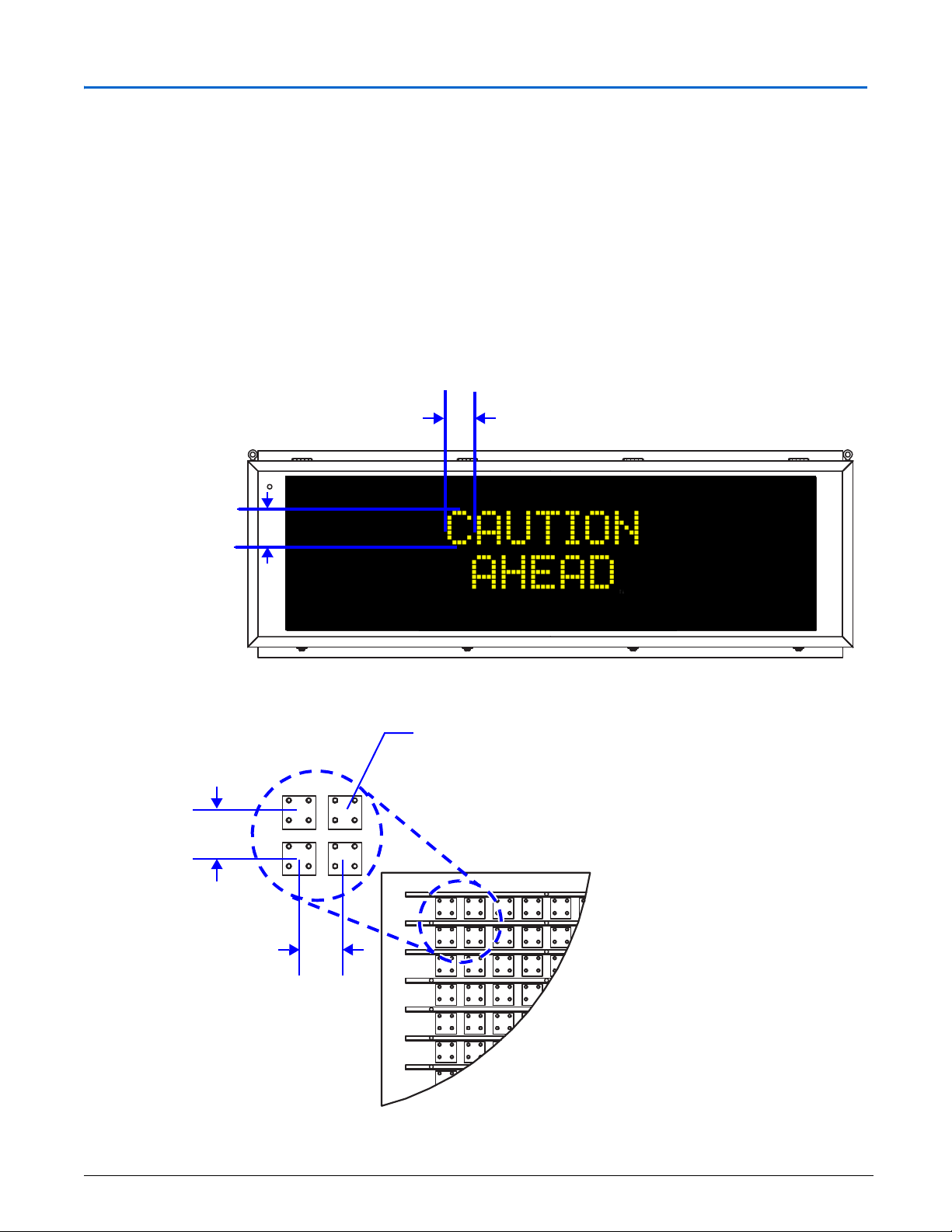

Figure 2: 5x7 font dimensions, page 13

Figure 3: LED pitch, page 13

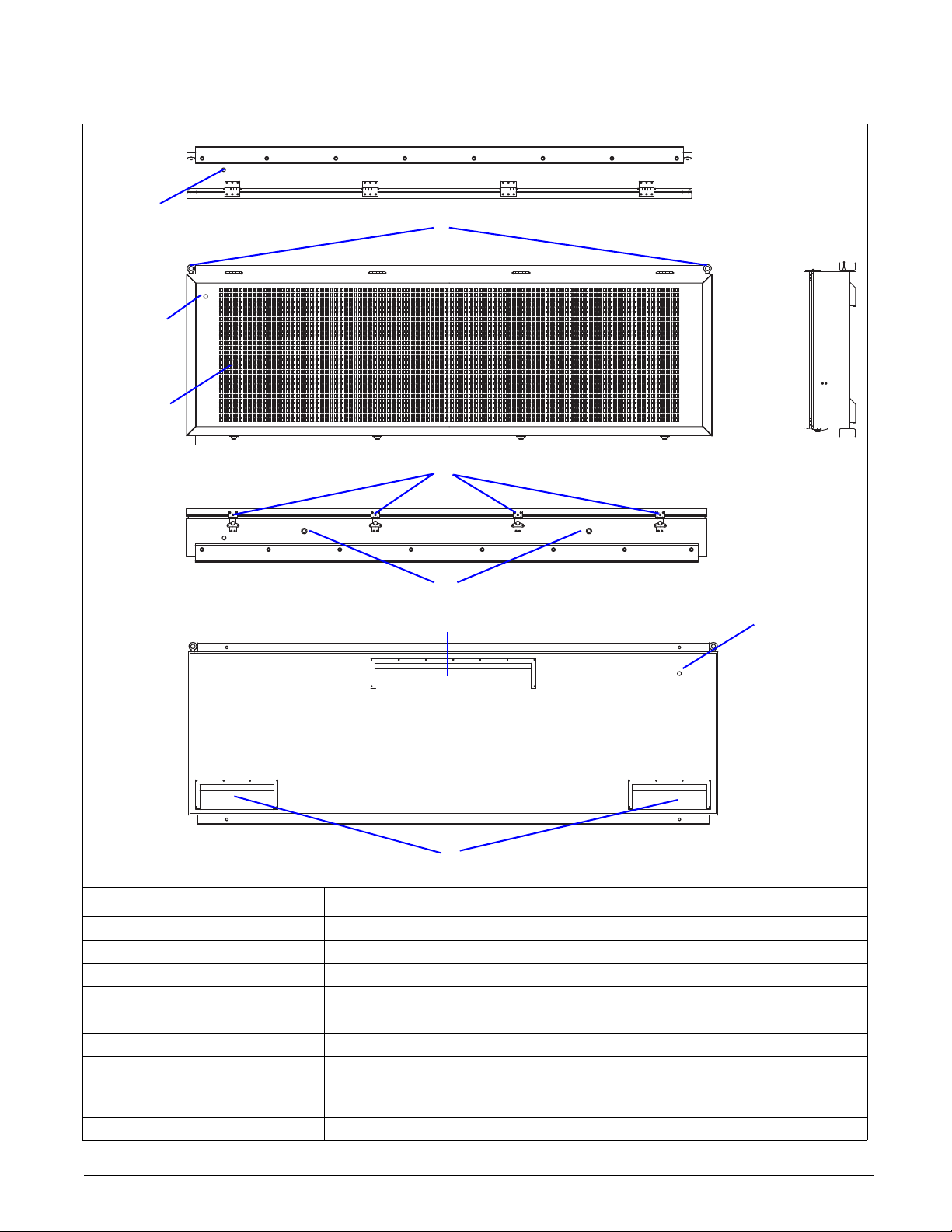

Figure 4: Exterior top, front, bottom, back, and side views of a 1.07-inch sign, page 14

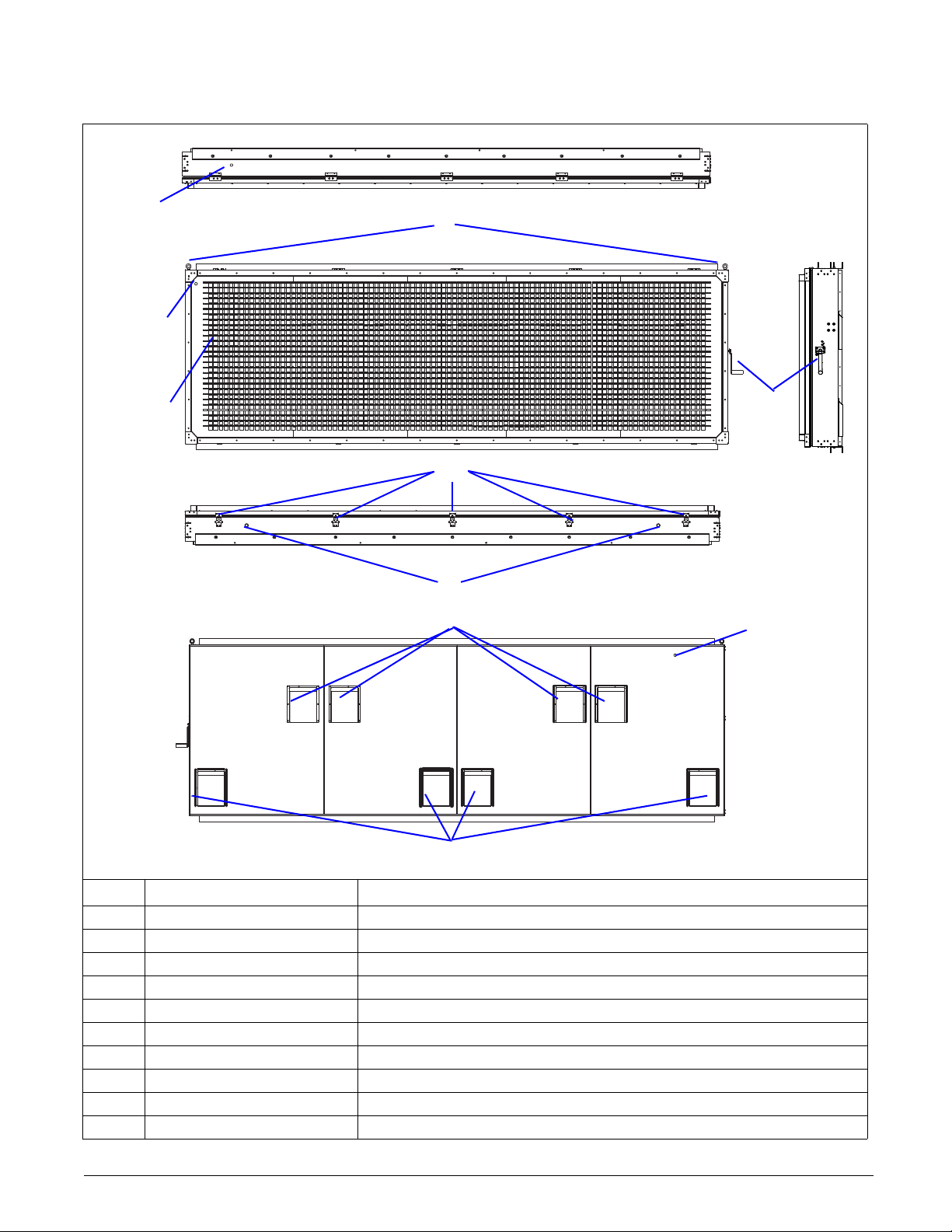

Figure 5: Exterior top, front, bottom, back, and side views of a 1.35-inch sign, page 15

Figure 6: Exterior top, front, bottom, back, and side views of a 1.75-inch sign, page 16

Figure 7: Internal components of a 1.07-inch sign, page 17

Figure 8: Internal components of a 1.35-inch sign, page 18

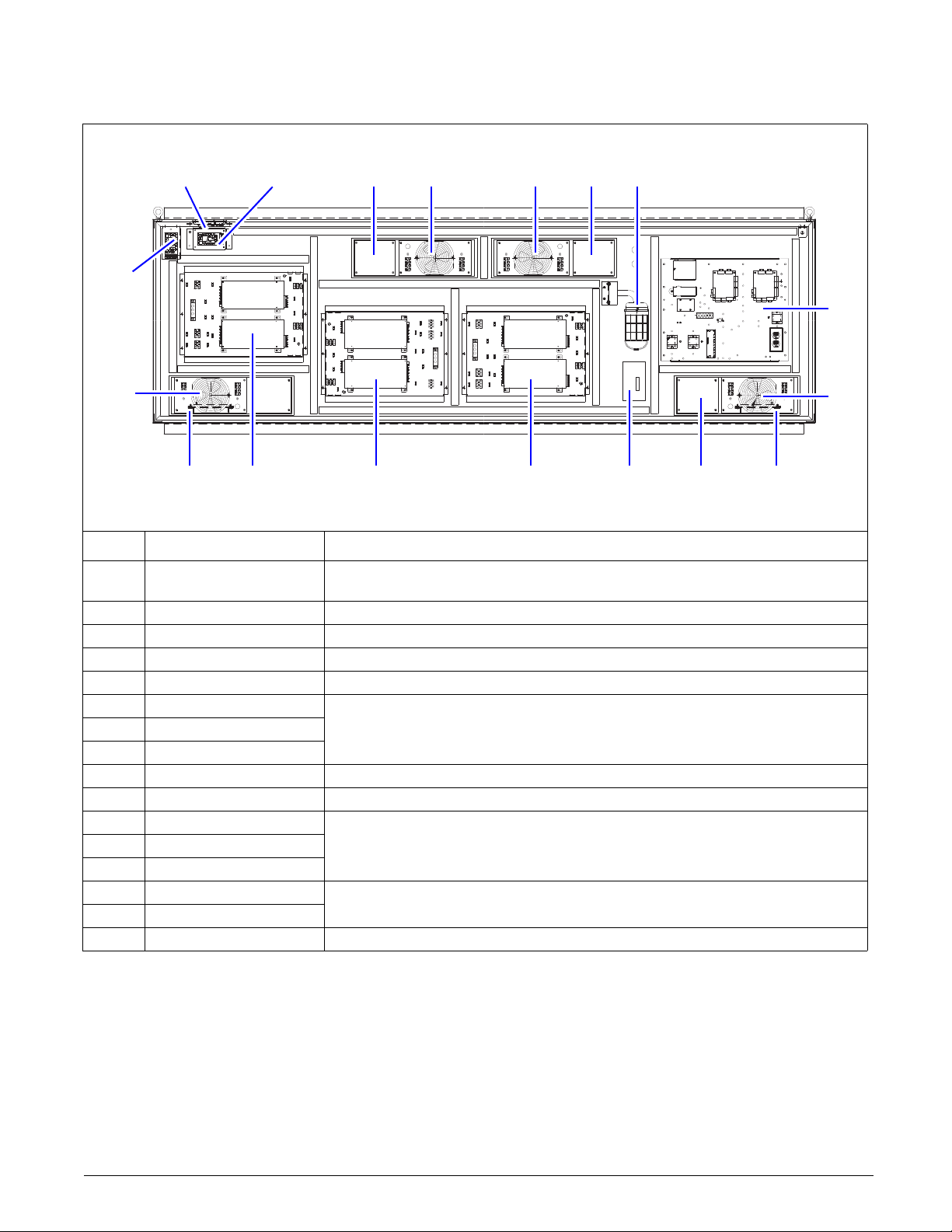

Figure 9: Internal components of a 1.35-inch sign, page 19

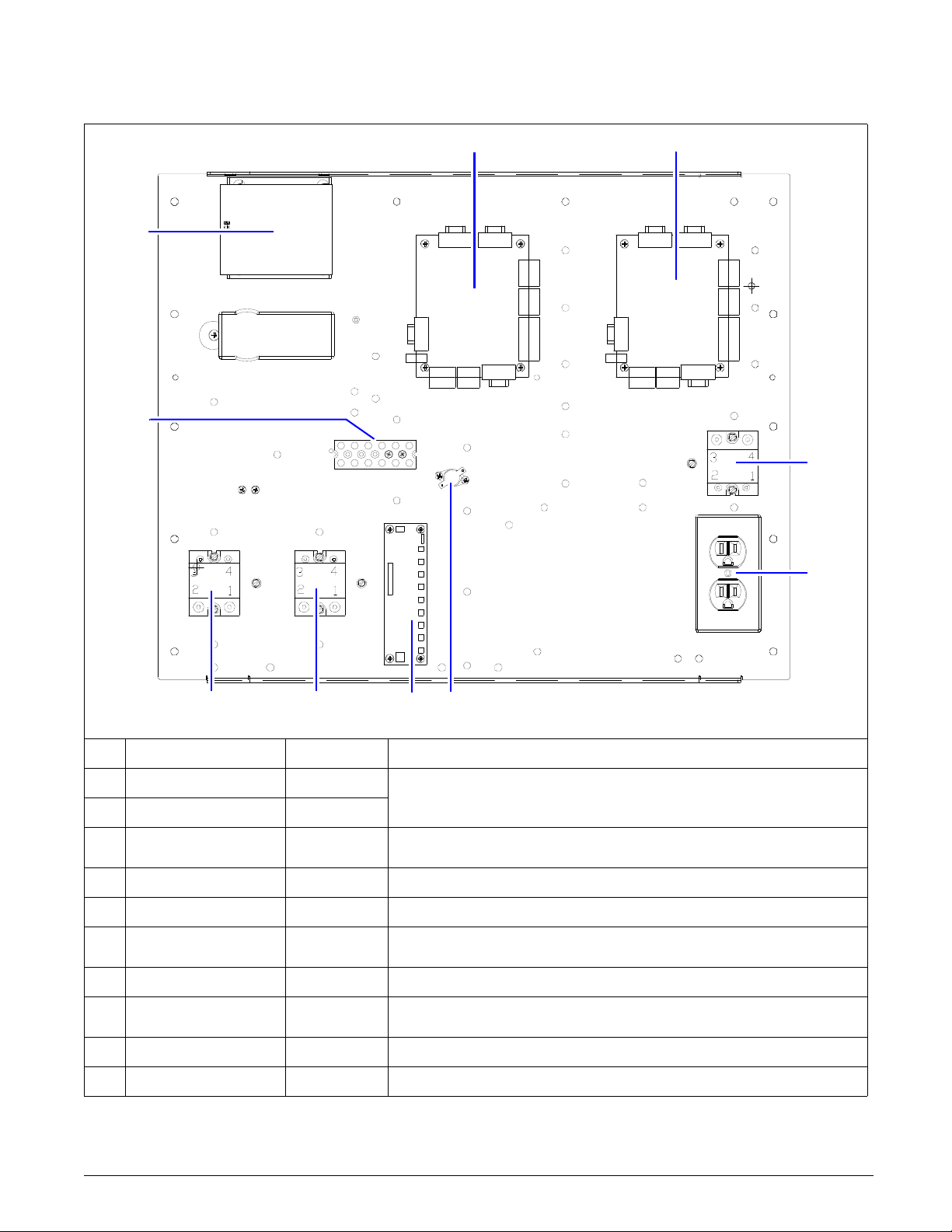

Figure 10:Controller plate components, page 20

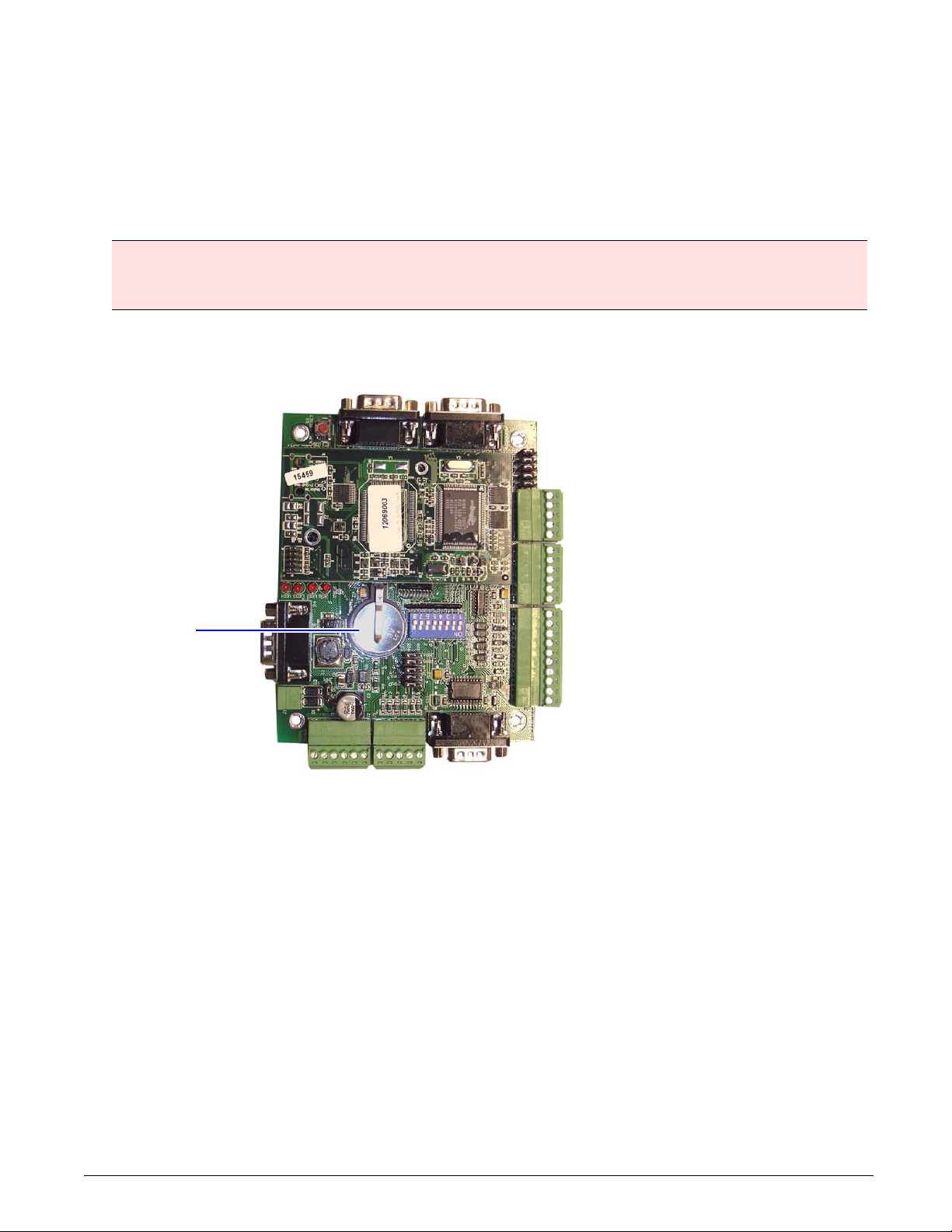

Figure 11:Sign controller components, page 21

Figure 12:Power panel components, page 23

Figure 13:LED driver board views and components, page 24

Figure 14:Air filter locations in the 1.75-inch pitch sign.The 1.07-inch and 1.35-inch pitch signs have 4 fans, see “In-

ternal view — 1.07-inch pitch sign” on page 17 or “Internal view — 1.35-inch pitch sign” on page 18 for

locations, page 26

Figure 15:Door latch locations on 1.07-inch and 1.35-inch pitch signs, page 28

Figure 16:Front face frame and prop rod, page 28

Figure 17:Fastening LED panels, page 28

Figure 18:Removing quick release pin and unfastening LED panels, page 29

Figure 19:Door latch locations on the 1.75-inch pitch sign, page 29

Figure 20:Loosening the seal, page 29

Figure 21:Turning the winch handle, page 30

Figure 22:Lift arms and door support arms on the 1.75-inch pitch sign, page 30

Figure 23:Disengaging the door’s support arms, page 31

Figure 24:Cranking the door closed, page 31

Figure 25:Push the door completely closed, page 31

Figure 26:Controller jumper locations and dip switch settings, page 32

Figure 27:Controller board screws and jumpers, page 33

Figure 28:Settings in the IP Set Utility, page 34

Figure 29:Power supply wiring, page 35

Figure 30:Screw locations on the power supply, page 36

Figure 31:Nuts securing the diode module to the power plate, page 37

Figure 32:Diode module connections, page 38

Figure 33:Relay locations, page 39

6Front Access Full Matrix LED Sign Maintenance Manual (pn 1507610501 rev. A)

Figure 34:Relay, page 40

Figure 35:Example of a 1.07-inch/1.35-inch pitch sign. The larger 1.75-inch pitch signs have lift arms and winch

handles, page 41

Figure 36:Fan locations, page 42

Figure 37:Screws securing the fan panel housing, page 42

Figure 38:Locations of the 6-32 nuts on the fan guard, page 42

Introduction December 10, 2007

Front Access Full Matrix LED Sign Maintenance Manual (pn 1507610501 rev. A) 7

Introduction

Purpose

This manual is intended as a guide for maintenance and repairs considered field serviceable.

This field service manual supplies technical information for service and technical personnel so that they can

maintain the equipment at the assembly but not the component level.

Revision history

Related documentation

Technical documentation can be found at Adaptive’s Web site (http://www.adaptivedisplays.com).

Safety information

Equipment symbols

Warnings and cautions

Warnings and cautions are posted in appropriate locations throughout this manual.

Revision Date Notes

1507610501 rev. A December 10, 2007 Initial release.

Part # Manual title Description

1507650207 Wiring Diagram Sign wiring diagram for the 1.07-inch pitch sign

with two controllers.

1507650201 Wiring Diagram Sign wiring diagram for the 1.35-inch pitch sign

with two controllers.

1507650202 Wiring Diagram Sign wiring diagram for the 1.75-inch pitch sign

with two controllers.

TechMemo #00-0005 Preventing Electrostatic Discharge

(ESD) Damage

Describes the precautions to take to protect

electronic components from ESD damage.

Chassis ground

Introduction P1509 21 x 125 Line Matrix

8Front Access Full Matrix LED Sign Maintenance Manual (pn 1507610501 rev. A)

Battery backup

In the event of power loss, a lithium battery provides power to the sign’s controller boards.

Note:

The backup battery provides only enough power to back up the sign controller’s memory, not the sign’s

LED displays.

3V lithium backup battery

One 3V lithium battery is located on each of the sign’s controller boards.

Figure 1. Location of the 3V lithium battery on the sign’s controller.

WARNING! Danger of explosion if battery is incorrectly replaced. Replace only with the same or

equivalent type recommended by the manufacturer. Dispose of used batteries according to the

manufacturer’s instructions.

3V lithium battery

(Panasonic CR2032 or

equivalent)

System overview December 10, 2007

Front Access Full Matrix LED Sign Maintenance Manual (pn 1507610501 rev. A) 9

System overview

This section contains the LED Variable Message Sign (VMS) systems description and a general explanation of

how each system operates.

Introduction

The Adaptive LED family of Variable Message Signs is considered to be one of the highest visibility sign

systems available. Utilizing the latest generation of light emitting diode (LED) technology has allowed us to

construct a high-reliability, variable message sign display system.

The LED Variable Message Signs discussed in this manual consist of front access types with a 28 x 96 display

board at 1.07-inch, 1.35-inch, and 1.75-inch pitch. The signs are designed for use as outdoor highway

information signs. The signs utilize a corrosion-resistant front access housing with enclosed control circuitry

within. The only connections necessary are AC power and Communications Input/Output between the sign

housings and the ground cabinets.

General system

The entire sign system can be broken down into four basic subsystems:

• VMS control system

• LED brightness control system

• Environmental control

• Electrical system

In the following sections, we explain each of the above-mentioned systems in general terms for ease of

understanding. Referring to the drawings throughout this manual should help you to gain a general

understanding of the LED Variable Message Sign system.

What is an LED?

LED-based signs are one of the most versatile and visible display systems available. We use a cluster of four

LEDs to form a single pixel. The pixels are arranged in various matrices to form alphanumeric characters.

These characters are then linked together to form an LED display line. The display line format used in the signs

discussed in this manual is full matrix, which allows for the display of any alphanumeric character, including

punctuation marks, as well as simple graphics characters.

VMS control system

The VMS control system utilized in the Variable Message Sign consists of the following components:

• IDI 1320 controller

• IDI 1321 controller

• LED display board/driver board

General operation

The controllers interface with the “Host” computer system, and communicate with the Host through a CAT5

Ethernet cable or an RS232 Input/Output (I/O) port. Using this network connection or I/O port, the host issues

commands to, and requests status information from, the LED VMS equipment. The controllers monitor and

control the entire LED VMS system. Communication by the controllers to and from the host and the VMS is

accomplished using industry standard 10/100 Ethernet or RS232 communications circuitry and NTCIP

protocol.

System overview P1509 21 x 125 Line Matrix

10 Front Access Full Matrix LED Sign Maintenance Manual (pn 1507610501 rev. A)

LED brightness control system

The VMS is equipped with a brightness control system for the LEDs. The brightness control system ensures

that the display is readable in all lighting conditions.

The main components of the brightness control system are the following:

• Photocell assembly

• Photocells (3: 1 upper, 1 front of sign, and 1 back of sign)

• IDI 1320 Controller

General operation

The photocells are enclosed in the cabinet to protect them from the environment. The photocells continuously

monitor the ambient light conditions and send the information directly to the controller. The controller assembly

determines exactly how much ambient light is present through the light-sensing photocells and sends the

proper command to the display module for it to adjust duty cycle of the LED current drive, thus dimming or

brightening the LED modules according to the ambient light. (If the on time of the duty cycle is 50%, then the

brightness will be at 50%; if the on time of the duty cycle is 75%, then the brightness will be at 75%, etc.)

Environmental control system — sign housing

The environmental control system in the sign housing is responsible for maintaining a working environment for

the sign display components and communication electronics in the sign display systems. The environmental

control system consists of the following components:

• Photo/temperature sensor

•Fans

• Fan filters

•Fanrelay

• Humidity sensor

• Fan monitor board

• Heater strip

• Heater relay

General operation

The fans are responsible for exchanging air in the sign for temperature control and ventilation through the sign.

The fans are automatically turned OFF or ON based on the readings from temperature sensors and sign

controller settings. The fan monitor board is used to determine if the fans are operating within specifications

and communicates the fan status to the controller. The humidity sensor, heater strip, fans, and temperature

sensors are all used to determine if there is an environmental condition that could cause the front plex to fog.

Based on an algorithm, if the situation dictates it is needed, the heater strip will be enabled and the fans will

blow hot air across the front face. The fans automatically turn on when the temperature exceeds 120°F (50°C)

and automatically turn off when the temperature goes below 113°F (45°C).

Electrical system

The electrical supply system is responsible for supplying the necessary power to operate the LED sign system.

The sign housing AC and DC electrical system consists of the following components:

• Load center

• GFCI service outlet

• DC power supply

System overview December 10, 2007

Front Access Full Matrix LED Sign Maintenance Manual (pn 1507610501 rev. A) 11

Electrical distribution (AC)

The AC input to the sign systems consists of 120VAC single-phase service wired to the load center located in

the sign. AC is also wired to the DC power supplies. The signs discussed in this manual require 15A service for

the 1.07-inch and 1.35-inch pitch signs and 20A service for the 1.75-inch pitch sign.

Electrical distribution (DC)

Attached to the back panels in the sign housing are the power supply boxes that contain two 12VDC switching

power supplies. The electronic power supplies convert the 120VAC to the required DC voltage to power all of

the electronics in the sign. DC power to the electronics is redundant and has a primary and secondary source

of DC power. Therefore, failure of a power supply will not impact sign performance. The controller monitors the

status of the power supplies.

Introduction

12 Front Access Full Matrix LED Sign Maintenance Manual (pn 1507610501 rev. A)

THIS PAGE INTENTIONALLY BLANK

Equipment description December 10, 2007

Front Access Full Matrix LED Sign Maintenance Manual (pn 1507610501 rev. A) 13

Equipment description

General description

• Serviceability: Front access.

• Dimensions: Refer to the appropriate sign wiring diagram (see “Related documentation” on page 7).

• Weight (approximate): 1.07-inch pitch – 500 lbs, 1.35-inch pitch – 525 lbs, 1.75-inch pitch – 615 lbs.

• Electrical: 120VAC, 50/60Hz, 15A for the 1.07-inch and 1.35-inch pitch signs and 20A for the 1.75-inch

pitch sign. Typical current draw is approximately 5-8A.

• Display: Full matrix 28 x 96 pixels.

Figure 2. 5x7 font dimensions

• Pitch (distance between each LED pixel): 1.07-inch, 1.35-inch, and 1.75-inch pitch.

Figure 3. LED pitch

(5x7 Font)

Character width (nominal)

1.07-inch pitch = 6”

1.35-inch pitch = 7”

1.75-inch pitch = 9”

(5x7 Font)

Character height (nominal)

1.07-inch pitch = 8”

1.35-inch pitch = 10”

1.75-inch pitch = 12”

LED pixel

composed of four

individual LED

lamps

Pitch of LED pixel

• 1.07 inches

• 1.35 inches

• 1.75 inches Pitch

Pitch

Equipment description P1509 21 x 125 Line Matrix

14 Front Access Full Matrix LED Sign Maintenance Manual (pn 1507610501 rev. A)

Outside views — 1.07-inch pitch sign

Figure 4. Exterior top, front, bottom, back, and side views of a 1.07-inch sign

Item Name Description

AUPPER PHOTO CELL Used for controlling LED brightness.

BLIFTING EYEBOLTS Used to lift sign. These should NOT be used to mount the sign.

CFRONT PHOTO CELL Used for controlling LED brightness.

DLEDS Used to display messages.

EFRONT FACE FRAME LATCH Used to fasten sign front face frame.

FDRAIN HOLE Allows water that may accumulate inside the sign to escape.

GEXHAUST VENT OUTLET (WITH

HOOD)

Permits hot air from inside sign to exit.

HBACK PHOTO CELL Used for controlling LED brightness.

IINTAKE AIR VENT Allows cool air inside sign.

A

Top view

Front view

Bottom view

Back view

Side view

B

C

E

H

F

G

D

I

Equipment description December 10, 2007

Front Access Full Matrix LED Sign Maintenance Manual (pn 1507610501 rev. A) 15

Outside views — 1.35-inch pitch sign

Figure 5. Exterior top, front, bottom, back, and side views of a 1.35-inch sign

Item Name Description

AUPPER PHOTO CELL Used for controlling LED brightness.

BLIFTING EYEBOLTS Used to lift sign. These should NOT be used to mount the sign.

CFRONT PHOTO CELL Used for controlling LED brightness.

DLEDS Used to display messages.

EFRONT FACE FRAME LATCH Used to fasten sign front face frame.

FDRAIN HOLE Allows water that may accumulate inside the sign to escape.

GEXHAUST VENT OUTLET (WITH

HOOD)

Permits hot air from inside sign to exit.

HBACK PHOTO CELL Used for controlling LED brightness.

IINTAKE AIR VENT Allows cool air inside sign.

A

Top view

Front view

Bottom view

Back view

Side view

B

C

E

H

F

G

D

I

Equipment description P1509 21 x 125 Line Matrix

16 Front Access Full Matrix LED Sign Maintenance Manual (pn 1507610501 rev. A)

Outside views — 1.75-inch pitch sign

Figure 6. Exterior top, front, bottom, back, and side views of a 1.75-inch sign

Item Name Description

AUPPER PHOTO CELL Used for controlling LED brightness.

BLIFTING EYEBOLTS Used to lift sign. These should NOT be used to mount the sign.

CFRONT PHOTO CELL Used for controlling LED brightness.

DLEDS Used to display messages.

EFRONT FACE FRAME LATCH Used to fasten sign front face frame.

FDRAIN HOLE Allows water that may accumulate inside the sign to escape.

GEXHAUST VENT OUTLET (WITH HOOD) Permits hot air from inside sign to exit.

HBACK PHOTO CELL Used for controlling LED brightness.

IINTAKE AIR VENT Allows cool air inside sign.

JHANDLE Used to assist with opening the sign. See “Opening a sign” on page 28.

Back view

Bottom view

Front view

A

Top view

Side view

B

C

E

H

F

G

D

I

J

Equipment description December 10, 2007

Front Access Full Matrix LED Sign Maintenance Manual (pn 1507610501 rev. A) 17

Inside view — 1.07-inch pitch sign

Figure 7. Internal components of a 1.07-inch sign

Item Name Description

ACONTROLLER PLATE Mounting sub plate for controllers, outlet, fan monitoring board, and fan/heater control

relays.

BINTAKE FAN (FAN #4) Draws in air from outside.

CHEATER #2 Used to control humidity inside sign.

DAIR FILTER COVER When removed provides access to fan air filters.

ELOAD CENTER Principal AC power for sign. 120VAC 20A service required.

FPOWER PANEL #3 Convert AC power from load center to DC power.

GPOWER PANEL #2

HPOWER PANEL #1

IHEATER #1 Used to control humidity inside sign.

JINTAKE FAN (FAN #1) Draws in air from outside.

KLIGHT SENSOR #0 — FRONT The address number of a light sensor is set via SW1 and is the same as the light

sensor number. To replace light sensor board, remove the four nuts attached to the

mounting plate.

LLIGHT SENSOR #1 — TOP

MLIGHT SENSOR #2 — BACK

NEXHAUST VENT (FAN #2) Vents hot air inside the sign to the outside.

OEXHAUST VENT (FAN #3)

PLIGHT Automatically turns on when front is opened.

A

B

DFEGH C

M

I

NO

J

K

LDD P

Equipment description P1509 21 x 125 Line Matrix

18 Front Access Full Matrix LED Sign Maintenance Manual (pn 1507610501 rev. A)

Inside view — 1.35-inch pitch sign

Figure 8. Internal components of a 1.35-inch sign

Item Name Description

AINTAKE FAN (FAN #4) Draws in air from outside.

BHEATER #2 Used to control humidity inside sign.

CAIR FILTER COVER When removed provides access to fan air filters.

DCONTROLLER PLATE Mounting sub plate for controllers, outlet, fan monitoring board, and fan/heater control

relays.

EPOWER PANEL #3 Convert AC power from load center to DC power.

FPOWER PANEL #2

GPOWER PANEL #1

HHEATER #1 Used to control humidity inside sign.

IINTAKE FAN (FAN #1) Draws in air from outside.

JLIGHT SENSOR #0 — FRONT The address number of a light sensor is set via SW1 and is the same as the light

sensor number. To replace light sensor board, remove the four nuts attached to the

mounting plate.

KLIGHT SENSOR #1 — TOP

LLIGHT SENSOR #2 — BACK

MEXHAUST VENT (FAN #2) Vents hot air inside the sign to the outside.

NEXHAUST VENT (FAN #3)

OLOAD CENTER Principal AC power for sign. 120VAC 15A service required.

A

B

D

FE

G

H

CC

MCC

I

NO

J

KL

Equipment description December 10, 2007

Front Access Full Matrix LED Sign Maintenance Manual (pn 1507610501 rev. A) 19

Inside view — 1.75-inch pitch sign

Figure 9. Internal components of a 1.75-inch sign

Item Name Description

AINTAKE FAN (FAN #8) Draws in air from outside.

BHEATER #4 Used to control humidity inside sign.

CAIR FILTER COVER When removed provides access to fan air filters.

DCONTROLLER PLATE Mounting sub plate for controllers, outlet, fan monitoring board, and fan/heater control

relays.

ELOAD CENTER Principal AC power for sign. 120VAC 20A service required.

FPOWER PANEL #3 Convert AC power from load center to DC power.

GPOWER PANEL #2

HPOWER PANEL #1

IHEATER #3 Used to control humidity inside sign.

JHEATER #2

KHEATER #1

LINTAKE FAN (FAN #1) Draws in air from outside.

MLIGHT SENSOR #0 The address number of a light sensor is set via SW1 and is the same as the light

sensor number. To replace light sensor board, remove the four nuts attached to the

mounting plate.

NLIGHT SENSOR #1

OLIGHT SENSOR #2

PEXHAUST VENT (FAN #2) Vents hot air inside the sign to the outside.

QEXHAUST VENT (FAN #3)

RINTAKE FAN (FAN #4) Draws in air from outside.

SINTAKE FAN (FAN #5)

TEXHAUST VENT (FAN #6) Vents hot air inside the sign to the outside.

UEXHAUST VENT (FAN #7)

A

B

D

FE

G

HJ

C

K

L

M

RPS

I

NO

C

CC

C

QTU

Equipment description P1509 21 x 125 Line Matrix

20 Front Access Full Matrix LED Sign Maintenance Manual (pn 1507610501 rev. A)

Controller plate

Figure 10.Controller plate components

Item Name Part # Description

ACONTROLLER #1 15029101 Controls display and communicates status information to central

communications.

BCONTROLLER #2 12069003

CRELAY #3 48000005 Only used on 1.07-inch pitch signs to turn the light on when the door switch

is open.

D120V OUTLET 64000024 Service outlet (GFCI).

EFAN THERMOSTAT 30670752 Normally open. Closes when temperature >120ºF and fans are activated.

FFAN MONITORING BOARD 1509110301 Monitors fan speed. Sends alert via NTCIP if fan speed falls below a

specified RPM.

GRELAY #1 48000004 Fan relay. This relay is used to control AC power being applied to the fans.

HRELAY #2 48000009 Heat strip relay. The relay is used to control AC power being applied to the

heaters.

ITERMINAL BLOCK 43201045 Distributes DC power and signal to control sub assembly.

JHUMIDITY SENSOR 30676015 Measures internal relative humidity within 2% accuracy.

AB

D

E

F

G

H

J

I

C

This manual suits for next models

1

Table of contents

Popular Lantern manuals by other brands

Knightsbridge

Knightsbridge BATC Series Installation & maintenance manual

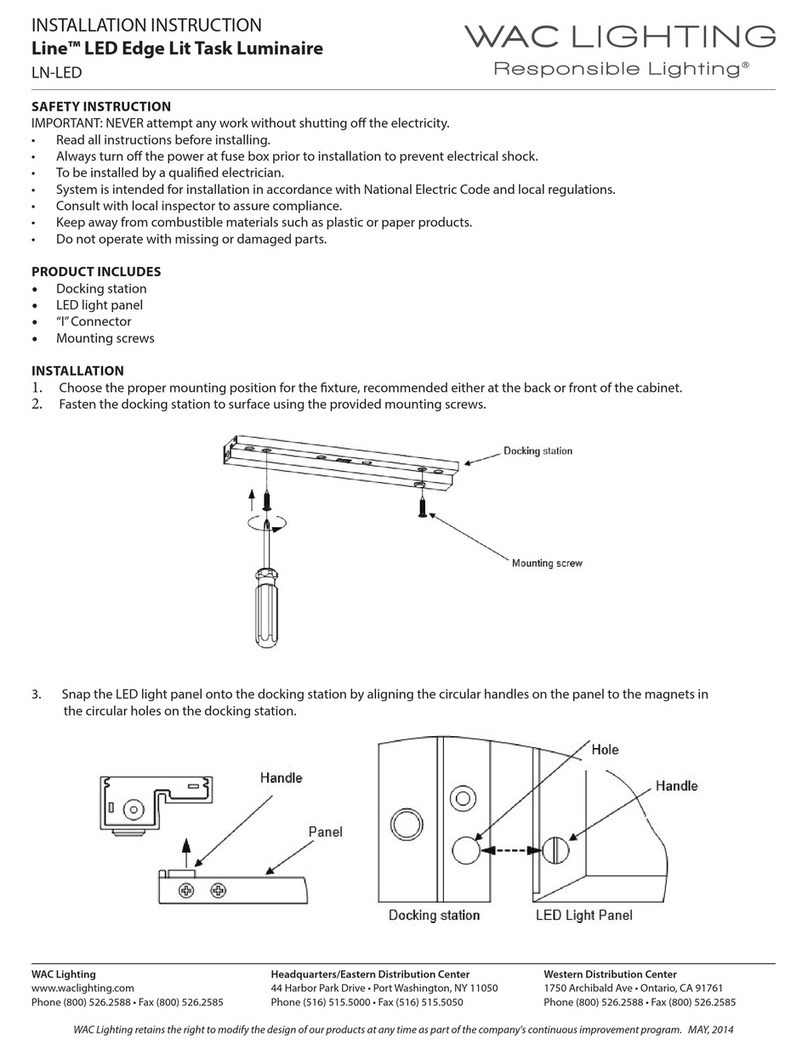

WAC Lighting

WAC Lighting Line LN-LED06 Installation instruction

Gama Sonic

Gama Sonic GS-97B-S instruction manual

IKEA

IKEA STRALA J2019 manual

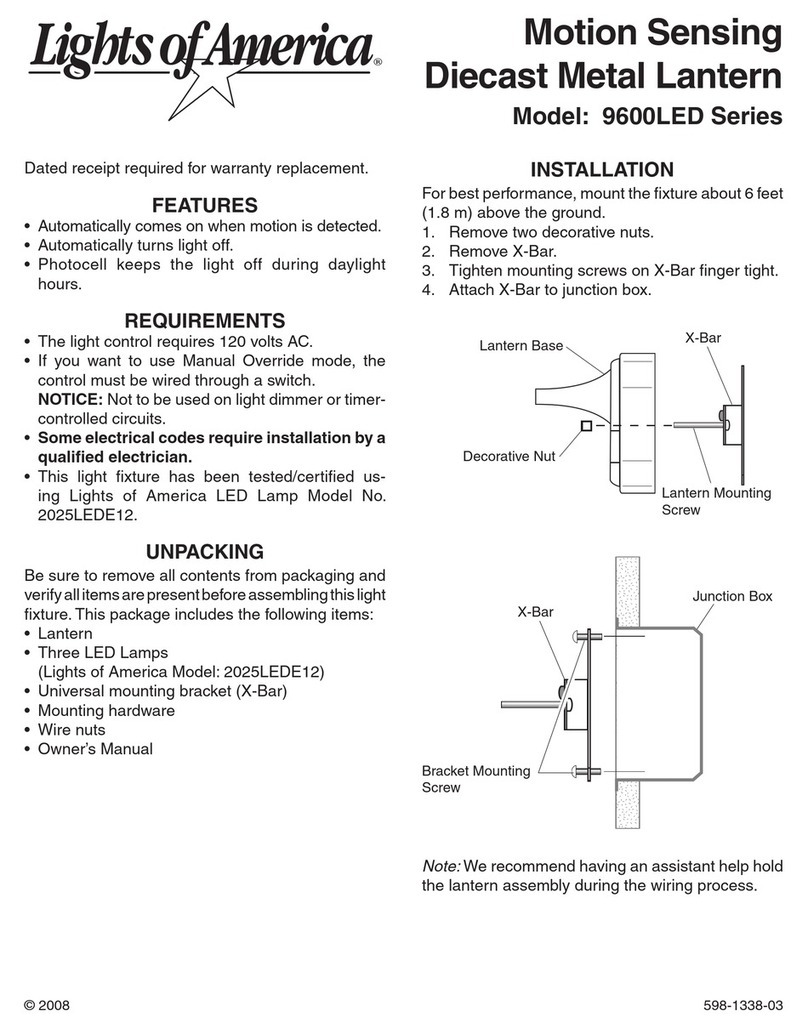

Lights of America

Lights of America Motion Sensing Diecast Metal Lantern 9600LED... owner's manual

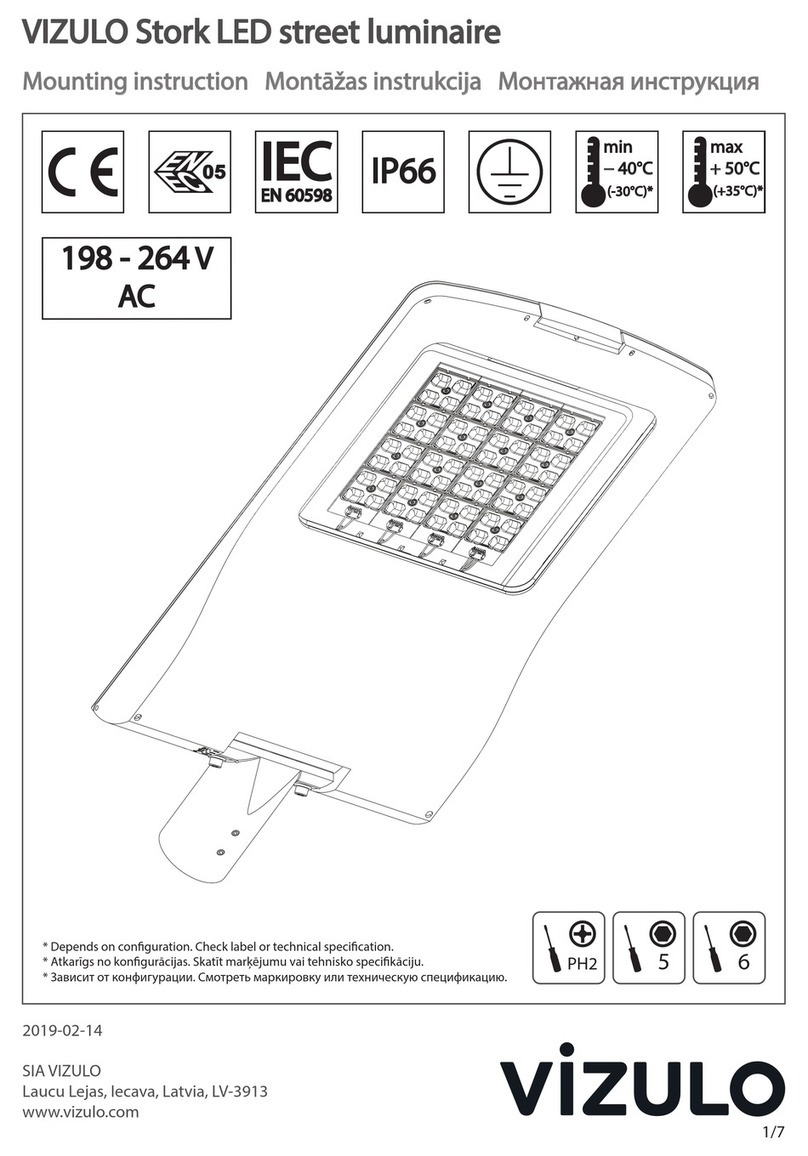

VIZULO

VIZULO Stork Series Mounting instruction